Escolhendo o certo lâmina de corte de rolo é crucial. Não se trata apenas de cortar; trata-se de cortar melhor. Uma lâmina de corte de rolo de qualidade proporciona bordas mais lisas e um trabalho mais rápido. Ela também tem uma vida útil mais longa, o que significa que você precisará substituí-la com menos frequência. Você sabia que usar as ferramentas certas pode economizar até 30% em custos? É um valor significativo! Se você optar por uma lâmina personalizada ou um padrão, selecionar o correto aumenta a precisão e minimiza o desperdício. Se não tiver certeza de por onde começar, entre em contato com fornecedores confiáveis, como Nanjing Metal. Eles podem ajudá-lo a encontrar a lâmina perfeita. Não hesite em Contato especialistas — eles estão lá para ajudar você.

Principais conclusões

- Escolher a lâmina de corte correta ajuda a cortar melhor o trabalho. Uma boa lâmina pode reduzir custos em até 30%.

- O desempenho da lâmina varia de acordo com o material. Use lâminas de carboneto para trabalhos pesados. Aço-liga é ideal para tarefas cotidianas.

- Lâminas personalizadas atendem a necessidades especiais de corte. Eles são mais precisos e duram mais, o que os torna mais vantajosos.

- Cuidar das lâminas é importante. Limpe-as e lubrifique-as para que durem mais e funcionem bem.

- Peça conselhos a especialistas ou vendedores de confiança. As dicas deles podem ajudar você a escolher a lâmina ideal para as suas necessidades.

Compreendendo as lâminas de corte de rolos

O que são lâminas de corte de rolo?

