When you pick new, used, or dụng cụ ép phanh tùy chỉnh, you should think about what you need to make, how much money you have, and what results you want. Press brake tooling helps bend and shape metal sheets for many jobs. The right tooling can change how much you spend, how fast you work, and how good your parts are. For example:

- One car parts company made less scrap by 25% and saved 15% on tooling costs by using custom press brake tooling.

- Some shops made their clients happier by 40% and got 20% more work with custom tools that could do more.

- An aerospace company made things faster by cutting wait times by 35% with custom tools.

- An energy equipment maker bent metal better and used 12% less energy.

The tooling you pick can really affect your profits.

Những điểm chính

- Picking the right press brake tooling affects how fast you work, how much you spend, and how good your parts are. New tooling has the newest features. It gives better accuracy and strong help. This makes it great for jobs that need high precision. Used tooling costs less at first. But it might need more fixing and may not last as long. Custom tooling is made for special jobs. It fits unique shapes and materials best. Always make sure your tooling works with your press brake. This helps you avoid expensive errors and keeps things safe. Think about all costs, like fixing and upkeep, not just the price you pay first. Taking care of your tooling often helps it last longer. It also keeps your work steady, no matter what type you use. Use a checklist or flowchart to help you choose. This helps you avoid mistakes when picking tooling.

Press Brake Tooling Guide

What Is Press Brake Tooling

Press brake tooling helps you bend and shape metal sheets. You use punches and dies to make different shapes and angles. There are standard V-dies, gooseneck punches, and custom shapes for special jobs. Nanjing Metal makes press brake tooling from strong materials like 42CrMo alloy steel. This means the tooling lasts long and works well for making metal parts. Tooling comes in many shapes and sizes for different bending needs. Some tooling is for simple bends, and some is for more complex shapes.

Here are some common types of press brake tooling you might see:

- Standard V-dies help with basic bends.

- Gooseneck punches are used for deeper bends.

- Precision ground tooling is for tight tolerances, like +/- 0.002 inches.

You need the right press brake tooling to make accurate bends and waste less metal.

Why Tooling Choice Matters

The press brake tooling you choose affects your whole job. Good tooling gives you steady results and fewer mistakes. Well-made tooling helps you work faster and keeps customers happy. You save money because you waste less metal and avoid errors. When your tooling matches your machine and job, you work better and keep things running smoothly.

Here’s how tooling can help your work:

- Steady performance means better quality parts.

- Checking and caring for your tooling keeps it working well.

- Good tooling design makes strong, high-quality parts.

- The right tooling saves time and helps you make more parts.

Industry rules want high precision and good fit. You need press brake tooling that fits your machine and meets these rules, especially for car and airplane parts.

Key Selection Factors

When you pick press brake tooling, think about a few important things. Start by knowing your material, bend angle, and bend radius. The kind of material you use—carbon steel, alloy steel, tool steel, or carbide—changes how long tooling lasts, how much it costs, and how well it works.

Here’s a table to help you compare tooling materials:

| Loại vật liệu | độ cứng | độ dẻo dai | Hao mòn điện trở | Trị giá | Sự phù hợp |

|---|---|---|---|---|---|

| Thép Cacbon | Trung bình | Cao | Thấp | Thấp | Good for low-strength jobs |

| Thép hợp kim | Cao | Trung bình | Trung bình | Trung bình | Good for medium-strength jobs |

| Thép công cụ | Cao | Thấp | Cao | Cao | Best for strong, precise jobs |

| cacbua | Rất cao | Thấp | Rất cao | Rất cao | Best for long-life, strong jobs |

You also need to make sure your tooling fits your press brake. Check that it matches your machine and the tolerances you need. Think about your industry’s rules and design needs. The right tooling helps you meet tough standards and keeps your work fast and smooth.

Here are the top three things to think about:

| Nhân tố | Sự miêu tả |

|---|---|

| Loại vật liệu | How thick, strong, and bendable your material is will help you choose the best tooling. |

| Góc uốn | The angle you want to bend will help you pick the right punch and die shapes. |

| Bán kính uốn cong | The size of the bend will change what tooling you need. |

Use this guide to choose press brake tooling that fits your job, machine, and industry. The right tooling makes your work easier, faster, and more dependable.

New Press Brake Tooling

Những lợi ích

Công nghệ

When you choose new press brake tooling, you get the latest technology for bending metal. New tooling uses advanced materials that last longer and keep their shape. You can count on better precision with every bend. Modern tooling works with CNC and servo machines, so you get more control and faster setup. You can use digital controls to set up your bends and check your accuracy. This means you spend less time adjusting and more time making parts.

New tooling also comes with safety features. You can trust that your equipment meets current industry standards. If you want to keep your shop safe and up to date, new tooling helps you do that. You can bend complex shapes with high precision, even if you work with tough materials. The right tooling lets you handle more jobs and keep your customers happy.

Tip: If you want to improve your bending speed and accuracy, look for tooling that matches your press brake’s automation features.

