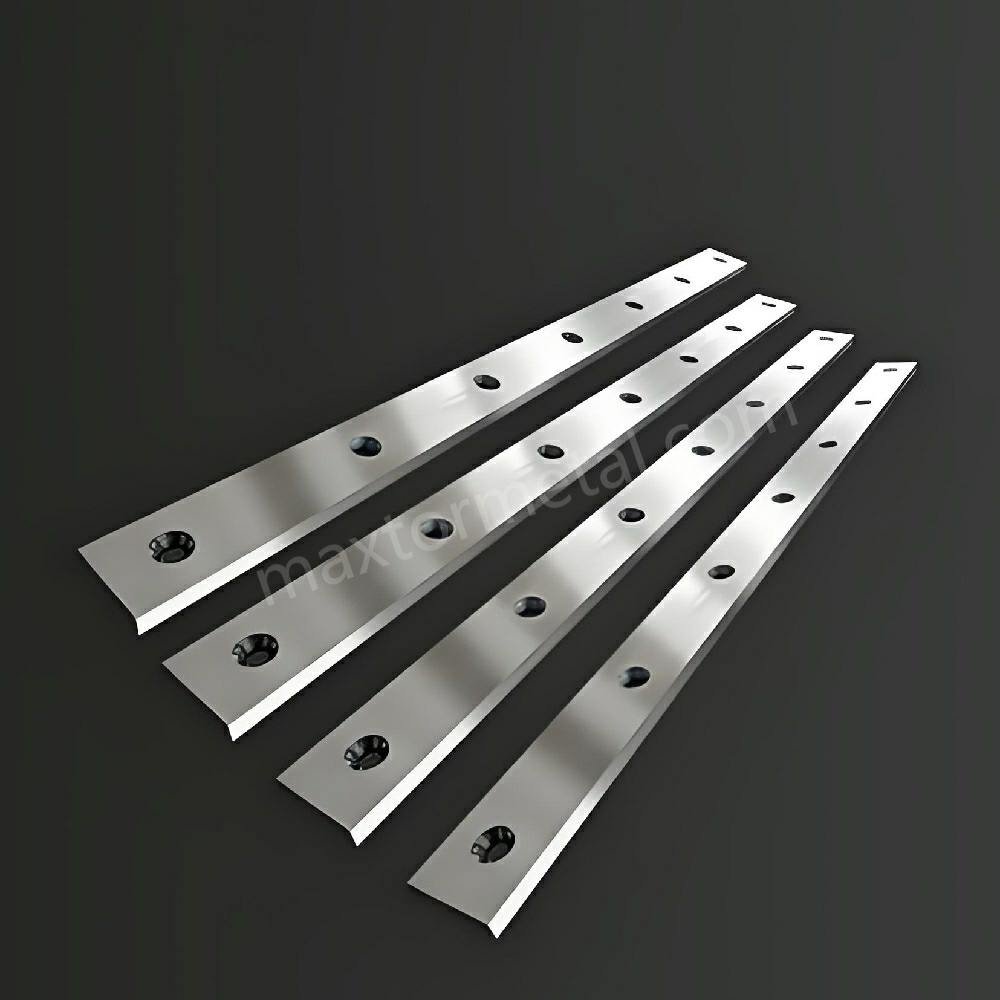

D2 Stahl Scherenmesser are great for cutting cold metal. These blades stay sharp for a long time. They do not wear out quickly. You get the same good results every time. Many workers pick D2 steel because it is very hard. It keeps its shape well and does not rust easily. Metal Industrial works hard to make good and new products. This means you can trust their blades to work well. Learn why experts say Nanjing Metal Industrie is the best place for cutting tools.

- Blades last longer because they do not wear out fast

- Hard blades stay sharp even when hit

- Blades keep their shape for accurate cuts

- Blades do not rust in hard places

Die wichtigsten Erkenntnisse

- D2 steel shear blades last a long time because they resist wearing out. This means you do not have to replace them often. These blades stay sharp even when used a lot. This helps them cut well every time. D2 steel is hard and tough. This makes it great for cutting cold metal. The blades make clean and exact cuts. They do not rust or corrode easily. This makes them good for many factory jobs. Picking the right hardness (60-62 HRC) helps D2 blades last longer. It also helps them cut better. You should take care of the blades. Sharpen them and check the space between blades. This stops chipping and helps them last longer. D2 steel shear blades can cut many things. They work on aluminum and mild steel. Buying D2 steel blades can save money over time. They last longer and need less fixing.