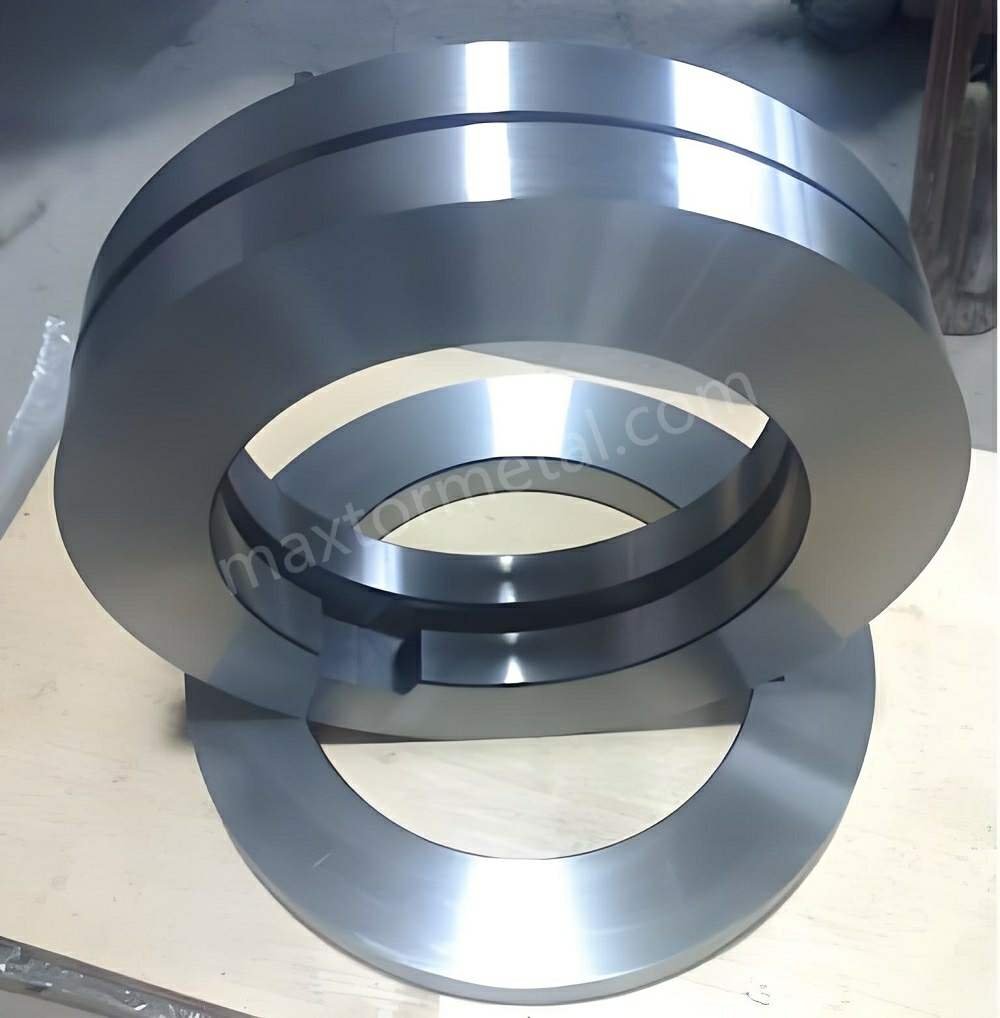

UM lâmina de corte de rolo é uma ferramenta especial para cortar materiais. Essas lâminas são utilizadas em indústrias que necessitam de cortes limpos e precisos. Elas funcionam girando contra outra lâmina, fatiando o material. Imagine uma tesoura, mas muito maior e mais forte. Indústrias como metalurgia, fabricação de papel e indústria automobilística dependem dessas lâminas.

Tipos de lâminas de corte de rolo

Existem diferentes tipos de Lâminas Circulares para Corte Longitudinal de MetalCada tipo é feito para uma função específica. Aqui está uma lista simples:

- Lâminas rectas:Melhor para cortes retos em metal ou papel.

- Lâminas Circulares: Ótimo para cortes contínuos em tecidos ou plásticos.

- Lâminas Serrilhadas:Feito de materiais resistentes, proporcionando melhor aderência e precisão.

- Lâminas Personalizadas: Projetado para necessidades específicas para funcionar perfeitamente.

O material da lâmina afeta o seu funcionamento. Consulte esta tabela para saber mais sobre materiais da lâmina:

| Tipo de material | Características |

|---|---|

| Aço com alto teor de carbono e alto teor de cromo | Muito duro, resistente ao desgaste, resistente, funciona em muitos materiais. |

| Aço para ferramentas de liga | Tenacidade e resistência ao desgaste equilibradas, duram mais. |

| Aço Rápido (HSS) | Permanece afiado em altas velocidades, ótimo para trabalhos difíceis. |

| Carboneto | Extremamente duro, resiste ao desgaste, corta materiais abrasivos e dura muito. |

Aplicações em todos os setores

Lâminas Circulares para Corte Longitudinal de Metal são utilizados em diversos setores. Aqui estão alguns exemplos:

| Indústria | Descrição da aplicação | Resultado |

|---|---|---|

| Fabricação | Lâminas de aço fortes reduzir o tempo de inatividade em 30% com maior durabilidade. | Trabalhe mais rápido e economize tempo. |

| Fabricação Metal | Um estudo mostrou que as configurações de prensas dobradeiras ficaram mais rápidas com essas lâminas. | Economizou tempo e reduziu custos de mão de obra. |

Essas lâminas também são usadas em embalagens para cortar papelão ou plástico. Seus cortes precisos e designs inteligentes as tornam ferramentas essenciais em muitos setores.

Materiais usados em lâminas de corte de rolos

O material de um lâmina de corte de rolo afeta seu funcionamento. Você pode se perguntar: "Por que uma lâmina é melhor que outra?". A resposta está no material de que ela é feita. Diferentes materiais têm resistências únicas. Escolher a lâmina certa depende do que você precisa cortar.

Materiais comuns e suas propriedades

Aqui está uma comparação simples dos materiais usados nessas lâminas:

| Propriedade | Liga de aço | Aço ferramenta | Aço Rápido (HSS) |

|---|---|---|---|

| Dureza | HRC 57–59 (baixa liga) | HRC 58–62 | HRC 60+ |

| Dureza | Muito forte | Médio | Inferior (pode quebrar facilmente) |

| Resistência ao desgaste | Bom | Excelente | Melhor |

| Resistência ao calor | Médio a alto | Alto | Muito alto |

| Melhor para | Chapas grossas, aço inoxidável | Aço de alto carbono, chapas grossas | Materiais finos, corte rápido |

| Custo | Médio | Mais alto | Mais alto |

Cada material tem suas próprias vantagens. Por exemplo, o aço-liga é resistente e ótimo para chapas grossas. O aço rápido (HSS) é perfeito para trabalhos rápidos, mas pode quebrar com mais facilidade.