Ủng hộ

You get strong support when you buy new press brake tooling. Manufacturers offer technical help, training, and troubleshooting. If you run into problems, you can call for help or check official guides. You also get a warranty, so you know your investment is protected. If you need spare parts or updates, you can get them quickly.

Training helps you use your tooling the right way. You learn how to set up your bends, check your accuracy, and keep your tooling in good shape. Support makes your work easier and helps you avoid mistakes. You can focus on bending metal and improving your shop’s performance.

When to Choose New

You should pick new press brake tooling when you need high precision and steady performance. If your jobs require tight tolerances and perfect bends, new tooling is the best choice. You get consistent accuracy, even when you run large batches. If you use advanced machines or need to meet strict industry rules, new tooling helps you reach your goals.

New tooling works well for shops that want to grow or take on more complex bending jobs. If you want to reduce downtime and avoid costly repairs, new tooling gives you peace of mind. You can trust your equipment to deliver strong performance every day.

Here are some signs you should choose new tooling:

- You need to meet strict quality standards.

- You want to use the latest bending technology.

- You care about long-term reliability and low maintenance costs.

- You work with advanced press brake machines.

Trị giá

New press brake tooling costs more up front than used tooling. You pay for better materials, advanced features, and strong support. The higher cost often means you get a longer lifespan and fewer problems. You spend less on repairs and replacements over time.

Let’s look at how long new tooling lasts under normal use:

| Model Type | Tuổi thọ trung bình |

|---|---|

| Economy Models | 8-12 years |

| Mid-Range CNC Models | 12-18 years |

| High-End Servo Models | 15-25 years |

You can see that new tooling gives you many years of reliable bending. The longer lifespan helps you control your costs and improve your shop’s performance. You may need to wait for delivery or pay extra for custom features, but the value you get makes it worth the investment.

Note: If you plan for long-term growth, new tooling helps you manage costs and keep your bending jobs running smoothly.

Khả năng tương thích

When you buy new press brake tooling, it should fit your machine well. This is important for safety and smooth work. If your tooling fits, you avoid problems like parts not lining up or your machine getting damaged. You get better results and fewer breakdowns.

Here are things to check for compatibility:

| Specification | Tầm quan trọng |

|---|---|

| Tonnage Limits | Stops your machine from getting strained. Makes sure everything works together. |

| Stroke Length | Needed for making bends that are always the same. |

| Mounting System | Helps your tooling work safely and do its job well. |

You also need to think about clamping style, how much force your machine uses, and how long your tooling is. These details help you set up fast and keep your bends right.

| Specification | Tầm quan trọng |

|---|---|

| Clamping Style | Makes your work quick, safe, and accurate. |

| Sức chứa tấn | Stops damage and keeps your tooling working well. |

| Working Length | Lets you work faster and keeps your bends tight. |

New tooling is made for modern machines and automation. You spend less time fixing things and more time making parts. You lower mistakes and keep your shop running well. Good compatibility helps you avoid expensive errors and keeps your work on track.

If you want to upgrade your press brake, make sure your new tooling matches your machine. This gives you the best results and keeps everyone safe.

Hiệu suất

Performance means how well your press brake tooling works. You want tooling that bends metal with good accuracy every time. New tooling helps you keep your bends tight, even with hard jobs or lots of parts.

Here’s a table to show how you can measure performance:

| Hệ mét | Sự miêu tả |

|---|---|

| Tỷ lệ phế liệu | Shows how many bad parts you make. Lower rates mean better work and less waste. |

| Operator Efficiency | Tells how fast and well your team works. High efficiency means good training and results. |

| Thông lượng | Counts how many parts you make in a set time. More throughput means you get more done. |

| Cycle Time | Shows how long one bend takes. Shorter times mean faster jobs. |

| Thời gian chết | Tracks when your press brake is not working. Less downtime means you make more parts. |

| First Pass Yield (FPY) | Shows how many parts are perfect the first time. High FPY means your process is strong. |

| Overall Equipment Effectiveness (OEE) | Combines uptime, speed, and quality for a big-picture view of your press brake’s performance. |

| Setup Time | Tells how long it takes to get ready. Less setup time means you start jobs faster. |

| Tiêu thụ năng lượng | Shows how much power you use. Lower energy use saves money. |

| Quality Metrics | Includes defect rate and scrap rate. Helps you find problems and make your work better. |

New press brake tooling lets you bend more kinds of metal and handle tricky shapes. You get steady results, even when you work hard. You can trust your tooling to do a good job every day. If you want to make more parts and better quality, new tooling is a smart pick.

BẢO TRÌ

Maintenance keeps your press brake tooling working well. With new tooling, you spend less time fixing things because it is in great shape. You get clear steps from the maker, so you know what to do.

Here are some tips for maintenance:

- Handle your tooling gently. Wear gloves to keep it clean.

- Clean your tooling after you use it. Get rid of metal bits and dust.

