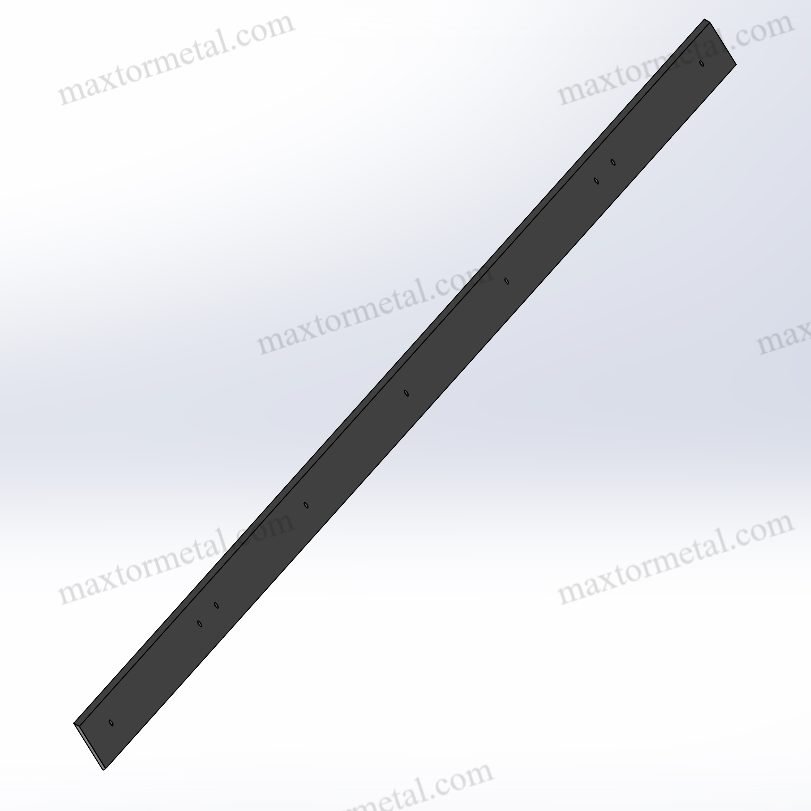

UM straight cutting knife is a special tool used for exact cutting. Its straight blade makes neat and accurate cuts, which is very useful in industries needing perfect results. It works well for cutting fabric, paper, and other materials, helping to avoid mistakes and save time.

The Straight Knife Cutting Machine is made to cut different materials in straight lines. It gives smooth and fast results, cutting down production time.

These tools are becoming more important worldwide. In 2023, their market value was USD 1.3 billion and is expected to grow to USD 2.1 billion by 2032. This growth is due to better technology and more demand in industries like textiles. Companies like Nanquim Metal make custom blades for specific needs, ensuring great performance. For help, Contato their expert team for advice.

Principais conclusões

- A straight cutting knife makes neat and exact cuts. It is very useful in industries like clothing and food.

- Taking care of the knife, like sharpening and cleaning it, keeps it working well and lasting longer.

- Special blades can cut better by matching the material, saving time, and reducing leftovers.

- Wearing safety gear, like gloves that resist cuts and goggles, helps avoid injuries when using these knives.

- Knowing the right blade type and shape gives better results for different cutting jobs.

What is a Straight Cutting Knife?

Definition of Straight Cutting Knife

A straight cutting knife is a tool made for industries. Its straight blade helps make clean and exact cuts. This knife is important for jobs where accuracy matters a lot. It is often used in fabric cutting machines, especially in the fashion industry. Professionals like it because it works well with many materials.

