Выбор правильного пластиковые лезвия для измельчителя helps you recycle better. If you pick the wrong blades, they can get dull fast or even break. This happens more with hard or fiber-filled plastics. When this happens, you have to stop work and pay more money. Better blades, like high-speed steel or tungsten carbide, last longer. They help your work go smoothly. Nanjing Metal Industrial has many shredder blades for different jobs. You should match the blade and material to the plastic and your recycling goal. Always think about technical, work, and money factors when you choose.

Tip: The right blade saves you money and makes recycling better.

Ключевые выводы

- Picking the right plastic shredder blades helps recycling work better and saves money.

- High-speed steel and tungsten carbide blades last longer. They also help stop machines from breaking down often.

- Taking care of blades often stops surprise breakdowns and expensive fixes.

- Knowing about different plastic types helps you pick the best blades for your recycling job.

- Buying good blades saves money over time and helps recycling work better.

- Custom blades can be made to fit special recycling jobs and materials.

- Always put safety first when you handle or put in shredder blades.

- Good supplier help makes sure you get the right blades and help when you need it.

Why Blade Selection Matters

Efficiency and Throughput

Picking the right plastic shredder blades makes recycling faster. The blades cut plastic into even pieces. This helps when you melt and shape the plastic later. Blades made from high-speed steel or tungsten carbide can shred tough plastics like PET bottles. These blades use less energy. You do not need to change them as often. Your machines can run longer without stopping.

- Sharp blades let you shred more plastic quickly.

- Strong blades stay sharp, so you stop less for new ones.

- Even shredding gives you better recycled plastic.

Maintenance and Downtime

The blades you pick change how often you stop for repairs. If blades wear out fast, you spend more time changing them. This means your shredders are not working, and you lose time. Some companies used carbon tool steel blades before. They switched to alloy tool steel blades. The new blades lasted six times longer. This helped them work more and stop less.

You should pick blades that are easy to clean and check. Blades that last longer mean fewer stops and lower repair costs. If you buy from a good supplier, you get blades that work well and cause fewer problems.

Note: Check your shredder blades often to keep them sharp and safe. Make a plan to look for problems early. This helps you avoid sudden breakdowns.

Cost Impact

The blades you choose can change your costs in many ways. Cheap blades may look like a good deal, but they wear out fast and need to be replaced often. This costs more over time. Strong blades, like ones with tungsten carbide tips, cost more at first. But they save you money later. You do not need to buy new blades or fix machines as much.

| Тип лезвия | Первоначальная стоимость | Продолжительность жизни | Частота замены | Долгосрочные сбережения |

|---|---|---|---|---|

| Углеродистая инструментальная сталь | Низкий | Короткий | Высокий | Низкий |

| Легированная инструментальная сталь | Середина | Длинный | Низкий | Середина |

| С напайкой из карбида вольфрама | Высокий | Очень длинный | Очень низкий | Высокий |

Buying good blades lowers your total costs. You also recycle more and waste less.

Picking the right plastic shredder blades helps you save money, work better, and trust your machines. Nanjing Metal Industrial has blades for these needs, so you can recycle more and spend less.

Identify Plastic Types

Common Plastics in Recycling

Many kinds of plastics are recycled. Each kind acts differently when you shred it.

- PET (Polyethylene Terephthalate) is clear and strong. You see it in water bottles and food boxes. In the U.S., about 31% of PET gets recycled. Europe recycles more, up to 52%. In 2018, PET bottles and jars had a 29.1% recycling rate.

- HDPE (High-Density Polyethylene) is tough and fights off chemicals. You find it in milk jugs and soap bottles. In 2018, HDPE natural bottles had a 29.3% recycling rate. Most recycling places take HDPE.

- ПП (полипропилен) is bendy and light. You see it in yogurt cups and bottle tops. PP does not break easily and is simple to shape.

- ПВХ (поливинилхлорид) can be stiff or bendy. You find it in pipes, window frames, and some boxes. PVC has extra stuff in it that makes recycling harder.

- АБС (акрилонитрилбутадиенстирол) is strong and does not break easily. You see it in toys, electronics, and car parts.

Tip: If you know the plastic type, you can pick the best blade and shredding way.