- Store your tooling safely. Keep it dry and neat.

New tooling needs less care than used tooling. You do not have to check or clean it as much. You avoid problems like worn edges or bad bends. If you follow the right steps, your tooling lasts longer and keeps your parts good.

If you skip maintenance, you can hurt your tooling and your press brake. Old tooling can mess up your bends and slow you down. Bad handling and storage make your tooling wear out faster. You want to keep your tooling in good shape to avoid expensive fixes.

Here’s a checklist for maintenance:

- Clean tooling after each job.

- Look for wear or damage.

- Store tooling in a safe, dry place.

- Follow the maker’s instructions.

- Wear gloves when you touch tooling.

You get help and spare parts when you buy new tooling. If you need help, you can call the supplier or check the manual. Good maintenance helps you avoid downtime and keeps your shop working well.

Tip: Make maintenance part of your daily work. You will save time, money, and keep your press brake tooling working great.

Used Press Brake Buying Guide

Thuận lợi

Tiết kiệm chi phí

When you start buying used press brake tooling, you can save a lot of money. Used tooling often costs much less than new tooling. You get more value for your budget, especially if you need special tools for your shop. Here are some ways you save:

- You spend less on the initial purchase, which helps you control your costs.

- Special tools can make your work easier and reduce operator fatigue. This means your team works faster and feels better.

- Used tooling can simplify your production process. You might skip some extra steps, which saves time and money.

- If you use the right tools, you can avoid expensive secondary operations. This helps you keep your costs low.

You can compare the price of used tooling with new tooling and see the difference. Many shops find that buying used tooling helps them stay competitive and grow their business.

Khả dụng

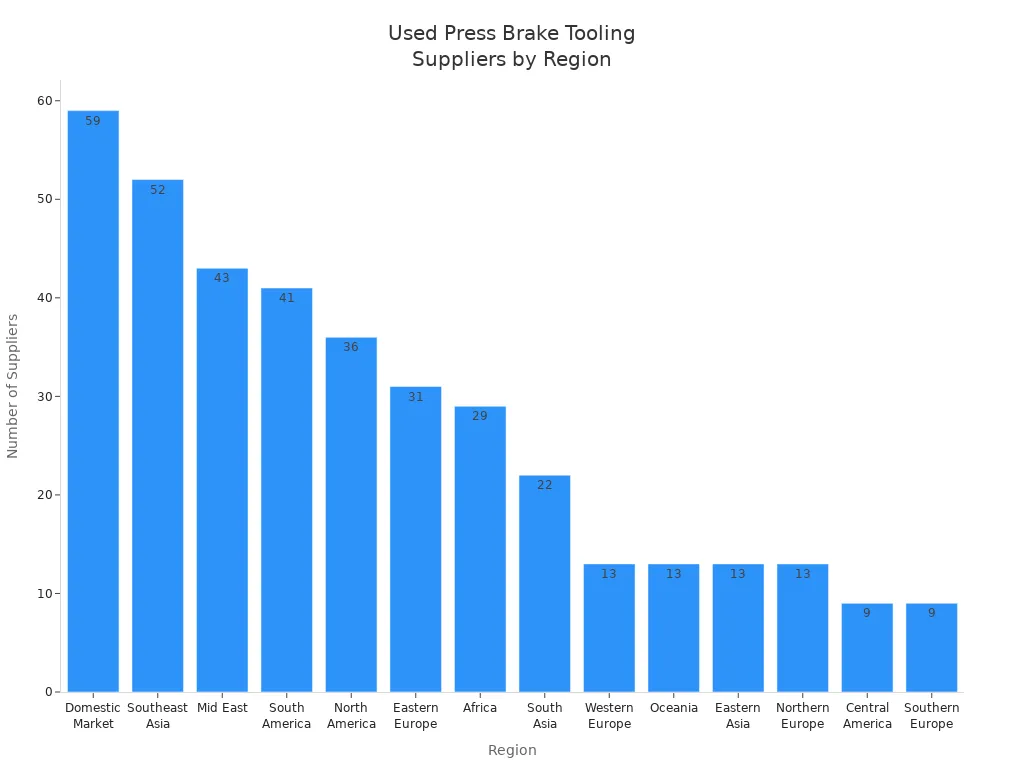

You have many options when buying used press brake tooling. Suppliers offer used tooling in different regions, so you can find what you need close to home or from overseas. The number of suppliers changes by region. Here’s a table to show you where you can find used tooling:

| Vùng đất | Number of Suppliers |

|---|---|

| Domestic Market | 59 |

| Southeast Asia | 52 |

| Mid East | 43 |

| South America | 41 |

| Bắc Mỹ | 36 |

| Eastern Europe | 31 |

| Africa | 29 |

| South Asia | 22 |

| Western Europe | 13 |

| Oceania | 13 |

| Eastern Asia | 13 |

| Northern Europe | 13 |

| Central America | 9 |

| Southern Europe | 9 |

You can see that the domestic market and Southeast Asia have the most suppliers. This means you have a better chance of finding the right used tooling for your needs. If you look in regions with fewer suppliers, you might need to search a bit more or wait longer for the right condition and type.