Characteristics of the Blade

The blade of this knife is built for sharp cutting. It can slice through many layers of material at once. The design makes it great for cutting small curves or detailed shapes. Many straight knives have a feature that sharpens the blade automatically. This saves time and keeps the knife working well without much effort.

| Feature/Benefit | Descrição |

|---|---|

| Neat Cutting | Cuts small curves and detailed shapes easily. |

| Low Noise | Works quietly, runs smoothly, and is easy to use. |

| Auto Knife Grinding | Sharpens itself, so it’s simple to maintain. |

| Velocidade de produção | Can cut up to 10 layers at one time. |

| Versatilidade | Cuts fabric from any direction. |

| Common Usage | Mostly used in garment factories in Bangladesh (99%). |

Aplicações Industriais

Straight cutting knives are used in industries needing fast and accurate cutting. In textiles, they cut fabric into exact shapes and sizes. They are also used in packaging and paper industries for clean cuts. Other uses include food processing and woodworking, showing how flexible they are.

Terminology Related to Straight Cutting Knives

Alternate Names

Straight cutting knives have different names based on where they are used. Some call them “straight knives,” while others use “dirk” in older or traditional settings. The word “dirk” once meant a specific straight knife but now refers to various cutting tools.

- The term “dirk” has changed meaning over time.

- It used to mean one type of knife but now covers more tools.

Usos comuns

Straight cutting knives are used in jobs needing accuracy and speed. They are popular in fabric cutting machines, especially in fashion work. These knives are also key tools in packaging and woodworking. Their ability to cut different materials makes them useful for many tasks.

Key Features of Straight Cutting Knives

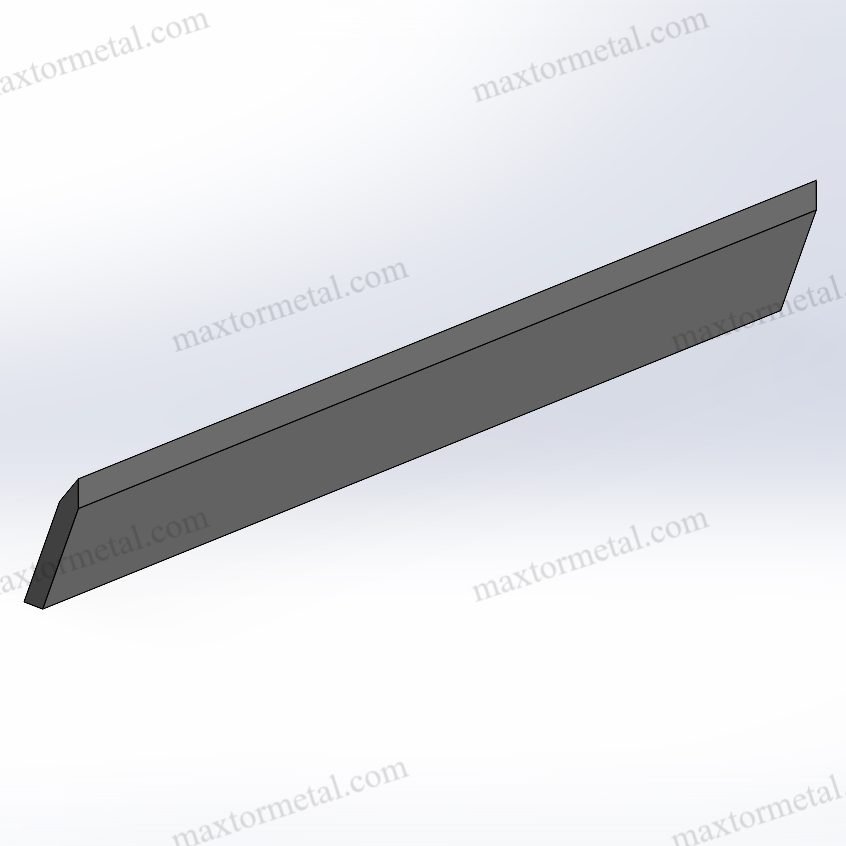

Design da lâmina

The blade of a straight cutting knife is made for sharp and strong cutting. Makers use tough materials like stainless steel to keep it sharp and long-lasting. The straight edge gives clean cuts, and the thick blade stays steady while cutting. These features help you get perfect results every time.

| Parâmetro | Resultados |

|---|---|

| Accuracy | Tests show accuracy is very important for good results. |

| Stability | Stability helps achieve the right precision during cutting. |

| Technological Parameters | Better speed and precise positioning improve cutting quality. |

Mecanismo de corte

Straight knives cut by moving the blade up and down. This motion lets them slice through many layers easily. The design reduces resistance, making cutting smooth. Modern machines have adjustable speed and pressure, giving users more control.

