Die Wahl des richtigen Arten von Kreismessern helps factories perform efficiently. Circular blades are widely used in packaging, textiles, food processing, and more. Selecting the appropriate blade type, material, and edge design speeds up work and reduces waste. The table below highlights how choosing different types of circular knives impacts speed and quality:

| Faktor | Effizienzsteigerung | Quality Advantage |

|---|---|---|

| Auswahl des Klingenmaterials | Fewer replacements, less downtime | Cleaner, precise cuts |

| Wolframkarbidklingen | Longer life, high-volume use | Fewer defects, sharp cuts |

| Korrosionsbeständigkeit | Less maintenance needed | Consistent results |

Nanjing Metal is a trusted manufacturer specializing in various types of circular knives. With 20 years of industry experience, they offer custom blades tailored to your specific needs. Discover more about their custom blade options.

Die wichtigsten Erkenntnisse

- Picking the right circular knife helps things get cut faster and better. It also helps use less material in many jobs.

- There are different blade types like slitter, crush cut, perforating, serrated, pelletizer, and guillotine knives. Each one is made for a special kind of cutting.

- The blade material and edge shape change how long the blade lasts. They also change how well it cuts and how often you need to fix it.

- Thin blades are best for films and labels. Medium blades are good for paper and textiles. Thick blades are used for hard things like rubber and plastics.

- Circular knives are very important in packaging, textiles, food processing, plastics, metalworking, and recycling jobs.

- Custom blades from skilled makers like Nanjing Metal help with special cutting problems. They also fit machines that are not standard.

- If you match the blade type, material, edge, and tolerance to the job and machine, the blade works better and lasts longer.

- Taking care of blades and using the right knife for each material saves time. It also makes less waste and helps make better products.

Importance of Circular Knives

Efficiency and Quality

Circular knives are very important in factories today. The right circular blade can change how materials get cut. This affects how fast work gets done, how much it costs, and how good the products are. When workers use circular knives made for their jobs, they work faster and get cleaner cuts.

- Kreismesser cut better than straight blades. They make cleaner cuts and use less power.

- These knives help save materials by making thin cuts. This means there is less waste and more product to use.

- Workers find circular knives simple to handle. The spinning motion keeps the blade steady and needs less effort.

- Shear slitting uses circular knives for fast cutting. This gives smooth edges, which is needed for packaging and textiles.

- Cutting quickly with circular knives means less stopping. Factories can do more work with fewer breaks.

Tipp: Picking the best blade material and tooth shape keeps cuts sharp and makes blades last longer. This helps machines last longer and keeps work moving.

The thickness and shape of circular knives are important too. Thin blades, like 0,4 mm, are best for films and labels. They cut fast, need less stopping, and make little waste or edge tearing. Medium blades work well for paper and textiles. They balance speed and waste. Thick blades, about 1.0 mm, are for hard things like rubber and plastics. They cut slower but are needed for tough jobs.

| Klingenstärke | Am besten für | Schnittgeschwindigkeit | Ausfallzeit | Waste | Defect Reduction |

|---|---|---|---|---|---|

| 0,4 mm | Films, Labels | 180 m/min | 2 hrs/week | 1.8% | Less edge tearing, fraying |

| 0,6 mm | Paper, Textiles | Mäßig | Mäßig | 2.5% | Improved cut precision |

| 1,0 mm | Plastics, Rubber | 140 m/min | Höher | 3.1% | Handles tough materials |

Special blade shapes and coatings, like TiN or DLC, help stop problems and make blades last longer. In one packaging factory, using better circular knives meant changing blades less often. They went from three changes a day to just one every two days. Pouches that were not lined up dropped from 7% to under 1%. Stopping time went from two hours a week to less than thirty minutes.