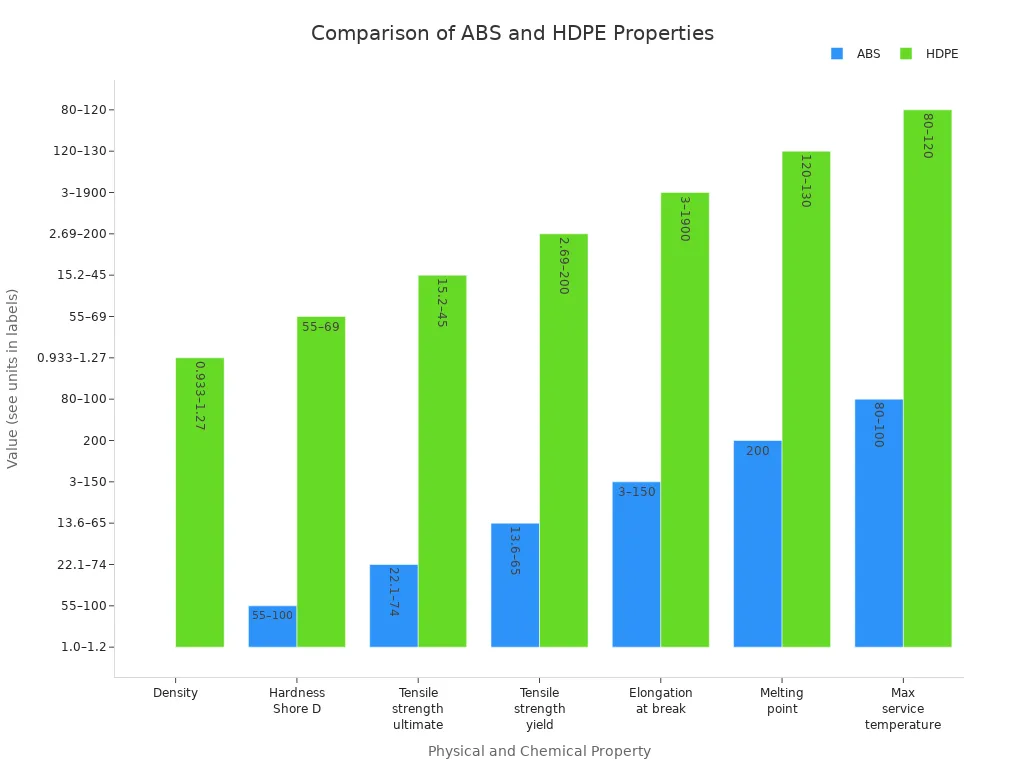

Here is a table with important facts about ABS and HDPE:

| Свойство | ABS (metric) | HDPE (metric) |

|---|---|---|

| Density | 1.0–1.2 g/cm³ | 0.933–1.27 g/cm³ |

| Hardness, Shore D | 55–100 | 55–69 |

| Tensile strength, ultimate | 22.1–74 MPa | 15.2–45 MPa |

| Tensile strength, yield | 13.6–65 MPa | 2.69–200 MPa |

| Elongation at break | 3–150% | 3–1,900% |

| Melting point | 200 °C | 120–130 °C |

| Max service temperature | 80–100 °C | 80–120 °C |

Shredding Challenges

Hardness and Brittleness

Hard plastics like ABS and PET can make blades dull fast. You need strong blades for these plastics. Brittle plastics break into uneven bits. This can lower the quality of recycled plastic.

Flexibility and Toughness

Flexible plastics like HDPE and PP can block shredders. These plastics stretch and bend, so they are hard to cut. Blades need special shapes to grab and slice flexible plastics.

Contamination and Impurities

Dirt, labels, or chemicals can hurt blades. Bad stuff makes blades wear out and lowers the quality. Mixed waste with plastics, metals, or cloth makes shredding harder. Batteries and chemicals can be dangerous for people and nature.

Mixed Plastics and Sorting Issues

Shredding mixed plastics gives random results. Each plastic has its own hardness and melting point. Mixed plastics wear out blades faster and make output less predictable. Sorting problems can slow work and cost more money.

Note: Sort plastics before shredding. This helps your blades last longer and makes recycling better.

Volume and Consistency

Feedstock Volume Variability

The amount of plastic you put in the shredder can change. Big loads can be too much for the machine. Small loads may not use the shredder well.

Batch Consistency

If batches are always the same, you can set the right speed and blade. If batches change, blades wear unevenly and shredding does not work as well.

Impact on Blade Selection and Performance

You must match blade shape to the plastic type and amount. The number and shape of blade edges help with different plastics. If feedstock changes a lot, blades wear out faster and shredding slows down. Picking the right blade shape and material keeps shredders working well.

Tip: Always look at your plastic before shredding. Sorting and knowing the type helps you pick the best plastic shredder blades for your job.

Choosing Plastic Shredder Blades

Picking the right blade for your plastic shredders is important. It can change how well you recycle. You should know the main blade types. Their shapes affect how they cut and how often you fix them.

Обзор типов лезвий

Одновальные лезвия

Single-shaft blades are good for hard and even plastics. These blades are on machines with one spinning shaft. They cut against a fixed blade. This setup makes the pieces even. You can control the size of the output. Use single-shaft blades for jobs that need neat cuts. They also work for wood and cloth.