Why D2 is the Standard for Cold Metal Shearing

Defining “Cold Metal Cutting” and the Role of the Shear Blade

You use cold metal cutting when you want to shape or trim metal sheets without adding heat. This method keeps the metal strong and prevents warping. In this process, you place the metal between two blades. The upper blade moves down and presses the metal against the lower blade. The force causes the metal to break along a straight line. You get a clean and smooth cut. The shear blade is the tool that does the actual cutting. It slices through the metal by pressing and compressing it. This gives you precise results every time.

The D2 Advantage: Combining High Wear Resistance with Affordability

You want blades that last long and stay sharp. D2 steel gives you that benefit. It stands out because it offers high wear resistance, which means the blade does not wear down quickly. You can use it for many cuts before you need to replace or sharpen it. D2 steel also keeps its hardness even when the blade gets hot from friction. You save money because you do not need to buy new blades often. The cost of d2 steel is lower than some other tool steels, but you still get top performance.

Here is a table showing what makes d2 steel special:

| Element | Role in D2 steel |

|---|---|

| Kohlenstoff (C) | Makes the blade hard and helps form strong carbides. |

| Chrom (Cr) | Adds high wear resistance and stops rust. |

| Molybdän | Improves toughness and keeps the blade strong. |

| Vanadium | Makes the blade tough and helps it stay sharp. |

| Manganese | Removes impurities and helps harden the steel. |

| Silicon | Strengthens the steel during making. |

| Phosphorus | Kept low to avoid brittleness. |

| Nickel | Adds a bit more toughness. |

| Sulfur | Kept low to keep the steel clean. |

You get a blade that combines high wear resistance, toughness, and cost savings. D2 steel blades keep their shape and edge, even after many uses.

Target Audience: Metal Fabricators, Stamping Houses, and Recycling Operations

You work in metal fabrication, stamping, or recycling. You need blades that can handle tough jobs and keep working for a long time. D2 steel is popular in these industries because it offers high wear resistance and stays sharp under stress. You see d2 steel used in metalworking shops, manufacturing plants, and recycling centers. Workers choose it for its ability to cut cleanly and last longer than other steels. You get reliable performance and less downtime. D2 steel blades help you finish jobs faster and with better results.

Tip: If you want blades that resist rust and keep their edge, d2 steel is a smart choice for your shop.

