- شفرات القاطع الحراري استخدم الحرارة لقطع المواد وختمها.

- يعملون على المواد الاصطناعية بحركة سلسة واحدة.

- تعمل هذه الشفرات على تنظيف الحواف ومنع التآكل أو التفكك.

- الحرارة تذيب المادة، مما يجعل القطع قوية ودقيقة.

- تستخدمها العديد من الصناعات مثل صناعة المنسوجات والتعبئة والتغليف والبناء.

- إنها مفيدة لمهام مختلفة لأنها توفر الوقت.

- Nanjing Metal يصنع شفرات مخصصة لمشاريع خاصة إذا لزم الأمر.

- أنت تستطيع اتصل بنا فريقهم للحصول على المساعدة أو مزيد من التفاصيل.

ما هي شفرات القاطع الحراري؟

التعريف والأسماء البديلة

شفرات القاطع الحراري هي أدوات تستخدم الحرارة للقطع والختم. تُسمى أيضًا شفرات السكين الساخنة أو القواطع الحرارية. تقطع هذه الشفرات المواد وتختم الحواف في آنٍ واحد. هذا يمنع التآكل ويمنح سطحًا أنيقًا ونظيفًا. تتوفر أنواع مختلفة من شفرات القاطع الحراري لمختلف المهام. الشفرات الخفيفة مناسبة للحرف اليدوية، بينما الشفرات الثقيلة تتحمل المهام الشاقة. على سبيل المثال، AZTC-20 رائع للرغوة والبلاستيك الرقيق. تعمل ZETZ-24 بشكل جيد لتقليم الألواح الشمسية وقطع المطاط.

الميزات والخصائص الرئيسية

تتميز شفرات القاطع الحراري بخصائص فريدة. فهي تستخدم شفرة كهربائية تُذيب المواد بدلاً من تمزيقها، مما يُنتج حوافًا ناعمة تدوم لفترة أطول وتبدو أجمل. تتوفر هذه الشفرات بأشكال مستقيمة أو منحنية أو خاصة لمختلف المهام. تُصنع الشفرات عالية الجودة من معادن قوية مثل الفولاذ المقاوم للصدأ، مما يجعلها تتحمل درجات الحرارة العالية وتعمل بكفاءة عالية لفترة طويلة. سواء كنت بحاجة إلى قطع دقيق أو شفرات قوية للمشاريع الكبيرة، فإن شفرات القاطع الحراري موثوقة.

المواد المناسبة لشفرات القاطع الحراري

شفرات القطع الحراري تُعطي أفضل النتائج على المواد الصناعية. يُمكن استخدامها على الرغوة والبلاستيك والأقمشة الصناعية والألياف البصرية. تُذيب الحرارة هذه المواد بسهولة، مما يجعلها مثالية للقطع. الشفرات خفيفة الوزن مثل AZTC-20 مثالية لقطع الرغوة أو البلاستيك الرقيق. الشفرات المتينة مثل ZETZ-24 أفضل للمهام الصناعية، حيث يُمكنها حفر المطاط أو قطع الأقمشة الصناعية السميكة. اختيار الشفرة والمادة المناسبين يُساعدك على الحصول على نتائج نظيفة واحترافية في كل مرة.

كيف تعمل شفرات القاطع الحراري

عملية التسخين

عناصر التسخين الكهربائية

تستخدم شفرات القاطع الحراري الحرارة الكهربائية للقطع والختم. تنتقل الحرارة مباشرة إلى الشفرة، مما يجعلها تسخن بسرعة. تُذيب هذه الحرارة المواد الاصطناعية للحصول على قطع ناعمة ودقيقة. على عكس القواطع العادية، تمنع هذه الشفرات تآكل الحواف عن طريق ختمها. هذا يجعلها مثالية لتشطيبات قوية وأنيقة.

ميزات التحكم في درجة الحرارة

يمكنك تغيير مستوى حرارة شفرات القاطع الحراري. يساعد هذا على مطابقة الحرارة مع المادة التي تقطعها. تحتاج الرغوة إلى حرارة أقل، بينما يحتاج البلاستيك السميك أو المطاط إلى حرارة أعلى. تسخن الشفرات بسرعة، وتصل إلى حتى 1050 درجةتمنع ميزات السلامة ارتفاع درجة الحرارة، مما يحافظ على أمان استخدام الأداة. إليك جدول بأهم الميزات:

| ميزة | ماذا يفعل |

|---|---|

| نطاق درجة الحرارة | يسخن بسرعة من 0 إلى 1050 درجة |

| تنظيم الطاقة | يتيح لك ضبط الحرارة للحصول على تحكم أفضل |

| سرعة التسخين | تسخين سريع مع أمان ضد ارتفاع درجة الحرارة |

| توافق الشفرة | يعمل مع الشفرات القياسية والكبيرة |

| وزن | خفيف الوزن، أقل من 12 أونصة، سهل التعامل |

تقنية القطع

الذوبان مقابل القطع

هذه الشفرات تذيب المواد الاصطناعية بدلاً من تقطيعها. الذوبان يُنتج حوافًا نظيفة دون تمزق أو تهترئ. هذا يمنح مشاريعك مظهرًا ناعمًا ويطيل عمرها. على سبيل المثال، حواف الحبال المذابة لا تتفكك، بل تبقى متينة مع مرور الوقت.

عملية ختم الحافة

أثناء القطع، تُغلّف الشفرة الحواف في الوقت نفسه. الحواف المُغلّفة أقوى ولا تتآكل بسهولة. لا تحتاج إلى خطوات إضافية لجعل القطع تبدو مصقولة. سواءً كان القطع من الفوم أو البلاستيك أو القماش، فإن الحواف المُغلّفة تُعطي نتائج احترافية.

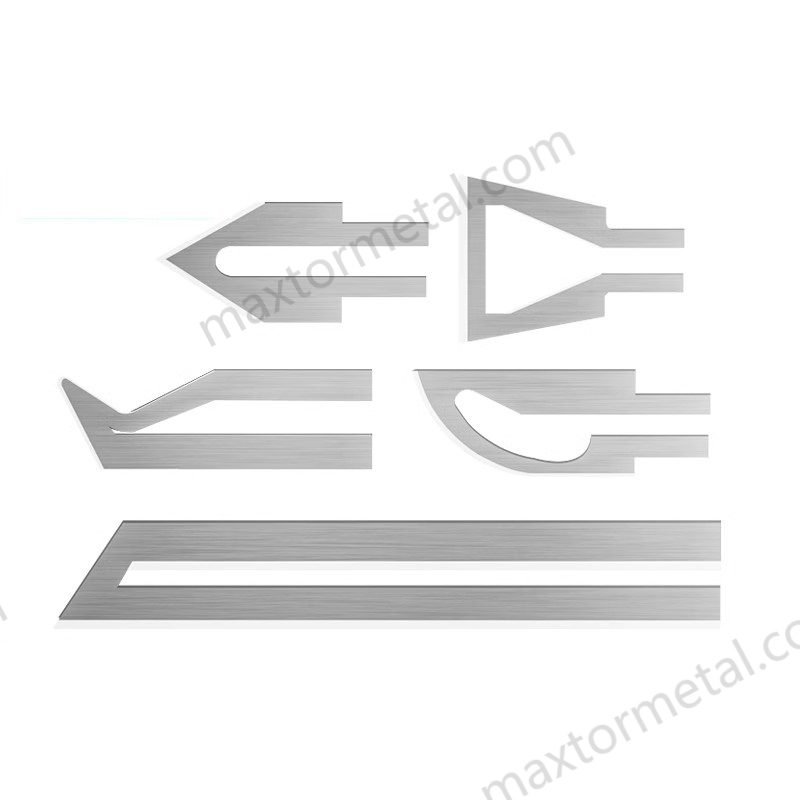

اختلافات الشفرة

شفرات مستقيمة

الشفرات المستقيمة مثالية للعديد من أعمال القطع. يمكنك استخدامها لقص الأقمشة أو تشكيل الإسفنج. إنها سهلة الاستخدام ومثالية للمبتدئين. تتيح لك هذه الشفرات الحصول على قطع مستقيمة ونظيفة بسهولة.

