Replacing wood chipper blades may look easy, but it is not. Your safety depends on doing every step the right way. If you hurry or miss a step, you can get hurt. Here are some facts to know:

- Every year, about 200 people die in landscaping accidents.

- Wood chippers cause about 3 deaths and 200 injuries each year.

- These injuries can be very bad, like losing fingers or arms.

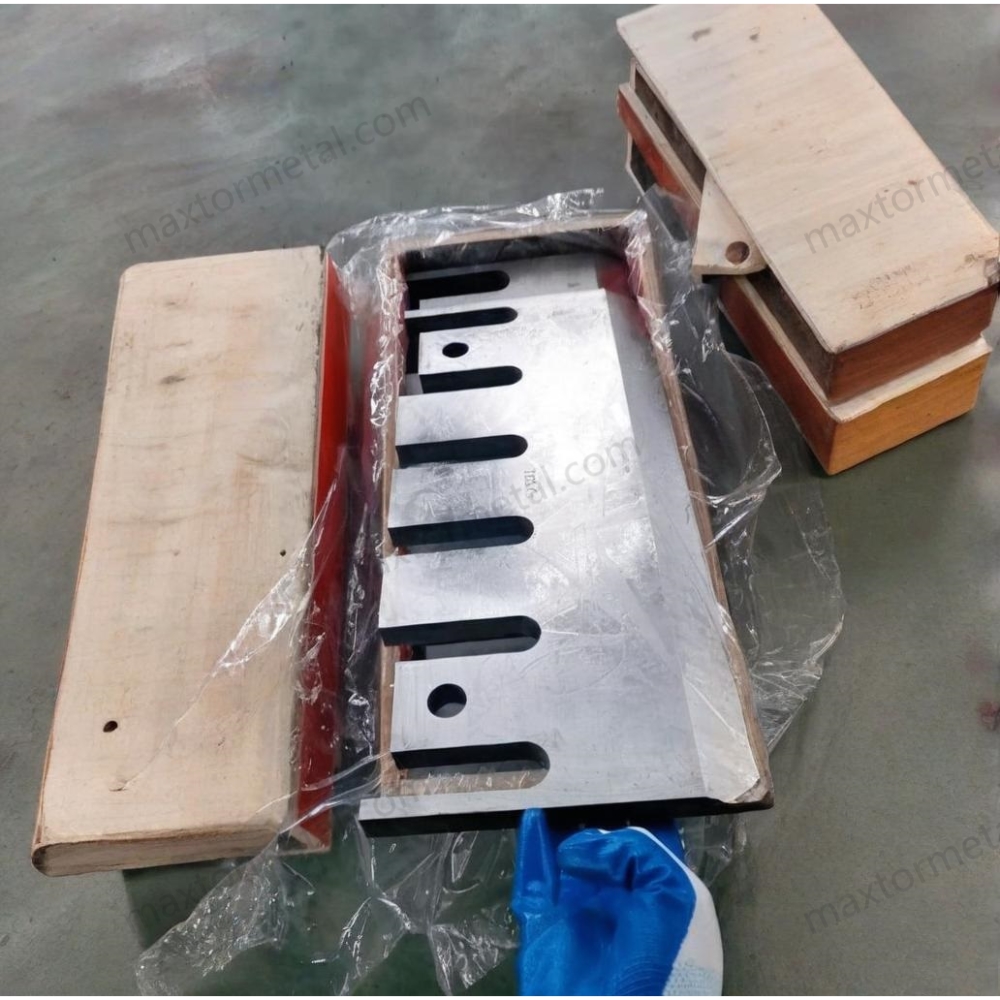

This is why you need good blades and the right way to do things. When you pick high-quality blades like those from Nanjing Metal Industrial, you get real benefits:

| Tính năng | Lợi ích |

|---|---|

| Precision Grinding | Gives sharp, even cuts and less work for your chipper. |

| Dynamic Balance Design | Lowers shaking and helps protect your machine. |

| Dual-Edge Design | Makes blades last longer and saves you money. |

| Corrosion Defense | Helps blades last longer, even in hard weather. |

If you want to stop accidents and keep your machine working well, you must take thay thế lưỡi dao máy băm gỗ seriously.