Двухвальные лезвия

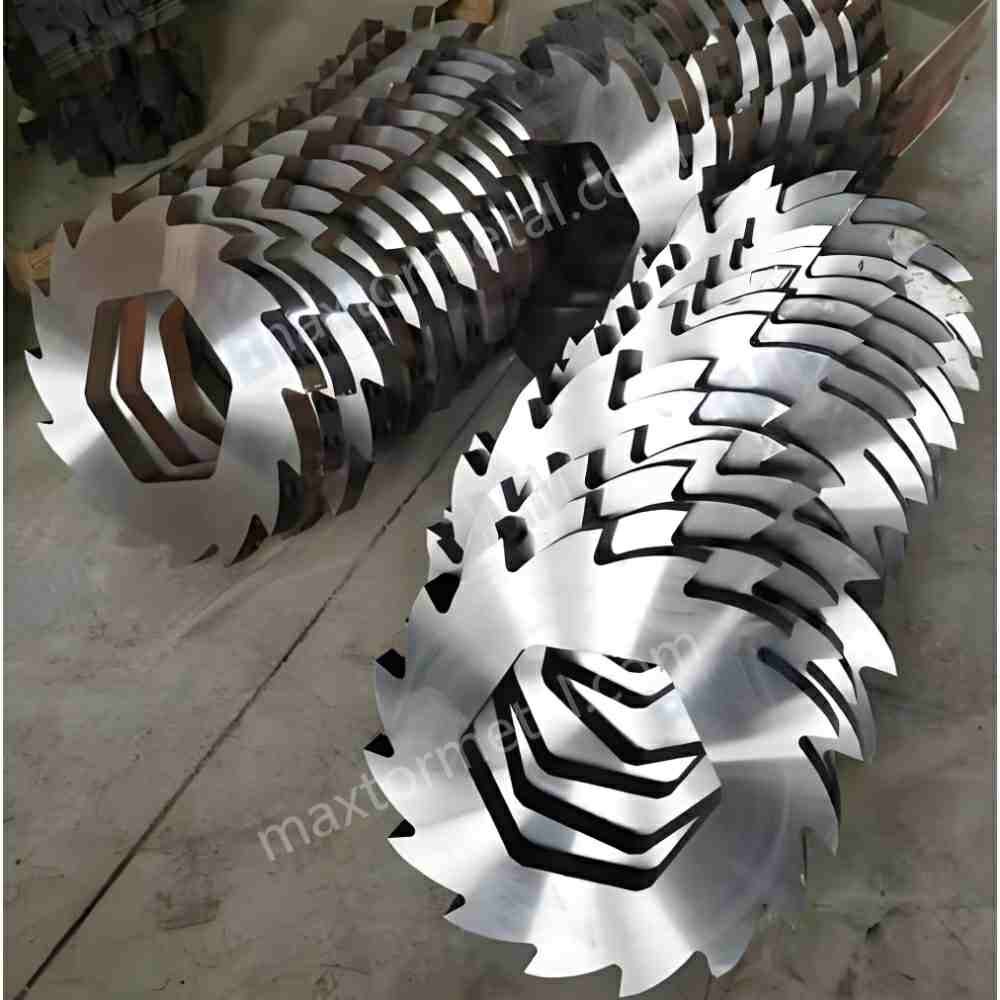

Double-shaft blades have two shafts that spin together. The blades fit into each other. This design gives strong power. You can shred big or tough plastic waste. Double-shaft blades work for mixed or dirty plastics. They handle things with many shapes. Recycling centers use these blades for tires, metals, and old electronics. Double-shaft shredders last a long time. They work for many kinds of jobs.

Четырехвальные лезвия

Four-shaft blades use two sets of double-shaft parts. You get better control over the size of the pieces. The output is more even. These blades break down hard materials. Use four-shaft blades for recycling lines with many steps. They help when you need small pieces and a good breakdown.

Claw Design Blades

Claw design blades have teeth like claws. These teeth grab and rip tough or stretchy plastics. Claw blades help shred things that normal blades cannot. You see less clogging with claw blades. They work well for big waste and tangled stuff. If you need a special blade, you can visit Nanjing Metal Industrial’s custom blades page.

Here is a table that shows what each blade type is used for:

| Type of Blade | Applications in Recycling Operations |

|---|---|

| Single-shaft blades | Plastic recycling, wood shredding, textile shredding |

| Double-shaft blades | Metal shredding, tire shredding, e-waste recycling |

| Four-shaft blades | Multi-stage recycling, precise sizing, complex material breakdown |

| Claw design blades | Bulky waste, tough plastics, fibrous or elastic materials |

Tip: Pick the blade type that matches your plastic and recycling goals. This helps you get good results and avoid problems.

Геометрия лезвия

Slice, Flat, V, Claw

Blade shape changes how your shredder blades cut. It also changes how often you need to fix them. Each shape works best for certain plastics and jobs.

- Slice blades make clean, straight cuts. Use them for thin or breakable plastics. These blades help you get smooth edges and even pieces.

- Flat blades have a wide cutting area. Use them for general shredding. Flat blades last longer and work for thin films or layers. Some flat blades have special coatings to stop sticking.

- V-shaped blades put force at one spot. Use them for hard or thick plastics. V-shaped blades cut deeper and make cutting easier.

- Claw blades have sharp teeth. Use them for tough or tangled materials. Claw blades grab and rip, which helps with stretchy or stringy plastics.

Here is a table that shows how changing blade shape can help:

| Before Adjustment | After Geometry Optimization |

|---|---|

| Blade changes: 3× per day | Blade changes: Once every 2 days |

| Misaligned pouches: 7% | Misaligned pouches: <1% |

| Line downtime: 2 hours/week | Line downtime: <30 minutes/week |

Plants that check their blades often have less downtime. They save money. A survey in 2022 showed these plants had 38% less downtime. They saved about $5,200 each month.

Note: Pick the blade shape that matches your plastic and shredding needs. This helps you work faster and spend less fixing things.

Blade Spacing and Particle Size

Blade spacing decides how big the shredded pieces are. If the blades are close, you get smaller pieces. These are good for jobs that need pure plastic or more steps. If the blades are far apart, you get bigger pieces. This means faster work and less fixing.

- Close spacing: Smaller pieces, cleaner output, uses more energy, needs more fixing.

- Wide spacing: Bigger pieces, faster work, uses less energy, needs less fixing.

Change blade spacing to match your recycling goals and plastic type. This helps you get the right size and keeps your machines working well.

Tip: Check your blade spacing often. Change it to match your plastic and what you want. This keeps your plastic shredder blades working well and helps you recycle better.

Industrial Shredder Blades: Material Selection

When you pick industrial shredder blades, the blade material is very important. The right material helps blades last longer and cut better. It also means you do not need to fix them as much. There are three common materials: tool steel, hardened steel, and alloy steel.

Инструментальная сталь

Tool steel is used a lot for shredder blades. Many recycling plants use it because it does not wear out fast. Tool steel blades stay sharp for a long time. This lets you shred more plastic before changing blades. You might see tool steel types like D2 or Cr12MoV. These types are good for jobs that need careful cutting. Tool steel works for many kinds of plastics. But tool steel can break if you use it on very hard or dirty plastics. It costs more than carbon steel, but it lasts longer and works better.

Tip: Pick tool steel blades if you want neat cuts and less stopping.

Закаленная сталь

Hardened steel blades are made with heat treatment. This makes them harder and stronger than regular steel. These blades do not wear out quickly. Hardened steel is good for plastics with fillers or mixed waste. Hardened steel blades last longer than normal blades. They keep their shape and sharpness for many hours. You do not need to change them often. But hardened steel costs more and needs careful use. SKD-11 steel is a good example. It is hard and tough, so it works well for hard crushing jobs.