Industry Coverage

Circular knives are used in many industries. They are important tools for jobs that need to be done fast and in large amounts. The table below shows how different industries use circular knives and how big their markets are:

| Industry Sector | Use of Circular Knives | Market Size / Estimate |

|---|---|---|

| Food Processing & Packaging | Processing raw foods, slicing, packaging materials | Part of $5.1B industrial knife market (2024); forecast $7.8B by 2033 |

| Paper Production | Cutting paper, cardboard, labels | Included in overall industrial knife market |

| Textile and Garment Industry | Cutting fabrics, trimming, slitting | Included in overall industrial knife market |

| Automobilindustrie | Cutting rubber, plastics, composites | Included in overall industrial knife market |

| Aerospace and Defense | Specialized cutting for advanced materials | Included in overall industrial knife market |

| Healthcare and Medical | Manufacturing medical equipment, hygiene products | Included in overall industrial knife market |

| Construction and Manufacturing | General cutting and trimming | Included in overall industrial knife market |

| Logistics and Transportation | Cutting and packaging materials | Included in overall industrial knife market |

Circular knives are very important in food processing and packaging. They help keep work fast and clean. The textile industry needs these knives for cutting and trimming fabric. In cars and planes, circular knives cut hard things like rubber and composites.

Notiz: The world market for woodworking circular saw blades, which includes some circular knives, was $50.4 million in 2022. It may grow to $68.3 million by 2029.

By picking the right circular knives, companies can work faster, waste less, and make better products.

Arten von Kreismessern

Schneidklingen

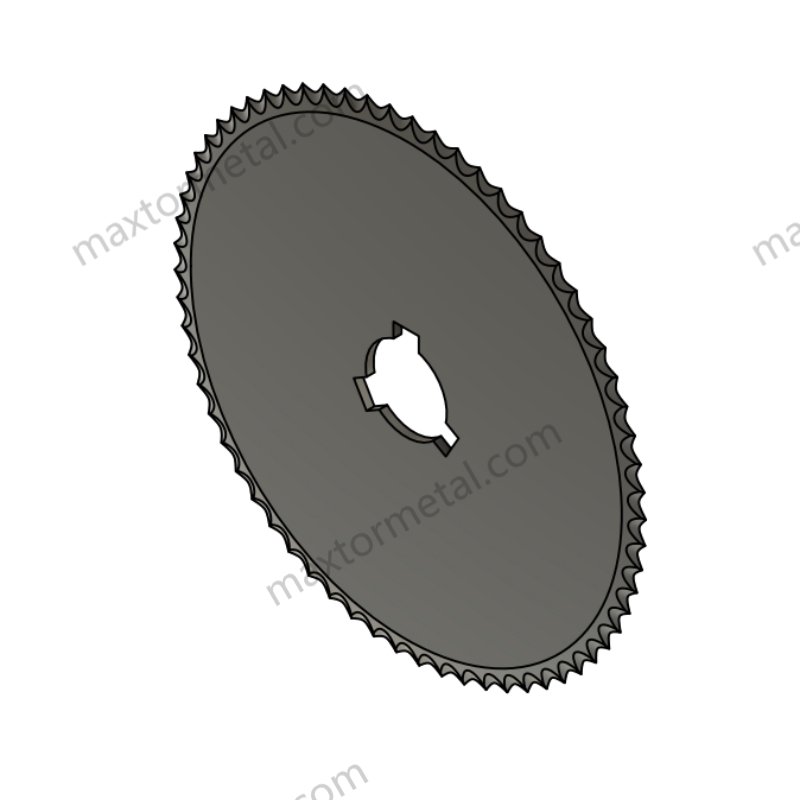

Slitter blades are a very common type of circular knife in factories. These blades spin to cut things fast and with care. Factories use slitter blades for many materials, from thin films to thick rubber.

- Razor blades are best for thin things like paper and film. Packaging and printing companies use them for neat, straight cuts.

- Shear blades cut thick things like cardboard and rubber. They are strong and last a long time, so they are good for tough jobs.

- Rotary slitter blades cut fabric into thin strips. They can cut many layers at once, which helps work go faster.

- Dished slitter blades cut films and foils without hurting them. Packaging and laminating companies use these blades to keep things smooth.

- Circular slitter blades help with nonstop cutting in places like medical device factories.

Slitter blades are made from strong materials like D2, HSS, and Cr12MoV. These materials help the blades stay sharp and last longer. Factories pick slitter blades because they cut with care and leave smooth edges. The blades can be as big as 600mm wide and cut things from 0.1mm to 24mm thick. Industries like packaging, paper, textiles, and metal use these blades for cutting, trimming, and shaping.

Tipp: Pick the right slitter blade for the material and the kind of cut you want. Razor blades are for thin films. Shear blades are for thick or hard things.

