توقف عن التنازل: لماذا تتفوق شفرات القص الصناعية المخصصة على البدائل الجاهزة

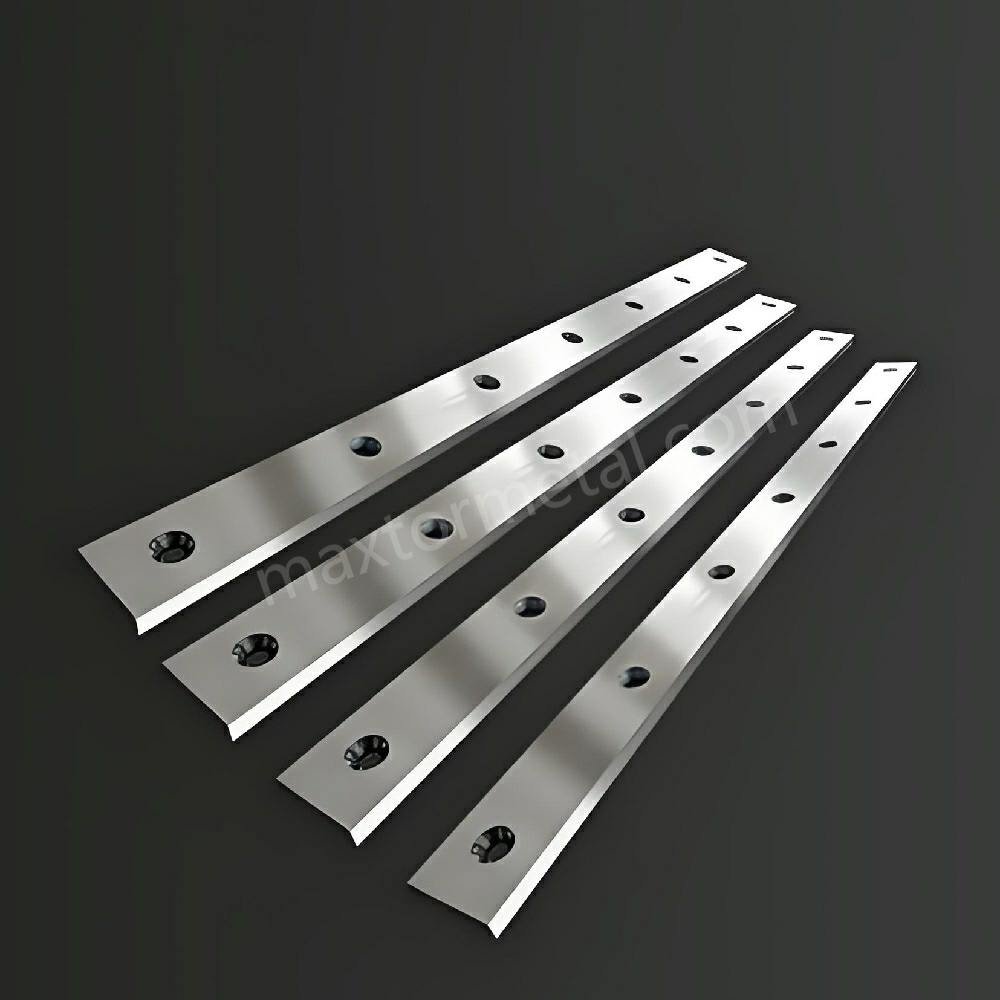

يجب أن تمتلك أدوات قطع تتجاوز مجرد الوظائف الأساسية. شفرات القص الصناعية المصممة خصيصًا أقوى وأكثر دقة من الشفرات العادية، ولا يمكن للشفرات الجاهزة أن تضاهي جودتها. تُصنع الشفرات المصممة خصيصًا بأشكال حواف خاصة، ومواد أفضل، وبمهارة عالية. تستخدم أدوات القطع من Metal Industrial، المصنعة في الولايات المتحدة الأمريكية، خطوات تصميم مخصصة للحفاظ على حدتها لفترة أطول.

الدليل الشامل لشفرات القص للفولاذ المقاوم للصدأ: المواد والهندسة للحصول على قطع عالي الجودة

When you pick shear blades for stainless steel, you face special problems. Stainless steel gets hard fast and wears out tools. Galling and strong metal make cutting hard. You may see too much burring, blade wear, and bent material. Good blade material and exact shape help stop bite and tear. Metal Industrial uses new ways to […]

تحليل تكسير شفرات القص: أهم 5 أسباب جذرية واستراتيجيات الخبراء للوقاية والإصلاح

Shear blade chipping analysis helps you find why blades get damaged. It also shows why the system fails in your hydraulic cutting process. When blades get tired or stressed, they chip. This makes you lose time and good cuts. Damage from bad maintenance or hydraulic problems can stop work and cost money. You need to check […]

ما وراء المعالجة الحرارية: إطلاق العنان لعمر افتراضي فائق مع شفرات القص المعالجة بالتبريد العميق

You want blades that work well and last longer in hard places. Cryogenic treated shear blades are better than regular heat-treated blades. Key Takeaways Cryogenic Treated Shear Blades: Process and Principles What Is Cryogenic Treatment Cryogenic treatment is a special way to make shear blades stronger and last longer. First, the blade gets heated to a high temperature. […]