Note: Check hardened steel blades often for cracks or chips. Looking at them often helps you stop problems early.

Легированная сталь

Alloy steel blades have extra things like chromium, molybdenum, or vanadium. These extras make the blades very hard and strong. Alloy steel does not rust easily. It is great for tough jobs and lasts a long time. Alloy steel blades work for both soft and hard plastics. They do not rust and can shred wet or dirty stuff. Alloy steel costs more than carbon steel, but you save money because you change blades less.

Here is a table to help you compare blade materials:

| Материал | Преимущества | Недостатки |

|---|---|---|

| Углеродистая сталь | Cheap, good for easy jobs | Rusts fast, wears out quickly |

| Легированная сталь | Very hard, strong, does not rust easily | Costs more, needs more care |

| Инструментальная сталь | Wears slowly, cuts well, works for many plastics | Can break, costs more |

| Нержавеющая сталь | Does not rust, easy to clean, handles heat | Wears out faster, costs more |

| Карбид вольфрама | Super hard, handles heat and hits well | Very costly, hard to fix, can break |

Tip: Use alloy steel blades if you want strong blades that last and do not rust.

The blade material you choose changes how long blades last and how well they work. High-speed steel blades last a long time and do not wear out fast. Tungsten carbide-coated blades are very hard and can handle lots of use. If you match the blade material to your recycling job, you get better results and save money.

Лезвия с твердосплавными напайками

Carbide-tipped blades are special in shredders. These blades have a steel body. The edge is covered with carbide. Carbide is very hard. It can do tough jobs that ruin other blades fast. These blades stay sharp for a long time. The carbide edge does not wear down quickly. You can shred hard plastics or glass-filled materials. You do not need to change blades often. This means you spend less time fixing things. You get more time to recycle.

Carbide-tipped blades are good for plastics with rough or strong fillers. If your plastic is mixed or dirty, these blades help. They keep your machines running well. You will have less downtime and fewer blade changes.

Some main benefits of carbide-tipped blades are:

- The carbide edge stays sharp for a long time.

- These blades last much longer than steel blades.

- The sharp edge gives you smooth, even cuts.

But, carbide-tipped blades cost more at first. The price is higher because of the special material. Making these blades takes extra work. Still, the long life and less fixing can save you money later.

You need to be careful with carbide-tipped blades. Carbide is very hard but can chip if dropped or hit. Always follow safety steps when you put in or take out these blades.

Tip: If you need to shred hard or rough plastics, carbide-tipped blades are best. They give you strong and steady performance. You get the most from your shredder blades.

| Особенность | Лезвия с твердосплавными напайками |

|---|---|

| Edge Material | карбид |

| Износостойкость | Очень высокий |

| Продолжительность жизни | Longest |

| Частота технического обслуживания | Очень низкий |

| Первоначальная стоимость | Высокий |

| Лучшее для | Abrasive, hard, or filled plastics |

Picking the right blade, like carbide-tipped ones, helps your recycling line work well. You can shred more plastic with fewer stops and less worry about blade wear.

Key Selection Criteria

Прочность

Material Hardness and Wear Resistance

When you choose shredder blades, you need to look at how hard and tough they are. Hardness helps blades keep their shape and stay sharp. Wear resistance means blades can handle lots of use without getting dull. Toughness stops blades from chipping or breaking when they hit hard things.

Here is a table that shows how different blade materials perform:

| Тип материала | Wear Rate (mm) | Processed Feedstock (kg) |

|---|---|---|

| Borided D2 Cutters | 0.08 | 79 |

| Baseline D2 Cutters | 0.26 | 78 |

Blades made from high-chrome tempered steel or iron borided D2 tool steel last much longer. They resist wear better than regular steel. If you pick a blade material with high hardness and wear resistance, you will spend less time and money on replacements.

Tip: Hard blades resist bending and stay sharp. Tough blades do not break easily.

Blade Lifespan in Continuous Operation

You want blades that last a long time, especially if your shredder runs all day. Blades with high wear resistance can shred more plastic before you need to change them. For example, borided D2 cutters wear down much slower than regular D2 cutters. This means you can process more plastic with fewer stops.

- Hardness keeps the edge sharp.

- Wear resistance lets blades handle rough plastics.

- Toughness stops chips and cracks.

If you use the right blade material, you will see longer blade life and fewer breakdowns.

Impact of Plastic Type on Durability

The type of plastic you shred changes how fast blades wear out. Hard plastics like ABS or PC need tougher blades. These plastics make blades dull faster. If you shred dirty or mixed plastics, blades can wear out up to 50% faster than with clean plastics.

| Тип пластика | Effect on Blade Wear |

|---|---|

| Hard plastics (e.g., PC, ABS) | Require tougher blades due to faster wear |

| Загрязненные материалы | Cause up to 50% more wear than clean materials |

You should always match your blade to the plastic you process. This helps your blades last longer and keeps your shredder running well.

Резкость

Initial Edge Quality

A sharp blade edge gives you clean cuts and smooth pieces. When you start with a high-quality edge, your shredder works better. You get less dust and fewer uneven pieces. Good initial sharpness also means your machine uses less power.

Сохранение кромки с течением времени

You want blades that stay sharp for a long time. If blades lose their edge quickly, you will need to stop and sharpen or replace them. Blades made from strong materials keep their edge longer. This means you can shred more plastic before you need to do maintenance.

- Sharp blades cut faster.

- Dull blades slow down your work and use more energy.

