كربيد مطلي بـ PVD blades last twice as long. They resist wearing out, have less friction, and stay stable in heat. Many industries use them, like packaging, FPCB, chemical fiber, textiles, food slicing, metal slitting, metalworking, and automotive. TiAlN coatings make tools last over 100% longer than tools without coatings. Many companies, from aerospace to automotive, say their blades last longer and work better with these coatings. Nanjig Metal Industrial sells tungsten carbide blades that help you get these great results.

النقاط الرئيسية

- PVD coated carbide blades last two times longer than uncoated blades. This helps you save time and money.

- These blades fight against wear and friction. This helps them stay sharp and work well during hard jobs.

- PVD coatings work as a heat shield. They keep blades cool and stop damage from heat.

- Different PVD coatings, like TiAlN and CrN, give special benefits for different cutting jobs.

- Using PVD coated blades means you change blades less often. This lets you work longer without stopping.

- PVD coatings help blades keep their sharp edge. Blades stay sharp for a long time, even after many uses.

- Buying PVD coated blades can save you a lot of money over time because they last longer.

- Taking care of your blades and picking the right coating for your job can help your cutting tools last longer.

PVD Coating on Carbide Blades

What Is PVD?

PVD means physical vapor deposition. This process puts a thin, hard layer on carbide blades. The blade goes inside a vacuum chamber. A metal turns into vapor and covers the blade. This makes a strong and even coating. PVD uses lower heat than other ways. This helps the blade stay strong and stable.

Here is a table that shows how PVD and CVD are different:

| ميزة | PVD Advantages | CVD Characteristics |

|---|---|---|

| صلابة | Makes the blade much harder | Depends on what materials are used |

| ارتداء المقاومة | Great at stopping wear and lowering friction | Good at stopping wear, but can change |

| Adhesion | Sticks very well to the blade | Sticks well, but can change |

| Processing Temperature | Uses low heat (250 °C – 450 °C) | Needs higher heat |

| التأثير البيئي | Usually safe for the environment | Can make harmful waste |

| التخصيص | Coatings can be changed easily | Not many ways to change coatings |

| التطبيقات | Used in many industries | Used in some special jobs |

PVD coatings help blades last longer and stay sharp. They also help the environment because they use less energy and make less waste.

How PVD Bonds to Carbide

PVD sticks the coating to the carbide blade at the atomic level. This strong bond keeps the coating from coming off, even during hard work. Scientists found that tiny textures on the blade help the coating stick better. Special treatments like plasma-assisted laser machining make the bond even stronger.

“Tiny textures on the blade help PVD coatings stick better. Making the bond stronger between the coating and blade gives better wear and longer tool life.”

Blades with a strong PVD bond keep their edge and do not break easily. You change blades less often and get steady results.

Types of PVD Coatings

TiN, TiAlN, CrN

There are different kinds of PVD coatings for carbide blades. Each kind has its own good points:

- Titanium Nitride (TiN): Gold color, keeps edge sharp.

- Titanium Carbon Nitride (TiCN): Low friction, good for many cuts.

- Titanium Aluminum Nitride (TiAlN): Very strong, resists heat.

- Zirconium Nitride (ZrN): Very hard, gray color.

- Chromium Nitride (CrN): Stops rust, tough.

- Aluminum Titanium Nitride (AlTiN): Works well in high heat.

For example, TiN keeps the blade sharp for a long time. TiAlN works well when cutting hot things. CrN helps the blade not stick or rust.

Coating Thickness

PVD coatings are very thin, about 2 to 5 micrometers. This thin layer does not change the blade’s shape or sharpness. It adds a hard shell for protection. The thinness lets the blade stay exact and get stronger and last longer.