If you want to make your buying process easier, check local suppliers first. You can inspect the tooling in person and ask about its condition. If you need something special, you can look at suppliers in other regions. The used press brake buying guide helps you compare options and find the best deal.

Cost Analysis

When you look at used press brake tooling, you probably want to know if you’re really saving money. Let’s break it down together.

You pay less up front for used tooling. That’s a big win if you need to stick to a budget. But you should also think about what happens over the next few years. Sometimes, used tooling needs more repairs or might not last as long as new or custom options.

Here’s what you should keep in mind:

- Used press brake tooling can help you save money right away. You spend less at the start, which is great for small shops or when you need to fill a gap quickly.

- If you find high-quality, precision-ground, or hardened tooling, you might pay a bit more, but these tools can last seven to nine times longer than cheaper options. That means you won’t have to replace them as often.

- Some manufacturers who switched to energy-efficient press brakes saved up to 15% on energy costs every year. Over three years, those savings paid for their investment.

- When you look at costs over five or ten years, high-quality tooling—even if it’s used—can end up costing you less than buying cheap tools over and over.

Tip: Don’t just look at the sticker price. Think about how long the tooling will last, how much you’ll spend on repairs, and if it helps you save on energy or labor.

If you want to see how costs stack up, try making a simple chart. List the price, expected lifespan, and any extra costs for each option. This helps you see which tooling gives you the best value for your money.

Khả năng tương thích

You want your used press brake tooling to fit your machine like a glove. If it doesn’t, you could run into big problems—like bad bends, machine damage, or even safety risks.

Here’s how you can check for compatibility:

- Match the Tooling to Your Machine: Look at the specs for your press brake. Check the tonnage, length, and clamping system. Make sure the used tooling matches these numbers.

- Check the Mounting System: Some machines use different mounting styles. If your tooling doesn’t fit, you’ll waste time and money trying to make it work.

- Look at the Tooling Length: Make sure the tooling is long enough for your jobs. If it’s too short, you might not be able to bend bigger parts.

- Ask About Previous Use: Sometimes, used tooling has been modified. Double-check that it hasn’t been changed in a way that makes it unsafe or hard to use.

Note: Always ask the seller for detailed measurements and photos. If you can, bring a sample or template to test the fit before you buy.

If you get the right match, your press brake tooling will help you make accurate bends and keep your machine running smoothly.

Hiệu suất

Performance is all about how well your used press brake tooling does its job. You want every bend to be the same, every time. But used tooling can sometimes have a few surprises.

Let’s look at how different machines handle repeatability:

| Type of Press Brake | Repeatability Characteristics |

|---|---|

| CNC Press Brake | Stores multiple programs, ensuring identical parts for repetitive tasks. |

| Traditional Hydraulic Press | Requires manual setup, leading to potential variations between parts, especially in high volume. |

If you use a CNC press brake, you’ll get more consistent results, even with used tooling. The machine remembers your settings, so every part comes out the same. With a traditional hydraulic press, you might see more differences between parts, especially if you’re making a lot of them.

Here are a few things that affect performance with used tooling:

- Tool Wear: Worn edges or dents can cause bad bends or scrap parts.

- Material Changes: If the tooling was used for different materials before, it might not work as well for your jobs.

- Setup Time: Sometimes, used tooling takes longer to set up, especially if it’s not a perfect fit.

Tip: Always test your used press brake tooling on a sample piece before starting a big job. This helps you catch problems early and avoid wasting material.

If you keep your tooling clean and check it often, you can still get great results—even with used tools. Just remember, the better you care for your tooling, the better it will perform for you.

BẢO TRÌ

Taking care of your used press brake tooling helps you get more life and better results from every job. If you skip maintenance, you might see more wear, bad bends, or even machine trouble. You want your tooling to last as long as possible, so let’s talk about what works best.

Here’s a quick look at how different maintenance steps help your tooling:

| Thực hành bảo trì | Lợi ích |

|---|---|

| Kiểm tra thường xuyên | Extends tooling life by 15% to 20% with early repairs. |

| Vệ sinh bề mặt | Cuts wear by 10% to 15% by stopping friction build-up. |

| Bôi trơn | Drops friction by 20%, making tooling last much longer. |

| Daily Maintenance Routine | Keeps everything working well and your bends consistent. |

You can follow a few simple steps every day to keep your press brake tooling in top shape:

- Check punches and dies for cracks, chips, or worn edges.

- Wipe down all tooling with a soft cloth and a safe cleaning agent.

- Make sure the tooling lines up right before you start bending.

- Add a little lubricant to moving parts to stop friction and wear.

- Store your tooling in a dry, safe spot when you’re done.

Want a quick routine? Try this:

- Wipe down your tooling after each shift.