Những điểm chính

- Always stay safe by using the lockout-tagout steps before you start work on the wood chipper. Wear the right safety gear like gloves, eye protection, and strong boots to stop injuries. Keep your work area neat and tidy to help avoid accidents and work better. Use the right tools and set the torque as your chipper’s manual says to stop damage and stay safe. Check all parts for wear or damage before you put in new blades to stop future issues. Make sure blades are lined up right when you put them in to stop shaking and help the chipper run smoothly. After you change the blades, check everything to make sure all parts are tight and the area is free of trash. Change blades and check them often to keep your wood chipper safe and working well.

Safety Protocols for Wood Chipper Blades Replacement

Before you start any wood chipper blades replacement, you need to make safety your top priority. Taking the right steps can keep you and everyone around you safe from serious injuries. Let’s break down what you need to do.

Lockout-Tagout and Power Off

Power Isolation Steps

You never want the chipper to start while you’re working on it. Here’s how you can make sure it stays off:

- Tell everyone nearby that you’re about to work on the chipper.

- Check your company’s safety rules to know what kind of energy the machine uses and how to control it.

- If the chipper is running, turn it off using the normal stop button or switch.

- Shut off all energy sources. This might mean unplugging it or turning off a breaker.

- Put a lock on the power switch or plug so nobody can turn it back on by mistake.

- Get rid of any leftover energy. Sometimes machines store energy in springs or moving parts, so make sure everything is safe.

- Double-check that the chipper is really off by trying the start button or control. It should not turn on.

- Only after you finish the job and everyone is clear, remove your lock and turn the power back on.

Zero-Energy Verification

Always test the controls after locking out the machine. If nothing happens, you know it’s safe to work. This step can save your fingers or even your life.

Thiết bị bảo vệ cá nhân

Safety Gear Checklist

You need the right gear to protect yourself. Here’s a quick table to help you remember what to wear:

| Thiết bị bảo vệ cá nhân | Why You Need It |

|---|---|

| Eye Protection | Stops wood chips from hitting your eyes. |

| Hearing Protection | Keeps your ears safe from loud noise. |

| Dust Mask | Blocks wood dust from your lungs. |

| Heavy-Duty Work Gloves | Protects your hands from sharp blades. |

| Sturdy Work Boots | Shields your feet from falling parts. |

Proper Use of PPE

Put on all your gear before you start. Make sure your gloves fit well so you can grip the blades safely. Tuck in loose clothing and tie back long hair. If your safety glasses fog up, clean them right away. You want to see clearly at all times.

Workspace Preparation

Clearing Hazards

A clean workspace helps you avoid slips and trips. Pick up any tools, wood chips, or trash around the chipper. Wipe up oil or water spills. Good lighting helps you see what you’re doing.

Organizing Tools

Lay out all the tools you’ll need before you begin. Keep wrenches, new blades, and cleaning rags within easy reach. This way, you won’t have to search for anything while you work. Staying organized helps you finish the job faster and safer.

Tip: Always follow these safety steps every time you do a wood chipper blades replacement. Skipping even one step can lead to accidents.

Tools and Materials for Blade Replacement

Getting ready for wood chipper blades replacement means you need the right tools and materials. If you prepare well, you can work faster and safer. Let’s look at what you need and how to pick the best things for your chipper.

Required Tools

Wrenches and Torque Tools

You need strong wrenches to loosen and tighten bolts. Torque wrenches help you make bolts tight enough. If you use too much force, you can break the blade or chipper. Always check your chipper’s manual for the right torque.

Specialty Tools for Models

Each chipper model is a little different. Some need special tools to reach blades or take off guards. Here is a list to help you get started: standard wrenches and sockets, torque wrench, Allen keys or hex drivers for some models, blade removal tool if your chipper has one, screwdrivers, and replacement knives. Keep extra knives so you do not have to stop working. If you do not know which tools fit your chipper, check the manual or ask your dealer. Sharp knives help you cut better, so always have extras.