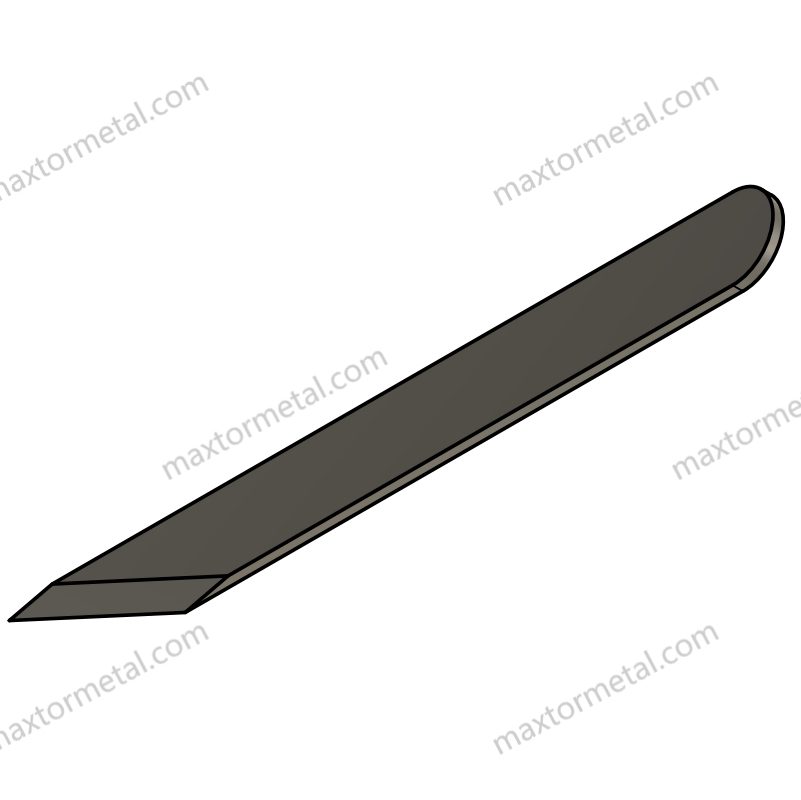

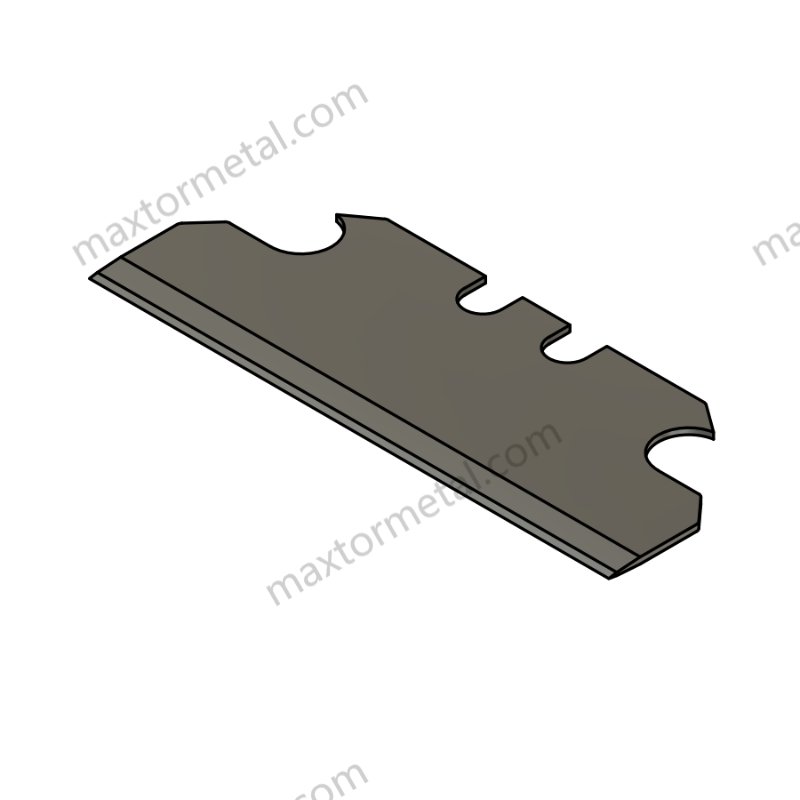

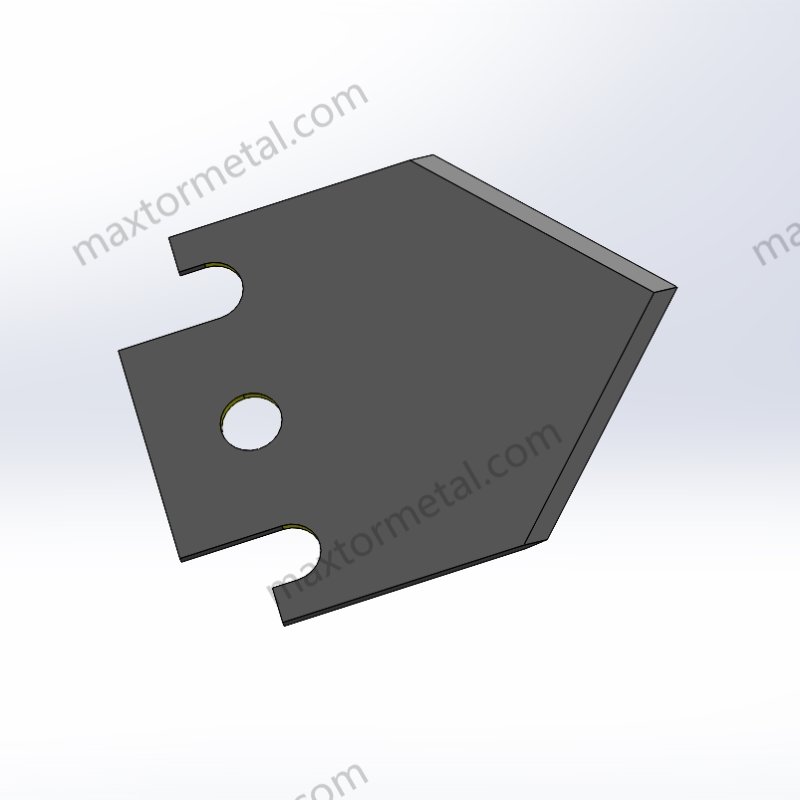

PVD Technology at Nanjing Metal Industrial

نانجينغ Metal الصناعية uses advanced PVD technology for their tungsten carbide blades. Their process lowers friction, keeps blades sharp, and makes blades last longer. Their PVD coatings give smoother cuts and better edge protection than others. You get blades that last longer and work better for hard jobs.

PVD coated carbide blades help you cut faster and stop downtime. You can trust these blades for packaging, metalworking, and many other jobs.

How PVD Doubles Tool Life

ارتداء المقاومة

You want your cutting blade to last as long as possible. Wear resistance is the key. When you use pvd coated carbide, you get a blade that stands up to tough jobs. The coating forms a shield on the blade. This shield fights off scratches and keeps the blade from wearing down fast.

Surface Hardness

Surface hardness tells you how tough the outside of your blade is. Hard coatings like TiN, CrN, and AlTiN make the blade much harder. When you use these coatings, you get a blade that can cut longer without losing its edge. The table below shows how different treatments change the hardness and wear rate:

| المعالجة السطحية | Hardness (HV0.01) | Wear Coefficient (K mm³/Nm) |

|---|---|---|

| PVD Only | 2938 | 1.47 × 10⁻¹⁰ |

| Hardened + PVD | 2679 | 6.32 × 10⁻⁹ |

You can see that pvd only gives the highest surface hardness and the lowest wear rate. This means your tool life increases. You spend less time changing blades and more time machining.

تقليل الاحتكاك

Friction makes your blade heat up and wear out. When you lower friction, you help your blade last longer. PVD coatings like CrN and AlTiN make the blade surface smoother. This smooth surface lets the blade slide through material with less effort.

Lower Coefficient of Friction

The coefficient of friction measures how easily things slide past each other. A lower number means less rubbing and less heat. Here are some facts about friction and pvd coatings:

- CrN coatings have a much lower coefficient of friction than uncoated blades, especially at high temperatures.

- CrN forms a special layer called Cr₂O₃ during cutting. This layer acts like a shield and keeps the chip from sticking to the blade.