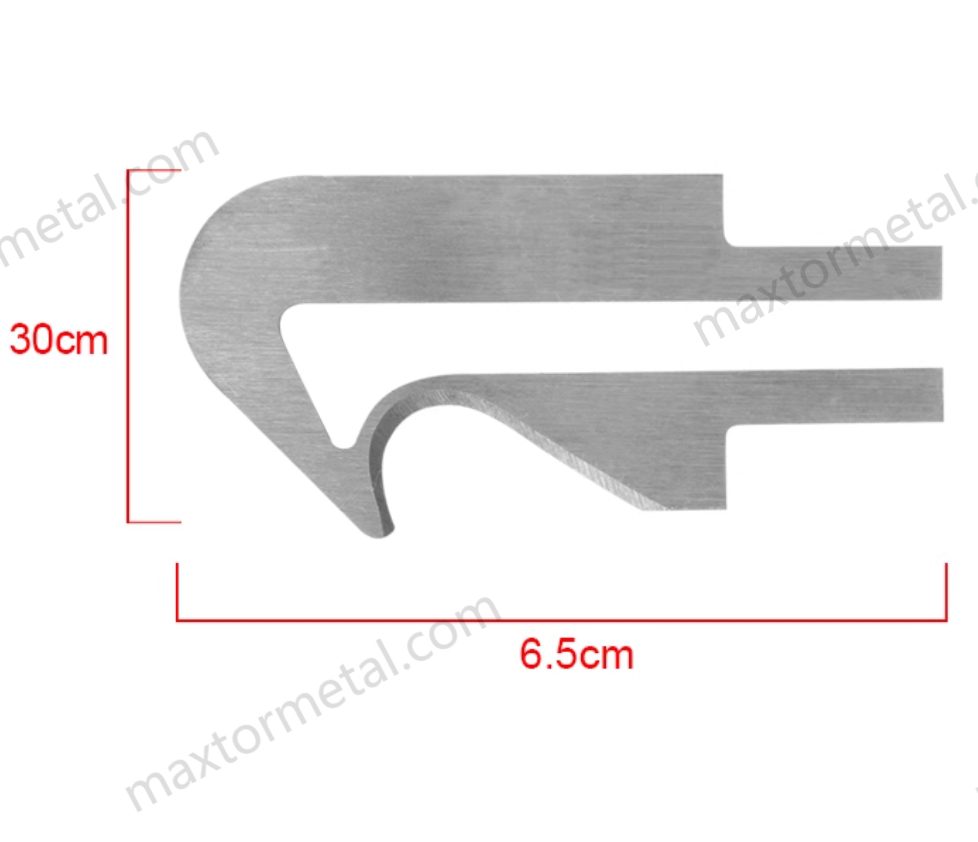

شفرات منحنية

الشفرات المنحنية مثالية للأشكال والتصاميم المعقدة. وهي مثالية للقطع الدائرية في الإسفنج أو البلاستيك. هذه الشفرات مثالية للمشاريع الإبداعية التي تتطلب دقة في التفاصيل. شكلها المنحني يساعد في التعامل مع الزوايا الضيقة والأنماط.

