You need to keep ножи для роликовых ножниц из нержавеющей стали clean. Do not let them get scratched or dirty. This helps the blades work well and keeps products good. Some things can make the blades dirty:

- Iron filings and dust from other machines

- Grease from hands or tools

- Touching carbon steel surfaces

If you do not take care of the blades, big problems can happen. The table below shows some risks and what they can do:

| Категория риска | Описание | Влияние на безопасность и эксплуатацию |

|---|---|---|

| Катастрофический отказ оборудования | Blades can break suddenly | People can get hurt. Machines can break. Work stops. |

| Операционная неэффективность | Blades can jam or cut badly | Time and materials are wasted. |

| Emergency Repairs vs Maintenance | Unsafe repairs may be needed fast | More danger and more problems. |

Doing these things will help you stop work delays, bad products, and mixing up materials.

Ключевые выводы

- Keep stainless steel roller shear blades clean. This helps them work well and keeps products good.

- Always wear gloves that do not scratch. This protects your hands and the blades from getting scratched.

- Use lifting tools made of plastic or wood. These tools stop the blades from getting damaged when you move them.

- Store blades in racks that do not scratch. Use covers to keep dust off the blades.

- Clean blades often with cleaners that do not cause rust. This removes dirt and grease but does not hurt the blades.

- Check blades often for scratches or damage. This helps you find problems early and keeps things working well.

- Do not mix blades for different materials. Use special blades for each material and use color codes to help.

- Keep a record of cleaning and checking the blades. This helps you know their condition and when to replace them.