- Less friction means less built-up edge and less crater wear.

When you use a blade with a low coefficient of friction, you get smoother cuts and longer cutting tool life.

الاستقرار الحراري

High-speed cutting makes blades hot. If your blade cannot handle the heat, it will lose its edge fast. PVD coatings help your blade stay strong, even when things get hot.

High-Temperature Performance

PVD coatings act like a thermal barrier. They keep heat away from the blade. This helps the blade stay sharp and not break down. The table below shows how pvd coatings improve thermal stability:

| وصف الأدلة | Key Points |

|---|---|

| Reduction of friction and heat | PVD coatings lower friction, so less heat builds up during cutting. |

| Thermal barrier effect | The coating blocks heat from reaching the blade, keeping it cooler. |

| مقاومة معززة للتآكل | PVD coatings stop edge chipping and microfracture, even at high speeds. |

When you use a blade with good thermal stability, you can cut faster and longer. Your tool life goes up, and you get better results every time.

Tip: Choose coatings with strong coating adhesion for the best performance in high-heat jobs.

PVD coated carbide blades give you the edge you need for tough machining jobs. You get better wear resistance, lower friction, and strong thermal stability. This means your cutting blade stays sharp and lasts longer, even in the hardest conditions.

الاحتفاظ بالحافة

Sharpness Over Time

You want your cutting blade to stay sharp for as long as possible. Edge retention means how well your blade keeps its sharpness after many uses. When you use a pvd coated carbide blade, you get a tool that holds its edge much longer than uncoated blades. The coating acts like a shield, protecting the edge from wearing down quickly.

PVD coatings help your blade keep its sharpness through many cutting cycles. Studies show that PVD-coated curettes can keep their edge for up to 15,000 strokes before the coating starts to wear off. In comparison, stainless steel blades lose their sharpness after just 45 strokes. Titanium-coated tools also perform well, keeping a smooth edge even after 2,500 strokes. This means you spend less time changing blades and more time working.

- PVD-coated curettes maintain edge retention up to 15,000 strokes.

- Titanium-coated instruments keep a low roughness value after 2,500 strokes.

- Stainless steel tools show major edge wear after only 45 strokes.

The coating on your blade does more than just protect against wear. It also helps the blade resist chipping and keeps the edge from getting dull, even when you use it in tough jobs. Research shows that when you use your blade in high-stress cutting, the pvd coating helps prevent the edge from breaking down. The coating reduces the strain on the blade, so it stays sharp and lasts longer.

You get a longer tool life when your blade keeps its edge. This means you can cut more materials with the same blade, saving you time and money. PVD coated carbide blades give you the confidence to handle hard materials without worrying about losing sharpness. Your blade stays reliable, and your work stays precise.

Tip: If you want the best edge retention, choose a blade with a strong pvd coating. This will help your cutting blade stay sharp and effective, even after many uses.

PVD Coated Carbide vs. Uncoated Blades

Tool Life Comparison

If you look at pvd coated carbide blades and compare them to uncoated carbide and steel blades, you will notice a big difference in how long they last. PVD coated carbide blades can work much longer, even when the job is hard. Many people say these blades last up to 142% longer than blades without coatings. This means you do not have to change blades as often, so you can keep working more.

- PVD coated carbide blades work well when milling titanium alloys, which are very hard to cut.

- Uncoated carbide blades wear out faster, especially with tough materials.

- Steel blades lose their sharpness quickly and need to be replaced often.

So, if you pick pvd coated carbide blades, you can finish more work before you need a new blade. This longer life is important for jobs that need strong cutting tools every day.

Durability and Edge Protection

Durability and edge protection are important if you want your blade to last. Hard coatings like AlTiSiN and TiN help a lot. These coatings make the blade harder, so it does not wear out fast. The coating sticks tightly to the blade, which is called coating adhesion. This strong bond keeps the coating from coming off when you use the blade a lot.

