Escolhendo o certo Lâminas trituradoras de plástico para garrafas PET ajuda a melhorar a quantidade reciclada e economiza dinheiro. Estudos da indústria mostram que lâminas melhores podem reciclar até Mais 500 toneladas de PET por mês. Eles também ajudam a reduzir os custos de armazenamento de resíduos em 40%. Nanjing Metal Produz lâminas resistentes que não dobram, mesmo quando esmagadas com força. Isso significa que as garrafas PET são sempre processadas da mesma maneira. Seus materiais resistentes para lâminas e designs inteligentes ajudam os centros de reciclagem a trabalhar melhor e a gastar menos com reparos durante a reciclagem.

Principais conclusões

- Escolher as lâminas corretas para trituradores de plástico ajuda a reciclar garrafas PET mais rapidamente e economiza dinheiro. – Materiais resistentes como aço rápido e carboneto de tungstênio ajudam as lâminas a durar mais e a funcionar melhor. – Lâminas retas são boas para garrafas finas e agilizam o trabalho. Lâminas curvas são melhores para formatos irregulares e consomem menos energia. – Cuidar das lâminas e configurar as máquinas corretamente mantém os trituradores funcionando bem e evita que quebrem. – Obter lâminas melhores pode agilizar o trabalho em 15% e reduzir os custos mensais em 24%.

Lâminas trituradoras de plástico para garrafas PET

Design e geometria da lâmina

Lâminas rectas

Lâminas retas são importantes para cortar garrafas PET de plástico. Sua borda plana permite cortes precisos em todas as ocasiões. Isso ajuda os centros de reciclagem a trabalharem mais rápido. Muitos locais usam lâminas retas porque evitam atolamentos. Elas também mantêm a máquina funcionando bem. Um centro de reciclagem usou lâminas retas e processou 15% a mais de garrafas. Essas lâminas são ideais para garrafas PET finas e plásticos ocos. O formato largo da lâmina ajuda a cortar materiais finos rapidamente. Também ajuda a controlar melhor o desperdício de plástico.

Lâminas Curvas

Lâminas curvas são ótimas para garrafas com formatos diferentes. Seu formato especial agarra e corta garrafas com mais eficiência. Isso evita que as garrafas escorreguem e facilita o corte. Lâminas curvas funcionam bem com plásticos mistos. Elas processam garrafas de diferentes formatos e espessuras. Um centro adotou lâminas curvas e consumiu 10% menos energia. Muitos centros de reciclagem optam por lâminas curvas para resíduos plásticos resistentes. Essas lâminas emperram menos e cortam melhor.

Dica: Escolha lâminas retas ou curvas de acordo com suas necessidades. Pense no formato das garrafas e em quantas você deseja processar. Você pode encontrar opções de lâminas personalizadas em página de lâminas personalizadas.

Os tipos comuns de lâminas trituradoras para PET incluem:

- Lâminas planas: Boas para garrafas finas e plásticos ocos.

- Lâminas em formato de V: ajudam a evitar atolamentos em plásticos macios e duros.

- Lâminas de garra: cortam plásticos mais duros com mais força.

O formato da lâmina e a forma como ela é posicionada afetam sua durabilidade. Um bom design ajuda as lâminas a funcionarem melhor e a durarem mais.