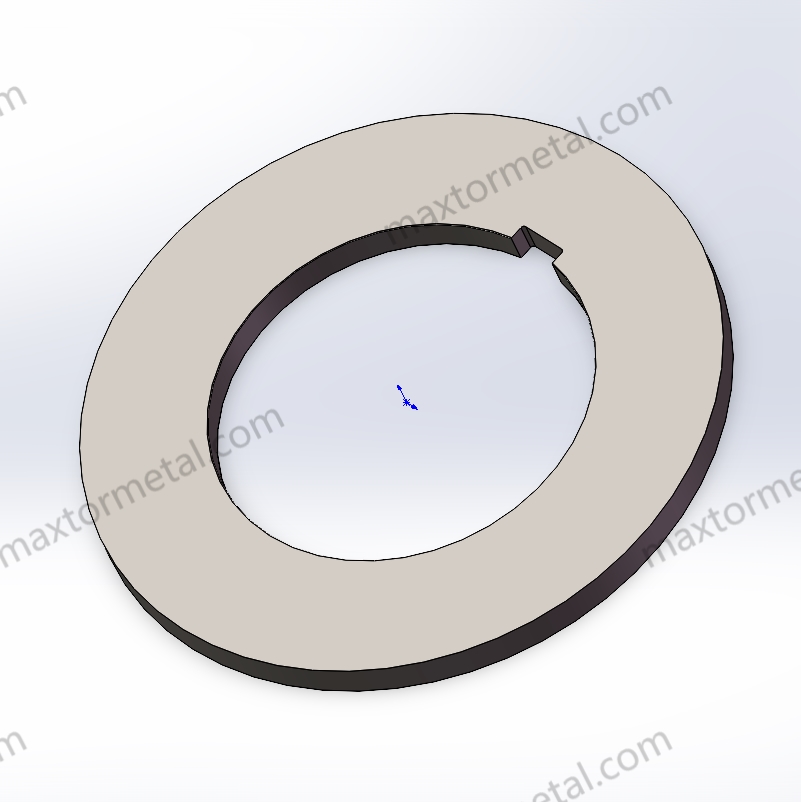

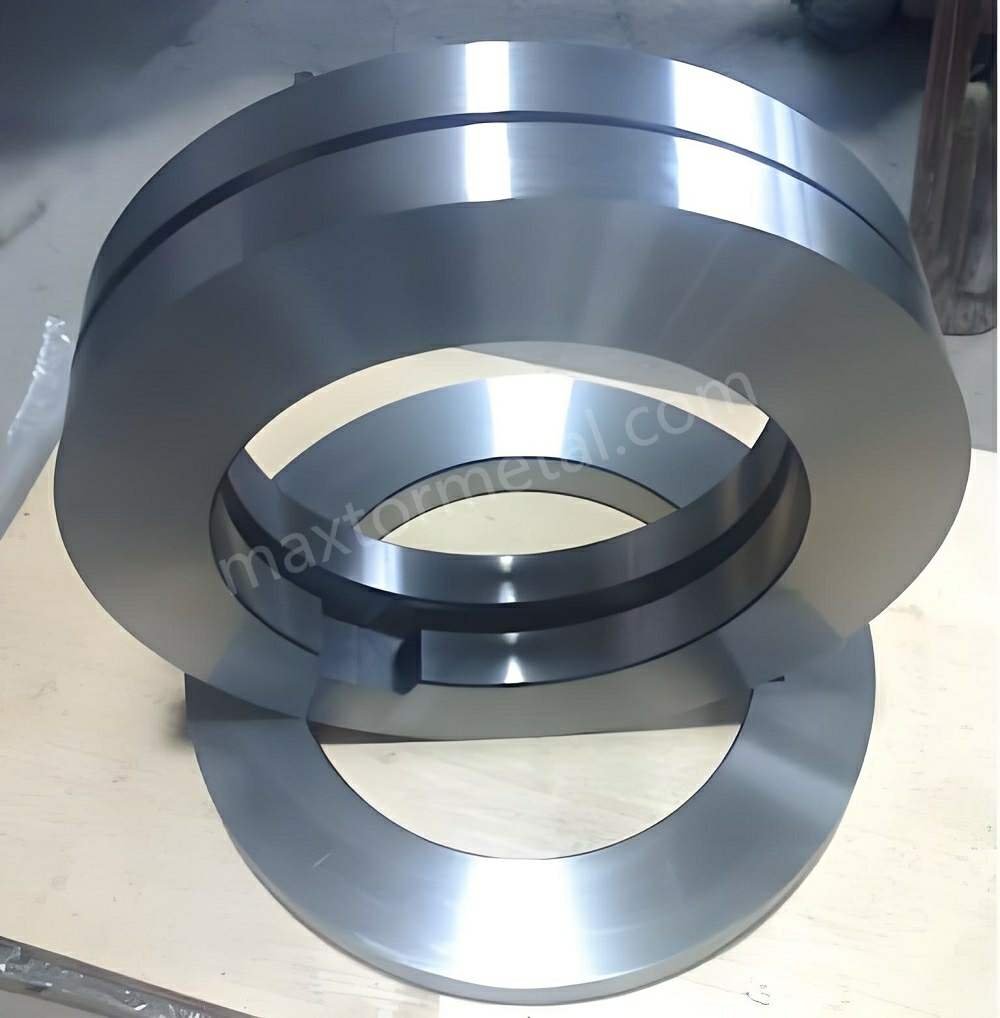

Handling Stainless Steel Roller Shear Blades

Taking care of stainless steel roller shear blades stops scratches and contamination. You should use the right gloves, tools, and storage ways. Keeping your workspace neat and handling blades carefully helps you avoid expensive mistakes.

Using Protective Gloves and Tools

Non-Abrasive Gloves

Always wear non-abrasive gloves when you touch stainless steel roller shear blades. These gloves keep your hands and the blade safe. Pick gloves made for metal work. Some good choices are:

- Leather gloves last long and feel comfortable.

- Kevlar gloves protect against cuts.

- Nitrile gloves resist chemicals and help you grip.

Steel mesh gloves are best in risky places. They give strong protection from cuts and pokes. Personal protective gloves keep your hands safe and help you work better.

Кончик: Do not use rough or dirty gloves. Dirt and grit can scratch the blade.

Dedicated Lifting Tools

Use special tools for lifting and moving blades. These tools stop drops and lower the chance of scratches. Do not use tools made from carbon steel. Choose lifting tools with plastic, wood, or stainless steel parts that touch the blade. This keeps the blade clean and smooth.

Безопасные методы хранения

Blade Racks and Covers

Put stainless steel roller shear blades in racks made of wood, plastic, or stainless steel. These materials do not scratch the blade. Use blade covers to protect the edge from dust and bumps. Store each blade in its own spot.

- Stand blades up or lay them flat, depending on the rack.

- Make sure covers fit well and do not hold moisture.