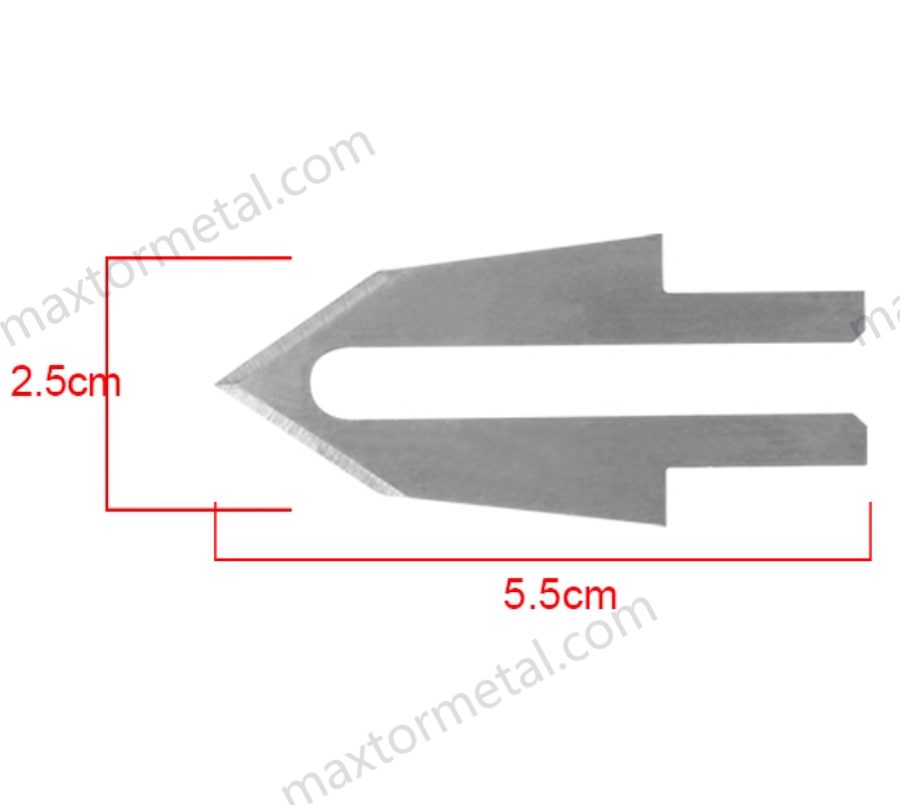

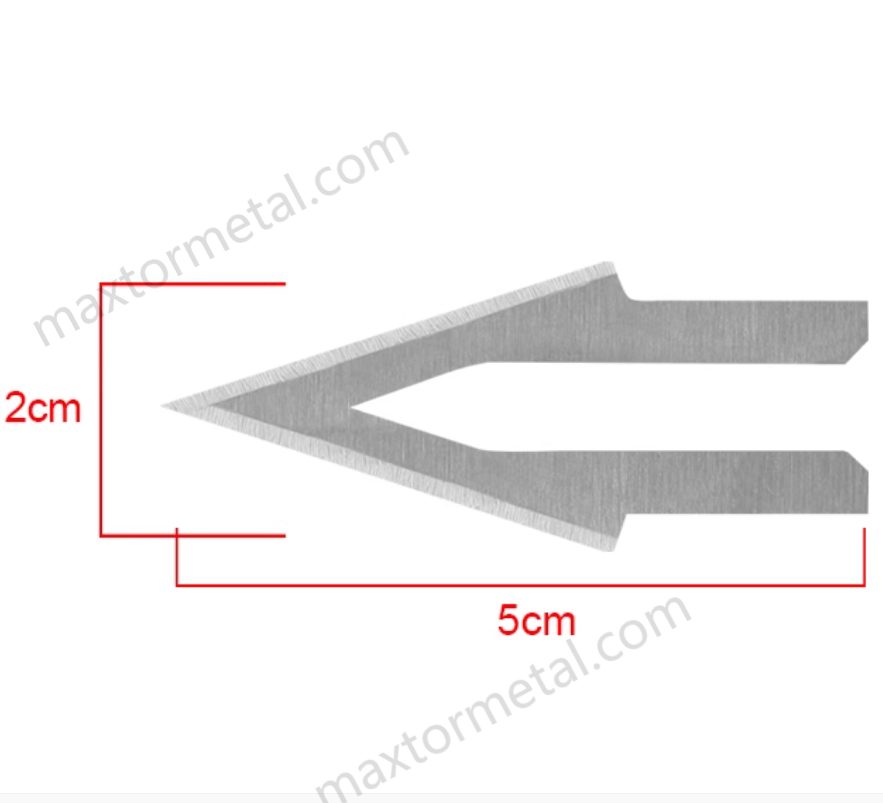

شفرات متخصصة

شفرات متخصصة مصممة لمهام محددة. تتوفر بأشكال وأحجام مختلفة تناسب مشاريع فريدة. بعضها مثالي لقطع المطاط السميك، بينما يُستخدم البعض الآخر لتشذيب الألواح الشمسية. تتميز هذه الشفرات بالمتانة والدقة في الأعمال الشاقة.

خيارات مصدر الطاقة

مواصفات الجهد

تستخدم شفرات القاطع الحراري الكهرباء للتسخين والعمل بكفاءة. تأكد من أن الجهد الكهربائي يتوافق مع احتياجات الشفرة لأداء أفضل. تعمل معظم الشفرات مع 110 فولت إلى 240 فولت، التي تناسب المنافذ الشائعة حول العالم. هذا يجعلها سهلة الاستخدام في المنزل، أو في الورش، أو في مواقع العمل.

بعض الشفرات المتطورة قادرة على التعامل مع نوعين من الجهد. فهي تتكيف تلقائيًا مع الطاقة المتاحة، مما يُسهّل السفر. عند زيارة دول ذات أنظمة كهربائية مختلفة، تعمل الشفرات ثنائية الجهد دون الحاجة إلى مُحوّلات إضافية.

نصيحة: تحقق دائمًا من تصنيف جهد الشفرة قبل توصيلها بالكهرباء. قد يؤدي استخدام الجهد الخاطئ إلى إتلاف الشفرة أو تقليل فعاليتها.

التوافق مع الأدوات

شفرات القاطع الحراري تناسب العديد من أدوات القطع. يمكنك استخدامها مع السكاكين الساخنة اليدوية، والآلات الصناعية، والأجهزة التي تعمل بالبطاريات. تتيح لك هذه المرونة التعامل مع المشاريع الصغيرة أو الأعمال الصناعية الكبيرة.

اختر شفرةً تتناسب مع قوة أداتك ونوع توصيلها. بعض الأدوات تحتاج إلى أحجام أو أشكال شفرات محددة لتعمل بشكل صحيح. على سبيل المثال، تستخدم القواطع اليدوية الصغيرة شفرات أصغر، بينما تحتاج الآلات الكبيرة إلى شفرات قوية ومتينة.