- Inspect alignment and look for damage.

- Check that safety devices work as they should.

Tip: If you make maintenance part of your daily work, you’ll see fewer breakdowns and better bends. Your press brake tooling will stay strong and reliable.

Keeping up with these habits means you spend less on repairs and replacements. You get more good parts and less scrap. Your press brake tooling will keep working for you, job after job.

Dụng cụ uốn sườn tùy chỉnh

Thuận lợi

Tailored Solutions

Sometimes, regular tooling will not work for your job. That is when you need custom press brake tooling. Custom tooling is made just for your needs. If you must bend a special shape or use a hard material, custom tooling helps you do it right.

- You can make parts with tighter tolerances and better precision.

- You get designs that fit special shapes.

- You can use tooling for certain materials, so you waste less and work better.

Custom press brake tooling is used in many fields. You see it in farm machines, medical tools, and electronics. It turns metal sheets into parts that fit your needs.

If you want to learn more about custom blades and how they help with special jobs, check out this trang lưỡi dao tùy chỉnh.

Complex Jobs

Some bends are too hard for regular tools. Custom press brake tooling makes these jobs possible. You get new ways to make tricky bends and shapes. This tooling is made for detailed designs, so you can do jobs others cannot.

Custom tooling helps you work with more accuracy and speed. You get tools made for your bending needs. These special tools help you finish jobs faster and keep your work good.

When to Go Custom

You should think about custom press brake tooling if your job has specific needs or needs high accuracy. If you use special materials or need to make odd shapes, custom tooling is best. It is great for jobs that regular tooling cannot do.

Real-World Case Study

Here is a real example. A furniture company needed to make a chair frame with a tight curve. Regular tooling could not bend it without cracks or rough edges. The company used custom press brake tooling made for their shape and material. The result? They made 30% less scrap, got more even parts, and worked faster.

You might have the same problems in your shop. Custom press brake tooling helps you fix these issues and take jobs that others cannot.

Custom Tooling Design and Production Process

Needs Assessment and Communication

First, you talk to your supplier about what you need. You tell them about your material, shapes, and any special things you want. The supplier listens and asks questions to learn about your job.

Solution Design

Next, the design team uses CAD software to make 3D models of your custom press brake tooling. They run tests on the computer to see how the tooling will work. You look at the design and can ask for changes.

Prototyping and Testing

After you say yes to the design, the supplier makes a sample. They test it with your material and bending needs. You see how it works and check the results. If something is wrong, they fix it.

Giao hàng và Hỗ trợ

When everything is right, the supplier makes your custom press brake tooling with strong materials and good machines. You get the finished tooling sent to your shop. The supplier helps you if you have questions or need help setting up.

If you want to know more about custom blades for special jobs, you can visit the trang lưỡi dao tùy chỉnh for more information.

Tip: Talking clearly with your supplier helps you get the best custom press brake tooling.

Trị giá

Cost Structure

When you look at custom press brake tooling, you might notice the price tag is higher than standard tools. But there is a reason for that. You pay for a tool that fits your job perfectly. Here’s what goes into the cost:

- Design and Engineering: You work with experts who listen to your needs. They use CAD software to create a tool just for you.

- Lựa chọn vật liệu: The right material makes your tooling last longer. Strong alloys like 42CrMo steel help your tool handle tough jobs.

- Chế tạo: Skilled workers use special machines to shape and finish your tooling. This step takes time and care.

- Testing and Quality Control: Before you get your tooling, the supplier checks it for accuracy. They test it to make sure it works as promised.

- Hỗ trợ và Dịch vụ: You get help with setup, training, and any questions you have. Good support means fewer problems down the road.

You pay for each of these steps. The total cost depends on how complex your part is, what material you need, and how fast you need the tooling. If you want a tool that lasts and fits your job, custom press brake tooling is a smart choice.

Tip: Talk with your supplier about your budget and needs. They can help you find the best balance between cost and performance.

ROI Comparison with Standard Tooling

You might wonder if custom press brake tooling is worth the extra money. Let’s look at how it compares to standard tooling. The main thing to remember is that custom tools can save you money in the long run.

Here’s a table to help you see the differences:

| Tính năng | Công cụ tùy chỉnh | Dụng cụ tiêu chuẩn |

|---|---|---|

| Độ chính xác | Hoàn toàn phù hợp với các thiết kế độc đáo | Mục đích chung |

| Trị giá | Trả trước cao hơn, ROI tốt hơn | Thấp hơn ở phía trước, kém bền hơn |

| Thời gian dẫn | Dài hơn nhưng đáng để chờ đợi | Có sẵn |

| Độ bền | Tuổi thọ kéo dài | Sử dụng ngắn hạn |

Custom press brake tooling costs more at first. But you get a tool that matches your job exactly. This means you make fewer mistakes, waste less metal, and spend less time fixing problems. Your shop runs smoother, and you get more good parts out the door.