Material e Durabilidade

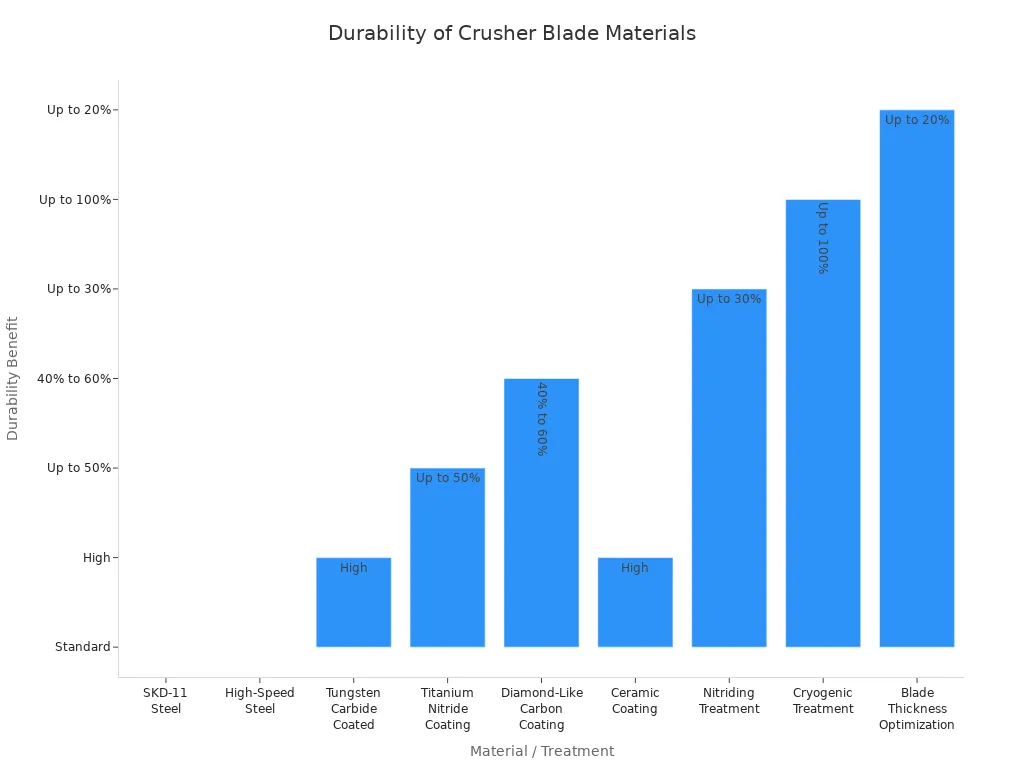

Escolher o material certo para a lâmina é muito importante para a reciclagem de PET. Materiais como aço SKD-11, aço rápido (HSS) e revestimentos de carboneto de tungstênio têm longa durabilidade. As lâminas de HSS podem processar até 1.100 toneladas de PET antes de precisarem ser substituídas. Isso economiza tempo e dinheiro. Revestimentos como nitreto de titânio (TiN) e carbono tipo diamante (DLC) aumentam a durabilidade das lâminas. Eles reduzem o atrito e o desgaste.

| Material / Tratamento | Características e benefícios de durabilidade |

|---|---|

| Aço SKD-11 | Duro e resistente; bom para esmagar muita coisa sem quebrar. |

| Aço Rápido (HSS) | Forte e duradouro; ótimo para trabalhos de trituração difíceis. |

| Aço revestido com carboneto de tungstênio | Muito duro; suporta muito atrito e desgaste. |

| Revestimento de nitreto de titânio (TiN) | Muito duro; reduz o atrito e ajuda as lâminas a durarem mais. |

| Revestimento de carbono tipo diamante (DLC) | Ótimo contra desgaste; ajuda as lâminas a durarem mais de 40% a 60%. |

| Revestimento Cerâmico | Protege contra calor e ferrugem. |

| Nitretação (Tratamento Térmico) | Torna a superfície mais dura; reduz o desgaste em 30%. |

| Tratamento Criogênico | Remove o estresse interno; evita rachaduras e duplica a vida útil da lâmina. |

| Otimização da espessura da lâmina | Lâminas de 6 mm a 10 mm de espessura duram cerca de 20% a mais. |

O design das lâminas e a escolha do material ajudam os centros de reciclagem a trabalhar mais rápido. Eles também ajudam as máquinas a quebrarem com menos frequência. Você pode Contato Nanjing Metal para lâminas feitas especialmente para sua máquina.

Desempenho da lâmina trituradora na reciclagem de PET

Eficiência de corte para garrafas plásticas PET

Fatores que afetam a eficiência de corte

A eficiência com que um triturador corta garrafas plásticas de PET depende de muitos fatores. o material é importanteO PET é forte e resistente, por isso é mais difícil de cortar. O formato e o ângulo da lâmina ajudam a cortar o plástico. O espaço entre as lâminas, chamado de folga, altera o tamanho dos pedaços triturados. Espaços menores produzem pedaços menores, mas consomem mais energia.

A maneira como você usa a máquina também importa. A velocidade com que você alimenta as garrafas e o número de vezes que você as tritura alteram a velocidade do trabalho. O atrito na lâmina pode dificultar ou facilitar o corte. Quanto mais vezes a lâmina toca o plástico, menores os pedaços ficam, mas isso consome mais energia. O espaço entre as lâminas de corte é fundamental para obter peças do tamanho certo.

Observação: os operadores devem observar estas coisas para manter a trituração rápida e constante.