Crush Cut Knives

Crush cut knives are another important kind of circular knife. These blades use pressure to crush and cut soft or layered things. Factories use crush cut knives for foam, textiles, and nonwoven fabrics. The blade pushes against an anvil roll to slice the material.

Crush cut knives are good for things that might fray or get messed up with other blades. Textile factories use them to cut soft fabrics without harm. The blades also help make hygiene products, carpets, and insulation. Their design lets them cut fast and keep working, which helps factories make more.

Nanjing Metal makes crush cut knives from strong, tough materials. Their blades stay sharp and do not bend, even after lots of use. The company’s team can make custom shapes and sizes for any machine or job.

Notiz: Crush cut knives help stop fraying and keep edges tidy. This is why they are great for fabric and nonwoven materials.

Perforiermesser

Perforating knives are very useful in packaging, printing, and converting. These circular knives make rows of tiny cuts or holes. This makes it easy to tear off parts of a material. Perforating knives help make tear-off packages, labels, tickets, and inserts.

- Factories use perforating knives to make packages easy to open but still strong.

- These blades help work go faster by cutting out extra steps.

- Perforating knives make neat, careful cuts, which makes products better.

Circular perforating blades work well in fast production lines. They cut quickly and last a long time, so there are fewer stops. Special perforating knives can cut both soft and hard things without damage. In food packaging, these blades help make packages that stay fresh and open easily.

Callout: Perforating knives make it easy for people to open packages and help companies work faster.

Serrated Knives

Serrated knives are special because they have a saw-like edge. This edge has sharp teeth that grab and cut tough or slippery things. Factories and food companies use these circular blades for many jobs. A smooth blade might slip or crush the food, but serrated knives do not.

- In bakeries, workers use serrated knives to slice bread and cakes. The teeth cut cleanly and do not squash the soft inside.

- Food workers use these knives to cut fruits and vegetables with tough skins. Tomatoes, peppers, citrus, and melons need a blade that grips and slices without crushing.

- Pastry chefs use serrated circular knives for cakes, pastries, and chocolate. The blade makes neat, fancy cuts and does not melt or press down the food.

- When making decorations, like tomato roses or thin citrus slices, serrated knives help. The teeth hold slippery foods and make even, pretty cuts.

The design of serrated circular knives lets workers use a gentle sawing motion. This gives more control and makes cutting easier. These knives help save food and make finished products look better.

Tipp: Serrated circular knives are needed in bakeries, food factories, and anywhere that needs neat, careful cuts on soft or tough foods.

Pelletiermesser

Pelletizer knives are important in plastics and rubber factories. These circular blades cut hot plastic or rubber strands into small, even pellets. Machines push hot material through holes to make strands. Pelletizer knives spin and slice these strands into same-sized pellets.

Pellet size and shape are important in factories. Even pellets help machines work well and make better products. Pelletizer knives must stay sharp and strong for fast work. Factories use different pelletizing ways, like strand, underwater, and die face pelletizing. Each way needs a special circular blade.

Rotor knives spin fast to cut the strands. Bed knives hold the material steady. The right blade material, like tool steel or carbide, helps the knives last longer. Some pelletizer knives have special coatings to stop heat and wear.

Pelletizer knives help make pellets the same size. This makes it easier to handle and use plastic and rubber in factories.

Tray and Guillotine Knives

Tray and guillotine knives are important circular knives in food and packaging. Guillotine knives have a straight edge and move up and down to cut. Workers use these blades to slice thick or stacked foods, like meats and seafood. The sharp, strong blade keeps food looking good and saves waste.

Food factories pick guillotine knives made from safe, approved materials. This keeps cutting safe and clean. These blades last longer, so factories change them less often.

Tray sealing knives are another kind of circular blade for packaging. These knives cut and seal things like food trays, blister packs, and vacuum containers. They come in many shapes and tooth styles for films, foils, and plastics. Tray knives help factories pack products fast and with less fixing.

- Guillotine knives make straight, even cuts for meats and thick foods.

- Tray knives shape, cut, and seal packages, making work faster and saving materials.

- Both knives help factories work quickly and keep things clean.

Notiz: Picking the right tray or guillotine knife helps factories keep food safe, cuts neat, and packaging quick.