Componentes-chave que fazem a diferença

O segredo da força de uma lâmina está nos seus ingredientes. Aqui estão alguns importantes:

- Cromo: Impede a ferrugem e torna a lâmina mais dura.

- Tungstênio: Adiciona resistência e mantém a lâmina afiada sob calor.

- Vanádio: Torna a lâmina mais resistente e duradoura.

- Molibdênio: Ajuda a lâmina a permanecer forte em altas temperaturas.

Essas peças trabalham juntas para produzir lâminas afiadas e duráveis.

O que isso significa para você?

Escolher o material certo não se resume apenas à sua durabilidade. Trata-se também de trabalhar mais rápido e melhor. Se você corta materiais grossos, aço-liga ou aço-ferramenta são boas opções. Para trabalhos rápidos, o aço rápido (HSS) pode economizar tempo. Conhecer esses materiais ajuda você a escolher a lâmina ideal para suas necessidades.

Fatores-chave para escolher a melhor lâmina de corte de rolo

Escolhendo o certo lâmina de corte de rolo Não é simples. Você precisa pensar em muitas coisas para garantir que funcione bem para as suas necessidades. Vamos analisar passo a passo.

Material da lâmina

O material da lâmina é muito importante. Diferentes materiais têm diferentes resistências. Conhecer esses detalhes pode ajudar você a escolher a melhor.

Tipos de Materiais

As lâminas são feitas de materiais diferentes, cada um adequado para tarefas específicas. Aqui está uma rápida olhada em principais características a serem consideradas:

| Recurso | O que isso significa |

|---|---|

| Força | Pode suportar pressão, atrito e força sem quebrar. |

| Fragilidade | Mostra o quão facilmente a lâmina pode quebrar sob estresse. |

| Dureza | Indica o quão bem a lâmina resiste à flexão ou danos. |

| Peso | Afeta o quão equilibrada e fácil é a utilização da máquina. |

| Usinabilidade | Mostra como é simples fazer ou ajustar a lâmina. |

| Soldabilidade | Explica como o material da lâmina funciona bem na soldagem. |

| Preço | Reflete quanto custa o material e sua disponibilidade. |

| Resistência à corrosão | Mostra o quão bem a lâmina evita ferrugem ou danos causados pelo ambiente. |

| Condutividade | Importante para tarefas de corte que envolvam eletricidade estática. |

| Resistência ao desgaste | Informa quanto tempo a lâmina dura quando usada muito. |

| Temperatura | Explica como a lâmina funciona bem em condições muito quentes ou muito frias. |

Dica: Se você corta materiais ásperos, escolha uma lâmina com alta resistência ao desgaste, como carboneto. Para cortes em geral, o aço-liga é resistente e acessível.

Recursos de desempenho

Cada material possui qualidades especiais. Por exemplo, lâminas de aço de alto carbono são resistentes e ótimas para cortes pesados. Lâminas de aço rápido (HSS) permanecem afiadas mesmo em altas temperaturas, tornando-as perfeitas para trabalhos rápidos. Sempre combine o material com suas necessidades de corte para obter os melhores resultados.

Tamanho e espessura da lâmina

O tamanho e a espessura da lâmina afetam a qualidade do corte e o ajuste à máquina. Vamos ver por que isso importa.

Combinando o tamanho certo

É importante combinar o tamanho da lâmina com a sua máquina e o material que você está cortando. Aqui estão alguns pontos a serem considerados:

- Materiais Finos: Use o Modo 3 (eco a eco) para maior precisão.

- Materiais espessos: O modo 2 (interface para o primeiro eco de retorno) funciona melhor.

- Faixa de espessura: Medidores de alta frequência podem medir materiais finos de até 0,15 mm (0,006 polegadas). Para materiais mais espessos, o Modo 2 trabalha até 0,5 mm (0,020 polegadas).