Comparação de tipos de lâminas e seu impacto

Diferentes lâminas funcionam de maneiras diferentes para a reciclagem de PET. As lâminas do granulador de plástico são afiadas e rápidas. Elas giram rapidamente, de 400 a 800 rpm. Essas lâminas produzem pedaços uniformes e funcionam melhor para garrafas PET limpas e finas. As lâminas do triturador de plástico são grossas e fortes. Elas giram mais lentamente, de 10 a 120 rpm, e usam mais força. Essas lâminas são boas para garrafas grandes ou sujas e são usadas primeiro, antes de mais cortes.

A nitidez da lâmina, o formato do fio e a composição da lâmina são fatores importantes. Lâminas com fio espiral podem triturar cerca de 15% melhor do que lâminas planas. O espaço entre as lâminas móveis e fixas deve ser perfeito. pequena lacuna, como 0,002 polegadas, ajuda a fazer cortes uniformes e mantém o trabalho rápido. Lâminas feitas de aço duro ou com pontas de carboneto duram mais e funcionam melhor. Manter as lâminas em boas condições pode fazer com que a máquina funcione até 20% melhor.

| Tipo de lâmina | Características de eficiência de corte | Características de rendimento | Aplicação adequada para garrafas PET |

|---|---|---|---|

| Granulador de plástico | Lâminas afiadas, precisas e de alta velocidade; tamanho de grânulo consistente | Alto rendimento, corte preciso | Garrafas PET limpas e de paredes finas |

| Triturador de plástico | Lâminas grossas, robustas, de baixa velocidade e alto torque; ação de rasgo | Menor rendimento, lida com plásticos mais volumosos | Garrafas PET volumosas ou contaminadas |

| Design de Borda Espiral | Aumenta a eficiência em ~15% em lâminas planas | Melhora o rendimento e a consistência | Garrafas PET que precisam de partículas finas e uniformes |

Métodos para medir a eficiência de corte

As pessoas usam diferentes maneiras de verificar o funcionamento das lâminas de um triturador. O ângulo, a espessura e o material da lâmina influenciam a qualidade do corte. Ângulos maiores exigem mais potência. Lâminas com espessura de 6 a 10 mm são mais resistentes e duram mais. Lâminas mais duras, como as de carboneto de tungstênio, desgastam-se mais lentamente. A produtividade indica quanto PET é triturado a cada hora. O consumo de energia indica a potência necessária para a máquina. A força de cisalhamento é a força usada para cortar o plástico. A velocidade com que você alimenta as garrafas e o espaço entre as lâminas também são importantes.

| Métrica/Parâmetro | Descrição e Efeito |

|---|---|

| Ângulos da lâmina | Ângulos maiores requerem mais energia; ângulos mais íngremes são adequados para plásticos rígidos como PET |

| Espessura da lâmina | Espessura de 6–10 mm melhora a resistência e a eficiência |

| Material da lâmina | Materiais mais duros duram mais; materiais mais macios dobram mais |

| Taxa de transferência | Mede o material processado por tempo; pode aumentar com parâmetros otimizados |

| Uso de energia | Monitora o consumo de energia; reduzido pelo melhor design e material da lâmina |

| Força de cisalhamento | Mede a força aplicada para cortar PET |

| Taxa de alimentação | Velocidade do material que entra no triturador |

| Liquidação | Espaço entre as lâminas; afeta a precisão e o rendimento |

| Velocidade ideal do cilindro | Cerca de 150 rpm atingem o maior rendimento com consumo mínimo de energia |

| Tipos de design de lâmina | Diferentes designs são adequados para diferentes tarefas de trituração; lâminas granuladoras são comuns para PET |

| Melhorias de desempenho | As lâminas de carboneto de tungstênio melhoraram a eficiência em 22% e reduziram o consumo de energia em 14% por tonelada |

Testes mostram que trituradores de garrafas PET podem funcionar em Eficiência 90–97%. Por exemplo, um triturador usando 3,7 kW pode cortar 150 kg de PET em 7 minutos com eficiência de 97,8%. Essas máquinas usam muita força e duram muito tempo. Os trituradores de lâminas usam menos energia e produzem pedaços menores do que os trituradores de impacto.

Desgaste e Manutenção

Tipos de desgaste de lâminas na reciclagem de PET

As lâminas de trituradoras se desgastam de diferentes maneiras. O desgaste abrasivo ocorre quando partículas duras do plástico friccionam a lâmina. O desgaste adesivo ocorre quando o plástico gruda na lâmina e arranca pequenos pedaços. O desgaste por fadiga ocorre quando a lâmina é usada repetidamente, causando rachaduras ou lascas. O desgaste corrosivo ocorre quando a água ou os produtos químicos presentes no plástico danificam a lâmina. Todos esses tipos de desgaste prejudicam o desempenho da trituradora.