Applications by Industry

Verpackung

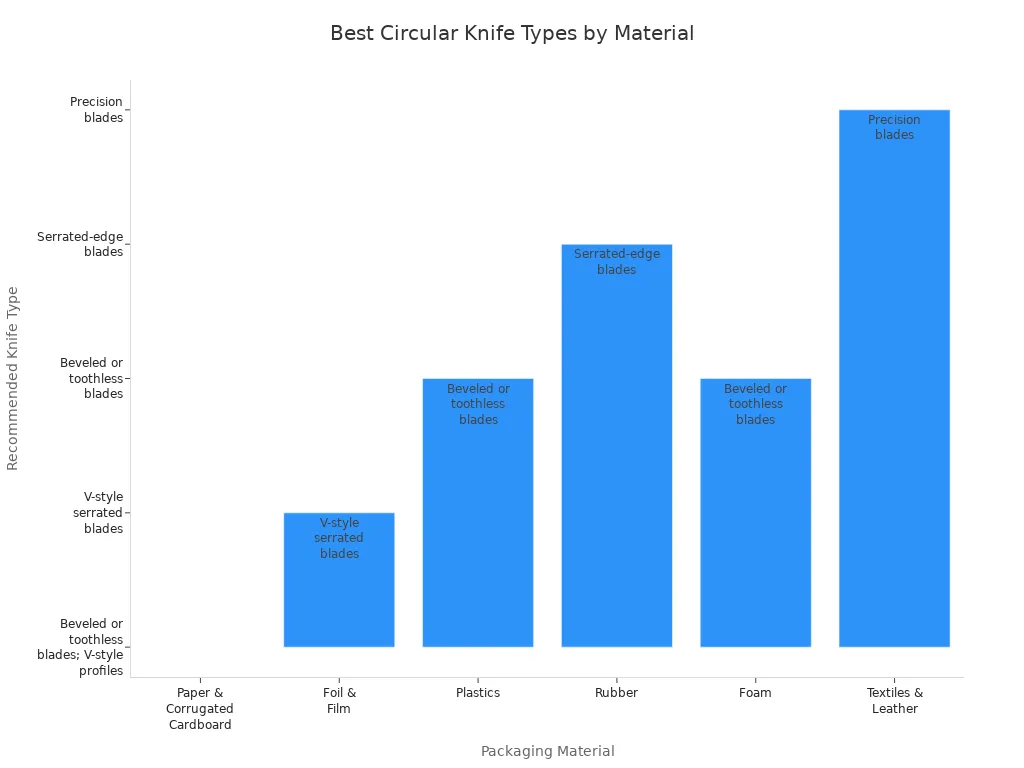

The packaging industry uses circular knives for many jobs. These knives cut lots of packaging materials. They work on films, paperboard, foils, plastics, rubber, foam, textiles, and leather. Factories use circular knives to cut things fast and right. The right blade makes clean edges. Clean edges help packages look good and stay strong.

The table below shows the best circular knife for each material:

| Packaging Material | Common Circular Knife Types | Blade Edge/Configuration | Blade Material Examples |

|---|---|---|---|

| Paper & Corrugated Cardboard | Beveled or toothless blades; V-style for scoring/perforating | Square edge, single-bevel, V-style serrated | High-carbon steel, stainless steel, 52100 |

| Foil & Film | V-style serrated blades | Serrated or beveled edges | Stainless steel, solid carbide |

| Kunststoffe | Beveled or toothless blades | Toothless or beveled edges | High-carbon steel, D-2, CPM 10V |

| Gummiindustrie | Serrated-edge blades | Serrated edges | M-2, D-2, CPM 10V |

| Schaum | Beveled or toothless blades | Toothless or beveled edges | High-carbon steel, ceramic |

| Textiles & Leather | Precision blades for splitting/perforating | Single-bevel, double sharp edges | 1075/1095 spring steel, stainless steel |

Factories use slitter blades to cut films and foils fast. These blades make smooth edges. Smooth edges are needed for sealing and safety. Perforating knives make easy-tear lines. This helps people open packages easily. Beveled and toothless blades split and trim paperboard and foam. Serrated blades cut thick rubber and tough packaging.

