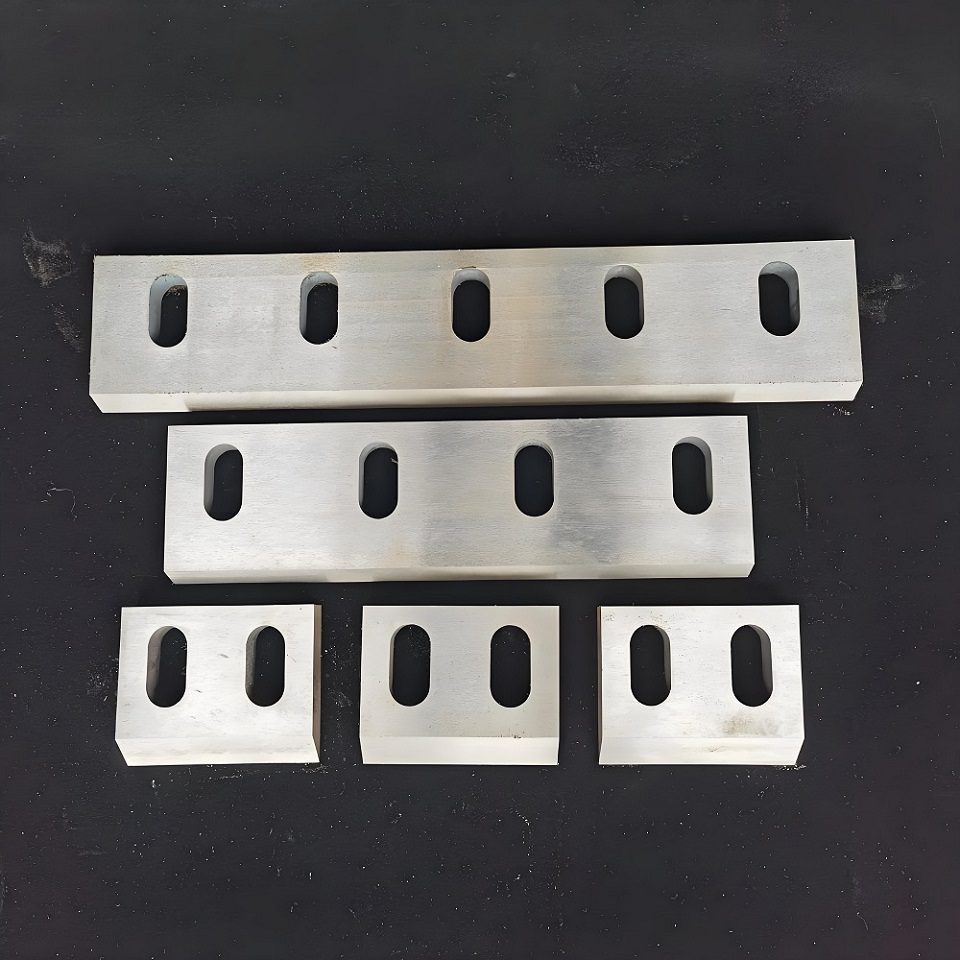

Your plastic crushing machine might stop working or produce uneven flakes, often due to issues with plastic crusher blade wear. Solução de problemas de desgaste da lâmina trituradora de plástico is essential because worn or broken blades cause frequent machine shutdowns and poor cutting performance. When blades become dull or cracked, the efficiency of your machine drops significantly. Using high-quality blades made from strong steels and special coatings can extend blade life and keep your shredding operations running smoothly. You can rely on Nanjing Metal for durable blade options that help maintain fast and efficient plastic crushing. Addressing blade wear promptly is key to ensuring your machine operates at its best.

- Blade condition impacts:

- Blade lifespan and machine downtime

- Cutting quality

- Operating costs

Principais conclusões

- Look at your plastic crusher blades often to find dull spots, cracks, or damage early. This helps stop the machine from breaking. Use clean plastic and the correct blade type. This stops the blades from wearing out fast or breaking. Always follow a good maintenance plan. Clean, sharpen, oil, and line up the blades. This keeps your shredder working well. Change the blades if you see deep cracks, missing pieces, or if they get too thin. This keeps the cutting good and the machine safe. Pick strong blades. They cut faster, last longer, and help you waste less time and plastic.