- Pontos Mortos: Lâminas ocas podem apresentar áreas que interferem nas medições. Escolha a ferramenta certa para evitar erros.

Observação: Consulte sempre o manual da sua máquina para obter sugestões de tamanho de lâmina. Usar o tamanho errado pode causar cortes ruins ou danificar sua máquina.

Impacto de corte

A espessura da lâmina altera a velocidade e a precisão dos seus cortes. Lâminas finas são ideais para trabalhos detalhados. Lâminas grossas são mais indicadas para trabalhos mais pesados, mas exigem mais potência. Certifique-se de que sua máquina seja compatível com o tamanho da lâmina. Uma boa combinação melhora o corte e reduz o desgaste da sua máquina.

Capacidade de corte

Quão bem um lâmina de corte de rolo O corte depende do tipo de lâmina e da velocidade. Vamos analisar esses detalhes.

Estilos de Borda

O estilo do fio determina como a lâmina corta o material. Os estilos comuns incluem:

- Bordas retas: Ideal para cortes limpos em papel ou metal fino.

- Bordas dentadas: Ótimo para segurar e cortar materiais resistentes.

- Bordas circulares: Perfeito para cortes contínuos em plásticos ou tecidos.

Cada estilo tem seu uso próprio, então escolha um baseado no seu trabalho.

Velocidade de corte

A velocidade de corte afeta a rapidez com que você trabalha e a durabilidade da lâmina. Velocidades mais altas economizam tempo, mas podem desgastar a lâmina mais rapidamente, especialmente em materiais ásperos. Pesquisas mostram que:

| Tipo de estudo | Resultados |

|---|---|

| Testes ANOVA | O tipo e a profundidade da lâmina afetam muito a força do corte e os resultados. |

| Comparação de Forças de Tração | Discos ondulados necessários 675 N (a maioria), discos entalhados necessitam de 579 N (mínimo). |

| Impacto de profundidade | A força de corte triplicou quando a profundidade aumentou de rasa (291 N) para profunda (965 N). |

| Forças Verticais | Os discos ondulados tinham 289 N (mais alto), os discos entalhados tinham 164 N (mais baixo). |

| Sucesso na redução de resíduos | Mediu o quão bem os resíduos foram removidos durante os testes. |

Dica profissional: Para materiais grossos ou resistentes, use uma velocidade mais baixa e um fio forte. Isso ajuda a lâmina a durar mais e proporciona cortes mais limpos.

Necessidades de manutenção

Cuidados regulares

Cuidando do seu lâmina de corte de rolo mantém a lâmina afiada e útil. A manutenção regular previne danos e economiza dinheiro ao longo do tempo. Sempre limpe a lâmina após o uso. Poeira e restos de material podem se acumular e prejudicar sua capacidade de corte. Use um pano macio ou escova para limpá-la. Mantenha distância de produtos químicos fortes que possam danificar a superfície da lâmina.

Lubrificar a lâmina também é importante. Adicione uma fina camada de óleo para evitar ferrugem e manter o funcionamento perfeito. Verifique se há danos, como rachaduras ou lascas, durante as inspeções regulares. Resolva os problemas rapidamente para evitar problemas maiores no futuro.

Dica: Faça verificações de manutenção mensais para detectar pequenos problemas precocemente.

Técnicas de Afiação

Uma lâmina cega causa cortes ruins e retarda você. Afiando sua lâmina de corte de rolo Geralmente, mantém o bom funcionamento. Use uma pedra de amolar ou uma máquina de amolar especial para obter melhores resultados. Primeiro, limpe a lâmina completamente e siga estes passos:

- Segure a lâmina no ângulo correto (20–30 graus).

- Deslize a ferramenta de afiar ao longo da borda com movimentos suaves.

- Teste a lâmina cortando algo para verificar se está afiada.

Para afiação especializada, procure profissionais. Eles usam ferramentas precisas para fixar o fio da lâmina sem danificá-la.

Dica profissional: Não afie demais, pois isso pode enfraquecer a lâmina e fazer com que ela se desgaste mais rápido.

