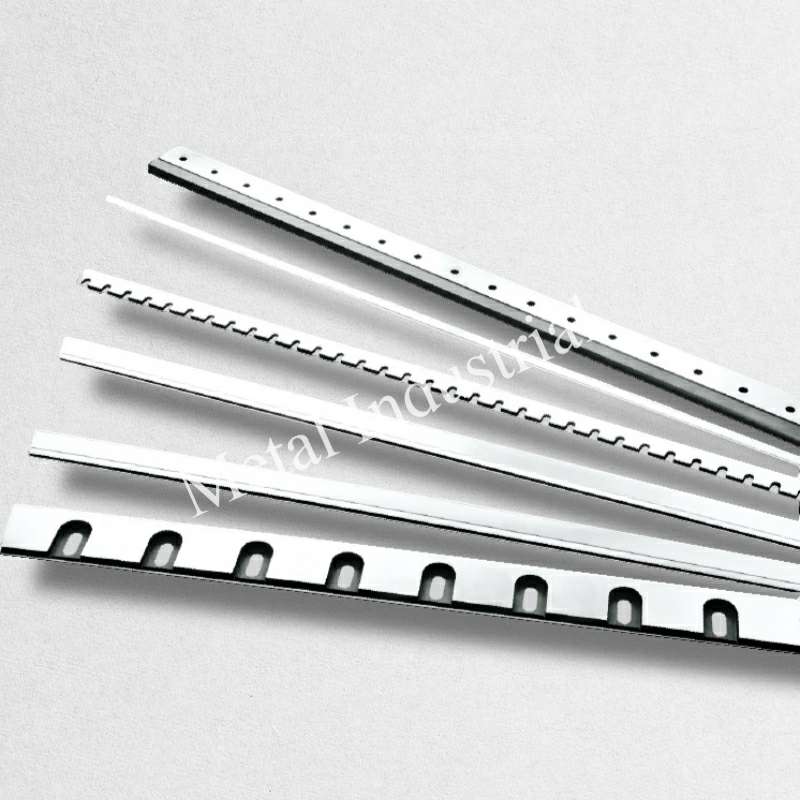

You can get zero-burr cuts by using good blades. You also need to set up the machine right. Skilled workers help a lot too. Precision Guillotine Shear Blades from Metal Industrial give you great results. These blades help you work faster and better. Blades with special edges and strong materials work best. Taking care of your blades keeps cuts smooth. Studies show blade quality matters most. Cutting speed and setup also change burr size and cutting results.

- Cutting speed affects burrs the most.

- Down-milling makes smaller burrs because of force direction.

- Faster cutting edge gives you better accuracy.

Những điểm chính

- Use high-quality blades to get zero-burr cuts. Sharp blades help make smooth edges. They also help you cut faster.

- Set up your machine the right way. Make sure the parts line up well. Blade clearance is important for smooth cuts.

- Check your blades often and take care of them. Clean and sharpen them to keep them working well.

- Pick the right blade for your material. Each material needs a special blade for the best results.

- Watch your cutting speed and change it if needed. Cutting faster can make cuts more accurate. But it can also make more burrs.

- Use blade coatings to lower friction and make blades last longer. Coatings can also help cuts look better.

- Have a daily maintenance routine. Check the hydraulic system and blade condition often to stop problems.

- Change your blades for special jobs. Custom features can help you work better and waste less.

Achieving Zero-Burr Cuts with Precision Guillotine Shear Blades

What Are Zero-Burr Cuts?

Zero-burr cuts give you a smooth edge after cutting. There are no rough spots or extra metal sticking out. You want your material to look nice and feel smooth. In metalworking, experts say the type of material is important. Less ductile materials, like glass, do not make burrs. You also need sharp blades to stop burrs from forming. Dull blades make bigger burrs and lower your work quality. Precision guillotine shear blades help you cut clean and get exact cuts every time.

Tip: Always check if your blade is sharp before you start. Sharp blades help you get zero-burr cuts and make your work faster.

Key Factors for Burr-Free Cutting

You need to think about a few things to get burr-free cuts with precision guillotine shear blades. Each thing helps your blade work better and gives you smoother cuts. The table below shows the most important things for better performance and faster work:

| Nhân tố | Sự miêu tả |

|---|---|

| Khả năng tương thích của vật liệu | Pick the right blade for your material. This stops damage and keeps edges smooth. |

| Burr Shape | Different shapes need different blades. Choose the best one for your job. |

| Cutting Speed and Durability | Use strong blades for longer life and faster cuts. This helps you work better. |

| Ergonomics and Handling | Light blades shake less and help you cut more exactly. |

| Chất lượng cạnh | Good blades give you nice edges, so you do not need extra work. |

| Reduced Mechanical Stress | The right blade puts less stress on your material, keeping it strong and clean. |

| Scrap Material Reduction | Precision guillotine shear blades make thin cuts, so you waste less material. |

You can see that using the right blade and setup gives you better work and less waste.