Choosing Replacement Blades

OEM vs. Aftermarket

Picking the right blade is important for wood chipper blades replacement. You can pick OEM blades or aftermarket blades. Dưới đây là một bảng giúp bạn so sánh.:

| Kiểu | Thuận lợi | Nhược điểm |

|---|---|---|

| Lưỡi dao OEM | Exact fit, quality assurance, longer lifespan, warranty protection | Higher price, harder to find during peak seasons |

| Lưỡi dao hậu mãi | Lower cost, wider availability, useful for older machines | Quality varies, fit may not be precise, may void warranty |

OEM blades fit perfectly and have a warranty. Aftermarket blades cost less, but you need to check if they fit and work well. If you want a special blade for your chipper, you can look at Lưỡi Dao Tùy Chỉnh for specific needs.

Material Options (D2, DC53, HSS, Tungsten Carbide)

Blade material changes how long blades last and how well they cut. Nanjing Metal Industrial has many choices for your job. Here is a table to help you pick:

| Vật liệu lưỡi | Đặc trưng | Ưu điểm | Nhược điểm | Application Suggestion |

|---|---|---|---|---|

| Thép công cụ D2 | High-carbon, high-chromium steel with great wear resistance. | Great wear resistance; saves money. | Medium toughness; can chip. | Good for clean, soft to medium-hard wood. |

| DC53 Tool Steel | Strong steel with high toughness and hardness. | Tougher; better against small cracks. | Costs more than D2. | Good for longer blade life in different wood types. |

| HSS Inlay | Bi-metal with high toughness and red hardness. | Handles big hits; keeps edge sharp. | Wears out faster than carbide; costs more to make. | Best for heavy-duty chippers with dirty feedstock. |

| Cacbua Vonfram | Very hard, almost like diamond, for best wear resistance. | Lasts a long time; less downtime. | Very easy to break; costs a lot at first. | Best for big jobs with lots of clean wood. |

If you want blades that last and cut well, pick high-quality ones from Nanjing Metal Industrial. Match the blade material to your wood and work. For hard jobs, DC53 or HSS inlay blades are good. For soft, clean wood, D2 steel works well. Tungsten carbide blades are best for big jobs with clean wood.

Safety and Cleaning Supplies

Lubricants and Rags

You need lubricants to help bolts and mounts move easily. Rags help you clean off old grease, wood chips, and dust. Clean parts make blade installation safer.

Disposal Containers

Do not forget a strong container for old blades and used rags. Sharp blades can cut trash bags, so use a metal bin or tough box. Safe disposal keeps your workspace clean and stops injuries.

Tip: Always check your tools and supplies before you start wood chipper blades replacement. If you have everything ready, you can do the job right and stay safe.

Step-by-Step Wood Chipper Blades Replacement

Accessing Blade Assembly

Removing Guards

Start by making sure the chipper is off and locked out. You do not want any moving parts while you work. Put on your gloves, safety glasses, and ear protection. Now, look for the guards that cover the blade area. These guards keep you safe when the chipper runs, so you must remove them before you reach the blades.

Use the right tool, like a wrench or screwdriver, to loosen the bolts or latches holding the guards. Some chippers have pins or special fasteners. Keep all removed parts in a safe spot so you do not lose them. If the guard feels stuck, do not force it. Check for hidden bolts or ask for help. Once the guard comes off, set it aside on a clean surface.

Mẹo: Always wait until all moving parts have stopped before opening the hood or removing guards. This step helps prevent serious injuries.

Identifying Mounts

Now, look inside the chipper. You will see the blade assembly. The blades attach to a disc or drum with bolts, screws, or clamps. These are called mounts. Take a moment to study how the blades sit and how the mounts hold them in place. Some chippers use locking pins to keep the disc or drum from turning. If your chipper has these, use them now. This will stop the blade assembly from moving while you work.