When you use coated blades, you get better wear resistance and thermal stability. This means your blade stays sharp, even when you cut hard things or work fast. The coating also helps stop the blade from chipping or breaking when chips hit it during cutting. In factories, these features help your blades last longer and lower the chance of sudden blade breaks.

Studies show that pvd coatings make the surface of carbide blades better. You get better results when you use these blades to cut tough metals like Inconel 718. The blade stays sharp, and the edge does not break easily. This helps you trust your cutting tools and keeps your work going smoothly.

If you want these good results, you can try tungsten carbide blades from Nanjing Metal Industrial. These blades use advanced pvd technology to give you strong durability and edge protection.

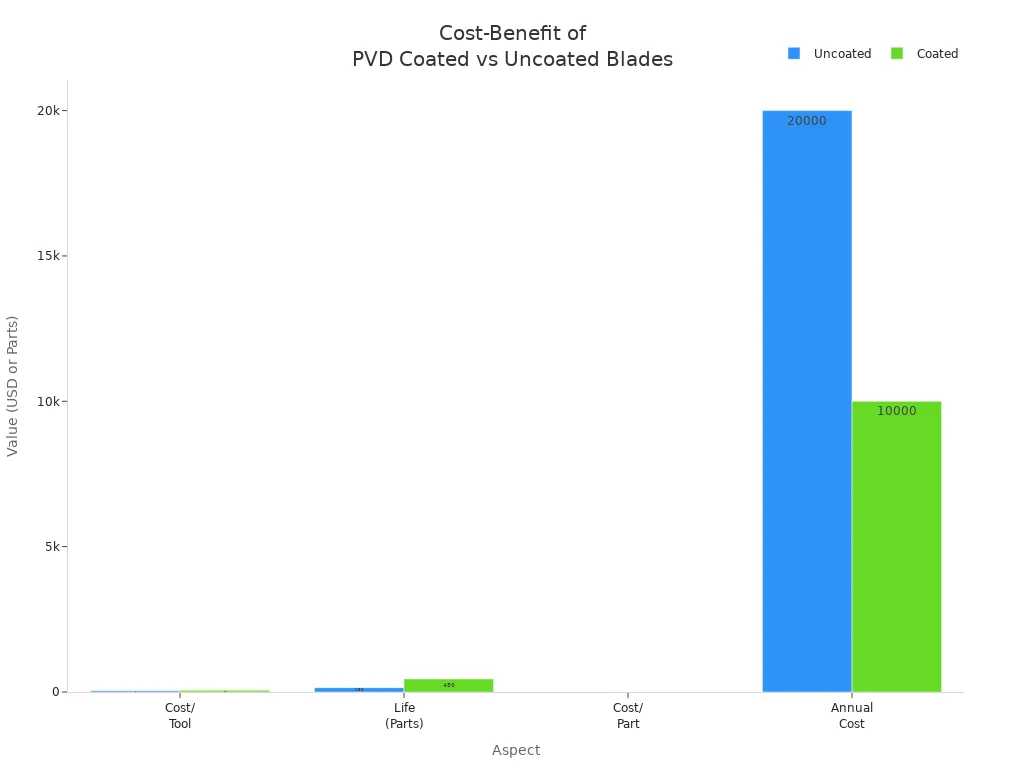

فعالية التكلفة

Cost is important when you pick cutting tools for your work. PVD coated carbide blades may cost more at first, but they help you save money later. You get more cuts with each blade, so you buy fewer blades every year. The table below shows how the costs compare:

| وجه | Uncoated | Coated |

|---|---|---|

| Cost/Tool | $40 | $60 |

| Life (Parts) | 150 | 450 |

| Cost/Part | $0.27 | $0.13 |

| Annual Cost (500 Tools) | $20,000 | $10,000 |

| Break-Even | - | 4–7 months |

You can see that coated blades cost less for each part and help you save money every year. You start saving money after just a few months. After that, you keep saving because you use fewer blades.

When you use pvd coated carbide blades, you also get other good things:

- You get more work done and your machines run longer.

- You change blades less often, so you save time and work.