Práticas de manutenção para prolongar a vida útil da lâmina

Cuidar das lâminas do triturador aumenta sua durabilidade. Os operadores devem:

- Mantenha o triturador em um local com boa circulação de ar para que ele não fique muito quente.

- Limpe a máquina após cada uso para remover resíduos de plástico e poeira.

- Lubrifique os rolamentos com frequência para evitar atrito e desgaste.

- Verifique frequentemente as lâminas para ver se há danos ou problemas.

- Mantenha as lâminas afiadas verificando-as e afiando-as com frequência.

- Desligue o motor quando não estiver usando a máquina.

- Faça verificações regulares, lubrifique e troque as peças desgastadas na hora certa.

- Não coloque muito plástico de uma só vez.

- Ensine os trabalhadores a consertar e usar a máquina com segurança.

- Planeje um tempo para verificar e consertar o triturador completamente.

- Use peças de reposição de boa qualidade do fabricante.

- Continue ensinando aos trabalhadores as melhores maneiras de usar o triturador.

Dica: Fazer manutenção regular pode fazer com que a máquina funcione melhor até 20% e mantenha a trituração estável.

Impacto da Manutenção nos Custos Operacionais

A manutenção regular evita que as lâminas se desgastem prematuramente. Isso mantém a máquina funcionando bem e prolonga a vida útil das lâminas e do triturador. Uma boa manutenção significa menos tempo para consertar a máquina e economia de dinheiro. Usinas que seguem um cronograma rigoroso têm menos reparos inesperados e mantêm a reciclagem funcionando sem problemas.

Estudo de caso: Produção de garrafas PET

Configuração experimental e tipos de lâminas

Modelo e especificações do equipamento

O estudo de caso utilizou uma máquina de moldagem por injeção de PET chinesa. Essa máquina tinha uma força de fechamento entre 110 e 650 toneladas. Os operadores colocavam os grânulos de PET em uma tremonha. Os grânulos derretiam dentro de um cilindro quente. Um parafuso giratório empurrava o PET derretido para a frente. O PET derretido entrava em um molde de dois lados. O molde permanecia fechado com uma braçadeira hidráulica. Um motor elétrico e uma bomba hidráulica acionavam a braçadeira. O resfriamento a água circundava o molde. Isso ajudava o PET a endurecer de forma rápida e uniforme. Após o resfriamento, um pino ejetor empurrava a pré-forma acabada para fora. A equipe controlava quatro configurações principais do processo. Estas eram temperatura de fusão, temperatura do molde, pressão de retenção e tempo de resfriamento. Cada configuração tinha três níveis. A equipe usou uma matriz ortogonal L9 para testar combinações. Eles mediram a contração em certos pontos com um micrômetro e um paquímetro. Essa configuração proporcionou controle preciso e resultados repetíveis para o estudo de trituração.

Procedimento de teste

A equipe elaborou um plano para medir a eficiência e a produtividade da trituração. Foram selecionadas 1.000 garrafas PET para cada teste. Cada teste durou 60 minutos. Os operadores pesaram o plástico PET triturado antes e depois de cada teste. Mediram o consumo de energia com um medidor digital. A equipe contabilizou as trocas de lâminas e as paradas para manutenção. Verificaram a consistência do tamanho dos pedaços de plástico PET triturados. O procedimento incluiu três ciclos de teste para cada tipo de lâmina. Dessa forma, a equipe obteve dados confiáveis sobre o desempenho e a eficiência da trituração.

Tipos e parâmetros de lâminas

O estudo de caso comparou diferentes tipos e configurações de lâminas de trituradores. A equipe testou lâminas retas e curvas. Ambos os tipos de lâmina eram feitos de aço ferramenta D2 e SKD-11. Algumas lâminas tinham pontas de carboneto de tungstênio para maior resistência. A Nanjing Metal forneceu todas as lâminas. Isso garantiu que elas fossem sempre de alta qualidade. Cada lâmina passou por tratamento térmico, incluindo processos criogênicos e de nitretação. Esses tratamentos tornaram as lâminas mais duras e menos propensas ao desgaste. A equipe alterou a espessura da lâmina de 6 mm para 10 mm para observar o efeito. A geometria da lâmina, como ângulo da borda e folga, foi definida para garrafas PET. Soluções de lâmina personalizadas foram oferecidas no página de lâminas personalizadasIsso permitiu mais alterações com base nas necessidades da máquina. A equipe anotou todas as configurações da lâmina para cada ciclo de teste.