- Accurate positioning is key for perfect cutting results.

- Users can adjust settings to improve cutting quality.

Materials Used in Straight Cutting Knives

The materials in a straight cutting knife are key to its strength and use. Picking the right material keeps the blade sharp and lasting longer. Let’s look at the common materials used in these knives.

Types of Steel

Steel is the top choice for straight cutting knives. It is strong and works well for many tasks. Different steel types are chosen based on what needs cutting. Here are some examples:

- Aço de alto carbono: This steel stays sharp for a long time. It is very hard and great for tough cutting jobs.

- Aço inoxidável: Stainless steel doesn’t rust and handles moisture well. It is durable and easy to care for, making it good for food cutting.

- Aço ferramenta: Tool steel is tough and resists wear. It works well in factories where knives are used often.

Tests show steel makeup affects how well knives cut. Things like hardness and blade shape matter a lot. Methods like CATRA testing check sharpness and edge life. For example, aço de alto carbono scores high for sharpness, making it great for precise cuts.

Other Materials

Steel is common, but other materials improve knife performance. These are often added to steel for better results:

- Revestimentos Cerâmicos: Ceramic coatings help blades cut smoothly. They lower friction and make cutting easier.

- Ligas de titânio: Titanium is strong but light. It makes knives sturdy without being heavy.

- Materiais Compósitos: Composite materials mix different substances for better features. A blade might have steel for strength and ceramic for sharpness.

These materials make knives cut better and last longer. Choosing the right mix helps knives work well in industries like textiles and woodworking.

Dica: Think about the blade material when picking a straight cutting knife. It affects sharpness, strength, and how well it fits your needs.

How Does a Straight Cutting Knife Work?

Basic Operation of Straight Cutting Knife

Blade Movement Mechanics

The straight knife machine works by moving its blade up and down. This motion lets it cut through many layers with accuracy. The blade’s shape, like its wedge angle and tip size, affects how it cuts. A sharper wedge angle makes cutting easier and smoother.

| Aspecto | Descrição |

|---|---|

| Geometria da lâmina | Wedge angle and tip size affect cutting ease. Sharper angles lower resistance. |

| Cutting Force Evaluation | Tests show blade shape impacts cutting force and durability. |

| Operational Effectiveness | Real-world tests check blade wear and cutting ability during use. |

Material Interaction During Cutting

The blade separates fibers or particles by slicing and shearing. Material thickness, density, and stretchiness change how cutting happens. Studies show blade shape, clearance space, and speed affect cutting results. For example:

- Smaller clearance space improves accuracy but raises cutting effort.

- A steeper blade angle makes cleaner edges with fewer rough spots.

Observação: Advanced tools like computer analysis help improve blade design for better cutting.

Factors Influencing Cutting Performance

Blade Sharpness and Maintenance

A sharp blade is key for clean cuts and less waste. Regular care, like sharpening, keeps the blade working well. Dull blades need more force and wear out faster. Following a care plan helps the blade last longer.

| Métrica | Antes da personalização | Lâmina personalizada Metal de Nanquim | Melhoria |

|---|---|---|---|

| Trocas de lâmina por semana | 10 | 3 | –70% |

| Taxa média de sucata de corte | 6.5% | 2.2% | –66% |

| Tempo de inatividade devido ao desgaste da lâmina | 4 horas/semana | 1 hora/semana | –75% |

Speed and Pressure Applied

Cutting speed and pressure change the results. Faster speeds save time but may lower accuracy if not managed well. Too much pressure can harm the material or blade. Adjust speed and pressure based on material type for the best cuts.

| Experimental Parameter | Effect on Cutting Performance |

|---|---|

| Velocidade de corte | Faster speeds affect cutting forces greatly. |

| Taxa de alimentação | Higher feed rates cause force changes. |

| Depth of Cut | Controls cutting force for different materials. |

Techniques for Effective Cutting

Proper Handling and Grip

Holding the knife correctly helps with safety and accuracy. Grip the handle firmly but not too tightly to avoid strain. Learning proper handling reduces accidents and improves cutting results.