فيما يلي دليل التوافق البسيط:

| نوع الأداة | أفضل ميزات الشفرة | مثال على حالة الاستخدام |

|---|---|---|

| سكين ساخن محمول باليد | شفرات خفيفة الوزن، مستقيمة أو منحنية | صناعة الرغوة أو قص الأقمشة |

| آلة القطع الصناعية | شفرات متخصصة شديدة التحمل | قطع المطاط أو البلاستيك السميك |

| الأجهزة التي تعمل بالبطارية | شفرات مدمجة ومنخفضة الطاقة | مهام القطع أثناء التنقل |

ملحوظة: احرص دائمًا على قراءة دليل استخدام أداتك للتحقق من توافق الشفرة. هذا يحافظ على سلامة معداتك ويجنبك التلف.

معرفة احتياجات الجهد وتوافق الأدوات يُساعد على إطالة عمر شفرات القاطع الحراري. هذه النصائح تضمن لك قطعًا نظيفًا واحترافيًا في كل مرة.

تطبيقات شفرات القاطع الحراري

شفرات القطع الحراري أدوات عملية تُستخدم في العديد من الصناعات. فهي تقطع وتُغلّف المواد الاصطناعية بدقة، مما يجعلها مفيدة للغاية. لنرَ كيف تُساعد هذه الشفرات في مجالات مختلفة.

الاستخدامات الصناعية

صناعة النسيج

في صناعة المنسوجات، تُعد شفرات القطع الحراري مثالية لقص الأقمشة الصناعية. فهي تعمل على مواد مثل البوليستر والنايلون، مما يُعطي حوافًا نظيفة. كما تمنع هذه الشفرات التآكل، مما يُحافظ على قوة الأقمشة ونظافتها. على سبيل المثال، تُستخدم هذه الشفرات في قص أحزمة التنجيد أو لفات القماش في المصانع.

مهام التعبئة والتغليف

شفرات القطع الحراري أساسية في التغليف المخصص. فهي تقطع وتُغلق الأغشية البلاستيكية، وألواح الفوم، وغيرها. هذا يُنتج حوافًا ناعمة ومُغلقة، أنيقة المظهر ومتينة. سواءً كان غلافًا منكمشًا أو حشوات فوم، تُقدم هذه الشفرات نتائج احترافية.

أعمال السيارات

في السيارات، تقطع شفرات القطع الحراري التنجيد، والأختام المطاطية، والإسفنج. وتُجري قطعًا دقيقة للمقاعد والأجزاء الداخلية. تحافظ الحواف المُحكمة على متانة المواد وطول عمرها، حتى مع الاستخدام المنتظم.

المشاريع الإبداعية

صناعة الرغوة

شفرات القطع الحراري رائعة لصناعة الفوم. استخدمها لتشكيل الفوم للنماذج والأزياء والديكورات. تتيح لك الحرارة صنع تصاميم دقيقة دون تمزيق الفوم. هذا يجعل المشاريع الإبداعية أسهل وأكثر متعة.

مشاريع التنجيد

للتنجيد حسب الطلب، تقطع هذه الشفرات الأقمشة والإسفنج بدقة. تساعد على إنشاء حواف أنيقة للأثاث أو ديكورات السيارات. يمكنك تصميم تصاميم مفصلة تبدو أنيقة واحترافية.

ديكور منزلي اصنعه بنفسك

يُحبّ مُحبّو الأعمال اليدوية شفرات القطع الحراريّة في مشاريعهم المنزلية. استخدموها لقصّ وختم مواد الستائر والوسائد ولوحات الجدران. كما أنّها تتحمّل الأقمشة الصناعيّة والإسفنج ببراعة، مُضيفةً لمسةً شخصيّةً إلى منزلكم.

الاستخدامات المتخصصة

المعدات الطبية

في الطب، تُستخدم شفرات القطع الحراري لقطع وختم مواد الأجهزة. كما تُشكّل حشوات إسفنجية أو تقطع أجزاء بلاستيكية للأدوات. تضمن دقتها نتائج عالية الجودة لتلبية الاحتياجات الطبية.

قطع غيار الطائرات

تستخدم صناعة الطيران هذه الشفرات للمواد خفيفة الوزن. فهي تقطع وتُغلق الأقمشة المركبة أو رغوة العزل. وهذا يُساعد في صنع قطع متينة وفعالة للطائرات والمركبات الفضائية.

البناء والعزل

في مجال البناء، تقطع شفرات القاطع الحراري مواد العزل مثل ألواح الفوم. وتُجري قطعًا دقيقة للجدران والأسقف والأرضيات. حوافها محكمة الغلق تمنع التآكل، مما يضمن عزلًا يدوم طويلًا.