Tipp: Picking the right circular knife for each material helps factories work faster, waste less, and make better products.

Textile and Leather

Textile and leather factories need circular knives for fast, careful cuts. These factories work with woven fabrics, nonwovens, real leather, and fake leather. Circular knives help with slitting, trimming, perforating, and splitting. They make clean edges and stop fraying.

- Machines with circular knives cut faster and more accurately. This means better products and less wasted fabric.

- Careful cutting stops fabric edges from fraying and keeps them smooth.

- Strong blade materials, like high-carbon steel and ceramic, help blades last longer and stop work from slowing down.

- Custom blades fit special fabrics, so even soft or stretchy materials get clean cuts.

Crush cut knives are good for soft or layered fabrics. They use pressure to cut without hurting the material. Serrated knives grip slippery or tough fabrics. They make cleaner cuts on thick or fake leather. Special leather blades cut and split leather well, making products better.

| Tool Type | Pro | Am besten für | Use On |

|---|---|---|---|

| Hand Side Hole Cutter | Produces clean circular cuts quickly | Punching holes in fabrics | Fabric, vinyl, leather, foam |

| Heißes Messer | Seals edges to prevent fraying | Synthetic fabrics | Synthetic leather, textiles |

Circular knives also work in CNC machines for textiles. These machines use custom blades to cut leather, fabric, and nonwovens very accurately. Carbide-tipped blades stay sharp longer, so factories stop less for sharpening.

Notiz: Using the right circular knives in textile and leather factories makes work faster, wastes less, and gives better products.

Lebensmittelverarbeitung

Food factories use circular knives for many jobs. These knives cut, slice, and portion lots of food. They work on frozen foods, baked goods, and meats. Factories need blades that stay sharp and cut the same every time.

- Circular blade slicers cut meats, cheeses, and packaged foods.

- These knives help with slicing, dicing, skinning, peeling, and portioning.

- Good blade materials and coatings stop wear and rust, so blades last longer.

- Circular knives help factories stop less and save money.

Serrated knives are best for bread and baked goods. The teeth stop crumbling and make smooth slices. Tray and guillotine knives are good for cutting frozen or sticky foods. These blades cut well and keep food looking nice.

Food factories have problems like surprise stops and blade wear. Circular knives made from strong materials help fix these problems. They help with planned repairs and make machines more reliable.

Callout: The right circular knives in food factories help work go faster, keep food good, and make sure everything stays clean and safe.

Paper and Printing

The paper and printing industry uses circular knives for many jobs. These knives cut coated paper, cardboard, and adhesive labels quickly and accurately. Factories use circular knives to slit, trim, and perforate paper products. This keeps work moving and helps reduce waste.

- Slitter blades are best for fast, careful slitting of paper rolls and sheets. They make clean cuts and keep edges smooth.

- Perforating knives make rows of tiny holes or cuts. This lets people tear off labels, tickets, or forms without ruining the rest.

Circular knives in this industry must stay sharp and work well. Makers use special hardening and machines to help knives last longer. Regular care and service keep the knives working their best.

Tipp: Careful manufacturing and close measurements make every cut clean. This means less wasted material and faster work.

Here are some ways circular knives help paper and printing factories:

- Perforator knives make sharp, even holes, which lowers waste.

- Strong materials help knives last through lots of use, so there is less stopping.

- Custom shapes let companies pick knives that fit their needs.

- Top and bottom slitter knives stay sharp and work well, even when cutting fast.

| Material | Messertyp | Application Example | Nutzen |

|---|---|---|---|

| Coated Paper | Schneidklingen | Roll slitting | Clean, accurate edges |

| Karton | Schneidklingen | Sheet trimming | Smooth, burr-free cuts |

| Adhesive Labels | Perforiermesser | Tear-off label creation | Easy, controlled separation |

Kunststoffe und Gummi

Factories that work with plastics and rubber use circular knives for many jobs. These knives cut, score, perforate, and slit plastic films, rubber sheets, and foam. The right knife gives smooth, even cuts and helps factories keep up with lots of work.

- Pelletizer knives cut hot, melted plastic into small, even pellets. This is important for recycling and making new plastic things.

- Slitter blades cut plastic films and rubber sheets all the time. They keep edges neat and help stop waste.