- Hold the handle firmly but stay relaxed.

- Guide the blade smoothly through the material.

- Avoid sudden moves to keep cuts even.

Angle of Approach for Cuts

The blade angle changes how clean the cut is. A shallow angle works well for thin materials. A steep angle is better for thicker ones. Adjusting the angle helps avoid tearing and gives smooth edges.

Dica: Practice blade angles on scrap material to find the best way to cut your project.

Safety Measures During Operation

Personal Protective Equipment

Wearing the right gear keeps you safe while using a straight knife. Start with cut-resistant gloves to protect your hands from the blade. Safety goggles shield your eyes from flying bits of material. A strong apron or protective clothing adds extra safety in case the blade slips.

Steel-toed boots are important when working with heavy items. They guard your feet from falling objects. Use earmuffs or earplugs to block loud noise if the machine is noisy. Always check that your gear fits well and isn’t damaged. Broken gear won’t keep you safe.

Dica: Keep a list of safety gear at your workstation. This helps you stay ready and avoid risks.

Safe Handling Practices

Using a straight knife carefully prevents accidents and keeps things running smoothly. Check the blade before starting. Look for damage or dull edges. A bad blade can make cuts uneven and cause injuries. Hold the machine firmly and keep your hands away from the blade.

Follow written instructions for safe knife use. Train yourself and others on how to use, clean, and store the machine. Stay focused while cutting and avoid distractions. If the machine makes strange sounds or feels stuck, stop and check it right away.

To make the workplace safer, inspect knives often to find problems early. Allow workers to report accidents without fear. This helps improve safety rules. Also, check the machine regularly to ensure it works properly.

Observação: Taking care of the machine improves cutting and lowers accident risks.

Advantages and Disadvantages of Straight Cutting Knives

Advantages of Straight Cutting Knives

Precision in Cutting

A straight cutting knife makes neat and exact cuts. Its sharp blade easily slices materials, lowering mistakes. Whether cutting fabric, paper, or other items, it gives precise results. This accuracy reduces waste and improves product quality.

Efficiency in Production

Straight knife machines work quickly and save time. They cut many layers at once, speeding up tasks. Unlike hand-cutting tools, they need less effort for repeated work. This speed helps finish projects faster and meet deadlines easily.

Versatility Across Industries

Straight knife machines are useful in many industries. They work well in textiles, woodworking, and packaging. These machines handle different materials, making them flexible. Whether cutting fabric for clothes or paper for boxes, they perform reliably.

Disadvantages of Straight Cutting Knives

Requisitos de manutenção

Straight knife machines need regular care to work well. The blade must be sharpened often to stay effective. If not maintained, dull blades can lower performance. Proper upkeep keeps the machine efficient and lasting longer.

Initial Cost Considerations

Buying a straight knife machine can cost a lot upfront. While it saves money over time, the starting price may seem high. However, its durability and efficiency make it worth the investment later.

Safety Risks During Use

Using a straight knife machine can be risky. The sharp blade and fast parts need careful handling. Without training or safety gear, accidents might happen. Following safety rules lowers risks and keeps the workplace safe.

Dica: Focus on safety and maintenance to get the most from straight knife machines.

Uses of Straight Cutting Knives in Different Industries

Straight cutting knives are important tools in many industries. They are known for their accuracy and speed. These knives are used for cutting fabric, food, and packaging materials. Below are examples of how they help in different fields.

Industria têxtil

Cutting Fabric Easily

In textiles, straight cutting knives are key for cutting fabric. They can cut through many fabric layers quickly and neatly. Whether the fabric is thin or thick, these knives make clean cuts. Machines with straight knives are often used to make clothes, where precision is very important.