If you are not sure which parts to loosen, check your chipper’s manual. You can also take a photo with your phone before you start. This way, you will remember how everything fits back together.

Removing Old Blades

Loosening Fasteners

You are ready to take out the old blades. Grab your wrench or the tool that fits the bolts. Turn each bolt slowly and carefully. Some bolts may feel tight because of dirt or rust. If you have trouble, use a little lubricant to help loosen them. Work on one blade at a time. Do not remove all the bolts at once, or the blade might fall.

Safety Alert: Make sure you use the lockout system and locking pins before you start. This keeps the chipper from moving and protects your hands.

Safe Blade Handling

Blades can be sharp, even if they look dull. Always wear heavy-duty gloves when you handle them. Hold the blade by the sides, not the edge. Place each old blade in a sturdy container right away. Do not leave blades on the ground or workbench. Someone could step on them or get cut.

Here is a quick table of safety precautions to remember when removing old blades:

| Safety Precaution | Sự miêu tả |

|---|---|

| Thiết bị bảo vệ cá nhân | Wear gloves, eye and face protection, and earplugs. |

| Locking Pins | Use pins to stop the disc or drum from moving. |

| Lockout System | Make sure the chipper cannot turn on. |

| Điều tra | Check for cracks or damage before you start. |

| Stopping Parts | Wait until all moving parts have stopped before opening the chipper. |

Inspecting and Preparing Mounts

Checking for Wear

After you remove the old blades, look closely at the mounts and the area where the blades sit. Check for cracks, dents, or worn spots. If you see any damage, do not install new blades yet. Damaged mounts can cause the new blades to break or come loose. If you find a problem, talk to a supervisor or a repair expert.

You should inspect the chipper every day before you use it. Look for broken or missing latches, pins, or worn hinges. This habit helps you catch problems early.

Cleaning Surfaces

Before you put in new blades, clean the mounts and the blade seats. Use a rag to wipe away dust, wood chips, and old grease. If you see rust, use a wire brush to remove it. Clean surfaces help the new blades sit flat and tight. This step also makes it easier to line up the blades during installation.

A clean and smooth mount keeps your new blades safe and helps your chipper work better.

By following these steps, you make wood chipper blades replacement safer and more effective. You also help your machine last longer and work at its best.

Installing New Blades

Căn chỉnh lưỡi dao

You have cleaned the mounts and checked for damage. Now, you are ready to install the new blades. Good alignment matters. If you do not line up the blades right, your chipper may shake or break down.

Start by placing the blade on the mount. Make sure the cutting edge faces the right direction. Most blades have marks or arrows to help you. If you are not sure, check your chipper’s manual or look at the old blade’s position.

Here is a simple way to check alignment:

- Hold the blade flat against the seat.

- Look for gaps between the blade and the mount. There should be none.

- Use a straight edge or ruler to check if the blade sits level.

- If your chipper uses more than one blade, make sure all blades line up the same way.

Mẹo: Take your time with alignment. A crooked blade can cause jams, uneven chips, or even damage your machine.

Correct Torque

Once the blade sits in place, you need to tighten the bolts. Do not guess the tightness. Use a torque wrench. Your chipper’s manual will tell you the right torque setting.

Here is a quick table to help you remember why torque matters:

| Bước chân | Tại sao nó quan trọng |

|---|---|

| Tighten to spec | Stops blades from coming loose |

| Do not overtighten | Prevents bolts from snapping |

| Use torque wrench | Keeps pressure even across all bolts |

Start with one bolt and tighten it halfway. Move to the next bolt and do the same. Keep going in a crisscross pattern. This helps the blade sit flat. When all bolts are snug, use the torque wrench to finish tightening each one to the correct setting.

Safety Alert: If you do not use the right torque, blades can fly off or break during use. Always double-check your work.

Reassembly and Final Checks

Securing Guards

You have installed the new blades. Now, you need to put the guards back on. Guards protect you and others from moving parts. Line up the guard with its mounts. Insert the bolts or pins you removed earlier.