نصيحة: اختر دائمًا الشفرة وإعداد الحرارة المناسبين لمادتك. هذا يساعدك على الحصول على أفضل النتائج في كل مرة.

فوائد شفرات القطع الحراري

الدقة والحواف النظيفة

شفرات القاطع الحراري تقطع المواد الاصطناعية بدقة عالية. تُذيب الشفرة الساخنة المادة، مما يُنتج حوافًا ناعمة دون تمزق. هذا مهم للمشاريع التي تتطلب لمسة نهائية أنيقة، مثل عزل الرغوة أو تشطيب الأقمشة. سواءً لديكور السيارة أو الأشغال اليدوية المنزلية، فإن هذه الحواف النظيفة تُضفي على عملك مظهرًا أفضل وتدوم لفترة أطول.

القطع والختم في وقت واحد

شفرات القاطع الحراري قادرة على القطع والإغلاق في خطوة واحدة. فعندما تذوب المواد، تُغلق الحواف أيضًا. هذا يوفر الوقت، إذ لا حاجة إلى إغلاق إضافي. على سبيل المثال، حواف الحبال المُغلقة تمنع التفكك وتبقى متينة. هذه الميزة مفيدة في التغليف، حيث تحافظ الحواف المُغلقة على سلامة المنتجات.

يوفر الوقت ويقلل النفايات

شفرات القاطع الحراري فعّالة وتُقلل من هدر المواد. القواطع العادية تترك حوافًا خشنة أو تتطلب محاولات إضافية، مما يُهدر الموارد. تقطع هذه الشفرات بدقة من المحاولة الأولى، مما يُقلل من الأخطاء. وهي مفيدة في العديد من الصناعات، مثل صناعة السيارات، وقطع الرغوة، والأعمال الكهربائية. إليك جدول يوضح استخداماتها:

| مجال التطبيق | وصف |

|---|---|

| تجارة الإطارات والسيارات | يقوم بتقطيع وتشكيل مواد الإطارات. |

| مصنعي القوالب المصبوبة | يساعد على القطع الدقيق في الإنتاج. |

| التركيبات الكهربائية | يقوم بإزالة الأسلاك والمواد اللاصقة. |

| قطع الرغوة | يقطع الرغوة بسهولة وبدقة. |

| ختم الأقمشة الاصطناعية | يختم حواف المواد الاصطناعية. |

| إزالة طلاء المطاط | يزيل الطلاء المطاطي بشكل فعال. |

| لوحات التوزيع والتبديل | تستخدم في مهام التجميع الكهربائي. |

| تجريد الأسلاك | شرائط عزل الأسلاك. |

| إزالة اللاصق | يزيل المواد اللاصقة الملتصقة من الأسطح. |

| قطع المواد الاصطناعية | يقوم بتقطيع مختلف الأقمشة الصناعية بشكل نظيف. |

من خلال توفير الوقت وتقليل النفايات، تساعدك شفرات القطع الحراري على العمل بشكل أسرع وأكثر ذكاءً.

التنوع عبر الصناعات

شفرات القطع الحراري مفيدة في العديد من الصناعات. فهي تتكيف جيدًا مع مختلف المهام، مما يُسهّل العمل ويُحسّنه.

1. التصنيع والإنتاج

تساعد شفرات القطع الحراري على القطع الدقيق في المصانع. فهي تقطع الأقمشة الصناعية والبلاستيك والإسفنج لمقاعد السيارات ومواد التغليف والعزل. على سبيل المثال، تُجري قطعًا دقيقة لتنجيد السيارات تناسب تمامًا. كما أن الحواف المُحكمة تجعل المنتجات أقوى وتدوم لفترة أطول.

2. المجالات الإبداعية والفنية

هذه الشفرات مثالية لمشاريع الحرف والتصميم. استخدمها لتشكيل الإسفنج للأزياء والديكورات والمجسمات. كما أنها تقطع الأقمشة الاصطناعية لديكور المنزل أو تنجيد الأثاث حسب الطلب. تُغلّف الحواف بالحرارة، مما يمنح عملك مظهرًا أنيقًا واحترافيًا.

3. البناء والعزل

في مجال البناء، تقطع شفرات القطع الحراري ألواح الرغوة للعزل. وتُنتج أشكالًا دقيقة للجدران والأرضيات والأسقف. تمنع الحواف المُحكمة التلف، مما يُحافظ على قوة العزل وعمره الافتراضي. وهذا يُسهّل أعمال البناء ويجعلها أكثر موثوقية.

نصيحة: اختر الشفرة المناسبة للمادة والمهمة. هذا يساعدك على الحصول على نتائج أفضل ويطيل عمر أدواتك.