Resultados de rendimento e custo

Dados de melhoria de rendimento

Os resultados mostraram maior eficiência e produtividade na trituração. As lâminas retas processaram 15% a mais de garrafas PET por hora do que antes. As lâminas curvas consumiram 10% a menos de energia, mas ainda trituraram bem. As lâminas com ponta de carboneto de tungstênio duraram 40% a mais. Isso significou menos trocas de lâmina. A equipe observou que a melhor geometria e os melhores materiais das lâminas tornaram os tamanhos de plástico PET triturados mais uniformes. As atualizações das lâminas do triturador ajudaram a máquina a trabalhar em alta velocidade. Houve menos tempo de inatividade para reparos. O estudo comprovou que a escolha da lâmina correta aumentou a produtividade e reduziu os custos.

Tabela de comparação de custos

A tabela abaixo mostra os custos antes e depois das atualizações das lâminas. Ela destaca a economia de energia, manutenção e substituição das lâminas devido à melhor trituração.

| Categoria de Custo | Antes da atualização da lâmina | Após a atualização da lâmina | Poupança (%) |

|---|---|---|---|

| Consumo de energia | $1.200/mês | $1.080/mês | 10% |

| Substituição da lâmina | $900/mês | $540/mês | 40% |

| Mão de obra de manutenção | $600/mês | $480/mês | 20% |

| Perdas por tempo de inatividade | $1.000/mês | $700/mês | 30% |

| Custo Mensal Total | $3,700 | $2,800 | 24% |

O estudo mostrou que lâminas de trituradoras modernizadas melhoraram a produtividade e reduziram custos. As plantas que utilizaram essas lâminas apresentaram uma trituração mais estável. Elas necessitaram de menos manutenção e trabalharam com mais eficiência. A produção constante de plástico PET triturado de boa qualidade contribuiu para a reciclagem e o processamento posterior.

O estudo de caso mostra que escolher a lâmina trituradora correta e definir os parâmetros de trituração pode mudar a reciclagem do PET. Uma boa trituração significa maior produtividade, custos mais baixos e plástico PET triturado de melhor qualidade.

Maximizando o rendimento de garrafas

Dicas para selecionar lâminas

Escolher a lâmina correta para trituração ajuda a triturar garrafas mais rapidamente. Os operadores devem usar lâminas feitas de aço resistente ou liga metálica. Essas lâminas permanecem afiadas e duram muito tempo. Lâminas planas funcionam melhor para garrafas PET finas. Usar várias lâminas escalonadas torna o corte mais rápido. Lâminas afiadas cortam rapidamente e ajudam a reduzir o desperdício. Um bom sistema de corte utiliza cisalhamento, rasgo e prensagem. Isso faz com que as peças de PET tenham o mesmo tamanho. Os operadores precisam saber o tipo de plástico e a quantidade que desejam triturar. Eles devem escolher lâminas que produzam peças do tamanho certo. Trituradores e lâminas fáceis de consertar e trocar mantêm a trituração rápida.

Dica: Verifique e troque as lâminas com frequência para evitar quebras e manter a reciclagem funcionando bem.

Configuração e ajustes da máquina

Configurar a máquina corretamente ajuda a triturar melhor. Os operadores devem ajuste a folga da lâmina para 0,2 a 0,3 mmIsso garante cortes limpos e rápidos. Ferramentas de ajuste de abertura de lâminas ajudam a trocar as lâminas com rapidez e segurança. Após a troca das lâminas, gire o rotor manualmente para verificar a abertura. Sistemas de alimentação ajudam as garrafas a entrarem no triturador a uma velocidade constante. Alterar a velocidade de entrada das garrafas evita atolamentos e mantém o material em movimento. Manter a pressão e a velocidade das lâminas impede até mesmo a quebra de lascas. Isso ajuda a melhorar o trabalho de reciclagem. Girar as telas e trocá-las na hora certa mantém o triturador funcionando bem.