Tighten each fastener until the guard feels secure. Do not leave any bolts loose. If you see any damage on the guard, fix it before you finish. A strong guard keeps everyone safe.

Ghi chú: Never run the chipper without all guards in place. This step is key for accident prevention.

Double-Checking Connections

Before you finish, check every connection. Look at each bolt, pin, and latch. Make sure nothing is missing or loose. Wiggle the guards and blade mounts gently. They should not move.

Here is a checklist to help you:

- All blades sit flat and tight.

- Every bolt is at the right torque.

- Guards are secure and undamaged.

- No tools or rags left inside the chipper.

You have now completed the wood chipper blades replacement. Take a moment to review your work. Careful checks help you avoid problems when you start the machine.

✅ You are ready for the next step: post-replacement checks and testing.

Post-Replacement Checks

You finished installing the new blades. Now, you need to make sure everything is safe and ready. This step is just as important as the rest of the wood chipper blades replacement process. Let’s walk through what you should do before you start the machine.

Kiểm tra trực quan

Blade Security

First, look at the blades. Check if each blade sits flat against the mount. Try to wiggle the blades with your gloved hand. They should not move at all. If you see any gaps or loose bolts, grab your torque wrench and tighten them again. Secure blades keep you safe and help your chipper work better.

Debris Removal

Next, check the inside of the chipper. Look for any leftover tools, rags, or wood chips. Even a small piece of debris can cause big problems. Use a flashlight to see into dark corners. Pick up anything that does not belong. A clean chipper means fewer jams and less risk of damage.

Mẹo: Always count your tools before and after the job. If you are missing a wrench, it might be inside the chipper!

Functional Testing

Low-Speed Test

You want to test the chipper, but do it safely. Stand clear of the feed chute and discharge area. Turn the power on and run the chipper at the lowest speed. Watch and listen. The machine should start smoothly. If you hear strange noises or see shaking, turn it off right away.

Observing for Issues

Keep your eyes and ears open. Look for these warning signs:

- Unusual vibration or shaking

- Rattling or grinding sounds

- Blades not spinning evenly

- Any smoke or burning smell

If you notice any of these, stop the chipper. Check the blades and mounts again. Fix any problems before you try another test.

🚩 Never ignore strange sounds or movements. They can mean something is wrong.

Final Safety Review

Protocol Confirmation

Go through your safety checklist one more time. Ask yourself:

- Did I lock out the power before starting?

- Did I wear all my safety gear?

- Are all guards and covers back in place?

- Did I check every bolt and connection?

If you answer “yes” to all, you are ready to use the chipper.

Maintenance Documentation

Write down what you did. Record the date, the type of blades you installed, and any problems you found. Good records help you track blade life and spot patterns. If you work with a team, let others know the chipper is ready.

Here’s a simple table you can use for your records:

| Ngày | Task Performed | Loại lưỡi dao | Issues Found | Next Check Due |

|---|---|---|---|---|

| 2024-06-10 | Thay thế lưỡi dao | DC53 Tool Steel | Không có | 2024-07-10 |

Ghi chú: Keeping good records helps you plan future maintenance and keeps everyone safe.

You have now finished all the post-replacement checks. You can feel confident that your chipper is safe and ready for work.

Common Mistakes in Blade Replacement

Skipping Power Off Steps

You might feel tempted to skip turning off the power when you do a wood chipper blades replacement. Maybe you think it will save time. This is a big mistake. If you leave the chipper plugged in or powered up, it can start by accident. Even a small movement can cause the blades to spin. That can lead to serious injuries.

Here’s what often happens when you skip this step:

- You reach for a blade, and the machine moves.

- Someone else turns on the chipper without knowing you are working.

- You forget to lock out the power, and the chipper starts while your hands are inside.

Báo động: Always use the lockout-tagout method. Turn off the power, unplug the machine, and lock the switch. Put a tag on it so everyone knows you are working. Never trust that the chipper is off just because it looks quiet.