Solução de problemas de desgaste da lâmina trituradora de plástico

Sinais de desgaste

Processo de inspeção passo a passo

You should check your plastic crusher blades often. This helps your machine work well. Here are some easy steps to follow:

- Turn off and unplug the machine before you start.

- Look at each blade with a bright light. Try to find dull edges, chips, cracks, or rust.

- Wear safety gloves and gently touch the blade edge. Feel for rough spots or uneven places.

- Use a magnifier or caliper if you think the blade is worn. Check for small cracks or measure how thick the blade is.

- Compare the blade to a new one if you can. This makes it easier to see if the blade is less sharp or has changed shape.

Dica: Experts say you should check blades after every 40–50 hours of use. Finding problems early can stop your machine from breaking down.

Common Wear Phenomena Examples

You may see some signs that show blade wear:

- The cutting edge looks rounded or blunt

- There are nicks, chips, or small cracks

- You see rust spots or the color looks different

- The blade wears down unevenly, which can happen if it is not lined up right

- The plastic pieces after shredding are not the same size

These signs can make the machine cut slower and use more energy. If you notice these problems, you should start troubleshooting plastic crusher blade wear soon.

Practical Case: Determining When to Replace Blades

A worker heard the shredder making more noise and saw uneven flakes. After checking, the worker found blades with rounded edges and small cracks. By looking at a new blade, the worker saw a big difference. The team changed the old blades. The machine worked better and used less energy after that.

Quebra da lâmina

Processo de inspeção passo a passo

Blade breakage can make your machine stop working fast. Use these steps to check for broken blades:

- Look at all blades for cracks, missing parts, or breaks.

- Check for strange blade movement by moving the blade gently (with the machine off).

- Listen for odd noises like banging or grinding when the machine runs.

- Look for missing blade pieces inside the shredder.

Observação: Bad tool quality, wrong installation, dirty plastic, using the machine wrong, or not taking care of it can break blades.

Common Breakage Phenomena Examples

You might see:

- Big cracks in the blade body

- Broken tips or missing blade parts

- The machine stops suddenly while running

- The machine shakes or makes rattling sounds

These problems can happen if hard things are in the plastic, the blade is put in wrong, or the wrong blade is used.

Practical Case: Identifying and Responding to Blade Breakage

During a check, a worker found a plastic crusher knife with a big crack and a missing tip. The machine had stopped working. The worker put in a new blade and checked the rest of the machine for damage. After adding a high-wear-resistant blade from Nanjing Metal, the shredder worked again. If you need a special or new blade, you can look at soluções de lâmina personalizadas Para atender às suas necessidades.

Dullness Issues

Processo de inspeção passo a passo

Dull blades make shredding slow and use more power. To find dullness, do these steps:

- Look at the blade edge for rounded corners, chips, or burn marks.

- Test the blade by shredding a little plastic. See if the machine has trouble or makes uneven flakes.

- Compare the blade to a new or sharp blade to see if it is less sharp.

- Watch for signs like more power use, slower cutting, or loud noises.

| Detection Method | Indicators / Description | Accuracy / Reliability | Efficiency / Practicality |

|---|---|---|---|

| Inspeção visual | Look for chips, cracks, rounded corners, dark spots, burn marks under bright light or magnifying glass | Reliable for spotting physical blade damage | Quick and easy for routine checks |

| Operational Signs | Increased power consumption, slower cutting, uneven cuts, overheating, loud noises, vibrations | Good indicator of blade dullness during use | Efficient as it uses normal machine operation data |

| Borg Scale Measurement | Quantitative measure of cutting effort; dull blades score significantly higher; correlation r=0.89 with sharpness | High accuracy and correlation with sharpness | Requires specialized measurement but precise |

| Vibration Sensors & AI | Sensors detect early wear and tear; AI tracks blade condition and predicts replacement timing | Early and precise detection | Requires investment in equipment and setup |

Common Dullness Phenomena Examples

You may notice:

- Blades do not cut cleanly and leave rough flakes

- It takes more force to use the machine

- The cutting edge looks rounded

- The machine cuts unevenly and works slower

- The motor uses more energy

Dull blades can make the shredder get too hot and break if you do not fix them.

