You need good tools to cut billets well. Stabscherenmesser with the right shape and material help you make clean cuts. They also help you waste less material. If you pick the right blade size and edge shape for your material, you get better results. Your blades will last longer too. Many workers have problems like bent steel, lost time, and rough surfaces. Specialized blades from Metal Industrial use special heat treatment and forging. These blades help you stop these problems. They keep your work safe and fast.

Die wichtigsten Erkenntnisse

- Pick the right bar shear blade shape and material for clean cuts and less waste.

- Low rake angles and good cutting geometry help make cuts more precise and lower distortion.

- Regular maintenance, like sharpening and checking alignment, keeps blades working well and helps them last longer.

- Choose blade materials that are tough and resist wearing out to fit your cutting needs.

- Custom blades can work better for special jobs and give better results.

- Taking care of blades the right way means less downtime and lower maintenance costs.

- Knowing about blade geometry helps you get smoother cuts and stops problems like fishtailing.

- Using special blades in different industries makes work more efficient and improves product quality.

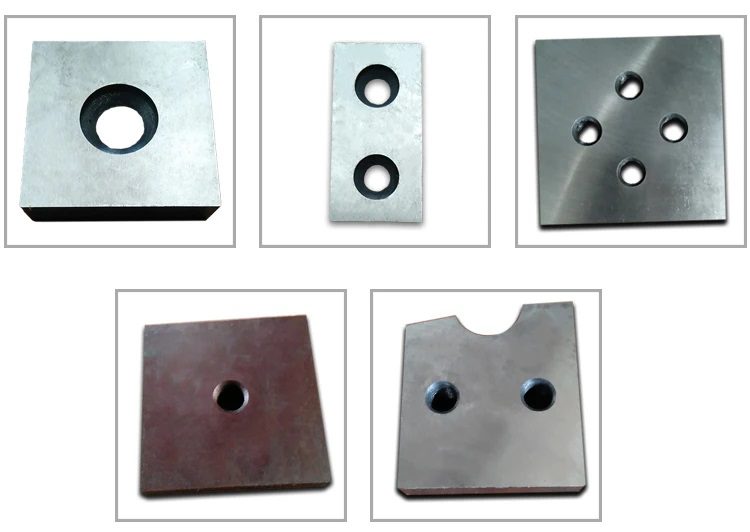

Bar Shear Blades: Specialized Design

Bar shear blades are important for cutting metal. You need the right blade design for good results. Special features help you cut steel billets with less waste. These features also give you better cuts. Let’s see what makes these blades special.

Precision Features

Low rake angles

Low rake angles help control how hard it is to cut. When you use blades with low rake angles, your cuts are smoother. You also get less distortion in the metal. This design helps you cut steel and other metals with high accuracy. It lowers the chance of bending or fishtailing when you cut billets.

Optimized cutting geometry

Optimized cutting geometry means the blade shape fits the job. You get better quality and more exact cuts. The geometry includes the blade angle, clearance, and edge shape. Here is a table that shows common design features:

| Besonderheit | Beschreibung |

|---|---|

| Klingenwinkel | Changes how much force you need to cut. |

| Blade Clearance | Usually about 7% of the material thickness; affects the cut edge. |

| Edge Configuration | Can be straight or slanted; changes how well the blade cuts. |

You can see how each feature changes the way you cut. If you want a blade that fits your needs, you can visit the Seite für benutzerdefinierte Klingen for more options.

- A sharp edge and a scooped back help you remove soft metal butts easily.

- If the cutting edge gets damaged, the blade can stick or break.

- Chips and cracks can mean the blade clearance is not correct.

Material and Manufacturing

Heat treatment processes

Wärmebehandlung makes shear blades strong and tough. You need strong blades for cutting steel and other metals. Special heat treatment and forging make the blade’s inside structure better. This helps the blade stay sharp and last longer. Methods like annealing, normalizing, and quenching change the blade’s inside. You get more strength, flexibility, and toughness. These things are important for good cuts and long blade life.

Toughness vs. hardness balance

You want a blade that is hard enough to cut steel. But it also needs to be tough so it does not break. Forging lines up the inside grain with the blade’s shape. This makes the blade stronger and helps it last longer. You get a blade that stays sharp and works well. Nanjing Metal Industrial uses these methods to make good shear blades.