Common Challenges in Precision Cutting

When you use precision guillotine shear blades, you might have some problems. Knowing these problems helps you fix them fast and keep your cuts smooth.

- Cuts are not exact when blades are dull or not lined up.

- Burrs and shaking happen if your machine is not set up right or if you handle the material wrong.

- Machines get too hot and make rough cuts or break equipment.

- Material splits before the cut is done, so you need more blade pressure or better setup.

- Servo motor problems make your machine cut uneven or stop.

- Dull blades, especially with hard materials, make more burrs and less exact cuts.

- If your material is too thick for your blade, you get rough edges.

- A wrong blade gap gives uneven force and makes more burrs.

Note: You can stop most problems by checking your blade, fixing your machine, and using the right blade for each job. This keeps your cuts exact and your work strong.

Precision guillotine shear blades help you fix these problems. You get better cuts, higher quality, and faster work when you pay attention to these things.

The Burr Equation in Precision Cutting

Burr Formation: Plastic Deformation vs. Clean Fracture

When you use a guillotine shear, you want a clean cut. Burrs form when the material does not break cleanly. This happens because the force from the blade pushes the metal past its yield strength. The metal bends and stretches before it breaks. This process is called plastic deformation. You see extra metal, or burrs, at the edge of your workpiece.

A clean fracture is different. The material separates without much bending or stretching. You get a smooth edge with almost no burrs. To get this result, you need to control how the blade moves through the material.

The cutting process has three main steps:

- First, the blade presses down and causes the edge to roll over.

- Next, the blade penetrates and creates a burnished band.

- Last, the material breaks off, and burrs can form if the process is not controlled.

If you want to avoid burrs, you must focus on how the blade interacts with the material during each step.

Three Critical Variables

You can control burr formation by paying attention to three main variables. These variables affect how the material reacts during cutting.

Khoảng cách lưỡi dao

Blade clearance means the space between the upper and lower blades. You must set this gap correctly for each material and thickness. If the blade gap is too wide, the material bends too much and forms large burrs. If the gap is too small, the blades can wear out quickly or even break.

Adjusting blade clearance is one of the most important steps for clean cuts. You should check the manufacturer’s guide for the right settings. Always adjust the blade gap before you start a new job. This helps you get the best results and keeps your blades in good shape.

Blade Sharpness and Edge Radius

Sharp blades make a big difference in cutting quality. A dull blade pushes and drags the material, which increases burr size. The edge radius, or how rounded the blade edge is, also matters. A small edge radius gives you a cleaner cut. You should inspect your blades often and sharpen them when needed.

Tool wear is a common cause of burrs. When you see more burrs, check your blade sharpness first. Keeping your blades sharp helps you maintain precision and reduces the need for extra finishing work.

Thành phần vật liệu

Different materials react in different ways during cutting. Softer metals may deform more, while harder metals can break cleanly. You need to know the properties of your material before you start. Some materials need a smaller blade gap, while others need a larger one.

Adjusting blade clearance for each material type helps you control burr formation. You should also consider the thickness and hardness of the material. This lets you set up your machine for the best possible cut.

Shearing Angle and Force Distribution

The shearing angle, or rake angle, changes how the force moves through the material. A small shearing angle lowers the force needed for cutting, but it can cause more bending and bigger burrs. A larger shearing angle needs more force, but it gives you a cleaner cut.

The angle between the blades also affects how the force spreads out. If you do not set the angle correctly, you may see more burrs and uneven edges. You should adjust the shearing angle based on your material and the type of cut you want.

Tip: Always check your blade gap, blade sharpness, and shearing angle before you start. Small changes can make a big difference in cutting quality.

Controlling these variables helps you get smooth, burr-free edges. You improve your results by adjusting blade clearance, keeping blades sharp, and choosing the right settings for each material. This approach gives you the precision you need for high-quality work.