Standard tooling is cheaper and easy to find. It works for simple jobs, but it might not last as long. You could end up replacing it more often or dealing with more scrap.

Custom tools may have a higher initial cost, but they can lead to better ROI by reducing waste, minimizing downtime, and extending the lifespan of the tools. Over time, you save money because you do not need to buy new tools as often. You also avoid costly delays and keep your production moving.

If you want to see the biggest return on your investment, choose custom press brake tooling for jobs that need special shapes, tight tolerances, or hard materials. You will notice the difference in your bottom line.

Khả năng tương thích

Custom press brake tooling gives you a perfect fit for your machine and your job. You do not have to worry about mismatched parts or setup problems. The tooling is made to match your press brake’s specs, like tonnage, clamping style, and working length.

You get a tool that lines up right every time. This means you spend less time adjusting and more time making parts. You also avoid damage to your machine because the tooling fits just right.

If you upgrade your press brake or change your production line, you can ask for custom tooling that matches your new setup. This helps you keep your shop running smoothly.

Tip: Always share your machine’s details with your supplier. This helps them design tooling that fits perfectly and works safely.

Hiệu suất

When you use custom press brake tooling, you see a big jump in performance. Your bends come out clean and accurate. You can handle tricky shapes and tough materials without trouble.

Custom tooling helps you:

- Get tight tolerances on every part.

- Reduce scrap and rework.

- Speed up your production because you do not need to stop and adjust.

- Keep your quality high, even on complex jobs.

You also get more life out of your tooling. Strong materials and smart design mean your tools last longer. You spend less time on maintenance and more time making parts.

If you want to boost your shop’s performance, custom press brake tooling is a great way to do it. You get better results, happier customers, and a stronger business.

BẢO TRÌ

Taking care of your custom press brake tooling keeps your shop running smoothly and your parts looking sharp. You spent time and money getting the right tool for your job, so you want it to last as long as possible. Good maintenance helps you avoid downtime, bad bends, and costly repairs.

You might wonder, “What does maintenance look like for custom press brake tooling?” Here’s what you need to know:

Tại sao bảo trì lại quan trọng

Custom press brake tooling often has special shapes or tight tolerances. Even a little wear or dirt can mess up your bends. If you skip maintenance, you risk ruining expensive parts or damaging your press brake. Regular care keeps your tooling accurate and your production on track.

Daily Maintenance Checklist

You don’t need fancy tools or a lot of time. Just follow a simple routine every day:

- Inspect for Damage: Look for cracks, chips, or worn edges. Pay extra attention to custom features or tight corners.

- Clean After Use: Wipe down your tooling with a soft cloth. Remove metal shavings, dust, and oil.

- Lubricate Moving Parts: If your tooling has moving sections, add a little lubricant to keep things smooth.

- Store Properly: Place your tooling in a dry, organized spot. Use racks or cases to prevent bumps and scratches.

- Check Alignment: Before each job, make sure your tooling lines up with your press brake. Misalignment can cause bad bends or even break your tool.

Mẹo: Set a reminder on your phone or hang a checklist by your press brake. A quick check each day saves you big headaches later.

Special Care for Custom Tooling

Custom press brake tooling sometimes needs extra attention. If your tool has a unique coating or is made from a special alloy, ask your supplier for care instructions. Some coatings need gentle cleaners. Some alloys need special storage to avoid rust.

Here’s a quick table to help you remember what to do:

| Nhiệm vụ bảo trì | Tần suất thế nào | Tại sao nó quan trọng |

|---|---|---|

| Kiểm tra trực quan | Mỗi ca làm việc | Catches damage before it gets worse |

| Vệ sinh | Sau mỗi lần sử dụng | Prevents buildup and wear |

| Bôi trơn | Hàng tuần | Keeps moving parts working smoothly |

| Storage Check | Hàng tuần | Stops rust and accidental damage |

| Kiểm tra căn chỉnh | Before jobs | Ensures accurate, safe bending |

When to Call for Help

If you spot deep cracks, broken parts, or anything that looks unsafe, stop using the tooling. Call your supplier or a tooling expert. Trying to fix it yourself can make things worse.

Ghi chú: Custom press brake tooling is an investment. Treat it well, and it will pay you back with years of reliable service.

By making maintenance part of your daily routine, you protect your press brake tooling and keep your shop running at its best. Clean tools, careful storage, and regular checks help you get the most out of every bend.

Compare Tooling Options

Bảng so sánh

Let’s look at a quick table to help you see the differences between new, used, and custom press brake tooling. This table gives you a side-by-side view so you can make a smart choice before you purchase.

| Tính năng | New Tooling | Used Tooling | Công cụ tùy chỉnh |

|---|---|---|---|

| Giá | Cao | Thấp đến Trung bình | Cao nhất |

| Độ chính xác | Xuất sắc | Thay đổi | Best for unique jobs |

| Ủng hộ | Full manufacturer | Limited | Full, tailored |

| Tuổi thọ | Dài | Ngắn hơn | Longest (if designed well) |

| Khả năng tương thích | Modern machines | Depends on age/model | Perfect fit |

| Thời gian dẫn | Immediate or short | Immediate | Longer (design time) |

| BẢO TRÌ | Easy, clear guides | Needs more care | Special instructions |

This table helps you compare the main features at a glance. You can see which option matches your needs and budget.