Considerações de custo

Equilibrando qualidade e preço

Encontrar a combinação certa de qualidade e preço é fundamental na hora de escolher um lâmina de corte de roloLâminas de alta qualidade custam mais no início, mas duram mais e funcionam melhor. Lâminas mais baratas economizam dinheiro no início, mas se desgastam rapidamente e precisam ser substituídas com frequência.

Ao pensar em custo, observe o material da lâmina e seu desempenho. Por exemplo, lâminas de carboneto custam mais, mas são resistentes ao desgaste e duram mais. Lâminas de aço-liga são mais baratas e adequadas para trabalhos de corte em geral.

Observação: Comprar uma lâmina que atenda às suas necessidades pode economizar dinheiro, reduzindo o desperdício e melhorando a velocidade do trabalho.

Investimento de longo prazo

Pense em seu lâmina de corte de rolo como uma compra de longo prazo. Gastar mais em uma lâmina resistente pode economizar dinheiro em reparos e substituições. Estudos mostram que materiais de alta qualidade, como aço rápido, reduzem o tempo de inatividade e aumentam a produtividade.

Aqui está uma visão simples dos fatores de custo-benefício:

| Aspecto-chave | Descrição |

|---|---|

| Desempenho vs. Preço | Materiais melhores custam mais, mas agregam mais valor ao longo do tempo. |

| Vida útil do material | Lâminas fortes duram mais, então você precisa substituí-las com menos frequência. |

| Custo total de propriedade | Inclui a compra, manutenção e uso da lâmina. |

| Poupança de Longo Prazo | Boas lâminas reduzem o desperdício e tornam o corte mais eficiente. |

| Relacionamentos com Fornecedores | Fornecedores confiáveis oferecem boa qualidade a preços justos. |

| Inventário Just-in-Time | Gerenciar bem o estoque reduz os custos de armazenamento e atende à demanda. |

| Considerações sobre sustentabilidade | Materiais ecológicos ajudam o meio ambiente e economizam dinheiro a longo prazo. |

Escolher uma lâmina durável e de ótimo desempenho economiza dinheiro e aprimora seu processo de trabalho. Construir bons relacionamentos com fornecedores também ajuda você a obter materiais de qualidade a preços melhores.

Dica: Concentre-se no custo total de propriedade, não apenas no preço, para fazer uma escolha mais inteligente.

O papel da personalização em lâminas de corte de rolos

Por que a personalização é importante

Nem todas as ferramentas de corte funcionam para todos os trabalhos. Cada tarefa tem suas próprias necessidades, e é aí que a personalização ajuda. Uma ferramenta personalizada lâmina de corte de rolo pode melhorar muito o seu trabalho. Garante que a lâmina se adapte exatamente às suas necessidades de corte, seja para materiais macios ou metais resistentes.

Usar uma lâmina comum para um trabalho específico costuma causar problemas. Você pode sofrer cortes feios, desperdiçar materiais ou até mesmo danificar sua máquina. Lâminas Personalizadas Resolva esses problemas adaptando-os às suas necessidades específicas. Isso resulta em melhores resultados, trabalho mais rápido e menos atrasos.

Dica:Se você lida com materiais difíceis ou tarefas de corte difíceis, uma lâmina personalizada é a melhor maneira de obter resultados precisos e estáveis.

Benefícios das lâminas de corte de rolo personalizadas

Por que escolher uma lâmina personalizada? Ela oferece mais do que apenas realizar o trabalho. Veja o que você ganha:

- Ajuste perfeito para suas necessidades: Lâminas personalizadas são feitas para combinar com sua máquina e material. Isso torna o corte mais suave e reduz o desgaste das suas ferramentas.

- Qualidade de corte aprimorada: Eles proporcionam cortes mais limpos e precisos, reduzindo o desperdício e melhorando seu produto.

- Durabilidade aprimorada: As lâminas personalizadas são feitas com materiais que duram mais em suas condições de trabalho.

- Eficiência de custos:Embora possam custar mais no início, eles economizam dinheiro ao longo do tempo, pois duram mais e reduzem o tempo de inatividade.