Blade Features and Materials for Precision Cutting

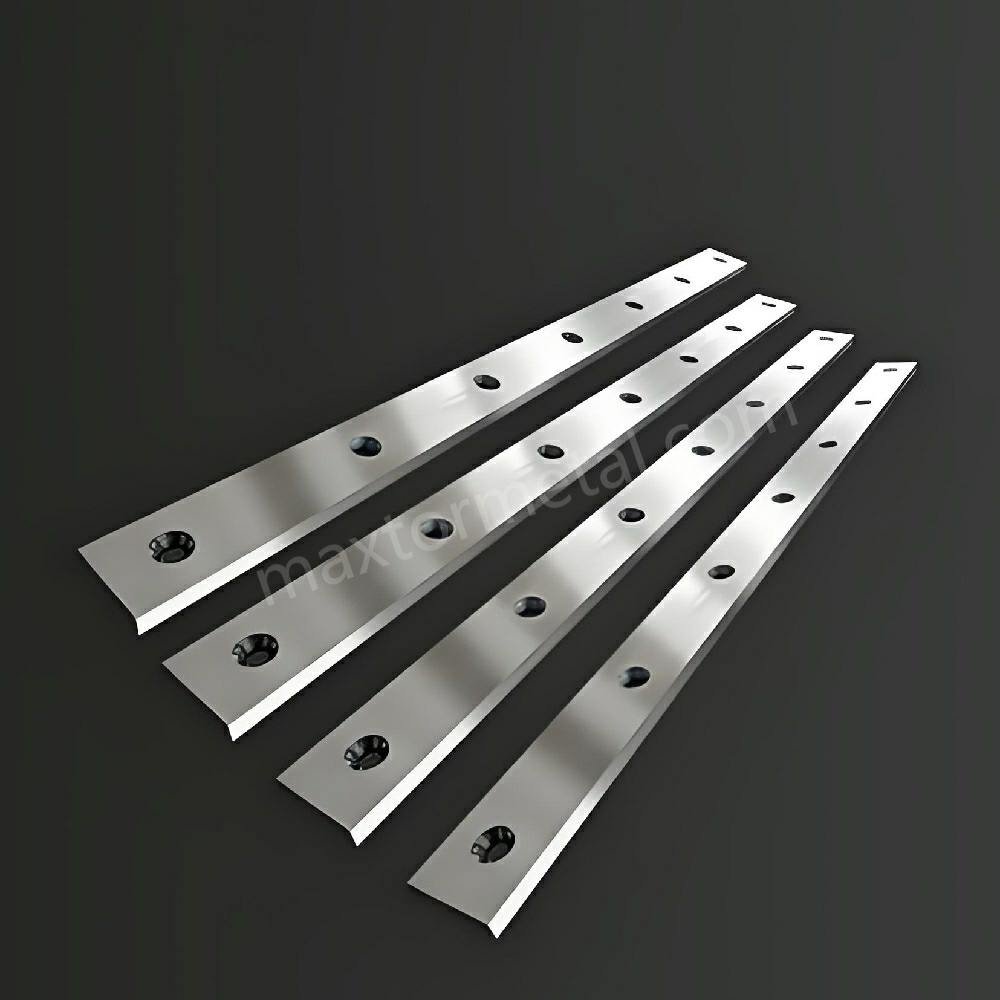

High-Quality Blade Materials

Picking the right blade material is important for cutting. The material you pick changes how long your blade lasts. It also changes how well it cuts and how much care it needs. Here are three top materials used for high-quality blades:

Cacbua Vonfram

Tungsten carbide blades are very hard and last a long time. You can use them for tough jobs and hard materials. They keep their sharp edge for a long time. You do not need to sharpen them often. Tungsten carbide does not get damaged by heat or rust. This helps you get clean cuts in tough places. These blades cost more money, but they last longer and work very well.

High-Vanadium PM Steels

High-vanadium PM steels are strong and do not wear out fast. You can use these blades when you need both strength and long life. Vanadium in the steel keeps the blade sharp and stops chips. These blades are good for fast cutting and work well in many jobs.

Cr12MoV Steel

Cr12MoV steel blades are tough and easy to make. You can use them for many cutting jobs. They do not break easily because they handle shock well. Cr12MoV steel blades last a long time and do not cost much.

You can see the main properties of these materials in the table below:

| Tài sản | Cacbua Vonfram | Steel (Cr12MoV, High-Vanadium PM) |

|---|---|---|

| độ cứng | Extremely high (8.5–9 Mohs) | Lower (4–8 Mohs, depending on grade) |

| Hao mòn điện trở | Xuất sắc | Good, but wears faster |

| Khả năng chịu nhiệt | Rất cao | Vừa phải |

| Chống ăn mòn | Cao | Thay đổi |

| độ dẻo dai | Vừa phải | Cao |

| Khả năng gia công | Difficult | Easy |

| Trị giá | Cao hơn | Thấp hơn |

Tip: Pick the blade material that fits your job. Hard blades last longer, but tough blades take hits better.

Edge Geometry and Compound Angles

The shape of your blade edge is called edge geometry. It is important for good cutting. You need to look at the angle and sharpness of the blade. Compound angles help control how the blade moves through the material. A sharper angle gives cleaner cuts but wears out faster. A bigger angle lasts longer but may not cut as clean.

Compound angles help you balance sharpness and blade life. The right edge geometry can lower burrs. If you use the wrong angle, you might get more burrs, rough edges, or cracks.

Here is a table that shows how burrs can change your finished parts:

| Impact of Burrs | Sự miêu tả |

|---|---|

| Fatigue Life | Burrs make your parts wear out faster. |

| Residual Stresses | Burrs add extra stress to the edges and can weaken parts. |

| Crack Initiation | Burrs can start cracks because they are sharp and uneven. |

| Corrosion Risk | Burrs make spots where rust can start and lower cut quality. |

| Safety Hazard | Burrs make sharp edges that can hurt people or damage tools. |

Note: Always check your blade angles before you cut. The right shape helps you get smooth, safe, and good cuts.

