- Nanquim Metal Industrial CO., Limited

- TGW International

- Baucor

- American Cutting Edge

- Midwest Knife Grinding

- Henion Dicing Products, LLC

- Bach Knives

- Sollex

- Fordura

- GSmach

Escolhendo o certo Facas de Peletização de Anel de Ar supplier is crucial for optimizing pelletizing performance and production speed. Each pelletizing knife brand offers unique advantages, with some providing custom blade options tailored to specific needs. Establishing clear contact with suppliers ensures companies receive the support necessary to enhance their operations and achieve the best results.

Principais conclusões

- Air ring pelletizing knives cut melted plastic into small pellets. This helps factories make good plastic products fast.

- Picking the best blade material and supplier makes better pellets. It also helps blades last longer and machines work better. This saves time and money.

- Custom pelletizing knives fit certain machines and plastics. They help make pellets faster, waste less, and keep knives working longer.

- Top companies like Nanjing Metal and TGW International sell good blades. They deliver fast and give expert help for many pelletizing jobs.

- Good after-sales help and worldwide service from suppliers keep things running well. This means less machine stoppage and steady pellet quality.

Air Ring Pelletizing Knives Overview

What Are Air Ring Pelletizing Knives

Air ring pelletizing knives are important in making plastic pellets. These special blades work inside machines called pelletizers. They cut melted or soft plastic strands into small, even pellets. The shape of these knives helps them make clean and exact cuts. This is important for making sure the pellets are all the same size and shape. Companies use different materials to make these knives. Some common materials are tool steel, high-speed steel, carbide-tipped blades, and powder metallurgy steels. Each material has its own strengths. Some are harder, some last longer, and some work better with certain plastics.

The cutting chamber is inside the pelletizing chamber. Here, the pelletizing knife spins or moves against a still surface. This is how it slices the plastic strands. The number of holes in the die plate, how hard the blade is, and how far apart the knives are all matter. These things change how well the knives work. They also affect the size and shape of the pellets. In many machines, like strand pelletizers and air cooling strand pelletizer systems, air ring pelletizing knives are very important. They help make lots of pellets quickly and keep the quality high.

Note: Taking care of air ring pelletizing knives and changing them when needed helps the machine work well and last longer.