D2 Steel Properties: The Metallurgy Behind the Performance

High Carbon, High Chromium: The Formula for Longevity

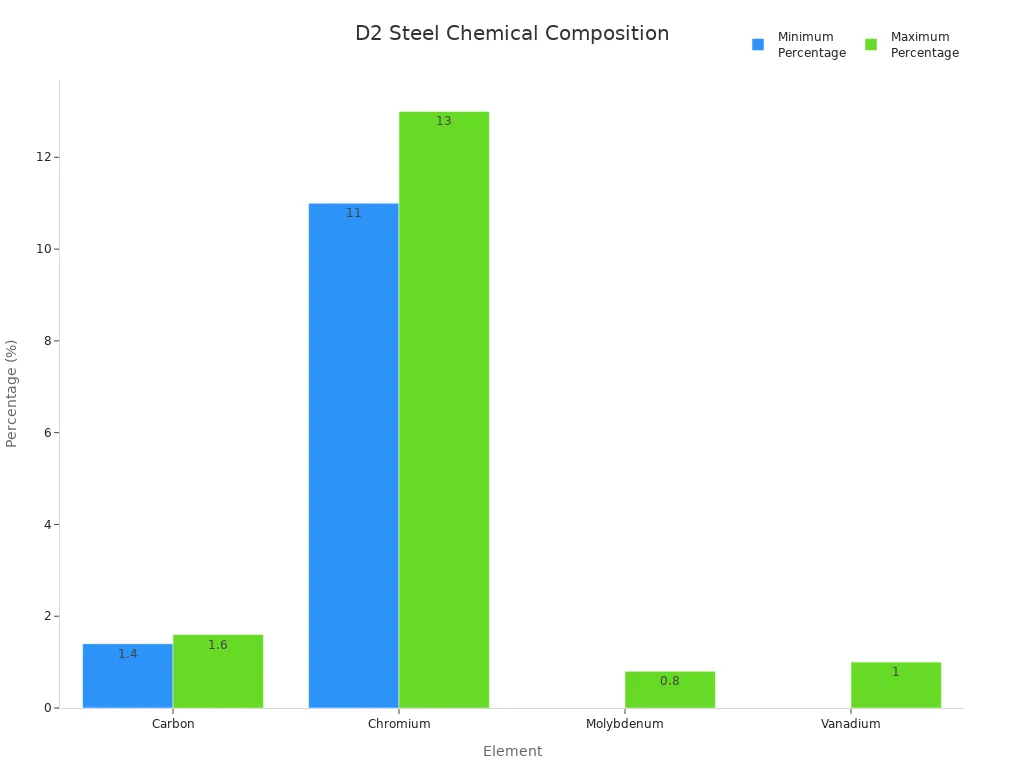

D2 steel is special because it has a lot of carbon and chromium. This mix helps the blade last longer and stay sharp. The chemical parts in D2 steel make it great for cold metal cutting. Here is what is inside D2 steel:

| Element | Percentage Range |

|---|---|

| Carbon | 1.4% – 1.6% |

| Chrom | 11% – 13% |

| Molybdän | Up to 0.8% |

| Vanadium | Up to 1% |

This mix gives you many good things:

- High carbon makes the blade tough and hard to scratch.

- The steel is easy to work with when it is soft.

- After heat treatment, the blade gets very hard.

Role of Chromium in Wear Resistance and Corrosion Inhibition

Chromium is very important for D2 steel blades. It makes the blade last longer by forming hard carbides. These carbides protect the blade from wearing out fast. Chromium also helps stop rust, so the blade does not get damaged. This means you do not have to change blades often. You can spend more time cutting and less time fixing blades.

Carbide Formation and Edge Retention (The Abrasion Defense)

D2 steel forms strong carbides when you use it. These carbides are like tiny shields on the blade’s edge. They help the blade fight off scratches and keep it sharp. D2 steel blades stay sharp much longer than other blades. That is why many workers pick D2 steel for tough jobs.

Note: High carbon and chromium together make D2 steel last long and cut well.

Dimensional Stability During Heat Treatment (A Toolmaker’s Priority)

You want blades that do not change shape when heated. D2 steel keeps its shape very well during heat treatment. This means the blade will not bend or twist when it gets hot and cools down. The special structure inside D2 steel helps it stay the same. The fine martensite and small carbides keep the blade true. You get blades that fit right and cut with high accuracy.

| Stahlsorte | Dimensionsstabilität |

|---|---|

| D2 | Exzellent |

| M2 | Gut |

D2 steel blades give you the same good quality after every heat treatment. This is important for toolmakers who need blades they can trust.

Understanding Hardness: Target HRC for D2 Shear Blades

Hardness is very important for cutting blades. You want a blade that is hard but not too brittle. D2 steel blades are usually between 60 and 62 HRC. This is the best range for keeping the blade sharp and tough.

- The best hardness for D2 shear blades is 60-62 HRC.

- Most blades are between 59-62 HRC, which is what most shops use.

If you pick a blade in this range, it will last longer and not chip easily. High hardness means the blade stays sharp for many cuts. If the blade is too hard, it can chip. If it is too soft, it wears out fast. You need the right hardness for the best results.

| Eigentum | Beschreibung |

|---|---|

| Kohlenstoffgehalt | About 1.55%, makes the blade very hard. |

| Chromgehalt | About 12%, forms carbides to stop wear. |

| Härte | 55-62 HRC after heat treatment, lets you pick blade strength. |

| Zähigkeit | Good for cutting, but not for heavy impacts. |

| Compressive Yield Strength | 275-319 ksi, strong enough for most cutting jobs. |

| Wärmebehandlung | Tempering at 500-550°F gives the best mix of toughness and wear resistance. |

| Performance Limitation | Best for straight or slicing cuts, not for heavy side loads. |

Tip: Always look at the hardness rating before you buy D2 steel blades. The right hardness gives you the best blade life and quality.

Now you know why D2 steel blades are trusted. They have high carbon and chromium, great hardness, and reliable performance. These things make them the best for cold metal cutting.

Optimal Heat Treatment: Maximizing D2 Blade Toughness and Life

The Critical Hardening Process and Quenching Method

Sie möchten Ihre D2 Stahl Scherenmesser to last long. The hardening and quenching steps make the blades strong. You must follow each step to get the best results.

- Vorheizen: Heat the blade slowly to 1200°F. For tricky shapes, heat again to 1450°F. This helps the steel heat evenly and stops cracks.

