يمكنك المساعدة في تمديد فترة إقامتك عمر شفرات المقصلة من خلال تبني عادات جيدة. باختيار شفرات عالية الجودة، مثل تلك التي من Nanjing Metal في المجال الصناعي، يمكنك القطع بكفاءة أكبر وتقليل عدد مرات تغيير الشفرات. راجع الجدول أدناه لمعرفة كيف يؤثر نوع مادة الشفرة على عمرها الافتراضي:

| نوع الشفرة | مقارنة العمر الافتراضي | تكوين المواد |

|---|---|---|

| كربيد التنغستن | 2-3 مرات أطول | التنجستن والكوبالت |

| شفرات فولاذية عالية السرعة قياسية | خط الأساس | الفولاذ عالي السرعة (HSS) |

يمكن لبعض التعديلات البسيطة في ممارساتك اليومية أن تُحسّن بشكل كبير من عمر شفرة المقصلة.

النقاط الرئيسية

- اختر شفرات جيدة، مثل شفرات كربيد التنجستن، لاستخدام أطول وقطع أفضل.

- لا تستخدم قوة مفرطة عند القطع؛ فقد يؤدي ذلك إلى كسر الشفرات أو تلفها بسرعة.

- تحقق من المواد بحثًا عن أي أجسام غريبة قبل القطع لمنع تلف الشفرة.

- حافظ على خلوص الشفرة المناسب لتقليل التآكل وإجراء عمليات قطع سلسة.

- نظف الشفرات وافحصها بانتظام لاكتشاف التآكل مبكراً ومنع الصدأ.

- قم بشحذ الشفرات قبل أن تصبح غير حادة للحفاظ على قدرتها على القطع بشكل جيد.

- قم بتخزين الشفرات بالطريقة الصحيحة في صناديق مبطنة أو ورق مشمع لمنع التلف.

- راقب كمية استخدامك للشفرات لتخطيط عمليات الاستبدال وتجنب فترات التوقف المفاجئة.

نصائح تشغيلية لإطالة عمر شفرة المقصلة

إذا كنت ترغب في أن تدوم شفرات المقصلة لفترة أطول، فإن عاداتك مهمة. إليك بعض النصائح البسيطة لمساعدتك على القطع بشكل أفضل والحفاظ على شفراتك حادة.

الاستخدام الصحيح للشفرة

تجنب استخدام القوة المفرطة

لا تُجهد جهازك أكثر من اللازم. فالضغط الزائد يُسرّع من تلف الشفرات. إذا واجهت صعوبة في القطع، توقف وافحص الشفرة. قد تحتاج إلى شفرة أخرى أو صيانة. الضغط على الشفرة بقوة قد يُسبب تشققات أو بقعًا باهتة أو حتى تلف الجهاز.

- الأخطاء التي تؤدي إلى تآكل شفرات المقصلة بشكل أسرع:

- قطع الأشياء السميكة أو الصلبة جدًا بالنسبة لشفرتك.

- استخدام منظفات خشنة تخدش الشفرة.

- عدم استخدام الزيت، مما يجعل الشفرة تسخن كثيراً.

إذا لم تعتني بشفرات الحلاقة، فقد تنكسر أو تتلف قبل الأوان. لذا، عليك فحصها وتنظيفها بانتظام. فهذا يساعد على الحفاظ على جودة الحلاقة وإطالة عمر الشفرات.

استخدم زوايا القطع المناسبة

طريقة ضبط شفرة المنشار مهمة للغاية. احرص دائمًا على استخدام الزاوية المناسبة للمادة التي تقطعها. هذا يضمن لك قطعًا نظيفًا ويُطيل عمر الشفرة. إذا كنت لا تعرف الزاوية المناسبة، فراجع دليل المستخدم أو استشر شخصًا خبيرًا.

كثير من الأشخاص الذين يستخدمون قواطع المقصلة لا يعرفون كيف يؤثر نوع أو شكل الشفرة على القطعأحيانًا، لا تعمل أداة القطع بكفاءة بسبب عدم حدة الشفرة. عند تركيب شفرة حادة، تعمل الآلة بشكل ممتاز. ينتظر معظم الناس حتى ظهور مشكلة قبل تغيير الشفرة.

مناولة المواد

فحص المواد

قبل البدء بالقص، تفحّص المواد جيدًا. تأكد من خلوها من أي عوائق مخفية كالدبابيس أو الشريط اللاصق أو المعادن، لأنها قد تُتلف الشفرة بسرعة. حتى جزيئات الغبار الصغيرة قد تُحدث خدوشًا أو بقعًا باهتة.

إزالة الأجسام الغريبة

احرص دائمًا على إزالة أي شيء لا ينتمي إلى مجموعة أدوات القطع. سيساعدك هذا على تجنب الإصلاحات المكلفة والحفاظ على أداء الشفرة بشكل جيد. كما ستحصل على قطع أكثر سلاسة ونتائج أفضل.

- افعل هذه الأشياء في كل مرة تقوم فيها بالقص:

- ابحث عن الدبابيس أو المشابك أو غيرها من الأشياء الصلبة.

- قم بإزالة الغبار والأوساخ بالفرشاة.

- تأكد من أن المادة مسطحة وناعمة.