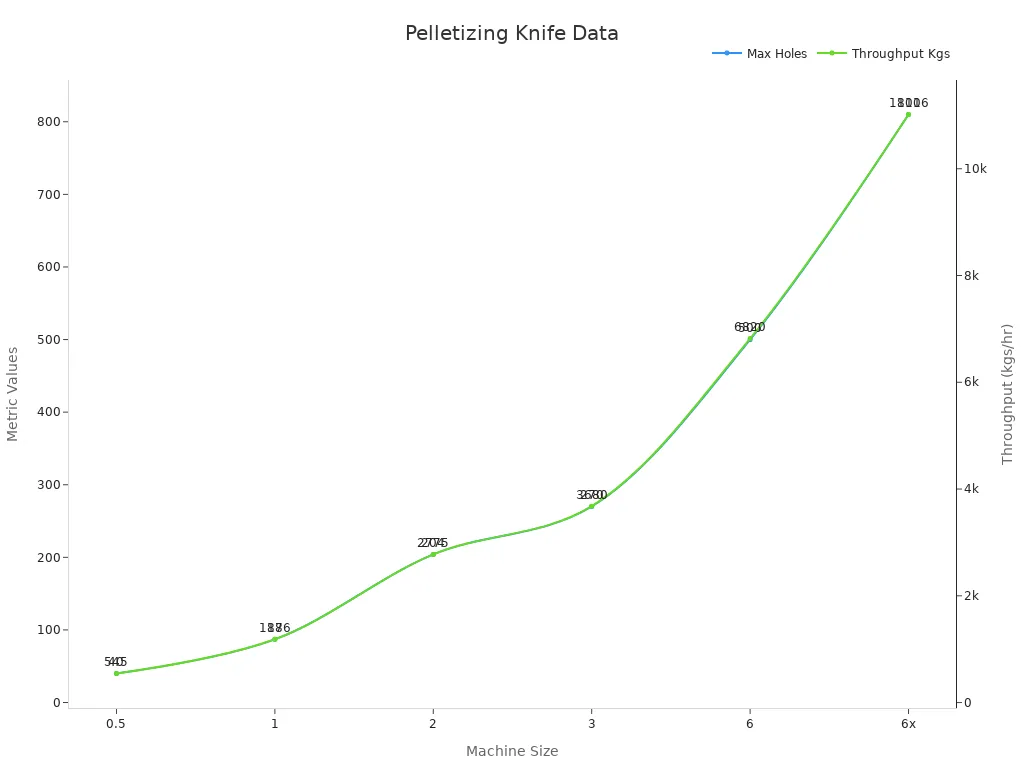

O table below shows important facts about pelletizing knives used in different machines:

| Machine Size | Maximum Number of Holes | Typical Drive Power | Power Consumption (kW) | Nominal Throughput (lbs/hr) | Nominal Throughput (kgs/hr) |

|---|---|---|---|---|---|

| 0.5 | 40 | 5 hp | 3.75 | 1,200 | 545 |

| 1 | 87 | 5 hp | 3.75 | 2,610 | 1,186 |

| 2 | 204 | 10 hp | 7.5 | 6,120 | 2,775 |

| 3 | 270 | 15 hp | 11.2 | 8,100 | 3,680 |

| 6 | 500 | 20 hp | 15 | 15,000 | 6,820 |

| 6x | 810 | 30 hp | 22.4 | 24,300 | 11,016 |

Choosing the right blade material is very important for different jobs. The next table lists common blade materials and what makes them special:

| Blade Material Type | Key Properties and Advantages | Typical Hardness (HRC) | Suitable Applications and Notes |

|---|---|---|---|

| Tool Steel (D2, A8, M2) | Hard and tough; has chromium for better wear resistance | 52 – 65 | Good for many plastics; balances toughness and wear resistance |

| Aço Rápido (HSS) | Stays hard at high heat; good wear resistance and toughness | 52 – 65 | Great for fast pelletizing jobs |

| Lâminas com ponta de carboneto | Very hard and lasts long because of tungsten carbide | Higher than tool steels | Best for tough plastics, filled polymers, fiberglass |

| Powder Metallurgy Steels | Even structure makes them tough and wear-resistant | 52 – 65 | Used for hard jobs needing strong blades |

| Coatings (Chromium, TiN) | Makes blades harder, lowers friction, and stops rust | N / D | Put on many blades to help them last longer and cut better |

Importance in Pelletizing

Pelletizing is a key step in making plastics. It turns raw or recycled plastic into small, even pellets. These pellets are used to make many plastic products. Air ring pelletizing knives and other types of pelletizing knives help make sure every pellet is the right size and shape. When pellets are all the same, it helps the next steps go smoothly and makes better products.

There are different kinds of pelletizers. Some are strand pelletizers, underwater pelletizers, water ring pelletizer systems, and air cooling strand pelletizer units. Each one uses a special way to cool and cut the plastic. Air ring pelletizing knives work best in air cooling strand pelletizer machines. In these, air cools the strands before they are cut. This way is simple and easy to take care of. It does not need as much work as water cooling systems, but it may not control pellet size as well.

The pelletizing chamber and cutting chamber hold the pelletizing knife and help it cut. In underwater pelletizers and underwater strand pelletizer systems, the plastic cools fast in water. This lets the pelletizing knife make even pellets without too much heat damage. The hot die face pelletizing system uses heated knives. This stops sticky plastics from sticking and keeps pellet quality high.

Some big trends are changing pelletizing technology:

- Many pelletizers now work with biodegradable plastics and new recycling methods. This means knives must be more exact and flexible.

- The hot die face pelletizing system is popular because it works with many plastics and keeps pellet quality high.

- Water ring pelletizer and underwater pelletizers cool faster and control pellet size better. This helps when making lots of pellets.

- The cooling pelletizing system, whether it uses air or water, changes how good the pellets are and how fast they are made.

- Keeping the knife at the right temperature in the pelletizing chamber is important for good results.