Avoiding Metal-to-Metal Contact

Do not let stainless steel blades touch other metals, especially carbon steel. Metal touching metal can scratch and contaminate the blade. Keep blades away from other tools and materials. If you stack blades, use soft things like plastic or paper between them.

Примечание: Keeping stainless steel roller shear blades away from carbon steel is very important in stainless steel fabrication. This step stops cross-contamination and keeps your blades working well.

A neat setup makes cleaning and protecting blades easier. You lower the chance of damage and keep blades ready to use.

Чистка и обслуживание

Cleaning your ножи для роликовых ножниц из нержавеющей стали helps you do better work. You need to pick the right cleaners and follow good routines. This part explains how to protect your blades and keep them working well.

Cleaning Agents for Stainless Steel Blades

Non-Corrosive Cleaners

Always use cleaners that do not hurt the blade surface. Some safe choices are:

- Mild detergents

- Изопропиловый спирт

- Specialized blade cleaners

These cleaners take off dirt and grease. They do not harm the blade. They also stop chemicals from building up, which can make blades work worse.

Avoiding Abrasive Pads

Do not use steel wool or strong chemicals on your blades. These things can scratch the blade and cause contamination. Scratches make it harder to finish stainless steel and can cause rust. Use soft cloths or pads that do not scratch for cleaning.

Кончик: Always read the label before using any cleaner. Make sure it is safe for stainless steel fabrication and does not leave bad stuff behind.

Процедуры очистки

Manual and Automated Methods

You can clean blades by hand or with machines. Cleaning by hand is good for small jobs or special spots. Use a soft cloth and mild detergent. For many blades, machines save time and give even results.

- Wipe blades gently so you do not scratch them.

- Rinse with clean water to wash off cleaner.

- Dry blades right away to stop water spots.

Removing Oil, Dust, and Grease

Oil, dust, and grease can build up on blades. These things can contaminate blades and make cuts worse. You should:

- Wipe blades with a pH-neutral cleaner after each use.

- Take off all oil and dust before storing blades.

- Check the blade for sticky spots or stains.

Keeping blades free from oil and dust protects the surface and keeps your workspace safe.

Частота технического обслуживания

Routine Schedules

Regular cleaning and care keep blades sharp and ready. You should make a schedule for these jobs. Many people clean blades after every use. This keeps the blade edge good and stops chemical buildup.

- Sharpen blades with the right tools to keep the edge sharp.

- Store blades in holders in a dry, cool place.

Maintenance Logs

You can use a log to track cleaning and repairs. Write down when you clean, sharpen, or check your blades. This helps you see patterns and plan for future care.

| Задача | Частота | Примечания |

|---|---|---|

| Уборка | После каждого использования | Use mild detergent |

| Заточка | По мере необходимости | Use proper sharpening tools |

| Инспекция | Еженедельно | Check for scratches or wear |

A good log helps you remember steps and keeps your stainless steel roller shear blades working well.

Taking care of blades is important for finishing stainless steel and keeping your tools working. If you follow these cleaning and care steps, you lower the risk of contamination and help your tools last longer.

Surface Protection and Protective Film

You need to protect stainless steel roller shear blades from scratches and contamination. Using the right protective film and interlayers gives you strong surface protection. This step is important for both storage and transport. If you skip this, you risk damaging the blade edge and lowering product quality.

Using Protective Film and Interlayers

Protective film acts as a shield for your blades. It keeps dust, dirt, and sharp objects away from the blade surface. You can also use interlayers, such as plastic or paper, to add another layer of temporary surface protection.

Plastic or Paper Interlayers

You have several choices for protective film. Each type works best for different needs. The table below shows common options and their features:

| Type of Protective Film | Описание |

|---|---|

| White PE Protective Film | Good for most uses. Has a rubber adhesive layer that sticks well and protects the surface. |

| Blue PVC Protective Film | Best for deep-drawing jobs. It is thicker and has a rubber adhesive for extra grip. |

| Black PVC Protective Film | Made for heavy-duty work. Offers strong adhesive power and stands up to weather. |

Plastic or paper interlayers help prevent metal-to-metal contact. You can place these between blades or between the blade and the rack. This simple step stops scratches and keeps the surface clean.

Application and Removal Tips

Applying and removing protective film the right way helps you avoid damage. Follow these best practices:

- Find an edge of the film and peel it back slowly at a sharp angle.