Surface Finish, Hardness, and Coatings

A smooth blade surface helps the blade move through material better. Less friction means cleaner cuts. Hardness is important too. Hard blades do not wear out fast and stay sharp longer.

Blade coatings give extra help. Ceramic coatings make blades last three to five times longer. Diamond-like carbon (DLC) coatings cut friction by half. This means you use less force and cut better. Some coatings also stop rust, which helps if you work in wet places.

Here is a table that shows how coatings help your blades:

| Loại lớp phủ | Mô tả lợi ích | Impact on Blade Life |

|---|---|---|

| Lớp phủ gốm | Makes blades last 3 to 5 times longer than uncoated steel | Significant longevity increase |

| DLC Coating | Cuts friction by up to 50%, making cutting easier and more efficient | Enhanced performance |

| Lớp phủ chuyên dụng | Stops rust in wet areas, keeps blades strong and sharp | Critical for durability |

Tip: Use blades with the right coating for your job. You will get better cuts and spend less time fixing your blades.

You can achieve better precision cutting by selecting the appropriate blade material, edge shape, and surface finish. These features help you get good cuts, lower burrs, and make your blades last longer.

Customization Options from Metal Industrial

You get better cuts when your blades fit your needs. Metal Industrial lets you change your precision guillotine shear blades in many ways. You can pick the features that work best for your job and machine. This helps you cut faster, waste less, and stay safe.

Here is a table that shows some main ways you can change your blades:

| Customization Option | Sự miêu tả |

|---|---|

| Diameter | You can pick the right diameter for your machine. |

| Góc cắt | Adjustable angles help you get cleaner cuts. |

| Dữ liệu hiệu quả | Custom slitter blades increased efficiency by 18% in a packaging line. |

You can also pick different coatings for your blades. These coatings help your blades last longer and cut better. For example:

- Titanium carbonitride coatings make your blades stronger and harder to wear out.

- Polytetrafluoroethylene coatings stop sticky stuff from building up on your blade.

- Some coatings make less friction, so your blade moves easier through the material.

You can choose the blade edge that works best for your job. Straight edges are good for slicing. Serrated edges help you cut tough materials. The shape, angle, and sharpness of the blade edge all change how well your blade cuts.

Custom blades can help you waste less and cut better. Many companies have less scrap and smoother cuts after using custom blades. You can see more about these choices on the trang lưỡi dao tùy chỉnh.

Tip: When you pick custom precision guillotine shear blades, you get blades that fit your machine and your material. This helps you get the best results every time.

You can talk to Metal Industrial about what you need. They will help you pick the right diameter, angle, coating, and edge shape. Custom blades give you more control and help you do your work better.

Matching Blades to Material and Shearing Machine Hydraulic System

Selecting the Right Blade for Each Application

You must pick the right blade for your job. Every material needs a blade with special features. The blade should match how hard and tough your material is. Good heat treatment makes blades last longer and work better. Some blade materials are best for certain jobs. T10A Carbon Tool Steel works well for most cutting. H13 Hot Work Die Steel is good for hot and tough jobs.

Here is a table to help you choose a blade:

| Tiêu chuẩn | Sự miêu tả |

|---|---|

| độ cứng | The blade stays strong and keeps its shape. |

| độ dẻo dai | The blade does not break and can take hits. |

| Xử lý nhiệt | Special heating makes the blade stronger and last longer. |

| Các loại vật liệu | Each blade works best for certain jobs and materials. |

You get better cuts when you match the blade to your material. This helps your blade work well and last longer.

Importance of Flatness and Parallelism

Blades need to be flat and line up right. Flatness means the blade surface is smooth. Parallelism means both blades match up perfectly. If blades are not flat or lined up, you get rough edges and burrs. Blades that are worn or not lined up can make wavy edges and mistakes. You want clean cuts, so check blade alignment often.

Tip: Use a straight edge or feeler gauge to check if blades are flat and lined up before you start. This helps you get smooth cuts and strong material.

Flat and lined-up blades help you cut with high accuracy. You get fewer burrs and better finished parts.

Adjusting for Material Thickness and Type

You need to change your blade setup for each material thickness and type. Thin materials need a small blade gap. Thick materials need a bigger gap. You can make your cuts better by changing the blade gap by hand. This helps control force and lowers burrs.

Different materials act in different ways. Soft metals bend more. Hard metals break cleanly. You should know your material before you start. Change the blade gap and angle to fit the material. This helps you get clean cuts and keeps blades safe.

You also need to think about the shearing machine hydraulic system. The hydraulic system controls how hard and fast you cut. You get better cuts when you match the blade setup to the hydraulic system. This helps you cut many materials and thicknesses with good results.

Note: Always check your blade settings and hydraulic system before you start a new job. This helps you get the best cuts and stops problems.