Edge Profile and Blade Shape

The edge profile and blade shape change how well you cut billets. You need the right edge angle and small details for good cuts. Studies show that blade shape changes how well the blade works and how long it lasts. For example:

| Study | Ergebnisse |

|---|---|

| Zhang et al. (2023) | Blade shape, including edge angle and small details, changes how well the blade works and lasts. |

| Kurt et al. (2009) | Blade angle changes the stress on the blade, which changes how well it cuts. |

| Mehrin et al. (2022) | Blade shape is important for how well the blade cuts. |

| Mróz et al. (2025) | Knife shape lowers burrs in strong materials, so blade shape matters for performance. |

You get better cuts and longer blade life with the right edge profile.

Tip: Always match the blade shape and edge profile to your steel billet and cutting needs. This helps you get the best precision and quality in your metal manufacturing process.

Bar shear blades with special designs help you cut steel with high accuracy and quality. You get blades that last longer, cut better, and work well in metal manufacturing.

Distortion Control in Metal Shearing

Distortion can mess up your work when you shear metal. You want your cuts to be straight and smooth. You also want to stop problems like fishtailing and smearing. The right blade shape and sharpness help you control distortion. You can use special ways to cut metal for better results.

Blade Geometry Impact

V-block and rake profiles

You need to look at the shape of your blade. V-block profiles hold the billet steady when you cut. This keeps the billet from moving and helps you cut straight. Rake profiles change how the blade touches the metal. Low rake angles make cutting smoother. You use less force and get more accuracy. The right profile helps you stop bending and stretching the metal. You see fewer distortion problems with blades that have the best shape.

Stress distribution

Stress distribution is important when you shear metal. If you spread the force evenly, you get cleaner cuts. The blade shape controls how stress moves through the billet. V-blocks and low rake angles help spread the force. This lowers the chance of fishtailing and smearing. You get better results with the right cutting methods. You also keep your blade safe from damage.

Tip: Always check your blade shape before you start shearing. Good blade shape gives you better accuracy and less distortion.

Edge Sharpness and Maintenance

Burr reduction

Sharp blades really help when you shear metal. You get fewer burrs and smoother edges. Burrs are rough bits left after you cut. They can cause trouble in later steps. When your blade is sharp, you see less fishtailing and smearing. Here are some facts about sharp blades and good cuts:

- Less edge stretch means sharp blades make better cuts. This helps you stop fishtailing and smearing.

- The best edge keeps damage and changes inside the metal low. You get better results when you cut billets.

- Bad edge quality can cause cracks. For example, rocker panels made from DP980 had more cracks when the edge was not sharp.

You need to keep your blades sharp for the best results when you shear metal.

Alignment and clearance

Blade alignment and clearance are key for good cuts. If your blades are not lined up, you get uneven cuts. You also see more distortion. Clearance is the space between the blade and the billet. You need the right clearance for each way you cut metal. Too much clearance makes burrs. Too little clearance can hurt the blade. You should check alignment and clearance before you start shearing.

You can use good care steps to keep your blades sharp and lined up. Here is a table that shows what you should do:

| Wartungspraxis | Beschreibung |

|---|---|

| Proper Grinding Techniques | Use a grinding machine, clean the blade first, and use coolants to stop overheating. |

| Regular Cleaning and Lubrication | Clean blades every day and use PTFE-based lubricants to lower friction and help blades last longer. |

| Sichere Handhabung und Lagerung | Wear safety gear, store blades in a dry place, and check for damage often. |

| Fehlerbehebung | Check for dullness, chips, and misalignment often to keep blades working well. |

You can follow these steps to keep your blades working well. You get better accuracy and less distortion when you shear metal. You also help your blades last longer.

Note: Good care helps you avoid stopping work and keeps your shearing process running well.

You control distortion in metal shearing by using the right blade shape, keeping blades sharp, and following good care steps. You get smooth cuts, better accuracy, and fewer problems like fishtailing and smearing. You also make your metal cutting better and your work easier.