These knives also work well for detailed fabric cutting. They can handle small patterns and curves, making them perfect for fashion designs. Using these knives helps save fabric, speeds up work, and ensures consistent results.

Faster Garment Making

Straight cutting machines make garment production faster. They cut large amounts of fabric at once, saving time and effort. This is helpful in big factories where deadlines are tight. These machines can cut fabric from any direction, adding to their usefulness.

By using straight knives, factories can work faster and keep quality high. These tools reduce mistakes and ensure every piece of clothing is made correctly.

Indústria de Processamento de Alimentos

Cutting Fruits and Vegetables

Straight cutting knives are very useful in food processing. They are great for cutting fruits and vegetables into even pieces. For example, they can slice cucumbers or dice apples perfectly. This keeps the food looking good and of high quality.

These knives are strong and last a long time, making them a good choice for food companies. They are also designed to be clean and safe for food use, meeting hygiene standards.

Slicing Meat Perfectly

In meat processing, straight knives are used for slicing and portioning. They are ideal for cutting large pieces of meat or deli items. These knives ensure each slice is the right size and looks good.

As demand for processed meat grows, straight knives have improved. Features like self-sharpening blades make them more efficient. They help reduce waste, save time, and keep meat preparation clean and safe.

- Benefits of straight cutting knives in food processing:

- Great for slicing bread, meat, and other foods.

- Made from strong materials for long-lasting use.

- Improve speed and meet food safety rules.

Paper and Packaging Industry

Accurate Paper Cutting

Straight cutting knives are widely used in paper and packaging. They cut paper and cardboard with clean edges and little waste. Their sharp blades prevent tearing, which keeps the product looking good.

Research shows better blades can improve production. For example, precise blades reduce downtime by 18% and increase output by 20%. Investing in good cutting machines can save money and improve results.

| Descrição da evidência | Estatística |

|---|---|

| Waste from bad cutting | 20-30% of packaging waste comes from poor cuts |

| Downtime reduction | 18% less downtime with better blades |

| Throughput improvement | 20% more production with optimized blades |

| Efficiency increase | 12-15% better efficiency with improved blades |

Cutting Packaging Materials

Straight cutting knives are also used for cutting packaging materials. They can cut plastic, cardboard, and foam neatly. This ensures packaging parts fit well and reduces waste.

Using these knives makes packaging work faster and better. They can handle many materials, making them a flexible tool for manufacturers. Their precision helps create high-quality packaging and supports eco-friendly solutions.

Woodworking Industry

Carving and Shaping Wood

Straight cutting machines are important tools in woodworking. They help carve and shape wood with precision. These machines make it easy to create detailed designs and smooth finishes. Whether making patterns or shaping panels, they ensure clean results.

The sharp blade works well with softwoods and hardwoods. You can change the cutting angle for different depths and details. A shallow angle is good for surface carving. A steeper angle works better for deeper cuts. This flexibility helps with furniture, sculptures, or custom wood projects.

Dica: Test the blade on scrap wood first. This helps adjust settings for better results.

Applications in Furniture Making

Straight cutting machines are essential for furniture making. They cut wooden parts accurately, ensuring perfect fits. From table legs to chair backs, these machines save time and improve efficiency.

Using a straight knife gives smooth edges and consistent sizes. This reduces extra sanding or fixing, saving effort. These machines work with many wood types, making them great for all furniture styles.

| Tarefa | Beneficiar |

|---|---|

| Cutting wooden panels | Ensures even size and shape |

| Shaping furniture parts | Improves fit and finish |

| Creating intricate designs | Adds beauty to furniture |

Observação: Keep the blade in good condition for better cuts and longer use.

Fabricação Metal

Cutting Metal Sheets

Straight cutting machines are also useful in metalwork. They cut metal sheets into exact shapes and sizes. The strong blade handles metals like aluminum, steel, and copper.

Accuracy is key when cutting metal sheets. Straight knives make clean cuts without rough edges, reducing extra finishing. This is crucial in industries like automotive and construction, where precision matters.