You get better cuts and less waste when you match your blades to the material and hydraulic system. You improve your cutting and save material.

Integrating with Shearing Machine Hydraulic System

When you use precision guillotine shear blades, you must think about the hydraulic system. The hydraulic system controls how hard and fast the blade moves. If your blade matches the machine’s power, you get better cuts and less burr.

The hydraulic system lets you change force and speed. You can set these for different materials and blades. Thick or hard materials need more force. Thin or soft materials need less force. Using the right settings helps your blades last longer and cut better.

Here are some important blade specifications and how they work with the hydraulic system:

| Specification | Chi tiết |

|---|---|

| Blade Length | Pick a blade that fits your machine’s cutting length. Most blades are 1000mm to 6000mm long. |

| Vật liệu lưỡi | Use High-Speed Steel (HSS) for exact cuts. Pick carbide blades for tough or rough materials. |

| Độ dày của lưỡi dao | Match blade thickness to your machine’s strength. Most blades are 20-50mm thick. |

| Góc cắt | Change the angle from 0.5 to 2.5 degrees for each material. This helps you get smooth, burr-free cuts. |

| Stroke Rate | Use a higher stroke rate to work faster. Lower the rate for more control and better cuts. |

Each part of the blade must fit your machine’s power and speed. If your blade is too long or thick, you can break the blade or the machine. If you set the wrong angle, you get rough edges or more burrs.

Tip: Always read your machine’s manual before you put in new precision guillotine shear blades. Make sure the blade size, thickness, and angle match your machine’s needs.

The hydraulic system also lets you control pressure and speed for each cut. Use less pressure for thin materials. Use more pressure for thick or hard materials. This keeps your cuts clean and helps your blades last longer.

When you use the right hydraulic settings with your blades, you get many good things:

- Cleaner and smoother cuts

- Less waste and fewer burrs

- Blades last longer

- Safer work

You can also obtain custom blades tailored for your machine and material. Metal Industrial makes blades in many sizes and materials. They check each blade for quality before sending it to you. This helps you get the best results from your machine.

Note: Matching your blade to your hydraulic system is one of the best ways to get better cuts. Take time to set up your machine and blades before each job.

When you know how your blades and hydraulic system work together, you can get zero-burr cuts and keep your work running well.

Setup, Alignment, and Operational Practices for Precision

Achieving Micro-Clearance Alignment

You need to set up blades with a tiny gap. This gap is called micro-clearance. It helps you get smooth cuts with no burrs. The gap between the blades must be small and even. This makes your cuts more accurate. Always check the blade gap before each job. The right gap depends on the material and its thickness.

A good tool holder keeps blades steady. If the holder is bent, cuts will not be straight. Always install blades so they are flat and the gap is even. Follow your machine’s manual for safety and good results.

You should do regular maintenance. Check the blade gap often and change blades when they wear out. This keeps your cutting quality high. The table below shows the best ways to set up micro-clearance:

| Thực hành tốt nhất | Sự miêu tả |

|---|---|

| Khoảng cách lưỡi dao | Change the blade gap for each plate thickness and material. |

| Tool Holder Condition | Make sure the holder is not bent or broken. |

| Standard Blade Installation and Adjustment | Put blades in firmly so they are flat and the gap is even. |

| Bảo trì thường xuyên | Check the gap often and change blades when needed. |

| Follow Operation Manual | Use the manual to stay safe and keep your machine working well. |

Tip: Always use a clearance gauge to check the gap. This helps you set the right micro-clearance for every job.

Step-by-Step Setup for Zero-Burr Results

You can follow steps to get cuts with no burrs. First, check your machine for special features. These features help you set up for better accuracy.

Use mandrels to hold tubes if you cut round parts. Mandrels stop burrs and keep tube ends straight. Before you cut, set up ways to check your work. Decide how you will inspect the cuts. Add your inspection plan to your job request and part details.

Set up a plan to check samples. Use a plan like AQL 1.0 c=0 to get zero defects. Agree on how to measure with your vendor. For small parts, use simple tools like pin gages. Use measuring tools that are checked and set the right limits.

Here is an easy setup process you can use:

- Check your machine for features that help with accuracy.

- Use mandrels to hold tubes and stop burrs.

- Set up ways to check quality before you cut.

- Decide how to inspect and add it to your job request.

- Use a sample plan to check for zero defects.

- Agree on measuring tools with your vendor.

- Use checked measuring tools and set the right limits.

Note: You get better cuts when you plan your setup and inspection before you start. This helps you find problems early and keep your cuts clean.

Troubleshooting Alignment and Cutting Issues

You might have problems with alignment and cutting. You need to fix these problems quickly. Check blade alignment often. If blades are not lined up, cuts will not be straight. Change the blade gap for each sheet thickness. This helps you avoid rough edges and burrs.