Blade Material Selection for Precision

Picking the right blade material is very important. It helps you cut billets with accuracy. You need to know how alloys and hardness ratings change blade performance. This helps you choose blades that make clean cuts. Good blades last longer and help you work faster.

Alloy Choices

You have many choices for blade material. Each alloy has special benefits for cutting billets. The table below shows three steel alloys used in shear blades:

| Alloy | Zähigkeit | Verschleißfestigkeit | Hardness (Rockwell C) | Anwendungen |

|---|---|---|---|---|

| A8 | Sehr gut | Intermediate | 55-60 | Punches, Dies |

| D2 | Gut | Hoch | N / A | Blanking, Forming, Trimming |

| S7 | Sehr hoch | Medium | N / A | Dies, Chisels, Punches |

Toughness for solid stock

Blades need high toughness for cutting solid stock. S7 steel is very tough. This helps the blade avoid cracks and chips. A8 steel is also tough and works well for many cuts. Tough blades handle stress and impact better. You get more reliable cuts with tough blades.

Verschleißresistenz

Wear resistance keeps blades sharp for longer. D2 steel has high wear resistance because of its carbon and vanadium. D2 is good for cutting rough materials. CPM steels are also great for wear resistance. They have a uniform structure inside. If you want blades that stay sharp, pick alloys with high wear resistance.

- Different alloys like A series, D series, and CPM steels change how long blades stay sharp.

- D series steels, like D2 and D7, work well in hard cutting jobs.

- CPM steels use a special process to make their structure even. This helps with toughness and wear resistance.

Hardness Ratings

HRC and durability

Hardness ratings use the Rockwell C (HRC) scale. They show how strong your blade is. Higher HRC means the blade is harder and keeps its edge longer. Hard blades are good for precise cuts. They resist wear and stay sharp for many uses. With the right hardness, you spend less time fixing blades. You get better and more steady results.

HRC ratings tell you how hard shear blades are. Hard blades last longer and cut better. High HRC means blades keep their sharpness and resist wear. This is important for good cutting over time.

You should match blade hardness to the steel you cut. For example, A8 steel with 55-60 HRC is good for punches and dies. D2 steel is best for blanking and trimming. S7 steel is great for jobs needing impact resistance.

If you want help picking blade material, you can ask Nanjing Metal Industrial. They know a lot about steel blade materials. They help you get the best results for billet cutting.

Tip: Always think about both toughness and hardness when picking blade material. This helps you get blades that last and cut well.

You get better cuts and longer blade life by picking the right steel alloy and hardness. This helps you work faster and get the accuracy you need for billet cutting.

Shear Blades for Different Applications

Cold Cropping vs. Hot Shearing

Speed and impact requirements

You must pick the best way to cut billets. Cold cropping uses strong blades and big machines. It cuts billets at room temperature. This method needs fast hits and lots of force. You get clean cuts if you line up the billet and blade well. Hot shearing is not the same. You heat the billet until it gets soft. The blade cuts with less force. The process goes faster. Hot shearing is good for big billets or hard metals.

Thermal fatigue resistance

Hot shearing makes blades face high heat many times. You need blades that can handle this heat. These blades keep their shape and stay sharp after many hot cycles. Special blade materials and coatings help them last longer. Cold cropping does not need as much heat resistance. But it does need blades that can take strong hits without breaking.

Process Workflow Comparison

You can see how cold cropping and hot shearing are different:

| Verfahren | Temperatur | Cutting Force Needed | Geschwindigkeit | Typische Anwendungsfälle |

|---|---|---|---|---|

| Cold Cropping | Room temperature | Hoch | Mäßig | Carbon steels, alloy steels, non-ferrous metals |

| Hot Shearing | High temperature | Untere | Schnell | High-alloy steels, large billets, aluminum alloys |

With cold cropping, you set up the billet and blade. You use a strong, quick hit to cut. This works best for metals that stay strong when cold. Hot shearing starts by heating the billet. The blade then slices through the soft metal. You use hot shearing for billets that are too thick or tough for cold cropping.

Suitable Materials Comparison

You must match your cutting way to the metal. Cold cropping works for metals that stay strong when cold. You use it for carbon steels, alloy steels, and non-ferrous metals. Hot shearing is better for billets that get soft when heated. You use it for high-alloy steels, big billets, and metals like aluminum. This helps you get good cuts and waste less material.