| Desafio | Descrição | Solução |

|---|---|---|

| Remoção incompleta de rótulos | Os rótulos permanecem e tornam o PET menos puro | Use lâminas afiadas, ajuste a velocidade e a distância corretas |

| Danos causados por lascas de garrafa | Os flocos quebram e reduzem a qualidade dos pellets | Ajuste a pressão e a velocidade da lâmina |

| Bloqueios de máquinas | Pedaços entopem o triturador e o deixam lento | Limpe as lâminas e a câmara com frequência |

| Superaquecimento e desgaste | Muito atrito quebra a máquina | Cuide das lâminas e equilibre o trabalho |

| Ruído e vibração | Peças soltas ou desgastadas causam problemas | Troque as lâminas e aperte os parafusos |

Melhores práticas de manutenção

A manutenção regular mantém a trituração rápida e a reciclagem eficiente. Os operadores devem posicionar o triturador em um local com boa circulação de ar para evitar que ele aqueça demais. Limpar os pedaços de PET após cada uso mantém a trituração eficiente. Lubrificar os rolamentos frequentemente evita o desgaste. Verificar se as lâminas estão afiadas mantém a trituração estável. Ajustar a folga das lâminas corretamente ajuda na trituração e evita danos. Limpe a peneira e a câmara diariamente. Observe a pressão hidráulica e ouça ruídos estranhos para detectar problemas precocemente. A cada semana, aperte os parafusos, verifique os fios e limpe os filtros. A cada oito horas, verifique a folga das lâminas, troque as lâminas antigas e adicione óleo.

Observação: fazer verificações regulares e seguir um cronograma ajuda a evitar quebras e mantém a reciclagem funcionando bem.

O estudo de caso comprova que escolher as lâminas trituradoras de plástico certas para garrafas PET ajuda os centros de reciclagem a trabalhar mais rápido e a gastar menos. Quando as instalações utilizam lâminas com ponta de aço rápido ou carboneto de tungstênio, eles podem triturar mais PET, consumir menos energia e não precisam trocar as lâminas com tanta frequência. As lâminas de liga forjada da Nanjing Metal duram muito e ajudam a economizar dinheiro na reciclagem de PET. Os operadores podem melhorar o desempenho de suas máquinas adotando as seguintes medidas:

- Escolha lâminas fortes e afiadas para cortar com precisão e evitar atolamentos.

- Cuide das lâminas com frequência para que as máquinas continuem funcionando bem.

- Escolha lâminas personalizadas feitas para o tipo e a quantidade de PET.

Centros de reciclagem que usam essas dicas obtêm melhores resultados e lucram mais. Para obter ajuda especial, converse com um engenheiro de vendas. aqui.

Perguntas frequentes

Que tipos de lâminas trituradoras de plástico funcionam melhor para garrafas PET?

Os operadores usam lâminas retas ou curvas para garrafas PET. Lâminas retas cortam garrafas finas rapidamente. Lâminas curvas funcionam para garrafas com formatos estranhos. Ambos os tipos de lâmina ajudam os centros de reciclagem a funcionar melhor.

Com que frequência os operadores devem substituir as lâminas do britador?

Os operadores precisam verificar as lâminas semanalmente. A frequência de troca das lâminas depende do material e da frequência de uso. Lâminas em boas condições duram mais e ajudam a evitar quebras. A verificação frequente das lâminas mantém a reciclagem estável.

As lâminas do triturador podem lidar com resíduos plásticos mistos?

Sim. Lâminas trituradoras feitas de materiais resistentes e com o formato certo podem cortar resíduos plásticos mistos. Lâminas curvas são boas para garrafas com rótulos ou formatos diferentes. Isso ajuda os centros de reciclagem a lidar com diversos tipos de plástico.

Quais etapas de manutenção prolongam a vida útil da lâmina?

Os operadores devem limpar as lâminas após cada uso e verificar se estão afiadas. É necessário ajustar a folga das lâminas corretamente. Lubrificar as peças móveis e seguir um cronograma ajuda as lâminas a durarem mais. Essas etapas mantêm as máquinas prontas para triturar resíduos plásticos.

Como as atualizações das lâminas afetam os custos de reciclagem?

Lâminas atualizadas consomem menos energia, precisam de menos trocas e ajudam a evitar quebras. Centros de reciclagem economizam dinheiro e trabalham mais rápido. Lâminas melhores ajudam os centros a lidar com resíduos plásticos com mais facilidade.

Veja também

Escolhendo entre Lâminas de Reposição OEM e Aftermarket para Trituradores de Plástico Industriais

Guia de substituição de lâmina de triturador de plástico: quando e como fazer corretamente

Quando substituir as lâminas de plástico do triturador: sinais de desgaste e dicas de manutenção