Check the blade often. If it is dull or broken, sharpen it with special tools. Replace blades that are too worn to fix. Use a clearance gauge to check and set the gap. Make sure the blade is tight and bolts are secure. Use tools to check that both blades are straight and the gap is even.

The table below shows ways to fix common problems:

| Troubleshooting Method | Sự miêu tả |

|---|---|

| Kiểm tra sự căn chỉnh | Check and fix blade alignment often for good cuts. |

| Adjust Blade Clearance | Change the gap for each sheet thickness. |

| Inspect Blade Condition | Check if the blade is sharp and not broken. |

| Sharpen the Blade | Use special tools to make the blade sharp again. |

| Replace the Blade | Change blades that are too worn to fix. |

| Use a Clearance Gauge | Check and set the gap between blades. |

| Check Blade Installation | Make sure the blade is tight and bolts are secure. |

| Correct Blade Position | Use tools to make sure blades are straight and the gap is even. |

You may have trouble cutting if blades are dull, not lined up, or not oiled. Sharpen or change dull blades, fix alignment, and check for oil. Uneven cuts can happen if blades are not straight, the table is broken, or the material is not even. Fix blade alignment, check the table, and use material that is the same thickness.

Tip: Keep a checklist for fixing problems. This helps you find and fix issues fast, so your cuts stay smooth and accurate.

Operational Tips for Consistent Precision

You can achieve consistent precision with your precision guillotine shear blades by following a few proven tips. These tips help you keep your cuts smooth and your edges burr-free.

- Always use sharp blades. Dull blades create more burrs and make your work harder.

- Watch for burrs as you cut. Burrs can show you when your blade needs sharpening or replacing.

- Choose the right blade for your material. The correct blade type improves cutting quality and reduces waste.

- Keep your work area clean. Dust and debris can affect how your blade moves and how your material sits.

- Check your machine settings before each job. Small changes in speed or pressure can change your results.

Tip: If you see more burrs than usual, stop and check your blade. A sharp blade gives you better results every time.

You can also follow a simple routine to keep your precision guillotine shear blades working at their best:

- Sharpen your blades on a regular schedule. Sharp blades cut cleaner and last longer.

- Adjust your cutting speed and feed rate. Lower speeds can reduce heat and keep your material from warping.

- Set the right cutting angle and depth. Careful adjustments help you avoid rough edges and keep your finish smooth.

- Inspect your blades and machine after each job. Look for signs of wear or damage.

- Record your settings and results. Keeping notes helps you repeat good results and fix problems faster.

Here is a table to help you remember the most important tips:

| Mẹo | Tại sao nó quan trọng |

|---|---|

| Use sharp blades | Reduces burrs and improves cut quality |

| Monitor burr formation | Shows when to sharpen or replace blades |

| Adjust operational settings | Controls heat and material deformation |

| Clean work area | Prevents debris from affecting precision |

| Inspect after each job | Catches problems early and extends blade life |

You can get the best results from your precision guillotine shear blades by following these tips every day. Consistent habits lead to smooth, accurate cuts and less wasted material.

Note: Good habits and regular checks help you keep your cutting process precise and reliable.

Maintenance and Cost Considerations for Precision Cutting

Daily Operation and Inspection

You keep your cutting process smooth by following a daily routine. Start each day by cleaning the blades. Wipe off dirt and metal shavings. This stops rust and keeps blades sharp. Look at the blades for chips or dull spots. If you see damage, plan to sharpen or change the blade soon. Check the hydraulic system for leaks or low oil. Make sure all bolts and fasteners are tight. A quick check helps you find problems early and avoid bigger trouble later.

Tip: A clean and checked machine gives you better cuts and keeps your work quality high.

You should also check if the blades line up right. Use a clearance gauge to make sure the gap fits your material. This small step can really help you get more exact cuts.

Blade Maintenance and Longevity

Taking care of your blades makes them last longer and work better. You need to keep blades sharp. Dull blades need more force and can hurt the blade or the material. Clean blades after every use to stop dirt from building up. Sharpen blades often to keep the edge in good shape and make sure each cut is clean.

Here are some best ways to care for your blades:

- Sharpen blades when you see dull or rough edges.

- Clean blades often to stop rust and dirt.

- Change blades with deep chips or cracks.

- Check the hydraulic and machine parts every week.

- Change hydraulic oil and filters every month.

You work faster and stop delays by doing these things. Good blades help you cut better and make your machine last longer.

Cost Efficiency and Replacement Planning

You can save money and keep your work going with smart planning. Make a schedule to change blades based on how much you use them. This helps you stop surprise breakdowns. Some models, like the Total Expected Discounted Cost policy, help you pick the best time to change blades. These models look at both how the blade works and how much it costs to find the best answer.