- Use a hair dryer to warm the film if it feels stuck. This makes peeling easier.

- Use a plastic scraper to lift the edge. Scrape gently as you peel.

- If the adhesive stays behind, use a mild solvent to clean it off.

Кончик: Always check the blade after removing the film. Make sure no glue or dirt remains on the surface.

Storage Environment

The place where you store your blades matters. Good storage keeps your blades safe from corrosion and contamination.

Dry, Ventilated Areas

Store your blades in a dry, well-ventilated area. Moisture on the metal surface can cause corrosion. High humidity, heat, and frequent rain make this worse. If you work near the coast or in a city, salt and pollution can speed up corrosion. You should keep the storage area clean and dry. Use fans or dehumidifiers if needed.

- Stainless steel is not fully stain-proof. You must handle and store it with care.

- Moisture and pollutants in the air can damage the blade surface.

- High humidity and salt in the air increase the risk of corrosion.

Avoiding Carbon Steel Contact

Never let stainless steel roller shear blades touch carbon steel. Even a small amount of contact can cause contamination. This can lead to rust spots and lower blade performance. Always use plastic or paper interlayers when storing blades near other metals. Keep carbon steel tools and parts away from your storage racks.

Примечание: Separating stainless steel from carbon steel is a key part of surface protection. This step helps you keep your blades in top shape.

By following these steps, you give your blades the best protection. You reduce the risk of scratches, stains, and corrosion. Your blades stay sharp and ready for use.

Operational Best Practices

You need to follow the right steps when you use stainless steel roller shear blades. Good practices help you avoid scratches and contamination. You also get better results when cutting stainless steel. This section explains how to install blades, set up machines, and choose the best materials.

Installation and Alignment

Arbor Precision

You must check the arbor before you install the blade. The arbor holds the blade in place. If the arbor is not straight, the blade can wobble. Wobbling causes uneven cuts and scratches. Use a gauge to measure the arbor. Make sure it is clean and free from dust. If you see any dirt, clean it before you put the blade on.

Tip: Always use a dedicated arbor for stainless steel fabrication. This step helps you avoid cross-contamination.

Зазор лезвия

Blade clearance means the space between the blade and the material. You need to set the right clearance for cutting stainless steel. If the gap is too small, the blade can rub and scratch the metal. If the gap is too big, the cut will not be clean. Use the machine manual to find the best clearance. Adjust the blade until it sits at the correct height.

- Check the clearance before each job.

- Use feeler gauges for accurate measurement.

- Make small changes if you see scratches or rough edges.

Monitoring Parameters

Cutting Speed and Feed Rate

You control the quality of your cuts by changing the speed and feed rate. Cutting stainless steel needs careful adjustment. Here is what happens when you change these settings:

- Higher cutting speeds can improve the surface finish. You get fewer built-up edges and less tool-chip sticking.

- If you increase the feed rate, you may see more roughness on the surface.

- Too much speed can cause heat damage. The blade may lose its sharpness and the metal can change color.

You should start with a moderate speed and feed rate. Watch the blade and the metal. If you see scratches or rough spots, slow down or adjust the feed. Always keep a record of your settings for each job.

Lubrication and Coolant

Lubrication and coolant play a big role in protection and cleaning. You need to use them every time you cut stainless steel. Here is why they matter:

- Lubrication and coolant lower friction and wear. This helps prevent scratches on the blade and the metal.

- They wash away small particles like iron oxide and metal slivers. This keeps the blade clean and stops contamination.

- Lubricants create a thin film between surfaces. This film stops welding and scratching.

You should pick a coolant made for finishing stainless steel. Apply it evenly during the cut. Check the coolant level before each job. If you need custom solutions for your blades, you can visit custom blade options для получения более подробной информации.

Выбор материала

Carbide vs. Tool Steel

The blade material affects how well you can cut stainless steel. You have two main choices: tungsten carbide and tool steel.

- Tungsten carbide gives you better wear resistance and hardness. It works well for slitting hard metals like stainless steel.

- Tool steel costs less and lasts a decent amount of time. It may not work as well for very hard metals.

- High-carbon tool steel hardened to 60-65 HRC is a good choice for cutting stainless steel and other tough materials.