Practical Case: Addressing Dullness and Restoring Performance

Workers saw the shredder needed more force to cut plastic. They checked and found all blades were dull and rounded. After sharpening, the machine worked faster, used less energy, and made even flakes. Checking and sharpening blades on time helps stop big repairs and keeps the machine running.

Causes of Plastic Crusher Blade Problems

Knowing what causes blade problems helps you stop them. This keeps your plastic crusher working well. Most problems come from a few main things. Let’s look at each cause and how to avoid it.

Material Impurities

If you put dirty plastic or metal in the crusher, blades can get hurt. These things can chip, crack, or make blades dull fast. Some plastics are rougher and wear blades out quicker. For example, fiber-reinforced plastics wear blades more than soft plastics like LDPE.

| Tipo de plástico | Características do material | Recommended Blade Hardness (HRC) | Suggested Coating |

|---|---|---|---|

| Soft plastics (PP, LDPE) | Softer, less abrasive | 50-55 | None or Titanium Nitride (TiN) |

| General plastics (PET, HDPE) | Tough, moderate impact | 56-60 | Titanium Nitride (TiN) or Tungsten Carbide (WC) |

| Tough/fiber-reinforced (glass-filled nylon) | Highly abrasive, fiber-filled | 60-65 | Tungsten Carbide (WC) |

Prevention Tip: Use clean, checked plastic. This lowers the chance of blade damage from dirt or metal.

Installation Errors

Blades can get damaged if not put in right. If blades are not lined up, or too loose or tight, problems happen. These mistakes make blades wear out unevenly and cause loud sounds.

- Blades not lined up right

- Blade tension is wrong

- Blades not held tight enough

- Wrong space between blades

These mistakes make cuts uneven and the machine noisy. You can stop many problems by checking blades before turning on the crusher.

Prevention Tip: Have trained people put in blades. Always follow the maker’s rules. Check that blades are tight and lined up before using the crusher.

Maintenance Lapses

Not taking care of blades is a big problem. If you skip checks, cleaning, or oiling, blades can get dull, chipped, or break. Over time, this can hurt both the blades and the machine.

- Skipping checks lets small cracks get bigger.

- Not cleaning lets dirt build up and dull blades.

- Not oiling makes blades rub and wear out faster.

Prevention Tip: Make a plan to check, clean, and oil blades often. Doing this early helps blades last longer and stops big problems.

Sobrecarga

Putting too much plastic in the crusher is bad for blades. Feeding too much or the wrong kind makes blades wear out faster. Overloading also makes more rubbing and pressure, which can break blades.

- Too much strain makes blades wear out fast.

- Overloading can shake the machine and break parts.

- Bad habits like overloading make blades not last long.

New shredders have systems to stop overload. These systems watch for too much power use. If they see overload, they slow or stop the machine to protect it.

Prevention Tip: Only use the crusher with the right amount of plastic. Do not put in too much or the wrong kind. This keeps blades safe and working longer.

Maintenance and Replacement

Taking care of your plastic crusher blades helps your machine last longer. You should check, sharpen, clean, oil, and change blades when needed. Doing these things keeps your machine working well. This part will show you how to do each step.