Circular knives for plastics and rubber must be strong. They often use tough materials like High Speed Steel or carbide coatings. This helps the knives stay sharp and last longer.

Here are ways circular knives help with plastics and rubber:

- They cut, score, and slit plastic products for good results.

- In rubber factories, they cut thick materials smoothly, even during long runs.

- Pelletizer knives cut melted plastic quickly and evenly. This keeps pellet size the same and helps work go faster.

- The right blade shape and hardness saves energy and lowers machine shaking.

| Material | Messertyp | Application Example | Nutzen |

|---|---|---|---|

| Kunststofffolien | Schneidklingen | Film slitting | Continuous, clean cuts |

| Rubber Sheets | Schneidklingen | Sheet cutting | Precise, smooth edges |

| Molten Plastic | Pelletiermesser | Pelletizing for recycling | Consistent granule size |

| Schaum | Schneidklingen | Foam trimming | Even, accurate shaping |

Metalworking and Recycling

Metalworking and recycling factories use circular knives for tough jobs. These knives cut thin metal sheets, aluminum foil, and scrap metal. Factories need strong, careful knives for these hard tasks.

- Slitter blades cut thin metals and foils with great care. They help make clean edges for the next steps.

- Special knives handle recycling jobs, like chopping scrap metal or shredding waste.

Makers design circular knives for metalworking and recycling with special features. They use hard, tough materials to keep knives sharp. Custom shapes and sizes fit different machines and jobs.

| Type of Circular Knife | Anwendungsbereich | Description and Use Cases |

|---|---|---|

| Rotary Metal Slitters | Metalarbeiten | Used for careful slitting of metal sheets and coils. |

| Rotary Tube Cutoff Knives | Metalarbeiten | Made for cutting metal tubes and pipes. |

| Metal Scrap Chopper Knives | Metalworking / Recycling | Used for chopping scrap metal into smaller pieces for easier handling and recycling. |

| Scherenmesser | Metalarbeiten | Used in shearing to cut sheet metal. |

| Schreddermesser | Recycling | Strong knives for shredding waste like metals, plastics, and rubber. |

| Granulatormesser | Recycling | Used to break down recyclable things like PET, plastics, copper, aluminum, and rubber. |

| Scrap Metal Recycling Knives | Recycling | Special knives for cutting scrap metals like cast iron. |

Circular knives in these jobs must meet strict rules. They need to cut hard things without getting dull.

Notiz: Picking the right circular knife for each job helps factories save time, waste less, and make better products.

Blade Materials and Edges

Materialoptionen

Picking the right blade material is important for good cutting. Each material gives the blade special strengths. Factories pick blade materials based on what they need to cut and how fast they want to work. The table below shows common materials used in circular cutting tools and what they are good for:

| Klingenmaterial | Description/Notes |

|---|---|

| HSS | High-speed steel, good for fast cutting |

| 65Mn | Spring steel, flexible and tough |

| 9CrSi | Tool steel, holds a sharp edge |

| Cr12MoV | Wear-resistant, good for heavy-duty work |

| SKD-11 | Tool steel, strong and durable |

| Edelstahl | Rust-resistant, safe for food |

| Wolframkarbid | Very hard, lasts a long time |

| Cemented Carbide | High hardness, resists wear |

High-speed steel is great for quick jobs. Stainless steel does not rust, so it is safe for food and medical work. Tungsten carbide blades last a long time and cut tough things.

Edge Types

The blade’s edge changes how it cuts things. Factories use different edge shapes for different jobs. Here are the main edge types and what they do:

- Serrated Edge: Has teeth like a saw. Cuts bread, rubber, and tough foods. Needs less force and works fast.

- Smooth Edge: Flat and sharp. Makes clean cuts in paper, film, and thin plastics. Good for accurate cutting.

- Perforated Edge: Has small notches or holes. Makes tear lines in packaging, labels, and tickets.

The table below shows how edge types affect cutting:

| Kantentyp | Cutting Force Needed | Am besten für | Schnittgeschwindigkeit |

|---|---|---|---|

| Gezähnt | Niedrig | Bread, rubber, textiles | Schnell |

| Glatt | Medium | Paper, film, thin plastics | Mäßig |

| Perforated | Niedrig | Packaging, labels, easy tearing | Schnell |

Serrated blades are fast and need little force. Smooth edges make neat, careful cuts. Perforated edges help with easy tearing. Factories pick the edge type based on what they are cutting and what they want the cut to look like.