Dica: Use a lubricant to lower friction and extend the blade’s life when cutting thick metal.

Precision in Component Manufacturing

Straight cutting machines are great for making precise parts. They produce items like brackets or panels with tight measurements. Adjustable speed and pressure give better control for exact results.

These machines can also cut complex shapes in metal. This makes them valuable in industries like aerospace, electronics, and machinery. High-quality machines boost productivity and ensure top precision.

| Indústria | Aplicação |

|---|---|

| Automotivo | Cutting body panels and parts |

| Aeroespacial | Shaping lightweight metal pieces |

| Eletrônica | Making detailed metal casings |

Observação: Always wear safety gear like gloves and goggles when cutting metal.

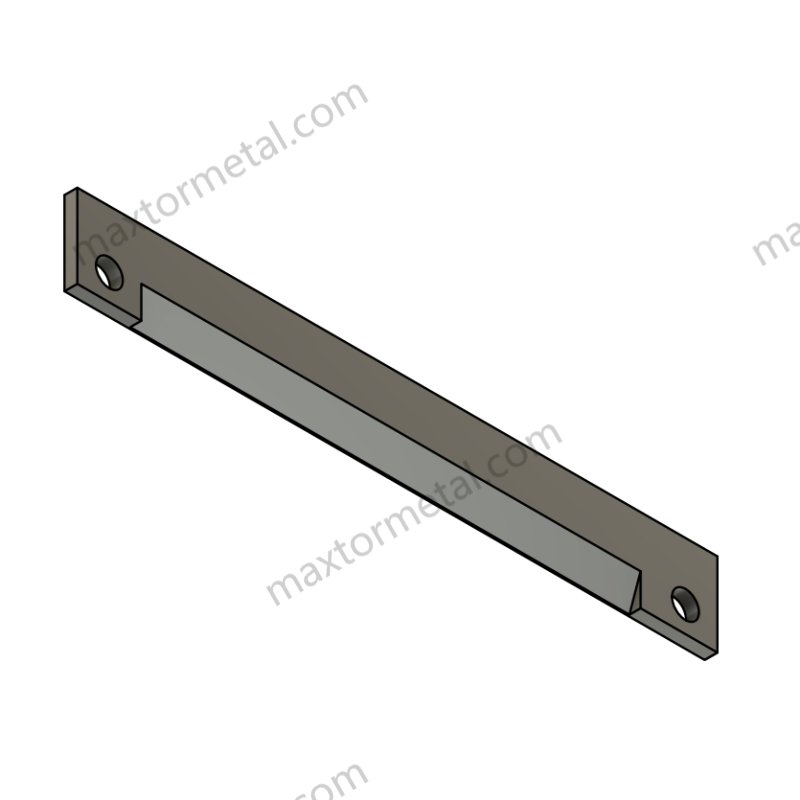

Custom Applications

Tailored Solutions for Specific Needs

Straight cutting machines can be customized for special tasks. You can choose blades for specific materials, like high-carbon steel for strength or stainless steel to resist rust.

Custom machines let you adjust blade speed, pressure, and angle. This helps achieve the best results for your project. Investing in custom solutions improves efficiency and reduces waste.

Dica: Work with experts to design a machine that fits your needs.

Benefits of Custom Straight Cutting Knives

Custom straight knives have many advantages. They offer better precision for cleaner cuts and finer details. This is especially helpful in industries like textiles and woodworking.

Custom blades are also more durable. They handle heavy work, needing fewer replacements. This lowers costs and reduces downtime. They can also be designed for unique materials, ensuring reliable performance.

| Vantagem | Descrição |

|---|---|

| Precisão aprimorada | Makes cleaner and more accurate cuts |

| Increased Durability | Lasts longer with less wear |

| Compatibilidade de materiais | Works well with special materials |

Observação: Trusted manufacturers like Nanjing Metal provide high-quality custom blades for your needs.