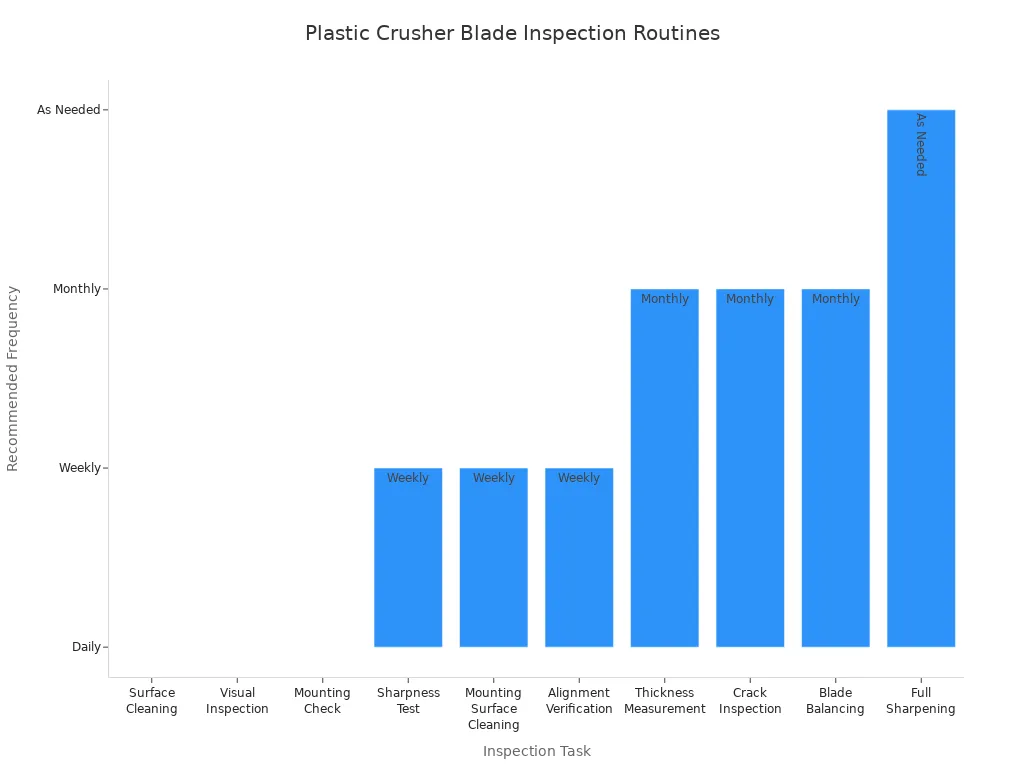

Rotina de inspeção

Check your blades often so you can find problems early. Looking at blades a lot helps you see cracks or other issues before they get worse. Here is a table that shows what to do and how often:

| Tarefa de Inspeção | Frequência recomendada | Purpose/Notes |

|---|---|---|

| Limpeza de superfícies | Diário | Clean and dry blades after use to stop dirt and rust. |

| Inspeção visual | Diário | Look for dull edges, color changes, or damage to spot blade problems. |

| Verificação de montagem | Diário | Make sure the blade is tight so it does not break or wear wrong. |

| Teste de nitidez | Semanalmente | Try cutting plastic; sharpen if the blade is dull or cuts badly. |

| Mounting Surface Cleaning | Semanalmente | Clean where the blade sits to stop dirt or rust from hurting the blade. |

| Alignment Verification | Semanalmente | Use a straight edge to check if the blade is lined up right. |

| Thickness Measurement | Mensal | Use calipers to see if the blade is getting too thin. |

| Crack Inspection | Mensal | Look for cracks with a flashlight or dye to catch damage early. |

| Blade Balancing | Mensal | Balance blades to stop shaking and help them last longer. |

| Full Sharpening | As Needed | Sharpen blades when they cut badly, not just by the calendar. |

You can also see how often to check blades in the chart below:

Dica: Check blades every week or after 20 hours of use. Use calipers and a magnifying glass to find small problems. Clean blades with gentle cleaners, not strong ones.

Sharpening and Cleaning

Sharp blades cut plastic better and make the machine work less hard. Cleaning and sharpening help blades stay good. Follow these steps to do it right:

- Wear gloves and safety glasses before touching blades.

- Clean blades to get rid of dirt and plastic stuck on them.

- Look for bent or broken blades. Change blades if you see big cracks or chips.

- Put the sharpening machine on a flat, steady table.

- Set the sharpening angle to what the maker says.

- Hold the blade at the right angle in the machine.

- Move the blade into the sharpening wheel slowly. Do not push hard.

- Stop and check if the blade is sharp so you do not make it uneven.

- Let blades cool down by themselves if they get hot.

- Look at the blade after sharpening to make sure it is smooth and has no nicks.

- Put the blade back in the machine carefully and follow safety steps.

Clean blades and shredder parts after every use. Check bearings, bolts, and toothed plates for damage. Take out anything that does not belong in the plastic. Teach workers to use and care for blades safely.

Lubrificação

Lubrication helps blades and moving parts work smoothly. It stops rubbing, keeps blades from wearing out, and helps your machine run well.