Pros and Cons

Every tooling choice has good points and some trade-offs. Here’s a simple list to help you weigh your options before you purchase.

New Tooling

- 👍 Latest technology and safety features

- 👍 Full support and warranty

- 👎 Higher upfront cost

Used Tooling

- 👍 Lower price, quick to get

- 👍 Good for short-term or backup jobs

- 👎 May show wear, less support

Công cụ tùy chỉnh

- 👍 Perfect for special shapes and tough jobs

- 👍 Best fit for your machine and process

- 👎 Highest price, longer wait

Tip: Think about what matters most for your shop. Do you want the best precision, the lowest price, or a tool made just for you?

Tác động đến chi phí và giá trị

Your choice affects your costs and the value you get over time. If you purchase new tooling, you pay more at first, but you get long life and fewer problems. Used tooling saves money now, but you might spend more on repairs or replacements later. Custom tooling costs the most, but it can save you money by reducing scrap and speeding up your work.

Here’s how each option can impact your bottom line:

- New tooling helps you avoid downtime and keeps your parts consistent.

- Used tooling lets you start projects fast and save money, but you need to check quality before you purchase.

- Custom tooling gives you the best results for tricky jobs, and it can boost your profits if you need special shapes or materials.

Note: Always look at the total cost, not just the price tag. Think about how your purchase will affect your shop’s speed, quality, and future growth.

Press Brake Tooling Decision Guide

Key Questions

You want to make the right choice for your press brake tooling. Start by asking yourself some key questions. These questions help you focus on what matters most for your shop. You can use them as a guide before you start your research or talk to a supplier.

- What type of parts do you need to bend?

- How often will you use the tooling?

- What is your budget for this purchase?

- Do you need special shapes or tight tolerances?

- Is your press brake machine new or older?

- Are you working with tough materials like stainless steel or aluminum?

- Do you need fast delivery, or can you wait for custom tooling?

- What are the most important buying considerations for your business?

- Where will you source your tooling?

- Have you checked if your tooling matches your machine’s specs?

Tip: Write down your answers. This makes your decision easier and helps you explain your needs to a supplier.

Checklist

You want a simple way to check if you are ready to buy press brake tooling. Use this checklist to make sure you have covered all the important considerations. You can print it out or keep it on your phone.

- Define your bending needs (part shape, material, thickness).

- Set your budget and stick to it.

- List any special requirements (tight tolerances, custom shapes).

- Check your press brake’s specs (tonnage, clamping style, working length).

- Research different tooling options (new, used, custom).

- Compare suppliers and their support services.

- Ask for samples or photos before you buy.

- Review the maintenance needs for each tooling type.

- Confirm delivery times and warranty details.

- Make sure your tooling source is reliable.

Note: If you miss a step, you might end up with tooling that does not fit your needs. Double-check your list before you make a purchase.

Flowchart

You want a quick way to see your path to the right tooling. Use this flowchart to guide your decision. Follow each step and see where you end up.

flowchart TD

A[Start: Need Press Brake Tooling] --> B{What is your budget?}

B -->|High| C[Consider new or custom tooling]

B -->|Low| D[Consider used tooling]

C --> E{Do you need special shapes or tight tolerances?}

E -->|Yes| F[Go custom]

E -->|No| G[Go new]

D --> H{Is used tooling compatible with your machine?}

H -->|Yes| I[Go used]

H -->|No| J[Research other sources or consider new]

F --> K[Check supplier support and warranty]

G --> K

I --> K

J --> K

K --> L[Review maintenance and delivery]

L --> M[Make your purchase]

Tip: Use this flowchart when you talk to your team or supplier. It helps you explain your decision and makes sure you do not miss any important steps.

Những sai lầm cần tránh

You want to make the best choice for your press brake tooling. Sometimes, small mistakes can lead to big problems. Let’s look at the most common errors people make and how you can dodge them.

1. Ignoring Compatibility

You might see a great deal on tooling and want to buy it right away. If you skip checking if the tooling fits your press brake, you could waste money. Tooling that does not match your machine can cause bad bends, damage, or even safety risks.

Mẹo: Always check your press brake’s specs before you buy. Match the tonnage, clamping style, and working length.

2. Overlooking Material Quality

You may think all tooling is the same. That’s not true. Low-quality materials wear out fast and give you poor results. If you pick tooling made from weak steel, you’ll spend more on repairs and replacements.

| Loại vật liệu | Good Choice? | Tại sao nó quan trọng |

|---|---|---|

| 42CrMo Alloy | 👍 Yes | Strong, resists wear |

| Thép Cacbon | 👎 No | Wears out quickly |

| Thép công cụ | 👍 Yes | Holds shape, lasts longer |

Choose tooling made from tough materials. You’ll get better bends and save money over time.