- You use coatings that are better for the environment and help your company follow new rules.

- You get ahead in your business because more companies use advanced coatings.

- You can see up to a 45% increase in output with new nanostructured and hybrid coatings.

If you want better results, think about using tungsten carbide blades from Nanjing Metal Industrial. These blades use hard coatings, strong coating adhesion, and advanced technology to give you the best value for your money.

Tip: Picking pvd coated carbide blades helps you save money, get better quality, and stay ahead in your field.

PVD Coatings for Cutting Tools in Industry

عبوة كرتونية

In packaging, you often cut thick layers. Cardboard can make blades dull fast. PVD coatings help blades last longer and stay sharp. With pvd coated carbide blades, you get clean and smooth cuts. The hard coating protects the blade from wearing out, even with rough cardboard.

A sharp blade makes less dust and fewer rough edges. Your machines can run longer without stopping to change blades. This means your tools last longer and you finish more work faster. PVD coatings also lower friction, so the blade moves through cardboard easily. This helps stop blade chipping and keeps your line working.

Tip: Pick blades with strong coating adhesion for the best results in fast packaging lines.

FPCB and Electronics

Flexible printed circuit boards and electronics need very clean cuts. You need blades that cut thin, soft materials without damage. PVD coated carbide blades give you the accuracy you want. The coating makes a hard, smooth surface that fights wear and keeps the edge sharp.

When you cut FPCB, you want no burrs or rough edges. PVD coatings help by lowering friction and stopping material from sticking to the blade. The coating also protects the blade from heat during fast cutting. This means you can cut more parts before changing the blade.

The table below shows how pvd coated carbide blades help in electronics:

| ميزة | Benefit for FPCB/Electronics |

|---|---|

| Hard coatings | Longer tool life |

| Low friction | Cleaner cuts, less heat |

| Strong coating adhesion | Fewer blade changes |

| Edge retention | جودة ثابتة |

You can count on these blades for precise results, even in tough electronics jobs.

Chemical Fiber and Textiles

In chemical fiber and textiles, you need blades for strong fibers and tough fabrics. PVD coatings make your cutting tools work better in these jobs. The coating sticks well to the blade, so it does not peel or wear off.

You get many good things when you use pvd coated carbide blades in textiles:

- Good cleaning helps the coating stick better to the blade. This makes cutting work better.

- You get more done because you have fewer bad parts and less fixing. You spend less time on problems and more time making good products.

- Less downtime means your machines run longer. You do not stop as much to change or clean blades.

PVD coatings also help stop chips from forming on the blade edge. This keeps cuts smooth and helps protect soft fabrics. You can trust these blades for steady results with both synthetic and natural fibers.

Note: Clean and care for your blades often to keep strong coating adhesion and make blades last longer in textile work.

تقطيع الطعام

You need blades that stay sharp and clean when you slice food. In food processing, every cut must be precise. If your blade dulls quickly, you risk uneven slices and wasted product. Pvd coated carbide blades help you solve these problems. The hard coating forms a barrier that keeps the edge sharp and smooth. This means you get cleaner cuts and less food sticking to the blade.

Food slicing often involves wet or sticky materials. Cheese, meat, and bread can all cause blades to gum up or lose their edge. When you use a pvd coating, you reduce friction between the blade and the food. This helps the blade glide through each slice. You also lower the chance of food residue building up on the blade. Your work becomes easier and more efficient.

Hygiene matters in food processing. Pvd coated carbide blades resist corrosion and do not react with food acids or moisture. You can clean these blades easily. The smooth surface of the coating helps prevent bacteria from sticking. This keeps your food safe and your equipment in top shape.

Here are some reasons why pvd coated carbide blades work well for food slicing:

- The coating keeps the blade sharp for longer periods.

- You get smoother, more uniform slices.

- Cleaning the blade is faster and easier.

- The blade resists rust and corrosion, even in wet conditions.

Tip: Always check your blades for chips or dull spots before each use. A sharp, clean blade gives you the best results and keeps your food safe.