Industry Versatility

Metal Industry Applications

Shear blades are used in the metal industry. They cut and size billets, bars, and sheets. These blades give you clean cuts and help you waste less metal. You can work faster and keep your line moving. Shear blades help keep the metal’s shape and quality. You see these blades in car and airplane factories. Here, you need good cuts and less waste.

- Shear blades help you:

- Get clean cuts and waste less metal.

- Arbeiten Sie schneller und sparen Sie Zeit.

- Keep metal strong with less bending.

- Make sure your products are always good.

You can trust shear blades to help your work and keep things running well. When you use good cutting methods, you get better results and less scrap.

Plastics Industry Applications

Shear blades are also important in plastics work. You use them to trim shapes, cut rods, and get materials ready for molding or recycling. Good blades give you clean, even cuts and help you avoid mistakes. You also waste less plastic, which helps with recycling.

| Nutzen | Beschreibung |

|---|---|

| Haltbarkeit | Strong materials make blades last longer. |

| Präzision | Clean cuts stop mistakes. |

| Betriebseffizienz | Faster work means less waiting. |

| Nachhaltigkeit | Less waste and better recycling. |

| Vielseitigkeit | Blades work with many machines and jobs. |

You can use shear blades for many plastic jobs. Good blades help your work go smoothly and keep your products nice.

Food Industry Applications

Shear blades are used in food factories too. They help you cut and shape food. You use them to slice dough, cut candy, and get food ready for packing. Good blades give you neat cuts and make food look nice.

| Anwendung | Beschreibung |

|---|---|

| Lebensmittelverpackungen | Shear blades make sure each package has the right amount. |

| Lebensmittelverarbeitung | Machines use shear blades to shape food fast and keep work moving. |

- Food factories need better cutting tools every year.

- Shear blades help you keep up with demand and make your work steady.

You can move the blade to cut different food sizes. This makes your work easier and faster.

Recycling Industry Innovations

In recycling, blades must cut mixed and dirty materials. New blade designs help you cut faster and fix blades less often. You see things like easy-to-fix designs, special coatings, and smart tech.

| Besonderheit | Nutzen |

|---|---|

| Modulares Design | Easy to fix and change parts |

| Energy-efficient hydraulic systems | Use less power |

| Customizable blade configurations | Work better for each recycling job |

| Tungsten-carbide coatings | Blades last longer and need less fixing |

| Smart technology integration | Track blades in real time for better control |

You use these new ideas to help blades work better and stop delays. You also waste less because blades last longer and cut better.

Tip: Pick the right shear blade for your job and material. This helps you get good cuts, waste less, and keep your work smooth.

Shear blades are used in many industries. You get better cuts, waste less, and work with more accuracy. The right blade helps you reach your goals, whether you work with metal, plastic, food, or recycling.

Maintenance for Metal Shearing Precision

Taking care of shear blades helps you cut better. You need to do regular maintenance to keep blades sharp. This makes your work more accurate and wastes less material.

Maintenance Protocols

Sharpening and edge care

You should sharpen blades often. Dull blades make rough cuts and slow you down. Most experts say sharpen every 500-700 uses or when cutting gets hard. Use the right tools for sharpening. Clean the blade before you start. Always check the edge for chips or cracks. Fix damage right away. Sharp blades help you cut fast and smooth.

Tip: Sharp blades give cleaner cuts and help stop burrs and fishtailing.

Parallelism and clearance

Check blade alignment often. If blades are not parallel, cuts are uneven and waste goes up. Use a gauge to check alignment. Adjust blades if you see gaps. Clearance is the space between blade and billet. Set the right clearance for each job. Too much clearance makes burrs. Too little can hurt the blade. Always follow the manufacturer’s rules for alignment and clearance.