A importância das lâminas personalizadas

Benefícios da personalização

Enhanced Cutting Precision

Custom blades help make cuts more exact and clean. They are designed for specific materials and tasks, improving accuracy. For example, a box factory reduced downtime from 14 hours to under 5 hours by using special micro-tooth blades. These blades lasted four times longer, cutting costs by 28%. Custom blades also lower mistakes, saving materials and boosting product quality.

| Tipo de evidência | Detalhes |

|---|---|

| Estudo de caso | A box factory cut downtime from 14 hours to under 5 hours. |

| Economia de custos | Companies saved 28% in costs with better blades. |

| Vida útil da lâmina | Blade life increased from 10 to 42 days, a 4x improvement. |

| Redução do tempo de inatividade | Downtime dropped by 65%, and blade changes fell by 50%. |

| Maintenance Savings | Annual blade costs decreased by $18,000. |

Tailored Solutions for Industries

Custom blades are made to fit different industries’ needs. Whether for textiles, food, or metal work, they handle specific materials and cutting conditions. For example, packaging companies saved $150,000 yearly by using high-concentricity blades, which reduced waste from 10% to 3%. These blades make operations faster and more cost-effective.

Applications of Custom Blades

Specific Industry Needs

Custom blades work well in industries needing strong and precise tools. In meat processing, high-concentricity blades stopped blade failures and cut machine downtime by half. On the other hand, low-concentricity blades caused more waste in fast cutting jobs. Switching to custom blades fixes these problems, making work safer and smoother.

- High-concentricity blades lowered breakage by 67%, improving safety.

- Packaging companies saved $150,000 yearly by reducing waste.

- Meat processing plants had zero blade failures with custom blades.

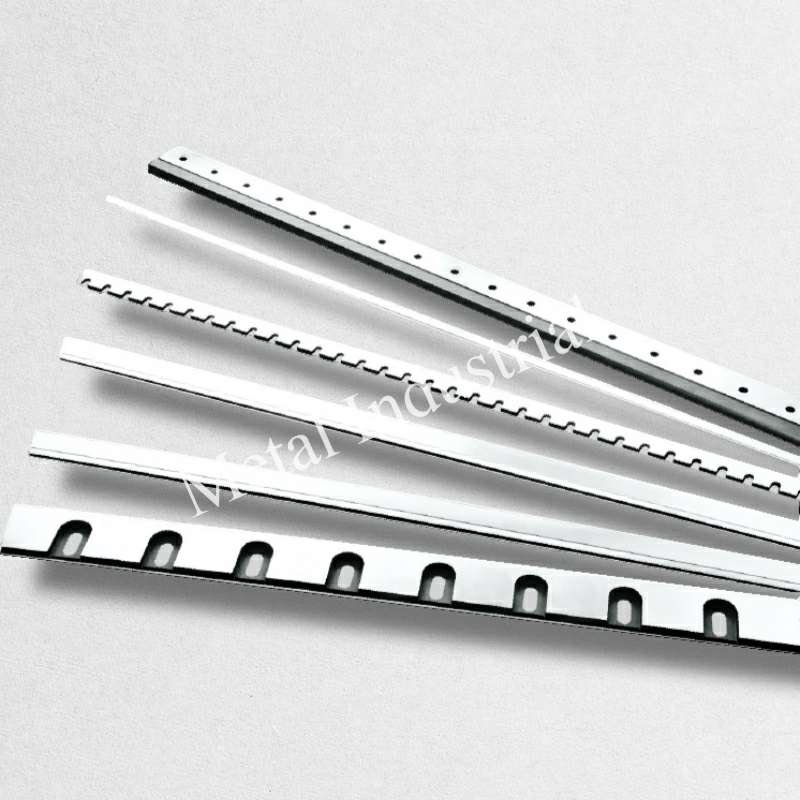

Examples of Custom Uses

Custom blades can be used in many ways. Mark IV and Mark V blades are great for cutting fibers, while hook blades work well for textiles and flooring. Pierret-compatible blades are perfect for recycled fibers. These examples show how custom blades meet unique needs.