Lubrication Process and Guidelines

Oil the bearings and moving parts often. Wipe off old grease and dirt before adding new oil. Make sure you cover all the places that move.

Recommended Lubricants and Application Points

Use special oil made for fast machines. Put oil on blade bearings, where the blade sits, and all moving joints. Do not use too much oil because it can collect dirt.

Lubrication Frequency and Best Practices

Oil the machine every day if you use it a lot. Check oil levels and add more if needed. Oiling often helps you see problems early and stops more damage. This saves money and keeps your crusher working well.

Oiling, cleaning, and checking blades all help stop wear and keep your machine working. These steps make blades and the machine last longer.

Substituição da lâmina

Sometimes, blades get too worn or break and must be changed. Knowing when and how to change blades keeps your shredder safe and working well.

Quando substituir as lâminas

Change blades if you see:

- Bad cutting, like flakes that are too big or uneven

- The motor gets hotter or makes weird sounds

- You see chips, cracks, or a lot of wear

- The blade is more than 30% thinner than when new

Checking blades often helps you find these signs early. Do not wait until blades break, or you could hurt the machine more.

Step-by-Step Replacement Procedure

- Turn off and unplug the machine.

- Put on gloves and safety glasses.

- Take off the blade cover and bolts.

- Carefully remove the old blade.

- Clean where the blade sits and check for rust or dirt.

- Put the new blade in the right spot.

- Tighten bolts to the maker’s recommended tightness.

- Check if the blade is lined up and tight.

- Put the cover back on and test the machine with a little plastic.

Keep a log to write down when you change blades and how they work. This helps you plan for new blades and avoid surprise problems.

Safety Tips and Replacement Sources

Always follow safety rules when changing blades. Use the right tools and wear safety gear. Teach workers how to handle blades safely to stop accidents.

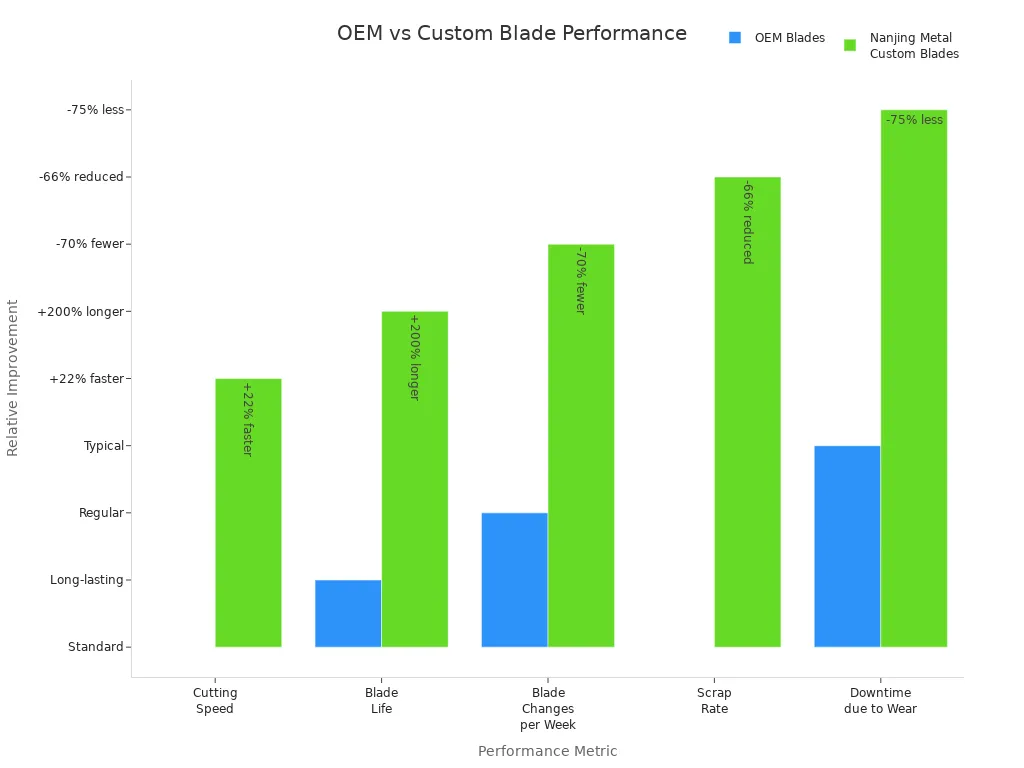

If you need a new or special blade, check out Nanjing Metal’s custom blades. Their blades fit your machine and last longer because they use strong materials and careful making. The table below shows how OEM blades and Nanjing Metal custom blades compare:

| Métrica | OEM Blades Characteristics | Nanjing Metal Custom Blades Improvements |

|---|---|---|

| Fit and Warranty | Exact fit, warranty-backed durability | Made for your needs |

| Velocidade de corte | Padrão | +22% faster cutting speed |

| Vida de lâmina | Long-lasting due to strong materials | +200% longer blade life |

| Blade Changes per Week | Regular replacement needed | -70% fewer blade changes |

| Scrap Rate (Cut Waste) | Standard scrap rate | -66% less waste |

| Downtime due to Wear | Typical downtime | -75% less downtime |

| Materiais usados | High-quality materials like manganese steel alloys | Advanced materials: D2, M2, SKD-11, Tungsten Carbide, Ceramic with heat treatments and coatings |

Preventing Blade Wear

Material Screening

You can keep your plastic crusher blades safe by checking materials before shredding. Clean plastic helps blades last longer. Dry cutting mills with parallel blades at medium speed remove most food from plastic packaging. This stops blades from getting clogged and makes fewer microplastics. Use small sample loads, about 20 grams, to stop jams and blade damage. Do not use water in the process. Wet plastic can clog the machine and make blades rusty. Always look for metal, dirt, or hard things in your plastic. Taking these out stops chips and cracks in your plastic crusher blades.

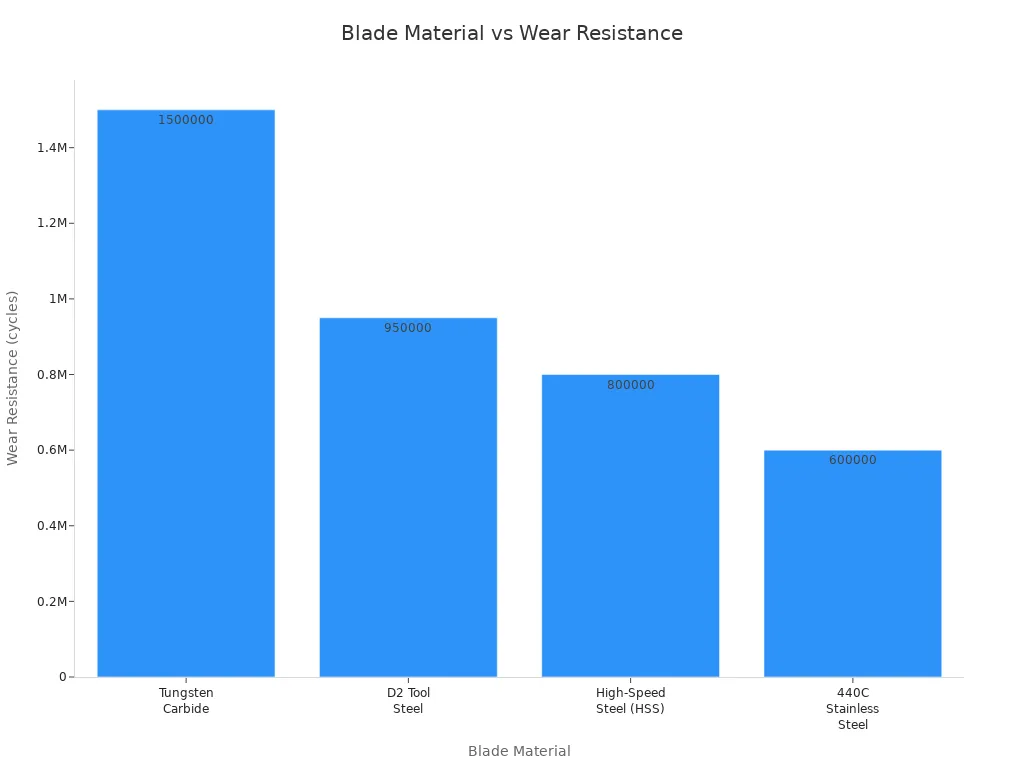

Dica: Pick the right blade material for your plastic. Hard plastics need strong blades like tungsten carbide. Soft plastics work well with stainless steel or tool steel.