Effect on Cutting Efficiency and Output Quality

Sharp blades help your shredder work at its best. You get even, clean pieces of plastic. This makes it easier to recycle the plastic later. If blades get dull, you will see more dust, uneven cuts, and lower quality output. Dull blades can also make your machine work harder, which can lead to more repairs.

Note: Check your blades often. Replace or sharpen them when you see signs of dullness. This keeps your recycling line running smoothly.

Техническое обслуживание

Ease of Blade Replacement

You should pick blades that are easy to replace. Quick-change designs save you time and lower your labor costs. If you can swap blades fast, your shredder spends less time not working.

Cleaning and Inspection Requirements

Clean blades last longer. If you clean your blades every day, they can last 25–35% longer than blades cleaned less often. Cleaning stops material from building up and keeps blades from rusting. Regular inspection helps you find problems early, so you can fix them before they get worse.

- Clean blades cut better.

- Inspected blades are safer and last longer.

Maintenance Frequency and Cost

Regular maintenance saves you money. If you follow a maintenance schedule, you can cut blade replacement costs by 25–40%. Some companies save up to $10,000 a year by keeping up with blade care. Sharpen your blades every 40–80 hours if you use your shredder a lot. For lighter use, you can wait up to 100 hours. Most blades last between 200 and 500 hours before you need to replace them.

Tip: Make a maintenance plan. Clean, inspect, and sharpen your blades on a regular schedule. This keeps your shredder working well and saves you money.

Стоимость против производительности

Initial Investment vs. Long-Term Savings

When you choose plastic shredder blades, you might see a big difference in price. High-quality blades cost more at first. You may wonder if the extra money is worth it. Think about how long these blades last and how often you need to replace them.

- High-quality blades need less maintenance.

- You spend less time fixing machines.

- Blades with better materials last longer.

- Over time, you save money because you buy fewer blades.

If you look at the return on investment, you see that strong blades help you save more in the long run. You get better results and spend less on repairs.

Общая стоимость владения

You should not only look at the price tag. The total cost of ownership includes many things. You pay for maintenance, repairs, and new blades. You also spend money on labor and machine downtime.

| Фактор стоимости | Описание |

|---|---|

| Замена лезвия | How often you need new blades |

| Техническое обслуживание | Time and money spent on cleaning and repairs |

| Время простоя | Lost work when machines stop |

| Labor | Workers needed for blade changes and fixes |

If you choose plastic shredder blades that last longer, you lower these costs. You keep your recycling line running and avoid surprise expenses.

Balancing Quality and Budget Constraints

You want the best blades, but you also have a budget. Try to find a balance between quality and price. Do not pick the cheapest blades if they wear out fast. Look for blades that fit your needs and last a long time.

- Compare blade types and materials.

- Ask suppliers about blade lifespan.

- Think about your recycling goals and plastic types.

If you choose wisely, you get good performance without spending too much.

Tip: Investing in durable plastic shredder blades helps you save money over time. You get better results and fewer problems.

Совместимость оборудования

Blade Fit and Mounting Specifications

You need blades that fit your shredder. Check the size and shape before you buy. Make sure the mounting holes match your machine. If the blade does not fit, you cannot use it.

| Фактор | Описание |

|---|---|

| Совместимость с машинами | Check if your shredder supports modular blades. |

| Прочность | Pick tool steel or tungsten carbide for tough jobs. |

| Supplier Consultation | Work with a supplier who offers support and advice. |

If you work with a good supplier, you get blades that fit and work well. This helps you avoid mistakes and keeps your recycling line running.

Machine Power and Speed Requirements

Your shredder has limits. Some blades need more power to cut hard plastics. If your machine is not strong enough, the blades may not work right. Check your shredder’s speed and power before you choose blades.

- Match blade type to machine power.

- Use strong blades for tough plastics.

- Make sure your shredder can handle the blade’s speed.

If you pick the right blades, your machine works better and lasts longer.

Integration with Existing Recycling Lines

You want your new blades to work with your current setup. Check if the blades fit with your conveyor, sorting, and washing systems. If you change blade types, you may need to adjust other machines.

- Ask your supplier about integration.

- Test blades before full use.

- Make sure all parts work together.

If you plan ahead, you avoid problems and keep your recycling line smooth.

Note: Always check blade fit and machine specs before you buy plastic shredder blades. This saves you time and money.

Безопасность

Safe Handling and Installation Procedures

Plastic shredder blades are sharp and heavy. You must handle them with care. Always wear protective gear when you work with blades.

- Put on safety glasses, dust masks, helmets, and gloves.

- Check that the machine’s guard is in place before you start.

Follow these steps when you install blades:

- Protect the alloy tips from damage.

- Check the main shaft for proper alignment.

- Clean the shaft and flange before installing the blade.

- Use the largest flange possible for stability.

- After installation, let the blade spin freely for 30 seconds.

- Tighten flange nuts to keep the blade secure.

If you follow these steps, you keep yourself and your team safe.

Blade Failure Risks and Prevention

Blades can fail if you do not install them right or use the wrong type. Always check for cracks or chips before use. Replace damaged blades at once. Keep your machine clean and well-maintained.

- Inspect blades before and after each use.

- Do not use blades that look worn or broken.

- Keep records of blade changes and problems.

If you watch for risks, you prevent accidents and keep your recycling line safe.

Operator Training and Protective Measures

You need trained workers to handle plastic shredder blades. Teach your team how to install, clean, and inspect blades. Make sure everyone knows the safety rules.

- Give safety training to all operators.

- Use signs and reminders near machines.

- Check that workers wear protective gear every time.

If you train your team well, you lower the chance of accidents and keep your recycling center safe.

Tip: Safety comes first. Always use protective gear and follow proper steps when working with plastic shredder blades.