Wrong Tools or Fasteners

Using the wrong tools or fasteners can cause big problems during wood chipper blades replacement. If you grab a wrench that does not fit, you might strip the bolts. If you use the wrong size fastener, the blade can come loose while the chipper runs.

Common mistakes include:

- Using pliers instead of the right wrench

- Mixing up metric and standard bolts

- Forgetting to check the torque setting

- Reusing old, worn-out bolts

Here’s a quick table to help you remember what to check:

| Tool or Fastener | What Can Go Wrong | How to Avoid It |

|---|---|---|

| Wrong wrench size | Stripped bolts, loose blades | Match tool to bolt size |

| Old or damaged bolts | Blades may fall out | Use new, high-quality bolts |

| Wrong torque setting | Over-tighten or under-tighten | Use a torque wrench |

Mẹo: Always read your chipper’s manual before you start. Lay out all the right tools and fasteners before you begin. Double-check each bolt and nut for size and condition.

Poor Blade Alignment

Blade alignment matters more than you might think. If you do not line up the blades correctly during wood chipper blades replacement, the chipper can shake, jam, or even break. Poor alignment also makes the blades wear out faster.

You might make these mistakes:

- Rushing and not checking if the blade sits flat

- Ignoring the marks or arrows on the blade

- Forgetting to use a straight edge to check the level

Here’s how you can avoid poor alignment:

- Place the blade flat against the mount.

- Look for any gaps between the blade and the seat.

- Use a straight edge or ruler to check if the blade is level.

- Make sure all blades line up the same way.

Ghi chú: Take your time with alignment. A well-aligned blade keeps your chipper running smoothly and safely.

By watching out for these common mistakes, you make wood chipper blades replacement safer and more effective. You also help your machine last longer and work better.

Ignoring Post-Checks

You might feel ready to use your chipper right after you finish a wood chipper blades replacement. Skipping post-checks can seem like a way to save time. This is a risky move. Post-checks help you catch mistakes before they turn into accidents.

When you ignore post-checks, you miss things like loose bolts, leftover tools, or misaligned blades. Even a small problem can cause big trouble once the machine starts. You could damage your chipper, ruin your new blades, or even get hurt.

Here’s a simple checklist you should always follow after replacing blades:

- Make sure every bolt is tight.

- Check that all guards are back in place.

- Look for any tools or rags left inside the chipper.

- Spin the drum or disc by hand (if safe) to check for smooth movement.

- Inspect the area for any debris.

Mẹo: Always do a slow-speed test before running the chipper at full power. Listen for odd noises and watch for shaking.

If you skip these steps, you risk more than just a broken machine. You put yourself and others in danger. Take a few extra minutes for post-checks. You will save time and trouble in the long run.

Overlooking Wear or Damage

You might think new blades mean your chipper is ready to go. That is not always true. If you ignore signs of wear or damage on the mounts, bolts, or blade seats during wood chipper blades replacement, you set yourself up for problems.

Worn or damaged parts cannot hold blades tightly. This can make blades come loose or break while the chipper runs. You might hear strange noises, see uneven chips, or notice extra vibration. These are warning signs you should never ignore.

Look for these signs of wear or damage:

| Part to Check | Những điều cần chú ý | Tại sao nó quan trọng |

|---|---|---|

| Blade Mounts | Cracks, dents, or rust | Weak mounts can fail |

| Bolts and Fasteners | Stripped threads, bending | Loose blades or sudden failure |

| Blade Seats | Uneven surfaces, pitting | Poor alignment and blade wobble |

| Guards | Bent or broken parts | Less protection from moving parts |

If you spot any of these problems, stop and fix them before you finish the wood chipper blades replacement. Sometimes you need to replace a bolt or clean off rust. Other times, you may need a new mount or help from a professional.

Báo động: Never install new blades on damaged parts. This can lead to accidents and costly repairs.

Taking time to check for wear and damage keeps your chipper safe and working well. You protect yourself, your team, and your equipment.