Here is a table that shows some ways to save money and plan for new blades:

| Strategy | Chi tiết |

|---|---|

| Scheduled Replacement | Change blades at set times to stop sudden problems. |

| Reliability Enhancement | Use data to find the best times for fixing, making your system stronger. |

| Cost Analysis | Match costs with what your machine needs for better spending. |

| Practical Applications | Use these ideas in jobs like shipping and factories for better results. |

Note: Doing regular checks and fixes saves money and helps you work better. You get more from your machine when you plan ahead.

By checking your blades often, taking care of them, and planning when to change them, you keep your cutting work sharp and save money. This way, you always get good results.

Application Case Studies: Precision Cutting Across Industries

Soft Foils and Plastics

Many jobs use soft foils and plastics. These jobs are in recycling, packaging, and making things. Precision guillotine shear blades help you cut these materials clean and straight. The table below shows how these blades help you:

| Khu vực ứng dụng | Lợi ích chính | Materials Cut |

|---|---|---|

| Tái Chế | Breaks down compressed bales for easy reprocessing | PET, PE, PVC |

| Bao bì | Delivers clean, uniform cuts and prevents tears or imperfections | Plastic film rolls |

| Industrial Processes | Improves equipment performance and reduces downtime | Dense or multi-layered materials |

You get smooth edges and waste less material with the right blade. In recycling, you can break plastic bales apart fast. In packaging, you stop tears and keep products looking nice. For factory jobs, you help machines last longer and cut thick layers easily.

Tip: Pick the right blade for your material to get the best cuts.

Paper, Board, and Textile Applications

You see these blades used in paper mills, board factories, and textile plants. They help you with slitting, cross-cutting, and die-cutting. You get neat cuts and save material, which saves you money and time.

- You use these blades for fast paper lines.

- You need them for straight cuts in making clothes.

- One blade can cut many kinds of textiles because it is flexible.

- Strong blades last longer, even in busy places.

These blades help you work faster and keep your products looking good. You can trust them to cut a lot without getting dull or making mistakes.

Note: Check your blades often to keep your cuts smooth and your products high quality.

Thin Gauge Stainless Steel and High-Strength Metals

Cutting thin stainless steel or strong metals is hard. You need blades with sharp edges and tough materials. These blades give you smooth cuts and you do not need to do extra work after. The table below shows how these blades help you:

| Tính năng | Sự miêu tả |

|---|---|

| Sharp Edge Geometry | Gives you smooth shearing and less finishing work |

| High-Grade Materials | Uses premium tool steels like D2, HCHCR, and HSS for better wear resistance and strength |

| Long Blade Life | Special heat treatment and finishing extend blade use and reduce downtime |

| Các ứng dụng | Sheet metal shearing, plate cutting, coil processing, scrap shearing, automotive, fabrication |

You get clean edges with no burrs and use less force to cut. Your machine does not get worn out as fast. Many jobs, like car making and heavy work, use these blades for good results and long life. You can use blades with HRC 60–65 for thin sheets and H13 or SKD61 for heat and strength.

- Your machine lasts longer and you change blades less.

- You get good cuts, even when you work for a long time.

Tip: Pick the right blade hardness and material for each metal to keep your cutting fast and easy.