- Flexibilidade: Precisa de uma lâmina para um trabalho especial? Lâminas personalizadas podem lidar até com as tarefas mais difíceis.

Empresas como Nanjing Metal são especialistas na fabricação de lâminas personalizadas. Com 18 anos de experiência, são conhecidos por soluções personalizadas e de alta qualidade. Sua equipe qualificada garante que cada lâmina atenda aos mais altos padrões.

Dica profissional: Trabalhar com fabricantes confiáveis como a Nanjing Metal garante que você tenha uma lâmina eficaz e confiável.

Como personalizar sua lâmina

Personalizando um lâmina de corte de rolo é mais fácil do que parece. Siga estes passos para começar:

- Identifique suas necessidadesPense no que você precisa cortar. Quais materiais você usa? Qual a precisão dos cortes?

- Escolha o fabricante certo: Encontre uma empresa com experiência em lâminas personalizadas. A Nanquim Metal, por exemplo, tem anos de experiência neste campo.

- Discutir especificações: Converse com o fabricante sobre o tamanho, o material e o tipo de fio da lâmina. Seja claro sobre suas necessidades para obter os melhores resultados.

- Teste a lâmina: Depois que a lâmina estiver pronta, experimente-a. Isso garante que ela funcione bem e permite quaisquer alterações.

- Mantenha uma comunicação regular: Mantenha contato com o fabricante para obter suporte e dicas sobre como manter a lâmina em boas condições.

Personalização não se trata apenas de fabricar uma lâmina — trata-se de criar uma ferramenta que se adapte perfeitamente ao seu trabalho. Uma lâmina personalizada é um investimento em melhores resultados e operações mais suaves.

Chamada para ação: Quer aprimorar suas ferramentas de corte? Entre em contato com os especialistas da Nanjing Metal hoje mesmo. Eles ajudarão você a projetar a lâmina perfeita para as suas necessidades com sua habilidade e dedicação à qualidade.

Erros comuns a evitar

Escolhendo a lâmina errada para o material

Usar a lâmina errada pode causar cortes ruins e danos. Os materiais têm necessidades diferentes, e as lâminas devem atendê-las. Uma lâmina muito dura pode rachar ou quebrar em materiais macios. Uma lâmina muito macia se desgasta rapidamente em materiais resistentes.

Aqui está uma tabela simples de problemas comuns com lâminas:

| Tipo de problema | O que acontece |

|---|---|

| Rachaduras no núcleo | A lâmina entorta ou quebra quando é dura demais para o material. |

| Perda de segmento | A lâmina torce ou emperra porque o material não é adequado para ela. |

| Fissuras de segmento | Rachaduras aparecem quando a lâmina é dura demais para o trabalho. |

Para evitar esses problemas, escolha uma lâmina adequada ao seu material. Em caso de dúvida, peça orientação ao seu fornecedor ou fabricante.

Pular manutenção

Não cuidar da sua lâmina pode fazer com que ela se desgaste mais rápido. Poeira e sujeira se acumulam, tornando a lâmina menos afiada. Ignorar a manutenção também pode levar a acidentes ou quebras da máquina.

Aqui estão algumas dicas para manter sua lâmina em boas condições:

- Limpe e verifique sua lâmina com frequência para evitar problemas.

- Anote as verificações de manutenção para detectar problemas precocemente.

- Lubrifique a lâmina para evitar ferrugem e mantê-la funcionando bem.

A manutenção regular mantém sua lâmina segura e funcionando por mais tempo. Um pouco de esforço economiza dinheiro e evita acidentes.

Ignorando a compatibilidade do equipamento

Uma lâmina não funcionará bem se não se ajustar à sua máquina. Usar o tamanho ou a espessura errados pode causar atolamentos ou cortes irregulares. Por exemplo, uma lâmina grossa pode emperrar, enquanto uma fina pode não cortar corretamente.

Antes de comprar uma lâmina, consulte o manual da sua máquina para obter detalhes sobre tamanho e espessura. Se você trocar de máquina, certifique-se de que as lâminas ainda servem. Reservar um tempo para verificar economiza dinheiro e evita danos.