Troubleshooting and Efficiency Tips

Damaged Mounts or Seats

You might notice your wood chipper does not run as smoothly after a blade change. Sometimes, the problem comes from damaged mounts or blade seats. These parts hold the blades in place. If they get bent, cracked, or worn out, your new blades will not sit flat. This can cause uneven cuts or even dangerous accidents.

Here’s how you can spot trouble:

- Look for cracks, dents, or rust on the mounts.

- Check if the blade seat feels rough or uneven.

- Try to wiggle the blade after tightening. It should not move.

If you find damage, do not install the new blade. You risk the blade coming loose or breaking. You should replace the damaged part before you finish the wood chipper blades replacement. Sometimes, you need a new mount or a custom part. If you are not sure what to do, call a professional or your chipper’s manufacturer for advice.

Mẹo: Always inspect the mounts and seats every time you change blades. Fixing small problems early keeps your chipper safe and saves money in the long run.

Stuck or Stripped Fasteners

Stuck or stripped bolts can slow you down during wood chipper blades replacement. You might run into a bolt that will not turn or one with a rounded head. Forcing it can break your tools or damage the chipper.

Here’s what you can try:

- Spray a little penetrating oil on the bolt. Wait a few minutes.

- Use the right size wrench or socket. Make sure it fits snug.

- Tap the bolt gently with a hammer to loosen rust.

- If the bolt is stripped, try a bolt extractor tool.

If you still cannot remove the bolt, do not force it. You could break the mount or strip the threads even more. Sometimes, you need to drill out the bolt or ask a repair shop for help.

Here’s a quick table to help you remember your options:

| Vấn đề | What to Try First | When to Get Help |

|---|---|---|

| Stuck bolt | Penetrating oil, tapping | If bolt will not budge |

| Stripped bolt head | Extractor tool | If extractor does not work |

| Broken bolt | Drill out, re-tap hole | If unsure, call a pro |

Báo động: Never reuse damaged bolts. Always use new, high-quality fasteners during wood chipper blades replacement.

Blade Imbalance or Vibration

You might feel your chipper shaking or hear odd noises after a blade change. This often means the blades are not balanced. Blade imbalance can wear out your chipper fast and make it unsafe.

Here’s how you can check for balance:

- Make sure all blades are the same size and weight.

- Check that each blade sits flat and tight on the mount.

- Spin the drum or disc by hand (if safe) and watch for wobbles.

If you notice vibration, stop the chipper right away. Double-check your alignment and torque. Sometimes, you need to swap out a blade for one that matches better. For best results, use blades from the same set or order custom-matched blades from your supplier.

Ghi chú: If your chipper keeps vibrating after you check everything, you may have a bent shaft or damaged drum. In this case, call a professional for help.

By following these troubleshooting tips, you can solve most problems during wood chipper blades replacement. You will keep your chipper running smoothly and avoid costly downtime.

Quick-Change Systems

Have you ever wished you could finish a wood chipper blades replacement in less time? Quick-change systems make that possible. These systems let you swap out blades faster and with less hassle. You do not need to remove as many bolts or parts. Some chippers even have special levers or clamps that hold the blades in place.

Here’s why you might want to use a quick-change system:

- Less Downtime: You spend less time with your chipper out of service. That means you get back to work sooner.

- Fewer Tools Needed: Most quick-change systems only need one or two tools. Sometimes, you do not need any tools at all.

- Safer Blade Changes: You do not have to reach deep inside the machine. This lowers your risk of cuts or pinched fingers.

Mẹo: Always read your chipper’s manual before using a quick-change system. Each brand and model works a little differently.

If you use your chipper a lot, a quick-change system can save you hours over the year. You also make fewer mistakes because the process is simpler. Some systems even have color-coded parts or built-in guides to help you line up the blades just right.

But remember, even with a quick-change system, you still need to follow all safety steps. Lock out the power, wear your safety gear, and double-check your work. Never rush, even if the system seems easy.

If your chipper does not have a quick-change system, you might want to ask your dealer or manufacturer about upgrade options. Sometimes, you can add a retrofit kit to your current machine. This can make future wood chipper blades replacement jobs much easier.