Here is a table with main maintenance steps:

| Maintenance Protocol | Beschreibung |

|---|---|

| Reinigung | Wipe blades with a dry cloth after each use to stop buildup. |

| Schmierung | Put shear oil on the pivot area weekly or more if you use blades a lot. |

| Schärfung | Sharpen every 500-700 uses or when cutting gets worse. |

| Ausrichtung | Check blade alignment often and fix misaligned blades. |

| Tension Adjustment | Check and adjust tension as the manufacturer says for smooth cutting. |

| Richtige Lagerung | Store shears in a case to stop damage and keep them clean. |

Use these steps to keep blades working well. Good care helps you get better cuts and makes blades last longer.

Maximizing Blade Life

Preventing rapid wear

You want blades to last a long time. Rapid wear happens if you use the wrong blade or skip maintenance. Pick the right blade material for your job. Tungsten carbide and ceramic blades are good for tough jobs. Use blades with the right edge shape and angle. Coatings protect blades and help cuts look better. Change cutting speed and pressure to lower heat and friction. Mirror polishing helps blades cut better and stay clean. Always keep machine settings correct. Check alignment and tension often.

| Cause of Rapid Wear | Prevention Method |

|---|---|

| Blade material choice | Use materials like tungsten carbide or ceramic for tough jobs. |

| Blade geometry | Pick the best edge shape and angle for your material. |

| Beschichtungen | Use coatings to protect blades and improve cuts. |

| Friction and heat | Change speed and pressure to lower heat and friction. |

| Polishing | Mirror polish blades to help cutting and keep blades clean. |

| Machine settings | Keep alignment and tension right to avoid too much load. |

Follow these steps to stop rapid wear and help blades last longer.

Reducing machine strain

Good maintenance helps blades and machines work well. If you skip care, you may get misalignment, vibration, and blade wear. These problems slow work and waste material. Sharp blades help you cut faster and lower strain on machines. Regular checks and part changes help machines run smoothly. You get better cuts and waste less.

Note: Taking care of blades and machines saves money on repairs and replacements. You also avoid long stops in work.

How Maintenance Affects Cost and Downtime

Regular maintenance lowers costs. Well-cared blades mean fewer stops and less wasted material. Premium blades last longer between maintenance. You pay more at first, but save money because you replace blades less and machines keep running.

| Beweisart | Beschreibung |

|---|---|

| Verbesserte Schnittpräzision | Well-cared blades mean fewer stops and less wasted material. |

| Reduzierte Ausfallzeiten | Premium blades last longer, so you need less maintenance and fewer replacements. |

| Lower Total Cost of Ownership | Higher first cost is balanced by longer life and lower running costs. |

If you follow good care steps, you get better accuracy, save money, and keep work moving.

Tip: Make maintenance a regular habit. You will get better results and spend less time fixing problems.

Selecting Shear Blades for Billet Cutting

Picking the right shear blade helps you make clean cuts. You need to match the blade to your billet’s material and size. This choice changes how well you cut and how fast you work.

Matching Blade to Material

Selection criteria

Think about what kind of material you want to cut. Also, check how thick your billets are. Each blade material works best for certain jobs. The table below shows which blade fits each job:

| Klingenmaterial | Eigenschaften | Bester Anwendungsfall |

|---|---|---|

| T8 / T10 (Carbon Tool Steel) | Hard and cheap, but not very tough, good for soft stuff. | Cutting thin sheets of low-carbon steel or aluminum. |

| 9CrSi (Low-Alloy Tool Steel) | Wears down slowly, pretty tough, good for medium or thin pieces. | Medium or thin carbon steel plates. |

| 6CrW2Si (Impact-Resistant Tool Steel) | Very tough, does not break easily, good for thick plates. | Cutting thick plates or scrap steel. |

| Cr12MoV (D2) High-Wear Cold-Work Mold Steel | Wears down very slowly, great for hard materials. | Cutting stainless steel or high-carbon steel. |

| H13 (Hot-Work Mold Steel) | Stays strong when hot, keeps shape under heat. | Fast cutting in tough, hot jobs. |

Use this table to help you pick the right blade. If you cut thick billets or strong metals, pick a tough blade. For thin sheet metal, use a blade that matches the thickness and hardness.

Tip: Always check your billet’s material and thickness before picking a blade. This helps you get the best cuts.