You should pick the blade material based on your job needs. If you cut stainless steel often, carbide blades may last longer and give cleaner cuts.

Managing Work-Hardening

Stainless steel can get harder as you cut it. This is called work-hardening. You need to manage this effect to avoid scratches and blade damage.

- Use sharp blades to reduce work-hardening.

- Keep the cutting speed steady.

- Do not let the blade dwell too long in one spot.

If you see the metal getting harder, stop and check your settings. You may need to change the blade or adjust the speed. Good management helps you get smooth edges and better results when finishing stainless steel.

Note: Always review your process after each job. Small changes in setup can make a big difference in protection and blade life.

By following these operational best practices, you keep your blades in top shape. You also get better results when cutting stainless steel. You lower the risk of scratches, contamination, and downtime.

Preventing Cross-Contamination

Cross-contamination can cause big problems with stainless steel roller shear blades. You need to keep blades clean and away from other materials. This helps stop rust, stains, and bad cuts. There are different ways to prevent cross-contamination in your shop.

Blade Segregation

Dedicated Blades for Different Materials

Always use a special blade for each material. Do not use one blade for both stainless steel and carbon steel. This rule keeps blades free from unwanted stuff. Using a blade only for stainless steel lowers the chance of rust and damage.

Here is a table that explains why dedicated blades are important:

| Особенность | Выгода |

|---|---|

| Устойчивость к коррозии | Stainless steel blades fight rust, which helps in wet places. |

| Формирование биопленки | Smooth, rust-resistant blades are easier to clean and keep safe. |

Dedicated blades help you keep tools working well. They also protect finished products from problems.

Color Coding

Color coding helps you know which blade to use for each material. You can use colored handles, labels, or bins. This system helps everyone avoid mistakes.

- Red is for carbon steel blades.

- Blue is for stainless steel roller shear blades.

- Green is for aluminum blades.

Color coding works best when your team learns the system. You can use colored tape or paint to mark tools and racks.

Кончик: Put a chart in your shop that shows what each color means. This helps new workers learn fast.

Cleaning Between Material Changes

Removing Residual Particles

When you switch materials, you must clean blades and tools. Even tiny bits of metal can cause problems. Wipe stainless steel roller shear blades with a soft, clean cloth. Use a gentle cleaner that does not hurt the blade.

- Clean all tools before using them on stainless steel.

- Remove dust, oil, and metal bits from blades and work areas.

- Use air or a vacuum to pick up small particles.

You can also use air filters in your shop. These help keep the air clean and lower metal dust.

Inspection for Contaminants

After cleaning, check your blades and tools. Look for leftover bits or stains. Run your finger along the blade edge to feel for rough spots. If you find anything, clean the blade again before starting work.

- Check the blade under bright light.

- Use a magnifying glass for a closer look if needed.

- Write down your inspection in a log.

Примечание: Regular checks help you find problems early. You can stop contamination before it hurts your work.

You can train your team to follow these steps. Good training makes sure everyone knows how to keep stainless steel roller shear blades clean and safe. You protect your tools, products, and your shop’s reputation.

Key ways to stop cross-contamination are:

- Use special blades and tools for each material.

- Use color coding to make things easy to spot.

- Clean tools and surfaces between jobs.

- Check blades before each use.

- Teach your team the best ways to work.

If you follow these steps, your stainless steel roller shear blades stay in great shape. You also make your shop safer and more organized.

Inspection and Replacement

Checking your stainless steel roller shear blades often helps your shop run well. You can find problems early and fix them before they get worse. This part explains how to look at your blades and know when to get new ones.

Плановый осмотр

You should check your blades a lot. Finding scratches or dirt early keeps blades sharp and products good.

Visual and Tactile Checks

You can use your eyes and hands to find blade problems. Here are some easy ways:

- Look at the blade with bright light. This helps you see marks and stains.

- Shine light from the side to make shadows. Shadows show small problems.

- Use soft light to see bigger marks.

- Use a magnifier to see tiny scratches.

- Run your finger along the blade edge. You can feel rough spots.

- Put a special liquid on the blade. Under UV light, it shows hidden cracks.

Кончик: Clean the blade before you check it. Dirt can hide small problems.

Surface Roughness Testing

Testing how smooth the blade is helps you get clean cuts. You want a smooth blade to stop dirt and scratches. You can use tools that touch the blade or tools that do not.