Sourcing Shredder Blades

Supplier Quality

When you need shredder blades, pick a supplier you can trust. Good suppliers help you get better results and save money. There are five things you should look for. First, check if the supplier knows about scrap recycling. Experienced suppliers make blades that last longer. Second, see if the blades are strong and built well. Strong blades last longer and you do not need to replace them often. Third, find out if you can get blades made just for your machine. Custom blades fit your needs better. Fourth, ask if the supplier gives good service and support. Good support helps you fix problems fast. Fifth, make sure you know what you are paying for. You should understand how the cost helps your business.

Nanjing Metal Industrial gives OEM and ODM services. You can work with their team to design blades for your needs. They check every blade before they send it to you.

Tip: Always ask about a supplier’s experience and support before you buy. This helps you avoid problems later.

Варианты настройки

Sometimes you need blades that fit your recycling line or work with special plastics. Many suppliers let you choose custom options. You can pick blade shapes, sizes, and motor power. This helps you get the best results for your job.

Here is a table showing common customization options:

| Аспект настройки | Подробности |

|---|---|

| Blade Configurations | Adjustable to meet specific processing requirements. |

| Shredding Sizes | Can be customized based on the type and volume of plastic waste. |

| Motor Specifications | Options available depending on processing needs. |

| Adjustable Cutting Sizes | Enables customization based on specific output requirements. |

| Motor Power Range | Available from 5HP to 100HP for varying processing capacities. |

| Индивидуальный дизайн | Shredders can be custom-designed to meet exact material and output requirements. |

If you need a special blade, visit the страница пользовательских лезвий to see your options. Custom blades help you shred plastics better and stop less for repairs.

Note: Customization lets you match blades to your recycling goals. This improves performance and saves money.

Warranty and Support

Warranty and support are important when you buy shredder blades. Good suppliers stand by their products. They help you fix problems and keep your machines working.

Here is a table comparing warranty and support from leading suppliers:

| Поставщик | Warranty Coverage | After-Sales Support |

|---|---|---|

| MBM Corporation | 1-year limited warranty on cutting shafts and wheels; 90-day limited warranty on electrical parts | Repair or replace defective parts; service team available for inquiries |

| Shunyin | 1-year warranty covering all mechanical and electrical components | Lifetime technical support; global spare parts availability |

| MTD | Н/Д | Н/Д |

Some suppliers, like MBM Corporation, will repair or replace broken parts. Others, like Shunyin, give lifetime help and spare parts around the world. You should ask how long the warranty lasts and what help you get before you buy.

Tip: Choose suppliers who offer strong warranty and support. This helps you avoid long delays and costly repairs.

Price Comparison

When you buy plastic shredder blades, you want to get the best value for your money. Prices can change a lot based on several factors. You should look at more than just the price tag. Think about what you get for the money you spend.

What Affects the Price of Plastic Shredder Blades?

- Материал лезвия: Stronger materials like tungsten carbide or tool steel cost more. They last longer and need fewer replacements.

- Blade Type and Size: Bigger blades or special shapes, like claw or V-shaped blades, usually cost more than standard flat blades.

- Настройка: Custom blades made for your machine or special plastics can raise the price.

- Order Quantity: Buying in bulk often lowers the price per blade.

- Supplier Services: Some suppliers include support, warranty, or faster shipping in the price.

Here is a table to help you compare common price ranges:

| Материал лезвия | Typical Price Range (USD) | Ожидаемый срок службы | Лучшее для |

|---|---|---|---|

| Углеродистая сталь | $10 – $30 | Короткий | Light-duty, soft plastics |

| Tool Steel (D2, Cr12MoV) | $30 – $80 | Medium to Long | Most plastics, general use |

| Легированная сталь | $40 – $100 | Длинный | Tough or mixed plastics |

| С твердосплавным наконечником | $100 – $250 | Очень длинный | Hard, abrasive, or filled plastics |

Кончик: Do not pick blades only because they are cheap. Cheap blades may wear out fast and cost you more in the long run.

How to Compare Prices from Different Suppliers

- Ask for a Quote: Get prices for the same blade type, size, and material from at least three suppliers.

- Check What’s Included: See if the price covers shipping, warranty, or after-sales support.

- Look at Blade Quality: Ask about the material, heat treatment, and quality checks.

- Think About Total Cost: Add up the cost of buying, replacing, and maintaining blades over time.

You can use this checklist when you compare offers:

- Does the price include customization?

- Is there a warranty or support?

- How long do the blades last?

- Are there extra costs for shipping or taxes?

Примечание: Sometimes, paying more at first for high-quality plastic shredder blades saves you money later. You spend less on replacements and repairs.

When you compare prices, focus on value, not just cost. The right plastic shredder blades help your recycling line run better and save you money over time.

Maximizing Efficiency

Мониторинг производительности

You need to watch your shredding equipment closely to keep your recycling line running smoothly. Start by checking your plastic shredders every day. Look for signs of wear, such as dull edges or chips on the blades. Use sensors or data tools if your machine has them. These tools can show you when a blade is getting dull or when the machine is working too hard. Real-time monitoring helps you spot problems before they stop your work.

Set up a checklist for your team. Include steps like checking blade sharpness, listening for strange noises, and looking for loose parts. Write down what you find. This record helps you see patterns and fix issues early. If you use advanced systems, you can get alerts when something needs attention. This keeps your industrial shredding process safe and efficient.

Tip: Regular checks help you avoid big repairs and keep your blades working longer.

Maintenance Scheduling

A good maintenance plan keeps your shredders in top shape. Make a schedule for cleaning, oiling, and checking all parts. Clean the blades often to stop plastic from building up. Lubricate moving parts so they do not wear out fast. Inspect the blades for cracks or damage. If you see a problem, fix it right away.