3. Forgetting About Maintenance

You might think new tooling does not need care. If you skip cleaning and checking your tooling, it will wear out faster. Dirty or damaged tooling can ruin your parts and slow down your work.

Ghi chú: Make maintenance part of your daily routine. Clean, inspect, and store your tooling after every job.

4. Not Asking for Support

You may feel confident setting up your press brake tooling. If you run into trouble and don’t ask for help, you could make mistakes that cost you time and money. Good suppliers offer training and support. Use it!

5. Focusing Only on Price

You want to save money, but picking the cheapest tooling can backfire. Cheap tools break faster and give you bad bends. You might spend more fixing problems than you saved.

| Sai lầm | What Happens | Cách tránh |

|---|---|---|

| Buying cheapest tools | More scrap, more downtime | Balance price and quality |

| Skipping inspection | Bad fit, safety risks | Always inspect before buying |

6. Ignoring Lead Times

You might need tooling fast. If you forget to ask about delivery times, your project could get delayed. Custom tooling takes longer to make. Plan ahead so you don’t get stuck waiting.

7. Not Reviewing Warranty and Return Policy

You may forget to check if your tooling comes with a warranty. If something goes wrong, you could be stuck with a bad tool and no way to fix it.

Báo động: Always ask about warranty and return policies before you buy. This protects your investment.

8. Skipping a Test Run

You might trust that your new or used tooling will work perfectly. If you skip a test run, you could find problems after you start production. Testing helps you catch issues early.

Quick Checklist: Mistakes to Avoid

- Did you check compatibility with your press brake?

- Did you choose high-quality materials?

- Are you ready to maintain your tooling?

- Did you ask for supplier support?

- Did you balance price and quality?

- Did you confirm delivery times?

- Did you review warranty and return policies?

- Did you run a test before full production?

If you avoid these mistakes, you’ll get better results from your press brake tooling. You’ll save money, work faster, and keep your shop running smoothly. 😊

Choosing the right press brake tooling shapes your shop’s success. Match your tooling to your production needs, your budget, and your long-term goals. Use the checklist or flowchart above to guide your choice. If you feel unsure, talk with a tooling expert for advice that fits your job.

Smart tooling decisions save you money, boost quality, and keep your work on track.

Ready to get started? Contact a sales engineer for help with your press brake tooling questions.

Câu hỏi thường gặp

What is press brake tooling?

Press brake tooling helps you bend and shape metal sheets. You use punches and dies to make different angles and forms. This tooling is key for making strong, accurate metal parts.

How do I know if my press brake tooling fits my machine?

Check your machine’s specs. Look at tonnage, clamping style, and working length. If you match these with your tooling, you get safe and accurate bends every time.

Can I use used press brake tooling for high-precision jobs?

You can, but inspect it first. Look for wear, cracks, or damage. Used tooling may not hold tight tolerances as well as new or custom options.

When should I choose custom press brake tooling?

Pick custom press brake tooling when you need special shapes, tight bends, or work with tough materials. Custom tools help you solve unique bending problems and boost your shop’s performance.

How often should I maintain my press brake tooling?

Clean and inspect your press brake tooling after each job. Lubricate moving parts weekly. Store tooling in a dry, safe place. Regular care keeps your tooling accurate and lasting longer.

What materials are best for press brake tooling?

Strong alloys like 42CrMo steel work best. These materials resist wear and keep their shape. Tool steel is also good for high-precision jobs.

Does new press brake tooling come with support or warranty?

Yes, most new press brake tooling includes technical support and a warranty. You get help with setup, training, and troubleshooting if you need it.

Can I mix different types of press brake tooling in one job?

You can, but make sure all tooling matches your machine’s specs. Mixing types works for complex jobs, but always test first to avoid mistakes.

Tip: Always run a test bend before starting full production with mixed tooling.

Xem thêm

Lựa Chọn Dụng Cụ Uốn Sườn Tốt Nhất cho Thép Không Gỉ

Dụng Cụ Uốn Sườn Kiểu Châu Âu so với Kiểu Mỹ: Loại Nào Phù Hợp cho Xưởng của Bạn?

Uốn trong Không Khí vs. Uốn Chạm Đáy: Lựa Chọn Dụng Cụ Uốn Sườn Phù Hợp cho Dự Án của Bạn

Hướng Dẫn Toàn Diện về Khuôn Cối Máy Chấn: Chọn Vật Liệu Tốt Nhất để Ngăn Ngừa Mài Mòn

Hướng Dẫn Dụng Cụ Uốn Sườn cho Người Mới Bắt Đầu: Chọn Độ Mở Khuôn Chữ V Phù Hợp

Cách Tính Toán Lực Uốn và Tải Trọng (Tonnage) của Máy Chấn Tôn

Một bình luận