إعداد الآلة

ضبط خلوص الشفرة

خلوص الشفرة هو المسافة بين الشفرة والطاولة. إذا كانت هذه المسافة كبيرة جدًا أو صغيرة جدًا، فسوف تتآكل الشفرة بسرعة أكبر. اضبط الخلوص وفقًا للمادة التي تقطعها. تحتوي العديد من الآلات على جداول تساعدك في ضبط المسافة المناسبة.

- طرق جيدة لإعداد جهازك:

- حافظ على فجوة الشفرة المناسبة لتقليل الإجهاد.

- تعلم كيفية استخدام مخططات تحديد الفجوات.

- افحص شفراتك بانتظام بحثًا عن أي تلف أو تآكل.

سطح عمل ثابت

تضمن الطاولة الثابتة استقامة القطع وحماية الشفرة. فإذا تحركت الطاولة أو اهتزت، قد تصطدم الشفرة بسطح غير مناسب، مما يؤدي إلى قطع غير متساوية وتلف الشفرة. تأكد من وضع جهازك على طاولة مستوية وصلبة قبل البدء.

إذا لم يتم ضبط جهازك بشكل صحيح، فقد تتحرك الشفرة من مكانها. هذا يجعل القطع غير دقيقة ويؤدي إلى تلف الشفرة بشكل أسرع، وقد تضطر إلى استبدالها بشكل متكرر.

نصيحة: خصص بضع دقائق كل أسبوع للتأكد من استقامة وثبات جهازك. هذه الخطوة البسيطة تساعد شفرات المقصلة على إطالة عمرها.

لماذا تُعدّ الهندسة الدقيقة مهمة؟

تستخدم شركة نانجينغ Metal الصناعية أساليب ذكية لتصنيع شفرات متينة. فهي تفحص شفراتها بدقة لضمان متانتها. وتُستخدم شفراتها في العديد من المجالات، مثل الطباعة والتغليف. وبفضل جودتها العالية، ستحصل على استخدام أطول لشفراتك.

| ميزة | فائدة لحياة الشفرات |

|---|---|

| التصنيع المتقدم | تبقى الشفرات حادة ومتساوية |

| مراقبة الجودة الصارمة | مشاكل أقل، استخدام أطول |

| التقنيات الحديثة (الطلاءات) | احتكاك أقل، ضرر أقل |

عندما تتبع عادات جيدة وتستخدم شفرات قوية، ستواجه مشاكل أقل وستحصل على نتائج أفضل. اعتني بشفراتك، وستساهم في ازدهار عملك.

صيانة شفرات المقصلة

تساعد العناية بشفرات المقصلة على إطالة عمرها. يمكنك تجنب المشاكل وتوفير المال باتباع روتين بسيط. إليك الخطوات التي يجب عليك اتباعها في كل مرة تستخدم فيها المقصلة.

التنظيف والتفتيش

نظف بعد الاستخدام

احرص دائمًا على تنظيف شفرة المنشار بعد الانتهاء من القطع. امسح الغبار والغراء وقطع المواد الصغيرة. إذا تركت الأوساخ أو الماء على الشفرة، فقد تصدأ أو تفقد حدتها. جفف الشفرة بقطعة قماش ناعمة. تجنب استخدام المواد الكيميائية القوية التي قد تضر بالمعدن.

نصيحة: تنظيف الشفرة مباشرة بعد استخدامها يمنع الصدأ ويحافظ على نعومة القطع.

افحص وجود أي تآكل

افحص شفرة المنشار قبل وبعد كل استخدام. تأكد من عدم وجود خدوش أو شقوق أو تغير في اللون. إذا لاحظت أي تلف، فقم بإصلاحه فورًا. فالمشاكل الصغيرة قد تتفاقم إذا تجاهلتها. يساعدك فحص الشفرة بانتظام على اكتشاف المشاكل قبل أن تصبح خطيرة.

إليك جدول يساعدك على تذكر ما يجب عليك التحقق منه:

| استراتيجية الصيانة | وصف |

|---|---|

| التنظيف المنتظم | جفف الشفرة بعد الاستخدام وتجنب ترك المواد التي يمكن أن تتسبب في تآكل المعدن. |

| فحص التآكل | افحص بانتظام بحثًا عن علامات تغير اللون أو الخدوش أو الشقوق لاكتشاف مؤشرات التآكل المبكرة. |

| تثبيت الشفرة بشكل صحيح | تأكد من تثبيت الشفرة بإحكام لمنع التآكل غير المتساوي والكسر. |

| الفحوصات الأسبوعية | افحص حدة ونظافة منطقة التركيب كل أسبوع. |

| إجراءات الصيانة الشهرية | قم بقياس سمك الشفرة ووازنها مرة واحدة شهرياً. |

جدول شحذ الشحذ

اشحذ قبل أن يصبح باهتًا

لا تنتظر حتى تصبح شفرة جهازك بالية تمامًا. شحذها مبكرًا يحافظ على جودة القطع ويحمي الجهاز. إذا لاحظت وجود نتوءات أو احتكاكًا في الشفرة، فقم بشحذها. الشفرة الحادة تمنحك قطعًا أفضل وتساعدها على البقاء لفترة أطول.