Lập lịch bảo trì

You want your wood chipper to last a long time and work its best. Regular maintenance is the key. If you set up a schedule, you will not forget important tasks like wood chipper blades replacement.

Here’s a simple way to plan your maintenance:

- Check the Manual: Your chipper’s manual tells you how often to replace blades and check other parts.

- Make a Calendar: Write down when you last changed the blades. Mark the next date on your calendar or phone.

- Inspect Often: Look at the blades, mounts, and guards every time you use the chipper. Catching problems early saves money and keeps you safe.

- Lưu giữ hồ sơ: Use a table or notebook to track each maintenance job.

| Ngày | Nhiệm vụ | Loại lưỡi dao | Ghi chú |

|---|---|---|---|

| 2024-06-10 | Thay thế lưỡi dao | DC53 Tool Steel | No issues found |

| 2024-07-10 | Điều tra | – | Minor rust cleaned |

Ghi chú: Good records help you spot patterns. If you see blades wearing out faster than usual, you might need to change your schedule or try a different blade material.

If you notice the chipper vibrating, making odd noises, or cutting poorly, do not wait for the next scheduled maintenance. Stop and check the blades right away. Sometimes, you need to do a wood chipper blades replacement sooner than planned.

For busy worksites, you can set reminders on your phone or use maintenance apps. Some companies even use color-coded tags or stickers to show when the next blade change is due.

If you ever feel unsure about your maintenance plan, talk to a professional or your chipper’s manufacturer. They can help you set up a schedule that fits your needs and keeps your machine running safely.

You now understand how to change wood chipper blades safely. Always do these things: First, make sure you follow your chipper’s rules and blade instructions. Next, pay attention to the weather because it can change how your machine works. Keep track of how long you use your knives. Before you start, check if you have enough blades. Make sure your chipper knives are sharp and ready to use. Stay careful, pick good blades, and never forget safety checks. If you want special help or have questions, talk to a sales engineer at Nanjing Metal Industrial. Your safety and how well your machine works are very important!

Câu hỏi thường gặp

How often should you do wood chipper blades replacement?

You should check your blades after every 20 hours of use. If you see chips, cracks, or dull edges, replace them right away. Regular checks help you avoid accidents and keep your chipper working well.

What signs show you need new blades?

Look for dull edges, chips, cracks, or uneven wood chips. If your chipper vibrates or jams often, it’s time for wood chipper blades replacement. Sharp blades make your job safer and easier.

Can you use any blade for your wood chipper?

No, you need blades that fit your chipper model. Always check your manual or ask your dealer. For specific needs, you can order custom blades to match your machine.

What’s the safest way to handle old blades?

Wear heavy-duty gloves and eye protection. Place old blades in a sturdy container. Never leave blades on the ground or workbench. Safe handling prevents cuts and injuries.

Do you need special tools for wood chipper blades replacement?

Most jobs need wrenches, torque wrenches, and sometimes specialty tools. Check your chipper’s manual for the right tools. Using the correct tools helps you avoid mistakes and keeps you safe.

Why does blade alignment matter?

Proper alignment stops vibration and uneven cuts. Misaligned blades can damage your chipper and cause accidents. Always check alignment before tightening bolts.

Where can you get help with blade selection?

You can contact a aftersales engineer for advice. They help you pick the best blade material and design for your wood chipper blades replacement.

What should you do if you find damage during replacement?

Stop and fix the problem before installing new blades. Replace damaged mounts or bolts. If you feel unsure, ask a professional for help. Safety comes first every time.

Xem thêm

D2, HSS, Carbide: Lựa chọn Thép Tốt Nhất cho Lưỡi Dao Guillotine trong Ngành In

Tiêu Hủy Tài Liệu An Toàn: Cách Lưỡi Dao Máy Xé Giấy Bảo Vệ Dữ Liệu Của Bạn

Hướng Dẫn Thay Thế Lưỡi Dao Máy Xé cho Người Mới Bắt Đầu và Chuyên Gia