شفرات القطع الحراري متعددة الاستخدامات. فهي تقطع وتُغلّف المواد الاصطناعية، مما يجعلها مفيدة للعديد من المهام. سواء كنت محترفًا أو هاويًا، تُحسّن هذه الأدوات عملك.

شفرات القطع الحراري المخصصة من نانجينغ Metal

لماذا التخصيص مهم؟

يختلف كل مشروع عن الآخر ويتطلب أدوات خاصة. قد لا تعمل الشفرات القياسية دائمًا بكفاءة. شفرات القطع الحراري المخصصة صُممت لتناسب احتياجاتك بدقة. هذا يساعدك على الحصول على قطع دقيقة، وأختام ناعمة، ونتائج أفضل. سواء كنت تعمل في السيارات، أو التغليف، أو الحرف اليدوية، فإن الشفرات المخصصة تُحسّن عملك وتوفر الوقت.

تساعد الشفرات المُخصصة أيضًا على تقليل الهدر. فالشفرة المُصممة خصيصًا لمهمتك تُقلل من الأخطاء وتُعطي نتائج ثابتة. في الأعمال التي تتطلب دقة عالية، مثل صنع الأدوات الطبية أو قطع غيار الطائرات، تُعدّ الشفرات المُخصصة بالغة الأهمية.

حلول مصممة خصيصًا لتطبيقات محددة

تُصنّع شركة نانجينغ Metal شفرات قاطعة حرارية مُخصصة للعديد من الصناعات. يُساعدك فريقهم من مرحلة التصميم إلى الاختبار. كما يُمكنهم تصميم شفرات بناءً على عيناتك أو رسوماتك، مما يضمن أن الشفرة تُلبي احتياجاتك تمامًا.

وفيما يلي بعض الخيارات المخصصة التي يقدمونها:

- تصاميم مخصصة:شفرات مصممة خصيصًا لمهام القطع والختم الخاصة بك.

- الدقة الأبعادية:نماذج أولية دقيقة ومنتجات نهائية ذات قياسات دقيقة.

- الخبرة المادية:اختيار أفضل المواد للقوة والأداء.

سواء كنت بحاجة إلى شفرات للرغوة أو الأقمشة الاصطناعية أو المطاط، فإن Nanjing Metal لديه الحل المناسب لك.

خبرة نانجينغ Metal في الشفرات المخصصة عالية الجودة

مع 18 عامًا من الخبرة، Nanjing Metal Industrial CO., Limited اسمٌ موثوقٌ في صناعة الشفرات. يتميزون بمهارةٍ فائقةٍ في اختيار المواد، والمعالجة الحرارية، وفحص الجودة، لإنتاج شفراتٍ عالية الجودة.

| وجه | تفاصيل |

|---|---|

| اختيار المواد | خبراء في الفولاذ الكربوني، وفولاذ الأدوات، وكربيد التنغستن، والمزيد. |

| عمليات المعالجة الحرارية | معالجة حرارية متقدمة للحصول على شفرات قوية ومرنة. |

| تدابير مراقبة الجودة | فحوصات دقيقة أثناء الإنتاج لضمان الجودة العالية. |

| التصنيع المخصص | يصنع الشفرات بالضبط بالطريقة التي يحتاجها العملاء. |

كما أنهم يساعدون في التصميم والاختبار لضمان جودة شفراتك. إذا كنت ترغب في شفرات قاطع حراري عالية الجودة، اتصل بنا فريق نانجينغ Metal اليوم.

نصائح لاختيار شفرة القاطع الحراري المناسبة

أشياء للتفكير فيها (المادة، السُمك، الاستخدام)

يبدأ اختيار شفرة القاطع الحراري المناسبة بمعرفة المادة المستخدمة. تحتاج مواد مختلفة، مثل الإسفنج والبلاستيك والأقمشة، إلى شفرات خاصة. على سبيل المثال، تحتاج الإسفنج الرقيق إلى حرارة أقل، بينما تحتاج المواد البلاستيكية السميكة إلى شفرات أقوى.

سُمك المادة مهم أيضًا. الشفرات الرفيعة مناسبة للقطع الصغيرة والدقيقة. أما المواد السميكة فتحتاج إلى شفرات أقوى لقطعها بدقة. احرص دائمًا على مطابقة درجة حرارة الشفرة مع درجة انصهار المادة. استخدام الشفرة الخاطئة قد يُفسد مشروعك أو يُؤدي إلى قطع غير متقن.