فترات شحذ المسار

دوّن مدة استخدامك للشفرة. تنص معظم الوظائف على شحذها بعد عدد محدد من الساعات أو القطع. على سبيل المثال، تدوم شفرات الفولاذ عالي السرعة في ورش المعادن حوالي من 50 إلى 100 ساعة قبل الشحذ. يمكن لشفرات الكربيد المخصصة للورق أن تقوم بما يصل إلى 100,000 عملية قطع. يساعدك تتبع هذه الأوقات على التخطيط وتجنب المفاجآت.

| صناعة | نوع الشفرة | ساعات القطع قبل التآكل الملحوظ |

|---|---|---|

| تصنيع Metal | الفولاذ عالي السرعة (HSS) | 50-100 ساعة |

| معالجة الأغذية | شفرات من الفولاذ المقاوم للصدأ | 100–150 ساعة |

| الورق والأفلام | سكاكين تقطيع الكربيد | 80,000–100,000 قطع |

| النجارة | رأس من كربيد التنجستن | 200–300 ساعة |

ملاحظة: إن شحذ الشفرة في الوقت المناسب يحافظ على عملها بشكل جيد ويمنع حدوث جروح سيئة أو مشاكل في الماكينة.

تشحيم

ضع مادة مزلقة (مثل الجلسرين)

تزييت الشفرة يجعل القطع أسهل وأكثر سلاسة. يمكنك استخدام الجلسرين أو زيوت أخرى آمنة للشفرات. يقلل المُزلِّق الاحتكاك، مما يجعل حركة الشفرة أسهل. مع كل قطع، يُستهلك بعض الزيت، لذا يُنصح بوضع المزيد منه باستمرار.

- يساعدك التزييت على:

- قم بإجراء المزيد من القطع قبل الشحذ.

- تقليل التآكل والاهتراء على الشفرة.

- قص أكثر سلاسة وسهولة.

منع الصدأ

يُمكن أن يُتلف الصدأ النصل بسرعة. يُساعد التشحيم المُنتظم على منع وصول الماء والصدأ إليه. إذا كنتَ تُخزّن النصل لفترة طويلة، فضع عليه طبقة رقيقة من الزيت. تُحافظ هذه الخطوة البسيطة على النصل في حالة جيدة وتُطيل عمره.

نصيحة: افحص شفرة القطع دائمًا بحثًا عن الصدأ قبل البدء بالقطع. إذا وجدت صدأً، فنظف الشفرة وقم بتزييتها على الفور.

اتباع جدول صيانة جيد يمنحك فوائد عديدة. فمعداتك تدوم لفترة أطول، وشفراتك حادة، وتعمل بأمان أكبر. كما أن العناية بشفراتك تُحسّن أداء شركتك وتزيد من ثقة عملائك.

| فائدة | وصف |

|---|---|

| عمر المعدات | الصيانة الدورية تجعل قاطعتك تدوم لفترة أطول وتقلل من أعطالها. |

| كفاءة الإنتاج | الشفرات الجيدة تضمن لك إنجاز عملك بسرعة وأمان. |

| جودة القطع | العناية المنتظمة تمنع ظهور النتوءات والجروح السيئة. |

| سلامة المشغل | فحص أجزاء السلامة يحافظ على سلامة الجميع. |

| القدرة التنافسية للشركة | الرعاية الجيدة تدل على رغبتك في الجودة، ويمكن للناس الاعتماد عليك. |

إذا اتبعت هذه الخطوات، سيتحسن عمر شفرة المقصلة لديك. ستقضي وقتًا أقل في إصلاح الأعطال ووقتًا أطول في إجراء عمليات قطع ممتازة.

تركيب الشفرة

تركيب شفرة المقصلة بالطريقة الصحيحة يُحدث فرقًا كبيرًا في عمرها الافتراضي. فإذا أغفلت بعض الخطوات أو استعجلت، فقد ينتهي بك الأمر بشفرة تتلف بسرعة أو تُسبب قطعًا غير متساوية. دعونا نلقي نظرة على أمرين مهمين يجب عليك فعلهما دائمًا عند تركيب شفرة المقصلة.