شفرات قص القضبان المتخصصة: تحقيق الدقة وتقليل التشوه في قطع البليتات

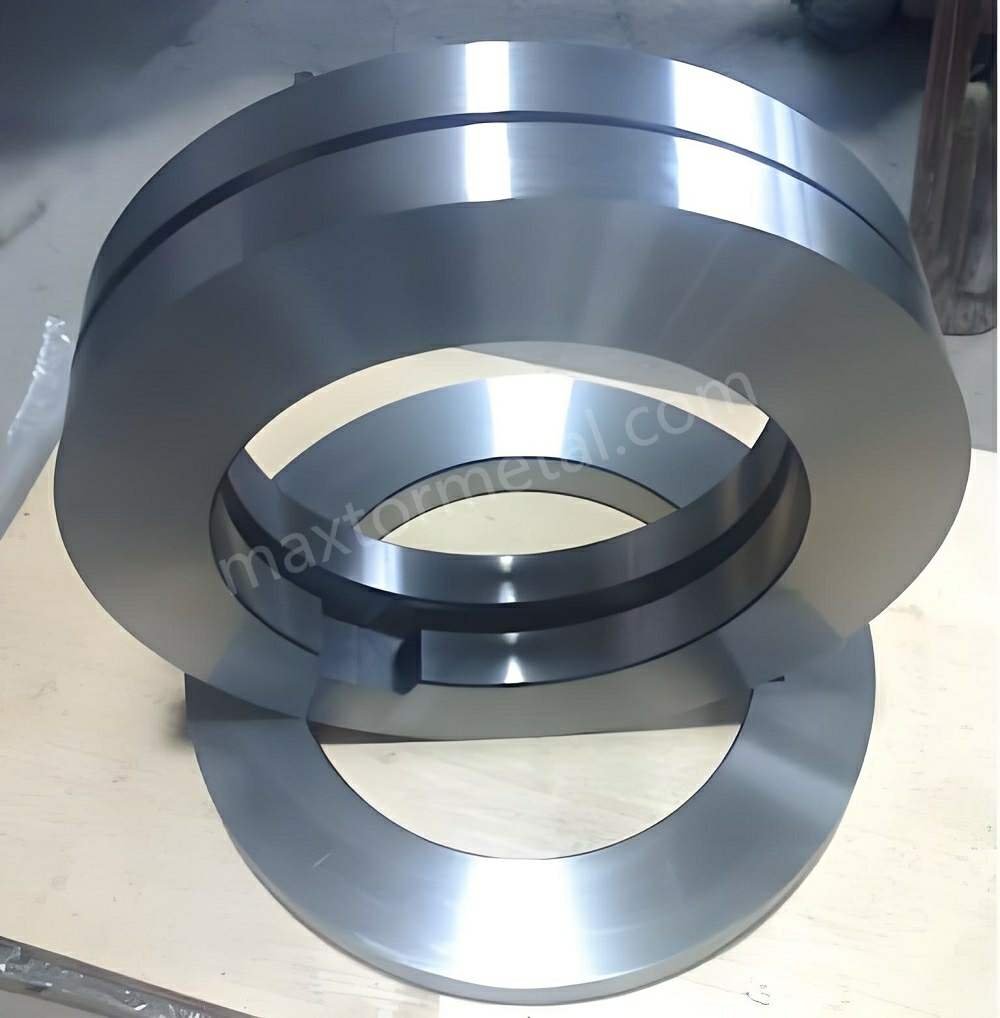

You need good tools to cut billets well. Bar shear blades with the right shape and material help you make clean cuts. They also help you waste less material. If you pick the right blade size and edge shape for your material, you get better results. Your blades will last longer too. Many workers have problems like bent steel, […]

شفرات القص الأصلية (OEM) مقابل خيارات ما بعد البيع: أيهما يقدم أفضل تكلفة إجمالية للملكية (TCO)؟

You want the best deal for your work. Picking OEM shear blades or aftermarket ones depends on your needs. It also depends on how much risk you can handle. It matters how important your job is. Total cost of ownership (TCO) means more than the price you pay. It also includes how long the blades last, the […]

إتقان القطع: الدور الحاسم لزاوية الانحدار (زاوية شطبة شفرة القص) في القص الصناعي

You will see that the rake angle is very important in industrial shearing. This angle changes how well you cut, how fast you work, and how long your blade lasts. The table below shows how different rake angles change shearing force and cut quality: Rake Angle Type Effect on Shearing Force Effect on Cut Quality […]

زيادة وقت التشغيل إلى أقصى حد: اختيار أفضل شفرات قص للخدمة الشاقة للمعادن الخردة ومعالجة الألواح السميكة

You want to keep machines working for a long time when cutting scrap metal and thick plates. Pick heavy duty shear blades that last long and have the right steel for your job. Match the blade material to the metal you cut. Find shear blades with new manufacturing and custom choices. Metal Industrial gives you these features. […]

شفرات القص الساخنة مقابل الباردة: الدليل الشامل لاختيار المواد وحدود درجة الحرارة

Imagine you choose the wrong blades for a job. The blades fail quickly because you did not match the material to the heat of the metal. You need to know the right blades for hot or cold metal. Metal changes when you cut it at high or low temperatures. The right blades make a big […]

دليل المشتري النهائي لشفرات القص الصناعية: 7 فحوصات جودة قبل الشراء

You should look at seven important things before buying industrial shear blades. These things are blade material, application match, manufacturing tolerances, edge design, equipment compatibility, supplier reputation, and total cost. If you do not check these, your machine may stop working. You could face safety problems and spend more money. Use the Buying guide for Industrial […]