Customization options

Sometimes you need special blades for tricky jobs. Custom blades can help you cut better and faster. Here is a table that shows some ways to change your blade:

| Customization Option | Auswirkungen auf die Schneidleistung |

|---|---|

| Coating technology | Makes blades last longer and work better in hot jobs. |

| Composite materials | Adds hard layers to make blades stronger and sharper. |

| Intelligent manufacturing | Helps make blades faster and better, so each one is high quality. |

You can ask for special blade shapes, edges, or coatings. These changes help you cut different materials or shapes. If you want more choices, check the Seite für benutzerdefinierte Klingen.

Performance and Efficiency

Minimizing downtime

You want your machines to keep working without stopping. Good blades stay sharp longer and need less fixing. Blades with special coatings or layers last longer. This means you do not have to stop and change them as much.

- Good blades make clean cuts, so you waste less material.

- Strong blades need less fixing, so you save money and time.

- Crop & Cobble Shear blades cut off bad ends, so you do not have delays.

Note: Check your blades often and pick the right ones to keep your line moving.

Improving cut quality

You need blades that make smooth, neat cuts every time. The right blade and custom options help you cut better. When you match the blade to your billet, you get less scrap and smoother edges. This helps you work faster and reach your goals.

- Good blades help you make more products with less waste.

- Special blade shapes and coatings help you cut better, even with hard metals.

- Custom blades help you with tough jobs, like thick billets or hard alloys.

If you want better results, try custom blades from Nanjing Metal Industrial. Their team knows how to make blades that work well for your needs.

Tip: Always check your blade and cutting needs before you start. This helps you get the best results and saves time.

You can work better and faster by picking the right blade, using custom options, and taking care of your tools. This helps you cut well, waste less, and keep your machines running.

You can get very exact cuts and less bending when you use specialized bar shear blades. Picking the right blade shape and material helps you cut billets neatly. Taking care of your blades often also saves you money. Look at the table to see how these blades help:

| Nutzen | Beschreibung |

|---|---|

| Reduzierte Ausfallzeiten | You spend less time fixing and checking blades |

| Increased Production | You cut more billets and waste less material |

| Geringere Wartungskosten | You change blades less and pay less for upkeep |

- Blades that are clean and sharp make smooth cuts.

- Checking and caring for blades often helps them last longer.

If you want better cutting, talk to our sales engineer on our contact page.

Häufig gestellte Fragen

What are bar shear blades used for?

Bar shear blades help you cut metal billets, bars, and sheets. You use them in factories to get clean, straight cuts. These blades work in many industries, including metalworking and recycling.

How do you choose the right bar shear blade?

You look at your billet’s material and thickness. Pick a blade with the right hardness and toughness. You can ask for custom blades if you have specific needs.

Why does blade geometry matter in billet cutting?

Blade geometry controls how the blade touches the metal. Good geometry helps you get smooth cuts and less distortion. You see better results when you match the blade shape to your job.

How often should you sharpen bar shear blades?

You should sharpen blades every 500-700 uses or when you notice rough cuts. Sharp blades help you work faster and get better results.

What materials are best for bar shear blades?

Steel alloys like A8, D2, and S7 work well. Each alloy gives you different toughness and wear resistance. You pick the best one for your cutting job.

Can you use bar shear blades for plastics or food?

Yes, you can use bar shear blades for plastics and food. These blades help you trim, slice, and shape many materials. You get clean cuts in different industries.

How do you reduce distortion when cutting billets?

You use blades with low rake angles and sharp edges. Keep blades aligned and set the right clearance. Good maintenance helps you get straight, smooth cuts.

What maintenance steps help bar shear blades last longer?

Clean blades after each use. Lubricate moving parts weekly. Check alignment and tension often. Store blades in a dry place. These steps help you avoid rapid wear.

Siehe auch

The Ultimate Buyer’s Guide to Industrial Shear Blades: 7 Quality Checks Before You Purchase

Scherenmesser Wie ein Profi Schärfen: Vermeidung Häufiger Schleiffehler und Verlängerung der TCO

H13 Warmarbeits-Scherenmesser: Meisterung des Hochtemperatur-Metallschneidens und Knüppelschneidens

Erzielen von Gratfreien Schnitten mit Präzisions-Guillotine-Scherenmessern