Strand pelletizers, underwater pelletizers, and water ring pelletizer systems all need good pelletizing knives to make lots of even pellets. The underwater cooling process and water cooling strand methods cool the plastic fast. This helps make high-quality pellets. Air cooling strand pelletizer systems are easier to use, but they still need air ring pelletizing knives to work well.

Tip: Picking the right pelletizing knife and keeping the pelletizing chamber in good shape can make pellets better and help the machine run longer.

Top 10 Pelletizing Knife Manufacturers

Nanquim Metal

Company Overview

Nanjing Metal is a top company in the pelletizing field. It is known for giving good solutions to plastic plants all over the world. The team works hard to make new things and keep customers happy.

Main Products

Nanjing Metal sells many kinds of pelletizing knife products. Its main item is the Plastic Pelletizer Blade. The company also makes rotor knives, stator knives, die plates, and fly knives. These fit many strand pelletizers, underwater pelletizers, and air ring pelletizing knives systems.

Unique Strengths

Nanjing Metal uses strong materials like SK2, HSS, M2, and SKD11. The company can make special pelletizing knives for each customer. It offers OEM and ODM services too. The blades get careful heat treatment and can have coatings to last longer. Customers get fast shipping and strict checks for quality. The company also helps with water ring pelletizer and underwater strand pelletizer systems.

Why Included in the Top 10

Nanjing Metal is in the top group because it cares about quality and custom service. It works with all big pelletizers, like strand pelletizers and underwater pelletizers. The company helps customers get better pelletizing chamber work and pellet quality.

TGW International

Company Overview

TGW International makes industrial knives and blades for the world. It helps many fields, like plastics, packaging, and food.

Main Products

TGW International makes pelletizing knives for strand pelletizers and underwater pelletizers. It also sells rotary knives, bed knives, and special blades for cutting chamber jobs.

Unique Strengths

TGW International uses new technology to make its products. The company gives custom answers for pelletizing and pelletizers. Its blades work well in fast pelletizing chamber places.

Why Included in the Top 10

TGW International is chosen for always giving good quality and steady supply. It supports many pelletizing systems, like underwater pelletizers and strand pelletizers. Its worldwide help and tech support let customers make better pellets.

Baucor

Company Overview

Baucor is known for making exact industrial blades and pelletizing knives. It works with plastics, recycling, and medical companies.

Main Products

Baucor makes pelletizing knives for strand pelletizers, underwater pelletizers, and air ring pelletizing knives systems. It sells circular knives, straight knives, and custom pelletizer blades.

Unique Strengths

Baucor uses top materials and advanced CNC machines. The company can quickly make new blade designs for pelletizing jobs.

Why Included in the Top 10

Baucor is picked for being flexible and fast. It helps with both regular and special pelletizing knife needs for pelletizers. The company knows how to meet all pelletizing chamber needs.

American Cutting Edge

Company Overview

American Cutting Edge is a famous supplier of industrial knives and blades. It has many years of experience in the pelletizing field.

Main Products

American Cutting Edge sells pelletizing knives for strand pelletizers, underwater pelletizers, and water ring pelletizer systems. Its list has rotary knives, bed knives, and die face blades.

Unique Strengths

The company uses special heat treatment and careful grinding. It gives tech help to make pelletizing and pelletizers work better.

Why Included in the Top 10

American Cutting Edge is chosen for its trusted products and good customer care. Its pelletizing knives help make better pellets and less downtime in the cutting chamber.

Midwest Knife Grinding

Company Overview

Midwest Knife Grinding gives industrial knives for plastics and recycling. The company cares about quality and quick service.

Main Products

Midwest Knife Grinding makes pelletizing knives for strand pelletizers and underwater pelletizers. It sells rotor knives, bed knives, and custom blades for pelletizing chamber use.

Unique Strengths

The company can regrind and sharpen knives. It uses strong steel for long-lasting pelletizing knives.

Why Included in the Top 10

Midwest Knife Grinding is known for its service and tough products. Its pelletizing knives help make pelletizing work well in many pelletizers.

Henion Dicing Products, LLC

Company Overview

Henion Dicing Products, LLC makes exact cutting tools for plastics and electronics. The company spends a lot on research and new ideas.