| Material da lâmina | Wear Resistance (ISO 3685 cycles) | Recommended Plastic Types | Key Characteristics and Use Cases |

|---|---|---|---|

| Carboneto de tungstênio | Very High (~1,500,000 cycles) | Tough plastics like PET | Best for high-speed, high-volume cutting; withstands high heat |

| Aço para ferramentas D2 | High (~950,000 cycles) | Brittle plastics like rigid PVC | General-purpose; good toughness; serrated edges recommended |

| Aço inoxidável 440C | Moderate (~600,000 cycles) | Soft plastics like PP, PE | Corrosion resistant; suitable for wet or corrosive environments |

| Aço de alta velocidade | High (~800,000 cycles) | Heat-sensitive plastics | Balances precision and wear resistance; sharp angled edges |

Operação apropriada

You can help your plastic crusher blades last longer by using the machine the right way. Keep the feed rate steady and even. Do not put too much plastic in at once. Too much can jam the shredder and hurt the blades. Always get rid of dirt and other things before shredding. This keeps blades sharp and stops rough wear. Do not overload the machine. Too much strain wears blades out faster and can break them. Set blade clearance to about 7% of the material thickness. This gives clean cuts and less friction.

- Keep feed rates steady to stop jams.

- Remove dirt before shredding.

- Do not overload to protect blades.

- Adjust blade clearance for better cutting.

Checking often and using the machine carefully helps your plastic crusher blades last longer and work better.

Manutenção Programada

You should make a regular plan to take care of your plastic crusher blades. Checking often helps you find wear early. Clean your machine a lot to stop blockages and keep it working well. Oil moving parts to lower friction and help blades last longer. Change worn blades quickly so the machine does not break down. Teach all workers how to do maintenance the right way. Write down all maintenance tasks. This helps you plan and stops surprise problems.

- Check blades and machine parts often.

- Oil and clean after each use.

- Change worn blades before they break.

- Teach staff and keep good records.

Doing regular maintenance keeps your plastic crusher blades sharp, stops downtime, and saves money on new blades. A good plan helps your shredder work well and saves money over time.

You can help your plastic crusher blades last longer by doing a few simple things. First, check the blades often and make sure the gap is between 0.2 and 0.3 mm. Change any blade that is dull or broken right away. This stops bad cuts and keeps the machine from breaking. Sharpen, clean, and oil the blades on a set schedule. Teach your team how to find blade problems and change blades safely. Checking and changing blades on time saves energy and keeps the machine running. It also helps you get better plastic pieces. If you need help or want strong blades, talk to Nanjing Metal’s sales engineer. Their experts can help you pick the right blades for your machine.

Perguntas frequentes

How often should you inspect plastic crusher blades?

Check your plastic crusher blades once a week or after 20 hours. Regular checks help you spot dullness, cracks, or chips early. This keeps your machine safe and working well.

What causes plastic crusher blades to wear out quickly?

Blades wear out fast if plastic is dirty or has metal pieces. Putting too much plastic in the machine also wears blades out. Using the wrong blade material makes blades last less time. Always use clean plastic and the right blade for your job.

Can you sharpen plastic crusher blades yourself?

You can sharpen plastic crusher blades if you have the right tools. Always wear safety gear and follow the maker’s instructions. If you are not sure, ask a professional for help.

When should you replace plastic crusher blades instead of sharpening them?

Change blades if you see deep cracks or missing pieces. Replace blades if they are more than 30% thinner than new. Sharpening will not fix big damage. New blades keep your machine safe.

What is the best way to prevent blade damage?

Clean plastic before shredding and use the right blade type. Follow a regular maintenance plan. Teach your team to find problems early.

Veja também

Escolhendo entre Lâminas de Reposição OEM e Aftermarket para Trituradores de Plástico Industriais

Guia de substituição de lâmina de triturador de plástico: quando e como fazer corretamente

Quando substituir as lâminas de plástico do triturador: sinais de desgaste e dicas de manutenção