Comparative Analysis and Key Takeaways

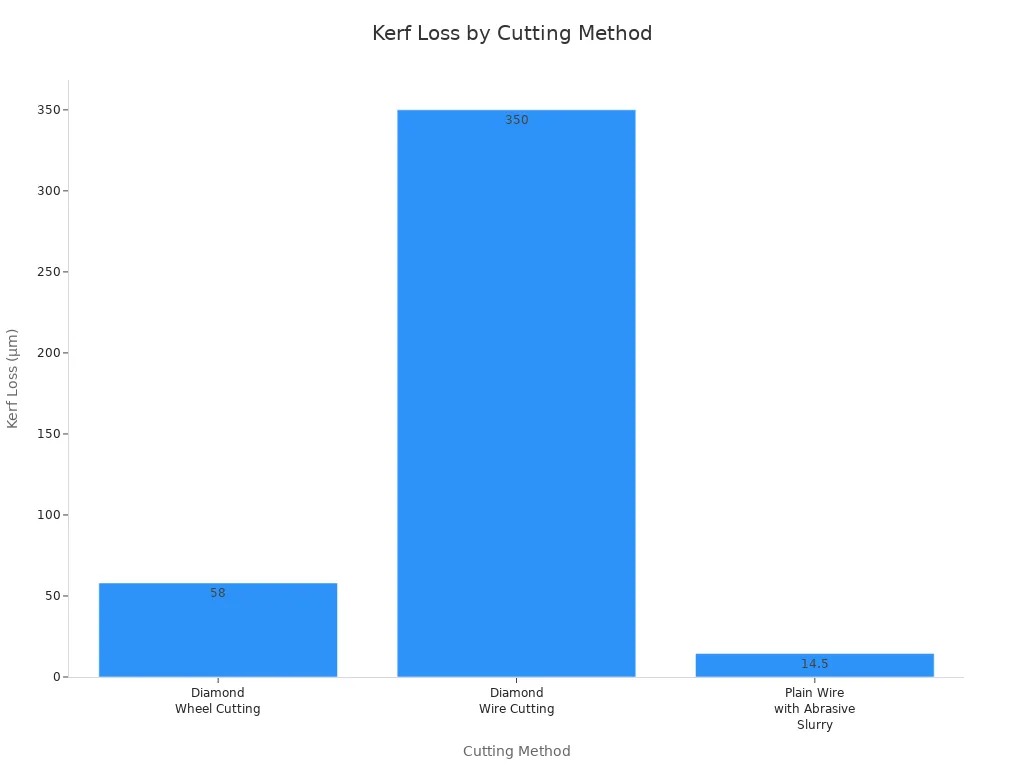

Many industries use different ways to cut materials. Each way gives you special results. You should look at kerf loss, edge chipping, and how fast you can cut. Picking the right method helps you get good quality and saves time.

The table below shows three cutting methods and how they compare:

| Phương pháp cắt | Kerf Loss (µm) | Edge Chipping | Hiệu quả cắt |

|---|---|---|---|

| Diamond Wheel Cutting | 58 | Cao hơn | Vừa phải |

| Diamond Wire Cutting | 350 | Thấp hơn | Cao |

| Plain Wire with Abrasive Slurry | 10-19 | Tối thiểu | Cao |

Diamond wheel cutting is not the fastest. It makes more edge chipping and wastes more material. Diamond wire cutting is quick and does not chip edges much. But it loses more material. Plain wire with abrasive slurry is different. It wastes very little material and makes almost no edge chipping. It is also fast, so you finish jobs quickly and save material.

The chart shows plain wire with abrasive slurry keeps kerf loss low. This helps you save material and makes your cutting better. Diamond wire cutting is good for speed, but you lose more material.

Different industries need different cutting ways. Soft foils and plastics need less edge chipping. Paper and textiles need smooth edges and fast cutting. Thin stainless steel and strong metals need a balance of speed and edge quality.

Here are some key things to remember:

- Pick your cutting way based on the material and finish you want.

- If you want less waste and high precision, use plain wire with abrasive slurry.

- For fast work, diamond wire cutting is good but may waste more material.

- Always check the edge after cutting to make sure it looks good.

- Using the right method for your job helps you get better results.

Tip: Check your cutting process often. Small changes in how you cut or set up your machine can help you get better quality and save time and materials.

You can utilize this information to assist you in selecting the best cutting method for your industry.

You can get zero-burr cuts by using simple steps. Pick blades that are high quality. Set up your machine carefully for good cuts. Take care of your equipment so it works well. The table below shows what you should do every day:

| Thực hành tốt nhất | Lợi ích |

|---|---|

| Vệ sinh hàng ngày | Helps you make accurate cuts |

| Kiểm tra lưỡi | Keeps the blade edge sharp |

| Hydraulic System Check | Makes your machine work better |

| Tightening Fasteners | Keeps your work safe |

Watch your cutting process and change settings if needed. If you want strong and custom shear blades, talk to a sales engineer đây.

Câu hỏi thường gặp

What is a zero-burr cut?

You get a zero-burr cut when the edge of your material is smooth and free from rough spots. This type of cut helps you avoid extra finishing work and keeps your projects looking clean.

How do I choose the right shear blade for my material?

You should match the blade to your material’s hardness and thickness. Check the manufacturer’s guide for the best fit. Using the correct blade improves cutting precision and extends blade life.

Why does blade alignment matter?

Blade alignment keeps your cuts straight and smooth. If your blades are not lined up, you may see rough edges or burrs. Always check alignment before you start cutting.

How often should I inspect my shear blades?

You should inspect your blades before each job. Look for dull edges, chips, or cracks. Regular checks help you maintain quality and prevent unexpected problems during cutting.

What affects the performance of guillotine shear blades?

Blade sharpness, material type, and machine settings all affect performance. Keeping blades sharp and using the right settings helps you get clean, accurate cuts every time.

Can I use one blade for different materials?

You can use one blade for several materials, but you may not get the best results. For top quality, use a blade designed for each specific material and thickness.

How do coatings help my shear blades?

Coatings reduce friction and protect against rust. They help your blades last longer and make cutting easier. Some coatings also improve the smoothness of your cuts.

What should I do if I see more burrs than usual?

Stop and check your blade for dullness or damage. Adjust your machine settings if needed. Replacing or sharpening the blade often solves the problem and restores cutting precision.

Xem thêm

Cách chọn lưỡi dao chém phù hợp với nhu cầu của bạn

Hướng dẫn tối ưu để bảo dưỡng lưỡi cắt Guillotine: Kéo dài tuổi thọ và tối ưu hóa hiệu suất

Lựa Chọn Giữa Máy Cắt Guillotine và Máy Cắt Dầm Đung Đưa: Một Phân Tích So Sánh Toàn Diện