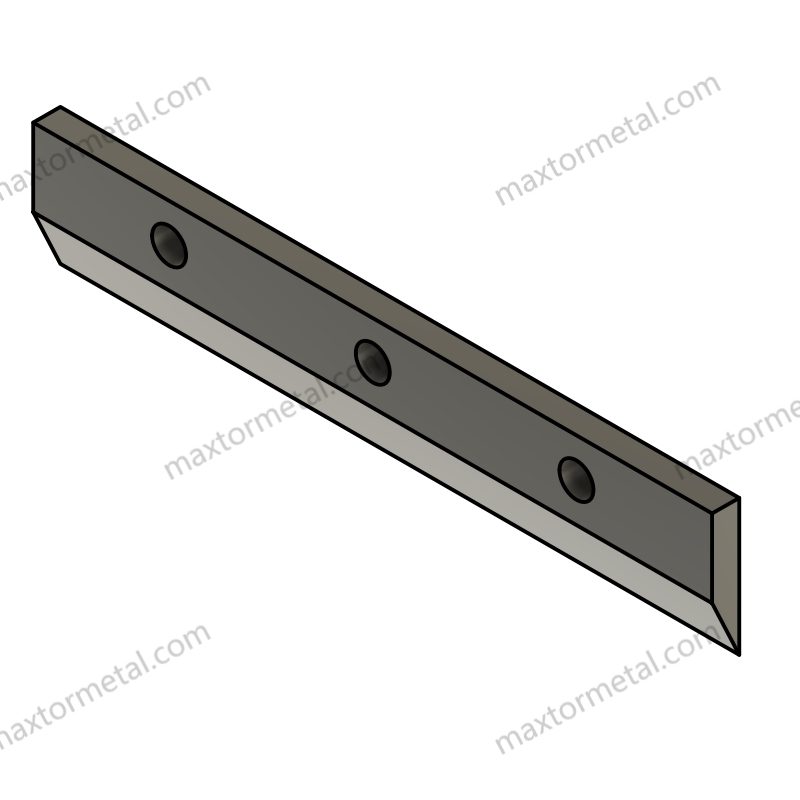

استخدم فتحات تثبيت مصممة هندسيًا

فتحات التثبيت المصممة هندسيًا ليست مجرد زينة. فهي تساعدك على محاذاة شفرة المقصلة بدقة في المكان المطلوب. باستخدام الفتحات الصحيحة، تحافظ على ثبات الشفرة وأمانها. أما إذا تجاهلتها أو استخدمت فتحات خاطئة، فقد تتحرك الشفرة أو تهتز أثناء القطع.

- لماذا تُعدّ فتحات التثبيت المصممة هندسيًا مهمة؟

- إنها تحافظ على شفرة المقصلة في الوضع الصحيح.

- فهي تساعدك على تجنب الضغط غير المتساوي على الشفرة.

- فهي تسهل عملية تركيب وإزالة الشفرة دون إتلافها.

نصيحة: راجع دليل استخدام جهازك دائمًا قبل تركيب شفرة المقصلة الجديدة. سيوضح لك الدليل الثقوب المناسبة لشفرة المقصلة الخاصة بك.

إليك جدول سريع لمساعدتك على تذكر ما الذي تبحث عنه:

| ميزة التثبيت | ماذا يفعل | لماذا هذا مهم |

|---|---|---|

| فتحات تثبيت مصممة هندسيًا | محاذاة الشفرة بشكل مثالي | يمنع الانزلاق والتلف |

| إحكام ربط البراغي بشكل صحيح | يمسك النصل بإحكام | يوقف الاهتزاز والارتخاء |

| تنظيف سطح التركيب | يحافظ على الشفرة مسطحة على الآلة | يتجنب التآكل غير المتساوي |

توزيع قوى القطع

تريد أن تقطع شفرة المقصلة بسلاسة في كل مرة. ولتحقيق ذلك، عليك توزيع قوة القطع على كامل الشفرة. إذا ركزت كل الضغط على نقطة واحدة، فسوف تتآكل تلك المنطقة بسرعة وقد تتشقق.

- كيف يمكنك توزيع قوى القطع؟

- قم بربط جميع البراغي بالتساوي عند تركيب الشفرة.

- تأكد من أن الشفرة مثبتة بشكل مسطح على سطح التثبيت.

- استخدم جميع فتحات التثبيت المتوفرة، وليس عددًا قليلاً منها فقط.

ملاحظة: إذا سمعت أصواتًا غريبة أو لاحظت قطعًا غير متساوية، فتوقف وتحقق من تثبيت الشفرة. قد تحتاج إلى ضبط البراغي أو تنظيف منطقة التثبيت.

إليك بعض الخطوات السريعة لمساعدتك على القيام بذلك بشكل صحيح:

- ضع شفرة المقصلة على سطح التثبيت.

- أدخل جميع البراغي من خلال الفتحات المصممة هندسيًا.

- قم بربط كل مسمار قليلاً في كل مرة، مع التحرك بنمط متقاطع.

- تأكد من أن الشفرة مستوية ولا تتحرك.

- اختبر المنتج بقطعة صغيرة قبل البدء في عملك الرئيسي.

عند تركيب شفرة المقصلة بعناية، فإنك تساعدها على البقاء لفترة أطول وتقطع بشكل أفضل. كما تحافظ على سلامة جهازك وعلى دقة عملك. خذ وقتك في هذه الخطوة، وستشكرك شفرة المقصلة على ذلك بقطع سلسة ونظيفة.

التخزين والتحكم البيئي

ترغب في أن تدوم شفرات المقصلة لديك لفترة طويلة. لذا، فإن تخزينها بالطريقة الصحيحة لا يقل أهمية عن استخدامها وتنظيفها. إليك بعض الطرق السهلة لحماية شفراتك من التلف والصدأ.

التخزين السليم

استخدم الأغطية الواقية

احرص دائمًا على تغطية شفرات المقصلة قبل تخزينها. تحمي الأغطية الحواف الحادة من الصدمات والخدوش. يمكنك لف الشفرات بورق مزيت أو استخدام حافظات خاصة بها. يحمي الورق المزيت الشفرات من الماء ويمنع الصدأ. إذا كنت بحاجة إلى تخزين الشفرات لفترة طويلة، فإن الأكياس المفرغة من الهواء تُعدّ خيارًا مناسبًا.