Plan to sharpen your blades with precision tools. Machines like CNC sharpeners keep the blade angle even. This stops uneven wear and helps your blades last longer. Some plants use automated sharpening systems. These systems save time and make sure every blade is sharp.

Check other parts too, like hammers or shafts. Balance them to prevent shaking and keep the shredder safe. Write down each maintenance task in a logbook. This helps you remember what you did and when you need to do it again.

- Clean and lubricate blades regularly.

- Inspect for wear, cracks, or chips.

- Sharpen blades with precision tools.

- Balance and check other moving parts.

- Keep a maintenance log.

Blade Upgrades

Sometimes, you need to upgrade your blades to keep up with new plastics or higher workloads. New blade designs, like claw or V-shaped blades, can help you shred tough or mixed materials. Stronger materials, such as carbide-tipped blades, last longer and cut better.

Talk to your supplier about new blade options. Ask if there are upgrades that fit your machine and your recycling needs. Upgrading blades can reduce downtime and improve the quality of your recycled plastic. You will also spend less time on repairs and replacements.

Note: Upgrading your blades is a smart way to boost efficiency and stay ahead in recycling.

Staff Training

You need well-trained staff to run your recycling center safely and efficiently. Good training helps your team use plastic shredders the right way. When your staff knows what to do, you see fewer mistakes and less downtime. You also keep everyone safe.

Start by teaching your team about the basics of shredding. Show them how plastic shredders work. Explain the main parts, such as the blades, shafts, and safety guards. Use simple words and clear examples. You can use pictures or short videos to help everyone understand.

Safety comes first. Make sure your staff knows how to handle blades and machines. Teach them to wear gloves, safety glasses, and ear protection. Show them how to check for loose parts or damage before starting the shredder. Remind your team to keep hands and tools away from moving blades.

You can use a checklist to help your staff remember important steps. Here is an example:

- Put on safety gear.

- Inspect the shredder for damage.

- Check blade sharpness.

- Make sure guards are in place.

- Start the machine slowly.

- Watch for strange noises or shaking.

- Stop the machine if you see a problem.

Regular training keeps your team ready for new challenges. Hold short meetings every month. Talk about new plastics, blade upgrades, or changes in recycling rules. Invite your staff to ask questions and share ideas.

You can use a table to track training progress:

| Staff Name | Last Training Date | Safety Test Score | Blade Change Skill | Примечания |

|---|---|---|---|---|

| Alex | 2024-05-10 | 95% | Хороший | Needs review |

| Jamie | 2024-06-01 | 100% | Отличный | Ready for lead |

| Taylor | 2024-05-20 | 90% | Fair | Needs practice |

Tip: Give rewards for good safety habits or quick learning. This helps your team stay motivated.

Teach your staff how to spot problems early. Show them what dull blades look like. Explain how to listen for odd sounds from the shredder. Encourage your team to report issues right away. Fast action stops small problems from getting worse.

You can also train your staff to clean and maintain the machines. Simple cleaning steps, such as wiping blades and checking for stuck plastic, help your equipment last longer. Teach your team to follow a maintenance schedule.

When you invest in staff training, you build a strong team. Your recycling center runs better. You see fewer accidents and more plastic recycled. Well-trained staff make your plastic shredders work at their best.

Распространенные ошибки

Ignoring Plastic Compatibility

Some people think any blade can shred plastic. This is not true. Every plastic type is different. Plastics have their own hardness and melting point. Using the wrong blade can hurt your machine. You might also get bad results. Hard plastics like ABS or PET need strong blades. These blades do not wear out fast. Softer plastics like HDPE or PP need special blade shapes. These shapes help grip and cut the plastic well.

If you do not match the blade to the plastic, blades wear out faster. Shredding may be uneven. You might have more machine stops. Repairs can cost more money. Always check what kind of plastic you have. Pick a blade that fits the plastic’s needs. This helps your machine work better and last longer.

Tip: Sort your plastics before shredding. This makes it easier to pick the right blade and helps recycling work better.

Overlooking Maintenance

Sometimes people forget to take care of shredder blades. This happens when work gets busy. Not doing maintenance is a big mistake. It can waste time and money. Blades need to be cleaned, checked, and sharpened often. If you skip these steps, blades get dull fast. Dull blades use more power. They can even break your shredder.

A good plan for maintenance helps blades last longer. Clean blades every day to stop plastic from building up. Check for cracks or chips before using them. Sharpen blades on a set schedule. Write down each job in a logbook. This helps you find problems early and stop sudden breakdowns.

Here is a simple checklist for blade care:

- Clean blades after every shift

- Check for damage once a week

- Sharpen blades every 40–80 hours

- Replace blades when they are worn

Note: Taking care of your blades saves money. It keeps your shredder working its best.

Focusing Only on Cost

Some people buy cheap blades to save money. This can cause bigger problems later. Cheap blades wear out quickly. You will need to buy new blades more often. Your shredder may stop working for repairs. Cheap blades can also hurt your machine. They may not cut plastic well.

It is smart to look at the total cost, not just the price. Good blades cost more at first. But they last longer and work better. You will buy fewer blades and fix your shredder less. Think about how long blades last and how much care they need. Also, think about how much time your shredder is stopped.

| Тип лезвия | Первоначальная стоимость | Продолжительность жизни | Частота замены | Долгосрочные сбережения |

|---|---|---|---|---|

| Лезвия низкого качества | Низкий | Короткий | Высокий | Низкий |

| Высококачественные лезвия | Выше | Длинный | Низкий | Высокий |

Tip: Buy strong blades for your shredder. You will save money and get better results over time.

Neglecting Supplier Support

Many people do not think about supplier support when buying plastic shredder blades. Some think their job is finished after they buy the blades. This is not true. Good supplier support helps you fix problems fast. It keeps your recycling line working well.