Main Products

Henion Dicing Products sells pelletizing knives for strand pelletizers and underwater pelletizers. It offers dicing blades, rotary knives, and custom pelletizer blades.

Unique Strengths

The company uses new materials and very close measurements. It gives answers for hard pelletizing chamber jobs.

Why Included in the Top 10

Henion Dicing Products, LLC is picked for its new ideas and exact work. Its pelletizing knives help make even pellets in fast pelletizers.

Bach Knives

Company Overview

Bach Knives is a worldwide supplier of industrial knives for plastics, paper, and metal. The company has made quality products for a long time.

Main Products

Bach Knives sells pelletizing knives for strand pelletizers, underwater pelletizers, and water ring pelletizer systems. It offers rotary knives, bed knives, and die plates.

Unique Strengths

Bach Knives uses top materials and special heat treatment. The company gives tech help for pelletizing and pelletizers.

Why Included in the Top 10

Bach Knives is chosen for its steady products and customer help. Its pelletizing knives help keep pellet size and quality the same in the pelletizing chamber.

Sollex

Company Overview

Sollex is a Swedish maker of industrial knives and blades. The company works with plastics, packaging, and recycling.

Main Products

Sollex makes pelletizing knives for strand pelletizers and underwater pelletizers. It sells rotary knives, bed knives, and custom blades for pelletizing chamber jobs.

Unique Strengths

Sollex works on new ideas and cares about the environment. The company uses strong materials for long-lasting pelletizing knives.

Why Included in the Top 10

Sollex is picked for its focus on quality and caring for nature. Its pelletizing knives help make pelletizing better in new pelletizers.

Fordura

Company Overview

Fordura makes industrial knives for plastics and recycling. The company is known for quick shipping and trusted products.

Main Products

Fordura sells pelletizing knives for strand pelletizers, underwater pelletizers, and water ring pelletizer systems. Its list has rotary knives, bed knives, and die plates.

Unique Strengths

Fordura uses new steel and careful machining. The company gives custom answers for pelletizing and pelletizers.

Why Included in the Top 10

Fordura is chosen for its good products and fast help. Its pelletizing knives help make pelletizing chamber work better and improve pellet quality.

GSmach

Company Overview

GSmach is a worldwide supplier of extrusion and pelletizing machines. The company helps plastics makers all over the world.

Main Products

GSmach makes pelletizing knives for strand pelletizers, underwater pelletizers, and air ring pelletizing knives systems. It sells rotary knives, bed knives, and die face blades.

Unique Strengths

GSmach puts pelletizing knives together with full pelletizers and extrusion lines. The company gives tech help to make pelletizing chamber work better.

Why Included in the Top 10

GSmach is picked for joining systems and tech skill. Its pelletizing knives help high-output pelletizers and make even pellets.

Tip: Picking the best pelletizing knife supplier can make pellets better, lower downtime, and help pelletizers last longer.

Comparison Table of Pelletizing Knife Suppliers

Picking the best supplier for facas de peletização is very important. It can change how well and how fast a factory works. Companies that use pelletizers, like strand pelletizers and underwater pelletizers, look at many things before choosing. They check how well the knives work, what materials are used, and if the supplier helps after buying. The table below shows important facts about top brands and regions.

| Region / Supplier | Key Performance Benchmarks | Market Growth & Drivers | Material & Durability Highlights | Notable Features |

|---|---|---|---|---|

| Asia Pacific | 6% CAGR; high demand for recycling and automation; advanced materials | Growth driven by recycling and sustainability | Tungsten carbide, high-speed steel, ceramic; double-sided edges; quick-change systems | Innovation leadership, especially in Japan |

| Japan | Precision cutting (±0.05 mm); blade speed 1,500–3,500 RPM; blade lifespan 6–18 months | Rapid innovation; strong R&D | HSS, carbide, ceramic; special coatings for durability | Quick-change systems; custom blades; exports to Asia |

| North America | Steady growth; reliable suppliers for pelletizers | Focus on OEM compatibility | Tool steel, carbide; strong stock and tech support | Quality service; broad machine compatibility |

| Europe | Emphasis on large-scale production; steady growth | Efficiency focus | Tungsten carbide blades up to 72 HRC; heat resistance | Process optimization; energy savings |

| Top Brands | Nanjing Metal, Fordura, American Cutting Edge, Sollex | Recycling, compounding, lab, specialty | SK2, HSS, M2, SKD11, tungsten carbide; coatings for lifespan | OEM/ODM, fast delivery, tech support, specialized solutions |