نصيحة: ارتدِ قفازات عند لمس الشفرات. فهذا يمنع بصمات الأصابع والزيوت من الوصول إلى المعدن ويساعد على منع الصدأ.

تجنب تكديس الشفرات

قد يؤدي تكديس الشفرات إلى تشققها أو انحنائها. خصص لكل شفرة مكانًا خاصًا بها. استخدم صناديق أو رفوفًا مبطنة لحفظ الشفرات متباعدة. إذا قمت بتكديس الشفرات، فقد تحتك حوافها وتتلف بسرعة.

إليك قائمة سريعة للتحقق من التخزين الآمن: ١. لف كل شفرة بورق مزيت أو استخدم غطاءً. ٢. ضع الشفرات في صناديق مبطنة. ٣. خزّن الشفرات بشكل مسطح، وليس فوق بعضها. ٤. أبقِ الشفرات بعيدة عن المعادن الأخرى.

العوامل البيئية

التحكم في درجة الحرارة والرطوبة

تؤثر درجة الحرارة والرطوبة على عمر شفراتك. الرطوبة العالية تُسبب الصدأ، والتغيرات الكبيرة في درجة الحرارة قد تُسبب تشقق المعدن. حافظ على درجة حرارة غرفة التخزين بين 20 و22 درجة مئوية (68 و72 درجة فهرنهايت). يجب ألا تتجاوز الرطوبة 50%. تُساعد أكياس جل السيليكا في الحفاظ على جفاف الخزائن.

- الحفاظ على درجة حرارة ثابتة يُقوّي الشفرات. – الرطوبة المنخفضة تمنع الصدأ. – أكياس جل السيليكا تمتص الماء الزائد.

ملاحظة: إذا رأيت قطرات ماء أو شعرت برطوبة في غرفة التخزين الخاصة بك، فأضف المزيد من أكياس المجفف وتحقق من أجهزة التحكم في المناخ.

يُحفظ في أماكن آمنة

اختر مكانًا آمنًا لشفرات المقصلة. تجنب وضعها بالقرب من النوافذ أو أجهزة التدفئة أو الماء. يُفضل استخدام الخزائن المزودة بنظام تحكم في الرطوبة. لا تضع الشفرات أبدًا على الأرض أو تحت أشعة الشمس المباشرة. احفظها بعيدًا عن الممرات المزدحمة حتى لا تسقط.

إليكم جدول يوضح كيف تحافظ شركة نانجينغ Metal الصناعية على سلامة الشفرات أثناء التخزين والشحن من خلال نظام مراقبة الجودة الخاص بها:

| مقياس مراقبة الجودة | وصف |

|---|---|

| شهادات الأيزو | يلتزم بقواعد صارمة تتعلق بالسلامة والقوة. |

| اختبارات صارمة | يفحص كل شفرة للتأكد من قوتها وحدتها. |

| توصيات التخزين | ينصح باستخدام غرف جافة ذات رطوبة مضبوطة للتخزين. |

| احتياطات التعامل | ينصحك باستخدام القفازات والأغطية لمنع حدوث الضرر. |

| إرشادات النقل | يستخدم صناديق مبطنة لمنع الحركة ومشاكل التكديس. |

باتباع هذه الخطوات، ستبقى شفرات المقصلة حادة وقوية. التخزين الجيد يعني مشاكل أقل وعمرًا أطول للشفرات.

يساعدك حفظ شفرات المقصلة في مكانها الصحيح، مع توفير الحماية اللازمة لها، على استخدام كل شفرة لفترة طويلة. بذلك توفر المال، وتتجنب المشاكل، وتحافظ على دقة القطع.

اختيار شفرات عالية الجودة

إذا أردتَ أن يدوم نصل المقصلة طويلًا، فابدأ بنصل جيد. فليست كل الأنصال تُصنع بنفس الطريقة. فالمادة والشكل اللذان تختارهما يُؤثران على عدد مرات شحذ النصل أو استبداله. دعونا نرى ما هو الأهم.

اختيار المواد

فولاذ الأدوات والفولاذ عالي السرعة

تُصنع بعض الشفرات من فولاذ الأدوات أو الفولاذ عالي السرعة (HSS). وهي شائعة الاستخدام لكفاءتها العالية. يوفر فولاذ الأدوات حافة قوية للعديد من المهام، بينما يُعد الفولاذ عالي السرعة أفضل، فهو لا يتآكل بسرعة ويحافظ على صلابته عند ارتفاع درجة حرارته، مما يعني أن شفرة المقصلة ستبقى حادة لفترة أطول، ولن تحتاج إلى شحذها كثيرًا.

إذا استخدمتَ فولاذًا عالي السرعة أو فولاذ الأدوات، فستتمكن من إنجاز المهام الشاقة. تساعد هذه المادة شفرتك على مقاومة التآكل والحرارة والصدمات. ستلاحظ أنك لست بحاجة إلى تغيير شفرتك أو شحذها كثيرًا، مما يوفر لك الوقت والمال على المدى الطويل.

كربيد التنغستن

إذا كنت ترغب في شفرة تدوم طويلاً، فجرب شفرة كربيد التنجستن. تحافظ شفرات كربيد التنجستن على حدتها لفترة أطول بكثير من شفرات الفولاذ. فهي تتحمل الحرارة والمواد الصلبة دون أن تفقد حدتها. ستحصل على قطع أكثر سلاسة واحتكاك أقل، مما يجعل شفرة المقصلة تعمل بكفاءة أكبر لفترة أطول.