When you pick a supplier, do not just look at price or product. You need a partner who helps you after you buy. If you have questions about putting in blades or need advice, good support matters a lot. Some suppliers give training, technical help, and quick answers. Others may not help you at all.

Here are signs of good supplier support:

- Clear communication: The supplier answers your questions fast and clearly.

- Technical guidance: You get help with picking, putting in, and fixing blades.

- After-sales service: The supplier helps with repairs, new parts, or upgrades.

- Warranty coverage: You know what is covered if something breaks.

- Custom solutions: The supplier can make blades for your specific needs.

If you do not care about supplier support, you may have these problems:

- You might put in plastic shredder blades the wrong way.

- You could use the wrong blade for your plastic.

- You may wait a long time for new parts.

- You might not get help if your machine stops working.

Кончик: Always ask about support before you buy. Good support saves you time and money.

A table can help you compare suppliers:

| Supplier Feature | Good Support | Poor Support |

|---|---|---|

| Fast response | ✅ | ❌ |

| Technical advice | ✅ | ❌ |

| Custom blade options | ✅ | ❌ |

| Warranty help | ✅ | ❌ |

| Training offered | ✅ | ❌ |

Pick a supplier who stands behind their plastic shredder blades. This helps you avoid long waits and costly mistakes. If you have a problem, you want someone to help you fix it fast.

Remember, plastic shredder blades work best with good support. Reliable supplier support keeps your recycling safe, fast, and not too expensive. Always think about supplier support when you buy new blades.

Исследования случаев

PET Recycling Success

You get better results when you pick good plastic shredder blades for PET recycling. A recycling center in the Midwest changed from regular blades to high-speed steel blades. The workers saw a big improvement. The blades stayed sharp longer. They cut PET bottles into even pieces. Sorting and washing got much easier.

The center watched their results for three months. Here is what they learned:

| Before Upgrade | After Upgrade |

|---|---|

| Blade changes: 8/mo | Blade changes: 2/mo |

| Downtime: 12 hrs/mo | Downtime: 3 hrs/mo |

| Output quality: Fair | Output quality: High |

You can see that changing blades less and stopping less helped the center recycle more PET. The new plastic shredder blades made work smoother and saved money.

Tip: For PET bottles, pick blades that do not wear out fast. This helps your recycling line work longer.

Mixed Plastics Processing

It is tough to shred mixed plastics. You might have soft films, hard boxes, and dirty things in one batch. A facility in Asia had this problem. They used double-shaft plastic shredder blades with a claw design. These blades grabbed and ripped all kinds of plastics, even when the mix changed.

The workers saw these results:

- Shredding speed went up by 30%

- Blade life was twice as long

- Output pieces looked more even

You can shred mixed plastics better with the right blade. Claw design blades help stop jams and keep machines running.

Note: Always look at your feedstock. Pick plastic shredder blades that fit the mix of plastics you have.

Efficiency Upgrades

Sometimes you want your recycling line to be faster and more steady. A plant in Europe switched to carbide-tipped plastic shredder blades. The new blades lasted much longer than the old ones. The plant also made a regular plan for maintenance.

After these changes, the plant saw:

- 40% less downtime

- 25% more plastic shredded

- Lower costs for fixing machines

You can use stronger blades and better care to improve your recycling results. The right plastic shredder blades help you reach your goals and keep your work running well.

Tip: Check your blade choice and care plan every year. Small changes can help your recycling center do much better.

You should think about your plastic types before picking blades. Your recycling goals and machine needs matter too. Match blade shapes and materials to your plastics. This helps you get better results. Check your choices often as your recycling changes. Nanjing Metal Industrial has many blade options and gives support. If you need help, contact their team.

Часто задаваемые вопросы

What are plastic shredder blades used for?

You use plastic shredder blades to cut and break down plastic waste into smaller pieces. This helps you recycle plastic more easily. The blades fit inside shredding machines and handle many types of plastic materials.

How often should you replace plastic shredder blades?

You should check your plastic shredder blades every week. Replace them when you see dull edges, chips, or cracks. Most blades last between 200 and 500 hours, but this depends on the plastic type and how much you use the machine.

Can you sharpen plastic shredder blades?

Yes, you can sharpen plastic shredder blades. Use a grinding tool or a sharpening machine. Sharpening helps you keep the blades cutting well and extends their life. Always follow safety rules when you sharpen blades.

Which plastics are hardest on shredder blades?

Hard plastics like ABS, PET, and polycarbonate wear out blades faster. Plastics with fillers, glass, or metal also cause more blade wear. You should use strong blades for these materials to avoid frequent replacements.

How do you choose the right blade material?

You choose blade material based on the plastic you shred. Use tool steel or carbide-tipped blades for hard or filled plastics. Alloy steel works well for mixed or dirty plastics. Always match the blade to your recycling needs.

What safety steps should you follow when handling blades?

Always wear gloves and safety glasses when you handle plastic shredder blades. Check for sharp edges and cracks before use. Make sure the machine is off before you change or clean blades. Follow your company’s safety rules every time.

Can you use the same blades for different plastics?

You can use some plastic shredder blades for many plastics, but not all. Hard or filled plastics need stronger blades. If you shred mixed plastics, pick a blade that handles different types without wearing out quickly.

Why does blade spacing matter in shredding?

Blade spacing controls the size of shredded plastic pieces. Close spacing gives you smaller pieces, which helps with further recycling steps. Wider spacing makes bigger pieces and increases shredding speed. Adjust spacing to match your recycling goals.

Смотрите также

Руководство по промышленным лезвиям измельчителей и их применению

Лезвия измельчителя: анализ классификации, выбор материала, срок службы и методы проектирования

Один ответ