А laser microscope can scan the blade without touching it. It shows a 3D picture of the blade surface. You can see tiny bumps and scratches. This test is good after cleaning or sharpening your stainless steel roller shear blades.

Примечание: Write down your test results in a log. Keeping notes helps you see changes over time.

Руководство по замене

You need to know when to get new blades. Using bad blades can slow work and hurt products.

Выявление повреждений

Check your blades for these signs:

- Deep scratches or cracks on the edge

- Chips or missing pieces

- Bent or uneven edges

- Blade is not sharp after sharpening

- Rust or dirt that will not come off

If you see these problems, get a new blade. Bad blades make machines work harder. They also cut slower and not as well.

Replacement Scheduling

Make a plan to check and change your blades. Do not wait for a blade to break during work. Here are some good steps:

- Check blades after every use.

- Change blades if you see big damage.

- Write down when you check or change each blade.

- Sharpen blades often to keep them working.

- Change blades after a set number of cuts or hours.

| Инспекционное задание | Как часто | What To Do If Problem Found |

|---|---|---|

| Visual/Tactile Check | После каждого использования | Clean or change blade |

| Surface Roughness Test | Ежемесячно | Sharpen or change if needed |

| Full Blade Inspection | Еженедельно | Write it down and fix problems |

Checking blades often helps you stop sudden problems and keeps your shop working well.

When you check and change blades on time, your shop works better. Sharp blades cut faster and cleaner. You waste less material and your machines last longer. You also have fewer emergency fixes and less downtime.

If you want help or need special blades, visit Nanjing Metal Industrial.

You can keep stainless steel roller shear blades working well by doing a few easy things: Clean blades with warm water and a soft cloth. Rinse them so no water spots stay. Do not use rough cleaners or pads that touched other metals. Store blades away from other metals. Use special packaging to stop contamination.

If you handle, clean, and check blades often, you get better results. Keep teaching your team and find ways to make your process better. If you need help or custom blade ideas, talk to our sales engineers здесь. 🛠️

Часто задаваемые вопросы

What makes stainless steel roller shear blades resist corrosion?

The blade has a special layer on its surface. This layer forms during passivation. It protects the blade from rust. The layer also keeps the mirror finish shiny. Scratches can weaken this layer. Try not to scratch the blade.

How do I keep a mirror finish on my blades?

Use gentle ways to clean your blades. Do not use rough pads or scrub hard. Store blades with protection on the surface. Clean with soft cloths and mild cleaners. This keeps the mirror look and stops rust.

Why is corrosion a problem for stainless steel blades?

Corrosion makes the blade weak and dull. You lose the blade’s rust protection. Rust spots can show up. The blade becomes unsafe and does not work well. Clean and treat blades the right way to stop corrosion.

What is the best cleaning method for stainless steel roller shear blades?

Clean blades with soft cloths and gentle cleaners. Do not scrub hard or use rough pads. Rinse with clean water. Dry the blade right after cleaning. This keeps the mirror finish and helps stop rust. Good cleaning keeps blades sharp.

How does treatment affect corrosion resistance?

Proper treatment, like passivation, makes the protective layer. This layer helps stop rust. If you skip treatment, rust can start. Always follow the right steps to keep blades strong and shiny.

Can I use the same blade for different materials?

Do not use one blade for many materials. This can hurt the mirror finish and lower rust protection. Mixing materials may cause rust. Use special blades and protect the surface for each material.

How do I know if my blade needs more treatment?

Look for dull spots or rust on the blade. If the mirror finish is gone or you see rust, treat the blade again. Cleaning and passivation help bring back rust protection. Keep blades dry and use surface protection.

Does a mirror finish improve blade performance?

A mirror finish lowers friction and makes cleaning easy. It also helps stop rust. You get better cuts and less buildup. The shiny surface also helps stop pokes and scratches.

Смотрите также

Дисковые Ножи для Продольной Резки Металла

Что Такое Валковые Ножницы и Как Они Работают

Изучение применения режущих лезвий Metal в производстве

Как выбрать подходящее лезвие роликовых ножниц для ваших нужд

Ножи Ротационного Слиттера Aftermarket против OEM: Анализ Затрат и Выгод