If you want reliable performance in your food slicing operation, consider upgrading your cutting tools to pvd coated carbide. You will notice the difference in both quality and efficiency.

Choosing the Right PVD Coating

Picking the best coating helps your blades work better. You need to match the coating to your job and material. Each coating has its own strong points. Use the table below to see which coating fits your needs.

| طلاء | Key Strength | الأفضل لـ |

|---|---|---|

| تين | Good wear resistance, easy to see blade wear | Mild steels, punches, forming tools |

| تي سي إن | Tough, low friction for sticky jobs | Stainless steel, aluminum, tapping, cut-off tools |

| AlTiN | Handles fast, rough cutting in dry or hard jobs | Cast iron, hardened steels, dry machining |

| AlTiN (HTY) | Smooth surface, fights rust from heat | Stainless, low-carbon steels, medical tools |

| TiB₂ | Very low friction, stops sticking | Aluminum, copper, magnesium, graphite machining |

| TiAlSiN | Made for fast cutting and high heat | Superalloys, hardened steels, aerospace tools |

| AlCrN | Fights rust when things get hot | Stainless steel, high-speed cutting, thermal cycling |

| AlTiN/TiSiN | Layers protect against heat and wear | Titanium, cast iron, hardened steels, superalloys |

Matching Coating to Application

You want your blades to last longer and work well. Picking the right coating helps a lot. Here are three coatings and what jobs they fit:

TiN for General Use

TiN works for many jobs. Use it for mild steels, punches, and forming tools. It helps the blade last and lets you see when it wears out. TiN is good for everyday work.

TiAlN for High-Temperature Cutting

TiAlN is best for hard or hot jobs. It keeps blades sharp when cutting fast or dry. Use TiAlN for cast iron, hardened steels, and hot jobs. If you want to go faster, TiAlN helps your blade last.

CrN for Anti-Adhesion

CrN helps with sticky or soft materials. It stops chips and dirt from sticking to the blade. You get cleaner cuts and less stopping. CrN also fights rust, so it works for food or chemical fiber jobs. If you want clean, sharp blades, CrN is a good choice.

Tip: If you need a special blade, check out شفرات مخصصة لتلبية احتياجاتك.

العوامل التي يجب مراعاتها

Think about a few things before picking a coating for your blades. The best choice depends on your job, material, and machine.

- Your job and material decide which coating is best. For example, TiCN is great for aluminum because it lowers friction.

- The coating process matters. PVD uses lower heat, so it keeps blades safe.

- The coating must stick well to the blade. A strong bond means your blade lasts longer.

- Blade shape matters. PVD works best for simple shapes.

- How you use the blade matters. Some coatings handle heat better, others fight wear or sticking.

| عامل | وصف |

|---|---|

| Coating Process | PVD uses low heat, so blades stay safe |

| Substrate Coatability | The coating must stick well for long life |

| Tool Geometry | PVD fits simple shapes; CVD fits complex ones |

| Machining Conditions | Pick coatings for your material and speed |

You can ask experts if you need help picking the right coating.

Note: Picking the right coating helps you get better results, save money, and keep your blades working longer.

Maximizing Tool Life with PVD Coated Carbide

You want your cutting tools to last as long as possible. You can follow some best practices to get the most from your PVD coated carbide blades. These steps help you cut better, save money, and keep your shop running smoothly.

أفضل الممارسات

Industry experts recommend several ways to boost tool life and tool performance. You can see these tips in the table below:

| نصيحة | توضيح |

|---|---|

| Use the Right Cutting Parameters | Adjust speed, feed rate, and depth of cut for your material and blade. |

| Apply Coolant Properly | Coolant lowers heat and friction, which helps prevent tool wear. |

| Regularly Inspect Tools | Check for wear often to catch problems before they cause failure. |

| Store Tools Correctly | Keep blades dry and organized to avoid damage. |

| Use High-Quality Carbide Tools | Choose trusted brands for better results and longer life. |

You can improve machining results by following these steps. You also help your blades resist chip buildup and keep a sharp edge.