إليكم جدولًا سريعًا يوضح كيف يختلف كربيد التنجستن عن الفولاذ:

| ميزة | شفرات كربيد التنجستن | شفرات فولاذية تقليدية |

|---|---|---|

| متانة | يبقى صلباً حتى في درجات الحرارة العالية | يتلف بشكل أسرع تحت تأثير الحرارة |

| طول العمر | يدوم لفترة أطول، مما يقلل من وتيرة الاستبدال | يحتاج إلى استبدال أكثر تكرارًا |

| دقة | يوفر قطعًا نظيفة ودقيقة مع احتكاك أقل | قد ينتج عن ذلك قطع أكثر خشونة |

| فعالية التكلفة | أكثر فعالية من حيث التكلفة على المدى الطويل نظراً لطول عمرها | تكلفة أولية أقل ولكن تكاليف طويلة الأجل أعلى |

| براعه | متوفر لأنواع مختلفة من المناشير | يقتصر على تطبيقات محددة |

قد تدفع مبلغًا أكبر في البداية مقابل شفرة مقصلة من كربيد التنجستن، لكنك ستوفر المال لاحقًا لأنك لن تحتاج إلى شراء شفرات جديدة كثيرًا. كما ستحصل على قطع أفضل في كل مرة.

التخصيص وتصنيع المعدات الأصلية

ملفات تعريف الحافة

تختلف كل مهمة عن الأخرى. أحيانًا تحتاج إلى حافة مستقيمة، وأحيانًا أخرى تحتاج إلى شفرة مائلة أو مشقوقة. تساعدك أشكال الحواف المخصصة على الحصول على أفضل قطع لمهمتك. عند اختيار شفرة مقصلة مخصصة، يمكنك مطابقتها مع المادة التي تستخدمها واحتياجاتك.

تُعدّ ملامح الحواف المخصصة مناسبة لما يلي:

- عبوات خاصة بأشكال مختلفة

- تقطيع وفصل الأفلام أو الأقمشة

- معالجة الأغذية حيث تُعدّ الملمس مهمة

- صنع الأدوات الطبية وفق قواعد صارمة

- قص القماش أو الجلد أو المواد الخاصة

- قطع غيار السيارات والطائرات ذات الأشكال الخاصة

- إلكترونيات لإجراء عمليات قطع صغيرة ودقيقة

- إعادة التدوير والنفايات للمواد الصلبة

يمكنك أيضاً اختيار شفرات مصممة خصيصاً للطعام، أو الأفلام، أو المطاط، أو البلاستيك، أو الورق، أو الكرتون. كل حافة مصممة خصيصاً تساعدك على الحصول على قطع أنظف وتقليل الهدر.

نصيحة: إذا كنت ترغب في رؤية خيارات مخصصة، فتحقق من صفحة الشفرة المخصصة.

شفرات خاصة بالتطبيقات

يمكنك إنجاز العمل بسرعة أكبر وبتكلفة أقل باختيار شفرات مصممة خصيصًا لعملك. هذه الشفرات مصممة خصيصًا لآلتك وطبيعة عملك، فهي تقطع بشكل أفضل، وتقلل الهدر، وتساعد آلاتك على العمل بكفاءة عالية. عند استخدام شفرة مصممة خصيصًا لعملك، لن تحتاج إلى شراء شفرات جديدة أو صيانة آلتك بشكل متكرر.

تستخدم الشفرات المصممة خصيصًا لتطبيقات محددة تصاميم ذكية لتلبية معايير دقيقة، مما يضمن لك قطعًا دقيقة في كل مرة، بالإضافة إلى استهلاك أقل للطاقة وإنجاز العمل بسرعة أكبر. ومع مرور الوقت، يُسهم ذلك في توفير المال وتحسين أداء أعمالك.

تُوفر شركة نانجينغ Metal الصناعية مجموعة واسعة من شفرات المقصلة لمختلف الآلات والمهام. ستجد شفرات بأحجام ومواد متنوعة، مثل الفولاذ عالي السرعة، وفولاذ الأدوات، وكربيد التنجستن. إليك جدولًا مختصرًا ببعض الخيارات:

| نوع المنتج | الحجم (مم) | مادة | السعر (بالدولار الأمريكي) | الحد الأدنى للطلب |

|---|---|---|---|---|

| شفرة آلة القص | 3100×70×20 | HSS أو LD | 3-60/قطعة | قطعة واحدة |

| شفرات صناعية | 600×80×30 | فُولاَذ | 3-60/قطعة | قطعة واحدة |

يمكنك شراء شفرة واحدة فقط أو عدة شفرات.

ملاحظة: اختيار شفرة المقصلة المناسبة لعملك يعني مشاكل أقل، وانتظار أقل، وقطع أفضل في كل مرة.

عند اختيار مواد جيدة وشكل مناسب، يدوم نصل المقصلة لفترة أطول ويعمل بكفاءة أعلى. تتيح لك الشفرات المصممة حسب الطلب الحصول على ما تحتاجه بالضبط. خذ وقتك في الاختيار، وستعمل شفراتك بكفاءة لسنوات.