| Tipo de lâmina | Descrição da aplicação | Opções de materiais |

|---|---|---|

| Mark IV and Mark V | Used for cutting fibers and chopping tow | Stainless steel, carbon steel, tungsten carbide, zirconia ceramic, titanium nitride, titanium carbide |

| Hook blades | Ideal for textiles, roofing, and flooring due to their design | Stainless steel, carbon steel, tungsten carbide, zirconia ceramic, titanium nitride, titanium carbide |

Choosing the Right Custom Blade

Fatores a considerar

Think about the material, precision, and durability when picking a lâmina personalizada. For example, low-speed saws work with many materials but may lack accuracy for detailed tasks. Wire saws are very precise but only work for certain jobs. Knowing these details helps you choose the best blade.

| Método de corte | Vantagens | Limitações |

|---|---|---|

| Low Speed Saw | Works with many materials | May not be precise enough for detailed tasks |

| Wire Saw | Very accurate with little material waste | Limited to specific jobs |

Consultation with Experts

Talking to experts helps you pick the right blade. Professionals can recommend blades that fit your needs. Nanjing Metal, with 18 years of experience, makes custom blades for many industries. Their team creates high-quality blades for your projects. Visit Nanjing Metal to learn more and improve your cutting tools.

Dica: For expert advice, contact Nanjing Metal’s sales team aqui.

Maintenance of Custom Blades

Regular Care Practices

Taking care of custom blades helps them last longer. After using a blade, wipe it with a soft, damp cloth. Dry it completely to stop rust or corrosion from forming. For aço de alto carbono blades, add a layer of knife oil to protect against rust.

Sharpening is also important for keeping blades effective. A sharp blade cuts better and wears out less quickly. But don’t sharpen too much, as it can weaken the blade. Check your blade often for damage like chips or dull spots. Fixing problems early stops them from getting worse.

Dica: Keep blades in a protective case with a clear cover. This keeps dust away and prevents accidental damage. Store them in a place with steady humidity and good lighting to avoid rust.

Longevity and Performance

Good maintenance makes custom blades last longer and work better. Cleaning and oiling regularly keep them in top shape. Sharpening often ensures they stay sharp, so you don’t need to replace them as much. This saves money and improves cutting results.

Using a protective display case adds extra safety. Proper lighting stops materials from breaking down, and stable humidity prevents rust. These steps keep blades in great condition, even during long storage.

Observação: Check blades regularly for wear. Spotting problems early helps keep them working well for many years.

Straight cutting knives are important tools for jobs needing accuracy. They make clean cuts, which boosts work speed and reduces waste. Lâminas Personalizadas go further by meeting special cutting needs. This helps get better results and saves money in the long run.

If you need strong custom blades, Nanjing Metal is a top choice. They make reliable tools designed for your tasks. Contact their team for expert advice and solutions.

Perguntas frequentes

What materials are good for straight cutting knives?

High-carbon steel is great for tough cutting tasks. Stainless steel doesn’t rust and is perfect for food cutting. Tool steel is strong and works well in busy factories. Pick the material that fits your job best.

How should you care for a straight cutting knife?

Wipe the blade clean after every use. Add knife oil to stop rust. Sharpen it often to keep it working well. Store it in a safe case to protect it from damage.

Can straight cutting knives handle many layers?

Yes, they can cut up to 10 layers at once. Their sharp blades and sturdy build make them perfect for thick materials.

Are straight cutting knives safe to use?

They are safe if used correctly. Wear gloves that resist cuts and safety goggles. Follow the instructions and check the knife often to avoid problems.

Why pick custom blades for your work?

Custom blades cut more accurately and last longer. They are made for specific jobs, saving time and reducing waste. Talk to experts to get blades designed for your needs.

Veja também

Segredos das facas Sheeter: substitua e faça a manutenção como um profissional

Lâminas Thermocutter simplificam o corte e a selagem

Como fazer a manutenção e afiar as lâminas do granulador de plástico

Como selecionar a lâmina de guilhotina certa para suas necessidades

Como encontrar as facas industriais de corte de papel certas para suas necessidades