نصائح الصيانة

You need to care for your blades to keep them working well. Good maintenance routines make a big difference. Here is a simple list you can follow:

- Check your equipment every day. Look at oil levels and vacuum readings.

- Clean the vacuum chamber walls after every 200 coating cycles.

- Change vacuum pump oil every two weeks during rainy months.

- Inspect seals and connections often. Replace them if you see leaks.

- Keep a log of repairs and changes. This helps you spot patterns and fix issues early.

You can use these steps to keep your hard coatings in top shape. Regular care means fewer surprises and better results.

متى يجب استبدال الشفرات

You should know when to change your blades. Watch for these signs:

- The blade does not cut as smoothly as before.

- You see chips or cracks on the edge.

- The coating looks worn or damaged.

- You notice more heat or noise during cutting.

If you see these problems, replace the blade right away. This keeps your work safe and your machines running well.

Tip: If you need help with blade selection or maintenance, you can reach out to Nanjig Metal Industrial. They offer 24/7 technical support, re-sharpening, and re-coating services. You can also get a warranty that covers defects and free re-sharpening.

You can get the best results from your PVD coated carbide blades by following these tips. Good habits help you cut more, waste less, and keep your tools working longer.

You can see how pvd coated carbide blades help you work better. These blades last longer because they resist wear, reduce friction, stay strong in heat, and keep a sharp edge. Many industries report big gains. For example, the table below shows tool life increases and less wear with different coatings:

| نوع الطلاء | Tool Life Increase | Wear Reduction |

|---|---|---|

| CrN/CrCN on M2 Steel | 170% | 50% |

| CrN/CrCN on Carbide | 110% | 50% |

| CrCN/CrN on HS18-0-1 | 200% | 50% |

You can upgrade your cutting tools for better results and lower costs. If you want advice or a custom solution, reach out to our sales engineer هنا.

التعليمات

What is PVD coated carbide?

PVD coated carbide is a cutting tool made from carbide with a thin, hard layer applied using physical vapor deposition. This coating improves wear resistance, reduces friction, and helps the blade last longer in tough jobs.

How does PVD coated carbide improve blade life?

The PVD coating forms a hard shield on the blade. This shield protects against wear, heat, and friction. You get a blade that stays sharp and lasts much longer than uncoated blades.

Can I use PVD coated carbide blades for food processing?

Yes, you can use PVD coated carbide blades for food slicing. The coating resists corrosion and keeps the blade sharp. You get cleaner cuts and easier cleaning, which helps keep food safe.

Which industries benefit most from PVD coated carbide?

Industries like packaging, electronics, textiles, food processing, metalworking, and automotive benefit the most. You get longer tool life and better performance in these demanding fields.

How do I choose the right PVD coating for my application?

You should match the coating to your material and job. For example, use TiN for general work, TiAlN for high heat, and CrN for sticky or corrosive materials. Ask an expert if you are unsure.

How often should I replace PVD coated carbide blades?

Replace your blade when you see chips, dullness, or coating wear. Regular checks help you spot problems early. This keeps your work safe and your machines running well.

Are PVD coated carbide blades cost-effective?

Yes, PVD coated carbide blades may cost more at first, but they last much longer. You buy fewer blades and spend less time changing them. This saves you money over time.

Do PVD coated carbide blades need special maintenance?

You should clean and inspect your blades often. Store them in a dry place. Follow best practices for your industry. Good care helps your PVD coated carbide blades last even longer.

انظر أيضا

سكين التنجستن: هل يستحق العناء؟ المزايا والعيوب والتطبيقات في الصناعة

كيفية سنّ وصيانة سكاكين كربيد التنجستن

لماذا تتشقق سكاكين كربيد التنجستن؟ - أسباب الأعطال الشائعة وكيفية تجنبها

كربيد التنغستن مقابل الفولاذ للشفرات الصناعية: الأداء والتآكل والتكلفة

كربيد التنجستن مقابل الفولاذ عالي السرعة (HSS): أيهما الأنسب لاحتياجات القطع لديك؟