بعد ذلك، فكّر فيما تفعله. هل تُمارس أعمالًا حرفية، أم تعمل على مشاريع ضخمة، أم تُنجز مهامًا خاصة؟ كل مهمة تتطلب نوعًا مُحددًا من الشفرات. الشفرات المنحنية مثالية للتصاميم المُفصّلة، بينما الشفرات المستقيمة أفضل للقطع المستقيم والنظيف.

نصيحة: دوّن المواد التي تستخدمها بكثرة. هذا يساعدك على اختيار الشفرة المناسبة لكل مشروع بشكل أسرع.

اختيار الشفرة المناسبة للمهمة

يجب أن تتناسب الشفرة التي تختارها مع مهمتك. الشفرات المستقيمة مناسبة للقطع العام، مثل قص الإسفنج أو القماش. أما الشفرات المنحنية فهي الأنسب للأعمال الدقيقة، مثل تشكيل الإسفنج للأعمال اليدوية. أما الشفرات المتخصصة، فهي مصممة للأعمال الشاقة، مثل قطع المطاط أو الألواح الشمسية.

فيما يلي دليل بسيط:

| نوع الشفرة | الأفضل لـ | مثال للمهمة |

|---|---|---|

| شفرات مستقيمة | القطع اليومي | قص حواف القماش |

| شفرات منحنية | تصاميم مفصلة | تشكيل الرغوة للحرف اليدوية |

| شفرات متخصصة | المهام الصناعية الخاصة | قطع المطاط السميك |

إن استخدام الشفرة المناسبة لعملك يمنحك نتائج أنيقة واحترافية.

اطلب المساعدة من الخبراء

إذا كنتَ غير متأكد، فاسأل خبيرًا. سيساعدك في اختيار الشفرة الأنسب لمادتك وسمكك ومهمتك. كما يمكن للخبراء اقتراح شفرات مخصصة لمشاريع خاصة.

تواصل مع شركات مثل Nanjing Metal. فريقهم قادر على تقديم المشورة وتصنيع شفرات مخصصة تناسب احتياجاتك.

ملحوظة: لا تتردد في طرح الأسئلة. الحصول على المشورة يوفر لك الوقت ويحسّن عملك.

شفرات القطع الحراري تُسهّل وتُسرّع عملية القطع والختم. تُستخدم في العديد من الصناعات، مثل المنسوجات والبناء، للحصول على نتائج ممتازة. اختيار الشفرة المناسبة يُحسّن جودة العمل ويُقلّل الهدر. شفرات نانجينغ Metal المُصمّمة خصيصًا لتلبية احتياجاتك الخاصة. بخبرة 18 عامًا، يُنتج فريقنا شفرات قوية وموثوقة خصيصًا لك.

التعليمات

ما هي المواد التي يمكن لشفرات القاطع الحراري قطعها؟

شفرات القطع الحراري تقطع المواد الصناعية مثل الرغوة والبلاستيك والنايلون والبوليستر. تعمل بشكل أفضل على المواد التي تذوب بالحرارة. هذه الشفرات مثالية للأعمال اليدوية والتعبئة والتغليف والصناعة.

كيف تتوقف شفرات القاطع الحراري عن التآكل؟

تسخن الشفرة وتُذيب المادة أثناء القطع. هذا يُغلّف الحواف فورًا، ويمنع التآكل أو التفكك. ستحصل على حواف ناعمة وقوية دون عناء إضافي.

هل شفرات القاطع الحراري آمنة للاستخدام؟

نعم، إنها آمنة عند استخدامها بشكل صحيح. العديد من الشفرات مزودة بتحكم حراري وميزات أمان لتجنب ارتفاع درجة الحرارة. اتبع دائمًا التعليمات وارتدِ معدات السلامة.

هل يمكن استخدام شفرات القاطع الحراري في المشاريع الإبداعية؟

نعم! هذه الشفرات مثالية لتشكيل الإسفنج، وقطع الأقمشة الصناعية، وصنع تصاميم دقيقة. وهي شائعة في مشاريع الأعمال اليدوية والأزياء وديكور المنزل.

كيف تختار شفرة القاطع الحراري المناسبة؟

اختر شفرةً مناسبةً للمادة والمهمة المطلوبة. الشفرات المستقيمة مخصصةٌ للقطع البسيطة، والشفرات المنحنية للأشكال الدقيقة، والشفرات المتخصصة للمواد الصلبة. إذا لم تكن متأكدًا، فاطلب المساعدة من خبير.

نصيحة: قم باختبار الشفرة على قطعة صغيرة من المادة قبل البدء بمشروعك.

انظر أيضا

سكاكين القطع الساخن: الطريقة الأذكى للقطع بشكل نظيف وسريع وبتكلفة معقولة