ممارسات متقدمة لإطالة عمر الشفرات

تريد أن تدوم شفرة المقصلة لديك لفترة طويلة. العناية الأساسية مفيدة، لكن الخطوات المتقدمة أكثر فائدة. دعونا نرى كيف يمكنك الحفاظ على شفراتك تعمل بشكل جيد.

فحوصات المحاذاة

التحقق من التوازي

يُعدّ ضبط محاذاة الشفرة أمرًا بالغ الأهمية في كل عملية قطع. إذا لم تكن شفرة المقصلة مستقيمة مع الطاولة أو المقياس الخلفي، فلن تكون القطع متساوية، وقد تظهر حواف خشنة أو نتوءات. يحدث هذا غالبًا عند تركيب الجهاز بشكل خاطئ أو عند تلف بعض الأجزاء. لذا، يُنصح بفحص الشفرة والمقياس الخلفي ومثبتات القطع بانتظام.

- إذا لم تكن الشفرة محاذية، فستحصل على حواف خشنة.

- المحاذاة الجيدة تمنحك قطعًا مستقيمة ونظيفة.

- توقف التآكل السريع وتحافظ على سلامة جهازك.

يمكنك استخدام مسطرة مستقيمة أو مقياس سماكة للتأكد من استقامة النصل. إذا لاحظت وجود فجوات أو مناطق غير مستوية، فستحتاج إلى إصلاح النصل.

اضبط حسب الحاجة

عند اكتشاف أي مشكلة، قم بإصلاحها فورًا. قم بفك البراغي، وحرك الشفرة، ثم أعد ربطها بالتساوي. استعن دائمًا بدليل استخدام جهازك لمعرفة أفضل طريقة للقيام بذلك. إذا لم تقم بإصلاح الشفرة، فقد تتلف الشفرة والقطاعة معًا.

نصيحة: افحص محاذاة شفرة شفرتك أسبوعياً. فالإصلاحات البسيطة الآن قد تمنع مشاكل كبيرة لاحقاً.

الاستبدال في الوقت المناسب

التعرف على علامات نهاية الحياة

تتلف جميع شفرات المقصلة مع مرور الوقت. عليك أن تعرف متى تحتاج إلى استبدالها. ابحث عن هذه العلامات:

- شقوق أو كسور على الحافة

- بقع باهتة لا يُصلحها الشحذ

- قطع غير متساوية، حتى بعد إصلاح الشفرة

- الكثير من النتوءات أو الحواف الخشنة

إذا لاحظت هذه العلامات، فهذا يعني أن شفرة جهازك بالية. استخدام شفرة قديمة قد يتسبب في تلف جهازك وإفساد عملك.

استبدال الجدول الزمني

لا تنتظر حتى تنكسر شفرة شفرتك أثناء العمل الشاق. خطط مسبقًا. دوّن عدد ساعات أو عدد مرات استخدام كل شفرة. ضع خطة لتغيير الشفرات بناءً على مدى استخدامك لها. إذا كنت تستخدمها يوميًا، فقد تحتاج إلى شفرة جديدة كل بضعة أشهر. أما إذا كنت تستخدمها بشكل أقل، فستدوم الشفرات لفترة أطول.

يمكنك استخدام دفتر ملاحظات أو جهاز كمبيوتر لتتبع عمر الشفرة. هذا يساعدك على تجنب المفاجآت ويضمن استمرار عملك.

ملاحظة: تغيير الشفرات في الوقت المناسب يحافظ على حدة القطع ويحمي جهازك. كما أنه يساعدك على إدارة أموالك بشكل جيد.

المورد والضمان

اختر موردين ذوي سمعة طيبة

يُعدّ اختيار مورد جيد أمرًا بالغ الأهمية. فأنت ترغب في شفرات تلبي احتياجاتك وتدوم طويلًا. ابحث عن موردين يصنعون شفرات حسب الطلب، ويضيفون ميزات أمان، ويستخدمون مواد متينة. الخبرة مهمة أيضًا، فالموردون ذوو الخبرة الواسعة يعرفون كيفية صنع شفرات جيدة.

إليك جدول لمساعدتك في مقارنة الموردين:

| معايير | وصف |

|---|---|

| حلول مخصصة | شفرات مصممة خصيصًا لمهامك الخاصة |

| ميزات السلامة | شفرات مصممة لمنع الحوادث |

| جودة المواد | مواد متينة لشفرات أفضل |

| خبرة | سنوات عديدة في صناعة الشفرات |

| فعالية التكلفة | شفرات توفر لك المال وتعمل بشكل جيد |

ينبغي عليك أيضاً التفكير في كمية القطع التي تقوم بها، وعدد مرات استخدامك للمقصلة، ومدى دقة القطع المطلوبة. واحرص على مطابقة هذه الاحتياجات مع ما يقدمه لك المورد.

- إذا كنت تقطع كثيراً، فأنت بحاجة إلى شفرات قوية.

- إذا كنت تستخدم قاطعتك بشكل متكرر، فاختر موردًا موثوقًا به.

- إذا كنت بحاجة إلى قطع مثالية، فاحصل على شفرات مصنوعة خصيصًا للدقة.