Geometry and Tolerances

Blade geometry and tolerance are important for good cuts. Geometry means the blade’s thickness, size, and edge shape. Tolerance is how close the blade is to its design size. Tight tolerances help with careful cutting, especially in fast or tricky jobs.

| Aspekt | Wichtige Überlegungen |

|---|---|

| Blade Tolerance Matching | Match blade tolerance to machine accuracy |

| Industry Tolerances | Medical: ±0.01mm, Packaging: ±0.05mm, Wood: ±0.10mm |

| Cost vs. Precision | Tighter tolerance costs more, but not always needed |

For example, packaging factories often use a tolerance of ±0.05mm. This gives good results and does not cost too much. Medical and aerospace jobs need tighter tolerances for safety.

Tip: Always match blade material, edge type, and tolerance to your cutting techniques and machine needs. This helps blades work better and last longer.

Selecting Industrial Knives

Assessing Needs

Picking the right industrial knives starts with knowing the job. Factories need to check what material they will cut. Thin film or soft fabric needs a sharp, thin blade. Harder things like rubber or metal need a thicker, stronger blade. The kind of cut is important too. Smooth edges make clean, straight cuts. Perforated edges are good for easy-tear packaging. Factories should also think about how fast they want to work and how often they want to change blades.

Here is an easy step-by-step guide for picking industrial knives:

- Find out what material you need to cut (film, fabric, rubber, metal, etc.).

- Choose the cut style you want (smooth, serrated, perforated).

- Look at how thick and hard the material is.

- Pick the blade type that fits the job (slitter, crush cut, serrated, etc.).

- Think about how fast you want to work and how much downtime you can have.

- Pick a blade material that will last a long time.

Tip: The right industrial knives help save time, lower waste, and make products better.

Maschinenkompatibilität

Factories must make sure their knives fit the machines they use. Machines have different tool holders, like single, dual, or triple holders. These holders let workers change cutting tools quickly. Some machines use two heads to cut more or do two jobs at once. This setup helps factories work faster and do more.

| Faktor | Beschreibung | Impact on Circular Knife Selection |

|---|---|---|

| Blade Size & Shape | Must match machine specs, including length, width, thickness, and edge profile | Ensures proper alignment, reduces friction, and maintains cutting quality |

| Dicke | Too thick increases energy use; too thin may chip | Affects durability and efficiency |

| Edge Profile | Different angles for shearing, slicing, or crushing | Determines cutting method compatibility |

| Beispiel | V-type granulator knife with 30° angle for plastic granulator at 500 kg/h | Optimizes machine performance and cutting precision |

Factories should always check the machine manual before buying new knives. The right fit keeps machines working well and helps make good cuts.

Customization and OEM

Some factories need special knives for unique jobs. Nanjing Metal is a top industrial knives maker with 20 years of experience. They offer custom blade solutions for many industries. Their team can make knives from customer drawings, sketches, or samples. They help improve designs to fit new machines or materials.

Nanjing Metal offers:

- OEM and ODM services for custom knives.

- Full quality checks from start to finish.

- Flexible orders with low minimums.

- Real-time updates and easy import help.

- Good prices and a focus on strong, accurate blades.

Note: Custom industrial knives help factories fix special cutting problems and keep production lines working well.

Knife Types vs. Industry Table

Quick Reference

Die richtige Wahl circular knife helps factories work faster. It also helps them make better products. Many industries use different Kreismesser for cutting and trimming. Each knife type is best for certain jobs and materials. A quick table helps match the right blade to each industry.