Companies in Asia Pacific, mostly in Japan, are very good at making new ideas for pelletizers. They use strong materials and quick-change systems to help factories work better. North America and Europe care about making sure pelletizers work well and save energy. They help many kinds of pelletizers, like strand pelletizers and underwater pelletizers. Top brands give custom answers and ship fast. This helps users make even pellets and stop machines from breaking down.

When picking a supplier, buyers should think about what kind of pelletizer they use. Some suppliers are best for strand pelletizers, and some are better for underwater pelletizers. The material, like tungsten carbide or high-speed steel, changes how long the blade lasts and how good the pellets are. Suppliers who give tech help and custom choices help companies do special jobs and keep pellet quality high.

Tip: Looking at suppliers by where they are and what tech they use helps companies pick the right one for their pelletizers and what they want to make.

Customization for Air Ring Pelletizing Knives

Por que a personalização é importante

Customization is very important in the pelletizing industry. Each factory has its own problems because of the plastics they use, their machines, and what they want to make. Custom pelletizing knives help solve these problems. They are made to fit what each company needs. When a company picks a custom knife, it can control the pelletizing process better. This helps the factory work faster and make better pellets.

Meeting Specific Application Requirements

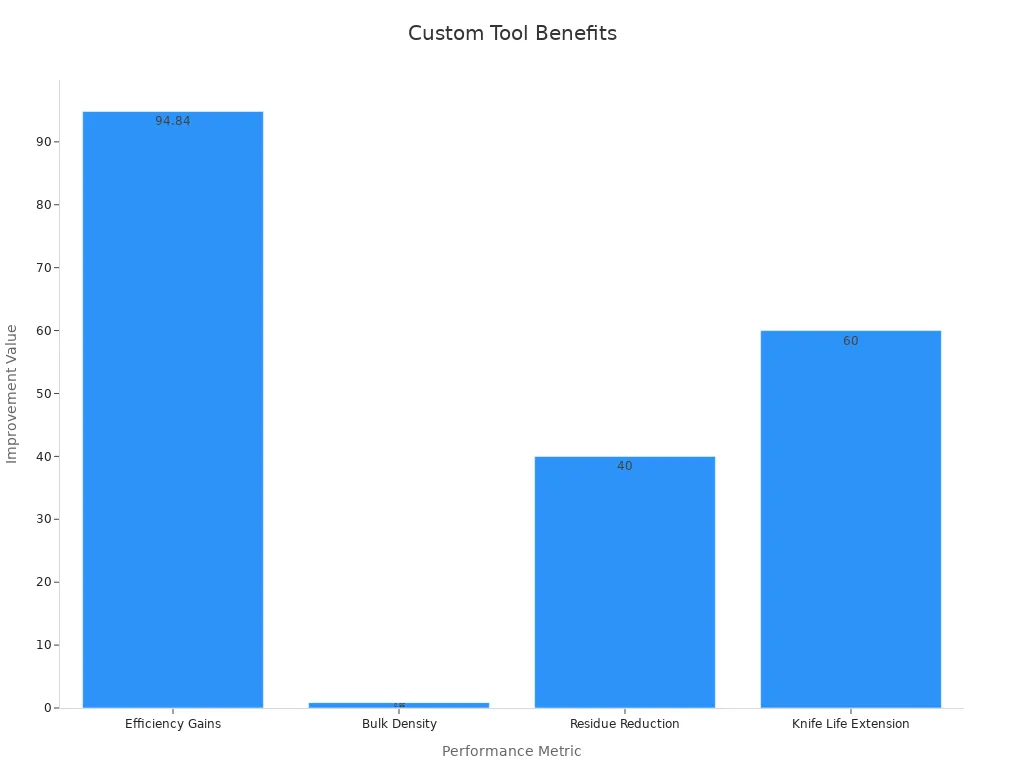

Factories use many kinds of plastics and different pelletizing systems. Each job needs a special knife shape, size, and material. Customization lets engineers design the knife for the cooling pelletizing system or other machines. This makes sure the knife fits right, cuts well, and makes even pellets. The table below shows how custom knives help machines work better:

| Métrica de Desempenho / Prática de Manutenção | Descrição | Melhoria Quantitativa / Benefício |

|---|---|---|

| Ganhos de eficiência | Machines run faster and make more pellets | Up to 94.84% efficiency increase |

| Densidade aparente | Mostra o quão bons são os pellets | Bulk density up to 0.850 g/cm³ |

| Redução de Resíduos por Limpeza | Cleaning every day lowers leftover plastic | Residue goes down by 40% |

| Extensão da vida útil da faca por meio da manutenção | Good care and sharpening make knives last longer | Knife life up by 60% |

| Economia de custos | Stronger knives and less stopping save money | Menores custos de reparo e mais trabalho realizado |

| Qualidade do Pellet | Pellets are more even and less wasted | Same pellet size and less waste |

Custom pelletizing knives made for certain jobs help factories work faster and make better pellets.

Enhancing Production Efficiency

Custom knives help machines work better because they fit just right. This means workers do not have to adjust them as much. When a knife matches the machine, it cuts better and keeps the process smooth. Some companies say they work almost twice as fast with custom knives. The chart below shows how custom knives help with speed, density, less leftover plastic, and longer knife life:

Custom knives also save money because machines stop less often. Knives that last longer mean fewer changes and less fixing. This helps factories make more pellets and reach their goals.

- Custom knives help machines make more pellets by fitting well.

- Knives that last longer mean less fixing and lower costs.

- Pellets are more even when using custom knives.

- Less dust and waste means less material is lost.

- Custom knives made for certain plastics and machines cut better and last longer.

Improving Product Quality and Consistency

Even pellets are important for making good products later. Custom pelletizing knives help every pellet be the same size and shape. This means less waste and better work from the cooling pelletizing system. Companies using custom knives see more even pellets and less dust, which makes handling easier.

- Custom pelletizing knives fit machines well, so cutting is more exact and pellets are more even.

- Using strong materials like tungsten carbide and D2 steel makes knives last longer and wear out less, so they need to be replaced less often.

- Custom knives help machines stop less by making it easier to put in new knives and by stopping problems like plastic building up or uneven cuts.

Compatibility with Different Pelletizing Systems

There are many types of pelletizing systems, like strand pelletizers, underwater, and cooling pelletizing systems. Customization makes sure each knife works well with the right system. Engineers pick the best blade shape, hardness, and finish for each machine. This helps the machines run smoothly and make more pellets, no matter what system is used.

Extending Knife Lifespan and Reducing Downtime

Custom knives that are made right last longer and need less fixing. Factories like knives that do not wear out, rust, or break easily. Cleaning and sharpening the knives, plus picking the right material, can make knives last up to 60% longer. This means machines stop less and keep working well.

Studies show that custom pelletizing knives help control moisture, save energy, and make pellets stronger. These studies prove that custom knives make better pellets, help machines work faster, and last longer.

Nanjing Metal Industrial CO., Limited: Expertise in Custom Solutions

Nanjing Metal Industrial CO., Limited is a top company for custom pelletizing knives. They offer many OEM and ODM services, so customers can send drawings or samples to get the right knife. They use materials like SK2, HSS, M2, and SKD11, and add special coatings to make knives last longer.

The team at Nanjing Metal works with customers to design knives for any pelletizing system, including cooling pelletizing systems and special machines for plastics. Their import service is fast, with delivery in 7 to 20 days. They check quality carefully and let customers buy in different ways. This makes Nanjing Metal a trusted choice for companies that want to work faster and make better pellets.

Tip: Companies that buy custom pelletizing knives from experts like Nanjing Metal Industrial CO., Limited can work faster, use knives longer, and make better pellets than others.