فهم شروط الضمان

الضمان يحمي أموالك. تختلف الضمانات من شركة لأخرى؛ فبعضها يغطي قطع الغيار لفترة طويلة، بينما يغطي البعض الآخر العيوب فقط. لذا، يُنصح بقراءة الشروط والأحكام قبل الشراء.

| الشركة المصنعة | تغطية الضمان | تفاصيل الدعم |

|---|---|---|

| الصناعة القياسية | ضمان لمدة 5 سنوات على قطع الغيار، وضمان لمدة سنتين على وحدات التحكم CNC | زيارات فنية مجانية للمساعدة خلال فترة الضمان. |

| داهل | ضمان مدى الحياة للعيوب (لا يشمل شفرات القطع) | الضمان مخصص للمالك الأول ولا يغطي سوء الاستخدام. |

- تقوم شركة ستاندرد إندستريال بإرسال فني مجاناً خلال فترة الضمان.

- تقدم شركة داهل ضمانًا مدى الحياة للعيوب، ولكن ليس للشفرات أو سوء الاستخدام.

تحقق دائمًا من بنود الضمان. هل يشمل المساعدة من فني؟ هل يغطي التلف الناتج عن الاستخدام أم العيوب فقط؟ معرفة ذلك يساعدك في الحصول على المساعدة عند الحاجة.

نصيحة: احتفظ بأوراق الضمان ورقم هاتف المورّد في مكان آمن. في حال واجهتك مشكلة، يمكنك الحصول على المساعدة بسرعة.

باتباع هذه الخطوات المتقدمة، ستعمل شفرة المقصلة بكفاءة عالية لفترة طويلة. ستحصل على قطع أفضل، وتوفر المال، وتتجنب المشاكل. يُسهم ضبط الشفرات بشكل صحيح، وتغييرها في الوقت المناسب، واختيار المورد المناسب، في إطالة عمر شفرات المقصلة.

يمكنك إطالة عمر شفرات المقصلة باتباع عادات صحية يومية. فعند تنظيف الشفرات وفحصها وتخزينها بالطريقة الصحيحة، تقلل التكاليف وتتجنب توقف العمل. اختيار شفرات عالية الجودة وقابلة للتخصيص يضمن لك قطعًا حادة وجهدًا أقل. وقد حققت العديد من الشركات وفورات كبيرة ونتائج أفضل بالتحول إلى خيارات متينة. إذا كنت ترغب في الحصول على نصيحة أو حل مخصص، فتواصل مع مهندس مبيعات. هنا.

التعليمات

كم مرة يجب عليك شحذ شفرة المقصلة؟

اشحذ شفرة المقصلة قبل أن تفقد حدتها. يُنصح بشحذها بعد 50 إلى 70 ساعة من الاستخدام أو عند ظهور نتوءات. يساعدك تتبع مدة استخدام الشفرة على معرفة الوقت المناسب لشحذها.

ما هي المواد التي يمكن لشفرة المقصلة قطعها؟

يمكن لشفرة المقصلة قطع الورق والكرتون والبلاستيك والمعادن الرقيقة. تأكد دائمًا من نوع الشفرة والآلة التي لديك للحصول على أفضل النتائج.

لماذا تصبح شفرة المقصلة غير حادة بسرعة؟

تصبح شفرة المقصلة غير حادة بسرعة إذا ضغطت عليها بشدة، أو قطعت بها أشياء متسخة، أو نسيت تنظيفها. لذا، افحص شفرتك ونظفها بانتظام لتجنب أي مشاكل.

كيف يتم تخزين شفرات المقصلة بأمان؟

ضع كل شفرة مقصلة في صندوق مبطن أو لفها بورق مزيت. حافظ على الشفرات جافة وبعيدة عن الهواء الرطب. استخدم أغطية لحماية الحواف الحادة.

ما هي العلامات التي تدل على أن شفرة المقصلة تحتاج إلى استبدال؟

ابحث عن الشقوق أو الكسور أو المناطق الباهتة التي لا يُجدي معها الشحذ. إذا كانت القطع غير متساوية أو خشنة، فعليك استبدال شفرة المقصلة قريبًا.

هل يمكن استخدام شفرة المقصلة نفسها لمواد مختلفة؟

بعض شفرات المقصلة قادرة على قطع أشياء كثيرة، لكن الشفرات الخاصة أفضل للأعمال الشاقة. تأكد من مادة الشفرة وشكل حافتها قبل استبدالها.

كيف تمنع الصدأ على نصل المقصلة؟

ضع طبقة رقيقة من الزيت على نصل المقصلة بعد تنظيفها. خزّنها في مكان جاف. استخدم أكياس السيليكا جل لحمايتها من الماء.

انظر أيضا

تحقيق قطع خالٍ من الشوائب باستخدام شفرات مقصلة القص الدقيقة

شفرات المقصلة مقابل شفرات القص: ما الفرق بينهما وأيهما الأفضل لعملك؟

كيفية اختيار شفرة المقصلة المناسبة لاحتياجاتك

الدليل الشامل لصيانة شفرات القطع المقصلة: إطالة عمرها وتحسين أدائها

الاختيار بين مقصات المقصلة ومقصات الشعاع المتأرجح: تحليل مقارن شامل