Dica:Se não tiver certeza, leia o manual da sua máquina ou peça ajuda ao fabricante.

Priorizando o custo em vez da qualidade

Escolhendo o mais barato lâmina de corte de rolo Pode parecer inteligente. Economizar dinheiro no início é bom, certo? Mas lâminas mais baratas costumam custar mais caro depois.

Lâminas baratas se desgastam rapidamente. Você as substituirá com mais frequência, o que acaba se acumulando. Há um ditado que diz: "compre barato, compre duas vezes". Lâminas de baixa qualidade podem causar cortes irregulares e desperdício de material. Elas podem até danificar seu equipamento, atrasando o trabalho e frustrando sua equipe.

Em vez de focar no preço, pense no custo total. Isso inclui a durabilidade da lâmina e suas necessidades de manutenção. Uma lâmina de alta qualidade custa mais no início, mas dura mais e funciona melhor. É como comprar um carro confiável: economiza dinheiro em reparos e permanece útil por anos.

Lâminas de qualidade também afetam a satisfação do cliente. Cortes limpos e precisos melhoram seus produtos e mantêm os clientes satisfeitos. Lâminas de baixa qualidade podem resultar em produtos ruins, o que pode afastar os clientes.

Como escolher com sabedoria? Faça uma análise de custo-benefício. Olhe além do preço e pense no desempenho. A lâmina reduzirá o tempo de inatividade? Tornará o trabalho mais rápido? Essas são perguntas importantes a se fazer.

Dica: Investir mais em qualidade é mais inteligente a longo prazo. Uma lâmina durável aumenta a produtividade e reduz custos futuros.

Dicas para escolher a melhor lâmina de corte de rolo

Pergunte aos profissionais

Escolhendo o certo lâmina de corte de rolo pode ser complicado. Especialistas sabem muito sobre materiais, tamanhos e métodos de corte de lâminas. Eles podem ajudar você a escolher a melhor lâmina para suas necessidades.

Entre em contato com fornecedores ou fabricantes confiáveis para obter conselhos. Empresas com bom suporte podem lhe ensinar sobre novas tecnologias de lâminas. Se você não tiver certeza sobre o ajuste ou o desempenho da lâmina, tire suas dúvidas. Especialistas também podem compartilhar dicas de manutenção e treinamento para aumentar a durabilidade da sua lâmina.

Dica: Trabalhe com um fornecedor confiável. A orientação dele melhora seus resultados de corte.

Comparar opções

As lâminas não são todas iguais. Comparar marcas e características ajuda você a encontrar a ideal. Procure marcas conhecidas por lâminas fortes e precisas. Leia avaliações para ver como elas se saem em trabalhos reais.

Verifique características como material, estilo da lâmina e velocidade de corte. Algumas lâminas lidam com tarefas difíceis, enquanto outras são melhores para cortes detalhados. Além disso, pense no armazenamento e nas peças de reposição. Marcas que oferecem esses extras podem evitar problemas no futuro.

Dica profissional: Não escolha a lâmina mais barata. Gastar um pouco mais pode economizar dinheiro ao longo do tempo.

Considere lâminas personalizadas

Lâminas padrão nem sempre funcionam bem para trabalhos especiais. Lâminas personalizadas são feitas para atender exatamente às suas necessidades. Você pode escolher o tamanho, o material ou o tipo de fio para a sua tarefa.

Primeiro, decida o que você precisa cortar. É um material macio ou um metal duro? Depois, converse com um fabricante sobre suas necessidades. Empresas como a Nanjing Metal fabricam lâminas personalizadas que combinam perfeitamente com sua máquina e material.

Teste a lâmina antes de usá-la completamente para garantir que ela funcione corretamente. Entre em contato com o fabricante para obter dicas sobre como obter os melhores resultados com sua lâmina.

Chamar: Lâminas personalizadas custam mais no início, mas economizam dinheiro porque duram mais e funcionam melhor.