Choosing the Right Air Ring Pelletizing Knife Supplier

Qualidade do produto

Product quality is very important for pelletizers to work well. The best suppliers make knives that follow strict rules. The table below shows what to look for when checking blade quality:

| Criterion | Details / Range |

|---|---|

| Velocidade da lâmina | 1,500–3,500 RPM |

| Precisão de corte | ±0.05 mm |

| Dureza (HRC) | 60-72 |

| Opções de materiais | Tungsten Carbide, D2 Tool Steel, Stainless Steel (440C) |

| Material | Dureza (HRC) | Resistência ao desgaste | Resistência à corrosão | Aplicação recomendada |

|---|---|---|---|---|

| Carboneto de tungstênio | 72 | Muito alto | Moderado | Corte de alta velocidade, longa vida útil |

| Aço para ferramentas D2 | 60-62 | Alto | Moderado | Peletização de uso geral |

| Aço inoxidável (440C) | 58-60 | Moderado | Muito alto | Ambientes corrosivos |

Good suppliers make sure pelletizers keep high blade speed and accuracy. These things help strand pelletizers make even pellets and work faster.

Capacidades de personalização

Customization helps pelletizers meet specific needs. Suppliers who make lâmina personalizada shapes, sizes, and materials help factories use strand pelletizers for many plastics. Custom knives help machines work better and faster. They also help control pellet temperature and stop pellets from sticking together. This makes pellet quality better.

- Custom knives are made for certain machines and jobs.

- Suppliers test knives to make sure they work well and keep pellets from sticking.

- Special coatings and additives can help stop pellets from clumping.

Global Reach

A supplier with global reach can help pelletizers in many places. Companies with worldwide shipping and support send knives quickly to factories using strand pelletizers everywhere. This wide network keeps supply steady and helps factories work well, even if demand changes.

After-Sales Support

After-sales support helps pelletizers keep running without problems. Good suppliers give technical help, advice, and quick replacement parts. This support lowers downtime and helps machines work better. Factories with strand pelletizers get expert help, which keeps production high and pellets good.

Tip: Picking a supplier with great after-sales support can stop expensive delays and help pelletizers work their best.

Picking the best air ring pelletizing knife supplier helps factories do well. Experts looked at more than twenty things about suppliers using real market facts. The most important things are speed, price, quality, and service. When companies buy a lot, price and quality matter most. For new products, speed and service are more important.

- Companies should make a simple list of what they need before talking to suppliers.

- Checking how well suppliers do helps make sure products stay good and suppliers can be trusted.

- For custom jobs, Nanjing Metal Industrial CO., Limited is a trusted choice.Choosing the right supplier means better pellets, saving money, and easier work.

Perguntas frequentes

What is an air ring pelletizing knife?

An air ring pelletizing knife is a tool for cutting. It works in air-cooled strand pelletizers. The knife cuts melted plastic strands into small, even pellets. Factories use these knives to make plastic pellets for many things.

How often should an Air Ring pelletizing knife be replaced?

You should change a pelletizing knife when it gets dull or does not cut well. Checking the knife often helps keep pellets good and machines working fast.

What materials are best for pelletizer blades?

| Material | Benefício principal |

|---|---|

| Aço de alta velocidade | Stays sharp longer |

| Carboneto de tungstênio | Very hard and strong |

| Aço para ferramentas D2 | Desgasta-se lentamente |

Engineers pick the blade material based on what plastic is used and how much is made.

Can pelletizing knives be customized for different machines?

Yes. Companies can make special pelletizing knives for different pelletizer models and jobs. Custom knives help cut better and last longer.

Why is after-sales support important for pelletizer knife users?

Good after-sales support means help is fast when there is a problem. It gives quick fixes, new parts, and advice. This keeps machines running and pellets looking good.

Veja também

Encontre as Lâminas de Pelletização Perfeitas para Suas Necessidades de Processamento de Plástico

Lâminas de Pelletização Comparadas: Encontre Facilmente a Certa

O Que São Lâminas de Pelletizador e Como Elas Funcionam na Indústria?

Como selecionar a faca peletizadora certa para sua indústria

Guia Completo para Escolher a Melhor Faca Peletizadora para Sua Máquina