Here is a table that shows which circular knife works for each job:

| Circular Knife Type | Recommended Industry Applications |

|---|---|

| Pelletizer knives | Plastics, Recycling |

| Schlitzmesser | Paper, Plastics, Packaging |

| Perforating knives | Packaging, Plastics |

| Serrated knives (bread roll, sweet, etc.) | Lebensmittelverarbeitung |

| Tray and guillotine knives | Food Processing, Packaging |

| Granulator knives | Plastics, Recycling |

| Metal processing knives | Metalarbeiten |

| Textile cutters and split knives | Textile, Nonwoven Materials |

| Cross-cut industrial knives | Paper, Packaging |

| Shear knives | Paper, Packaging |

| Sheeter knives | Paper, Packaging |

| Trimmer knives | Paper, Packaging |

| Tube cut-off knives | Plastics, Rubber |

| Foil cutting knives (smooth or toothed) | Packaging, Food Processing |

| Puncher and punching knives | Food Processing, Packaging |

| Cutting knives for vegetable processing | Lebensmittelverarbeitung |

| Scraping knives for filleting fish | Food Processing (Fish processing) |

| Fish skinning knives | Food Processing (Fish processing) |

| Industrial knives for core and tube cutters | Paper, Packaging, Plastics |

| Creasers and scorers | Paper, Packaging, Printing |

| Bag cutting knives | Verpackung |

| Rasper knives | Kunststoffe |

| Mitre knives | Verpackung |

| Packaging knives and anvils | Verpackung |

Tipp: Use this table to find the best knife for your job. This helps you make fewer mistakes and saves time at work.

A quick guide like this helps workers pick the right blade. They can see which knife matches their material, like film or rubber. The guide also shows which edge or tooth shape is best. For example, serrated edges are for bread. Smooth edges are for film.

- Kreismesser have many shapes and edge styles. Each one is made for a special job.

- Tooth shapes can be V, scalloped, or peg. These help with different cuts.

- Custom blades can be made for special machines or materials.

A good table saves time and helps factories avoid mistakes. Workers can check the table before buying new blades or setting up machines. This makes sure they always use the best tool for the job.

Picking the right circular knife, material, and edge helps every industry do a better job. The table below shows which blade works best for each job:

| Klingenmaterial | Beste Verwendung |

|---|---|

| D2 Werkzeugstahl | Tough materials, slitting |

| SKD-11 Alloy Steel | Strong plastics, hard jobs |

| Hochgeschwindigkeitsstahl | Fast, precise cutting |

| Wolframkarbid | Abrasive, continuous work |

| Edelstahl | Food, medical, hygiene |

Nanjing Metal is a trusted circular knives manufacturer with 20 years of experience. They offer custom industrial blade solutions.

If you need help or want the best blade for your job, reach out to Nanjing Metal today.

Häufig gestellte Fragen

What are the main types of circular knives used in industrial slitting?

Factories use slitter blades, crush cut knives, perforating knives, and serrated knives for slitting jobs. Each circular knife works best for certain materials and cutting needs.

How do I choose the right blade type for cutting adhesive film vs fabric?

Smooth-edge slitter blades work best for cutting adhesive film. They make clean cuts. Fabric needs crush cut or serrated knives to stop fraying.

Can circular knives be used in CNC fabric cutting machines?

Yes, many CNC machines use circular knives for textiles and leather. These blades cut fast and accurately. Nanjing Metal makes custom rotary blades for CNC systems. They support both regular and special fabric cutting jobs.

What materials are circular knives made from?

Manufacturers use high-speed steel, stainless steel, 65Mn, 9CrSi, Cr12MoV, and tungsten carbide. Each material has different strengths for sharpness and long life. Nanjing Metal picks materials based on what the customer needs.

How do I maintain circular knives for longer life?

Clean blades often, store them right, and sharpen them on time. Using the correct blade for each material also helps blades last longer. Nanjing Metal gives tips on caring for all types of circular knives.

Which industries use different types of circular knives?

Packaging, textile, food processing, plastics, rubber, metalworking, and recycling all use circular knives. Each industry needs special blade shapes and materials for the best results.

Siehe auch

Industrielle Kreismesser: Leistungs- und Materialvergleich

Top 10 Tipps, wie Sie die Lebensdauer Ihrer Kreisrasierklingen verlängern

So wählen Sie die richtigen Kreisschneiderklingen für lang anhaltende Leistung

So halten Sie die Klinge Ihres Rundmessers scharf und langlebig

So wählen Sie die richtigen Kreissägeblätter für Ihre Anwendung aus: Eine vollständige Anleitung

Die 5 häufigsten Verschleißprobleme bei Kreisscherenmessern und fachmännische Reparaturlösungen