Teste antes da compra

Antes de se comprometer a comprar uma lâmina de corte de rolo, testá-la pode economizar tempo, dinheiro e frustração. Pense nisso como um teste para garantir que a lâmina atenda às suas expectativas. Veja como você pode fazer isso:

- Inspecione a lâmina: Comece observando atentamente. Verifique se há falhas visíveis, como rachaduras, lascas ou bordas irregulares. Uma lâmina com defeitos pode não funcionar bem ou até mesmo danificar seu equipamento.

- Solicitar um corte de teste: Peça uma demonstração prática ao fornecedor. Observar a lâmina em ação lhe dará uma ideia clara da precisão e velocidade de corte. Você verá como ela lida com o material que planeja cortar.

- Verifique a qualidade com especialistas: Se não tiver certeza sobre a autenticidade da lâmina, consulte um especialista. Ele pode ajudar a identificar falsificações e confirmar a qualidade da lâmina. Esta etapa é especialmente útil ao lidar com lâminas personalizadas ou de alto custo.

- Avaliar desempenho: Preste atenção ao desempenho da lâmina durante o teste. Ela corta suavemente? O fio está afiado o suficiente? Um teste rápido pode revelar se a lâmina vale o investimento.

Dica: Sempre teste a lâmina no mesmo material que você usará em suas operações. Isso garante que os resultados sejam precisos e relevantes para as suas necessidades.

Testar antes da compra não serve apenas para evitar compras ruins. Trata-se de encontrar a ferramenta perfeita para o seu trabalho. Um pequeno esforço inicial pode resultar em cortes melhores, lâminas mais duráveis e operações mais suaves. Portanto, não pule esta etapa — vale a pena!

Escolher a lâmina de corte correta é muito importante. Escolha uma lâmina adequada ao seu material e às suas tarefas de corte. Certifique-se de que seja resistente e considere opções personalizadas para trabalhos específicos. Não cometa erros como ignorar a manutenção ou usar a lâmina errada. Peça conselhos a especialistas e concentre-se na qualidade, não apenas no preço. Uma boa lâmina economiza tempo, reduz o desperdício e funciona melhor. Escolhas inteligentes agora levam a melhores resultados no futuro.

Perguntas frequentes

Qual é o material mais resistente para lâminas de corte de rolos?

O carboneto é o material mais resistente. É muito duro e não se desgasta facilmente. Isso o torna ótimo para cortar materiais ásperos. Se você precisa de uma lâmina durável para trabalhos difíceis, o carboneto é a melhor escolha.

Dica:Para tarefas cotidianas, o aço-liga é forte e acessível.

Com que frequência devo afiar minha lâmina de corte rotativa?

Afie sua lâmina quando os cortes ficarem ásperos ou o desempenho cair. Verificações regulares ajudam a detectar o corte precocemente. Se você usa a lâmina com frequência, afie-a a cada poucas semanas. Para um uso mais leve, afiar a cada poucos meses é suficiente.

Dica profissional: Não afie muito, pois isso pode enfraquecer a lâmina.

Uma lâmina pode funcionar para todos os materiais?

Não, não pode. Materiais diferentes requerem tipos de lâmina diferentes. Por exemplo, lâminas dentadas são melhores para materiais resistentes. Lâminas retas são melhores para cortes precisos em papel ou metal fino. Usar a lâmina errada pode danificar tanto o material quanto a lâmina.

Como posso verificar se uma lâmina é compatível com minha máquina?

Consulte o manual da sua máquina para obter detalhes sobre o tamanho e a espessura da lâmina. Em caso de dúvidas, pergunte ao fabricante ou fornecedor. Usar a lâmina errada pode causar atolamentos, cortes malfeitos ou até mesmo danificar sua máquina.

Observação: Sempre confirme a compatibilidade antes de comprar uma nova lâmina.

Lâminas personalizadas são uma boa escolha?

Sim, lâminas personalizadas são ótimas se você tiver necessidades especiais de corte. Elas são feitas para se adaptar perfeitamente à sua máquina e aos materiais. Isso melhora a precisão do corte e aumenta a durabilidade da lâmina. Embora custem mais no início, economizam dinheiro, reduzindo o desperdício e o tempo de inatividade.

Chamar: Entre em contato com fabricantes confiáveis como a Nanjing Metal para obter lâminas personalizadas de alta qualidade.