- Wärmebehandlung: Raise the temperature to 1800°–1850°F. Hold the blade at this heat until it is hot all the way through. This step makes the steel stronger.

- Kühlung: Cool the blade in still air or a vacuum. This keeps the blade clean and stops marks. Fast cooling makes the blade hard, but can cause cracks or bends if done wrong.

- Temperieren: When the blade cools to 150°F, temper it. This step lowers stress and sets the final hardness.

If you cool too fast, the blade can crack or bend. Always let the blade cool slowly for the best strength and shape.

Protecting Against Decarburization

Decarburization happens when carbon leaves the steel’s surface during heating. You want to stop this because it makes the blade weak. You can protect your D2 Stahl Scherenmesser by using a vacuum furnace or wrapping them in foil. This keeps the carbon inside, so your blades stay strong and sharp.

Tempering Cycles: Balancing Hardness and Toughness

Tempering helps balance hardness and toughness in D2 Stahl Scherenmesser. You need to pick the right temperature for your job. The right tempering cycle gives your blades strength and toughness.

| Tempering Temperature (°F) | Resulting Hardness (HRC) |

|---|---|

| 300-350 | 62 – 64 |

| 500-550 | 58 – 60 |

| 950 (double temper) | Max toughness |

Lower tempering temperatures give higher hardness. This is good when you need a sharp edge and wear resistance. Higher tempering temperatures give more toughness. This helps the blade handle hits and tough jobs.

Note: Tempering also lowers stress from hardening. This makes your blades safer and more reliable.

Preventing Premature Cracking: The Risk of Incorrect Tempering (Common Forum Issue)

Wrong tempering can make blades crack early. Many people online talk about this problem. If you temper at the wrong temperature or skip a step, the blade gets too brittle. You want to avoid this by following the right tempering steps. Double tempering at 950°F gives the best toughness and lowers the chance of cracks. This is important for blades used in hard jobs where strength matters.

Cryogenic Treatment: Does it Truly Benefit D2 Shear Blades?

Cryogenic treatment takes blades to very cold temperatures, sometimes as low as -196°C. This process can make D2 Stahl Scherenmesser work better in many jobs. Studies show cryogenic treatment can boost wear resistance by up to 69%. It also makes blades last longer, lowers cutting force, and improves the blade’s surface.

| Treatment Temperature (°C) | Treatment Duration (h) | Improvement in Wear Resistance (%) |

|---|---|---|

| -196 | 32 | 69 |

| -196 | 48 | 60-66 |

| -185 | 36 | 59.74 |

| -140 | 2 | 50.7 |

You get blades with better properties and steady strength. This means your blades last longer and work better in tough jobs. Cryogenic treatment also helps the blade keep its edge, so you sharpen less and cut more.

Tip: If you want the strongest and most wear-resistant D2 Stahl Scherenmesser, think about adding cryogenic treatment. This step can help a lot in hard jobs.

Now you know how the right heat treatment, tempering, and cryogenic steps give your D2 Stahl Scherenmesser the strength and toughness needed for all kinds of jobs. By following these steps, you get blades that work their best and last longer every time.

Application Success: When and How to Use D2 Shear Blades

You want to get the best results from your cold work tool steel. D2 steel shear blades help you cut many types of metal with high accuracy. You can use these blades in many industries, from stamping to recycling. Let’s look at the best ways to use them and what materials they handle well.

Ideal Materials for D2 Cutting

D2 steel shear blades work well with many metals. You get clean cuts and long blade life. The table below shows how different materials perform when you use cold work tool steel.

| Materialtyp | Leistungsergebnis |

|---|---|

| D2 Stahl | Good edge retention, better than VG10, 3V, A2, CruForge V, and Super Blue |

| S30V | 13% better edge retention than D2 |

| VG10 | Matches D2 in edge retention after heat treatment |

| 440 °C | Matches D2 in edge retention after heat treatment |

| ZDP-189 | Matches D2 in edge retention after heat treatment |

Carbon Steel and Mild Steel Shearing

You can cut carbon steel and mild steel with d2 steel shear blades. These metals are common in factories and workshops. The high carbon die steel in the blade gives you sharp cuts and long service life. You do not need to sharpen the blades often. This means you save time and money. You get smooth edges and less waste.

Aluminum and Non-Ferrous Alloys

You can use d2 steel shear blades for aluminum and other non-ferrous alloys. These metals are softer than steel. The cold work tool steel keeps its edge and does not wear down fast. You get clean cuts without burrs. This is important for industries that need high-quality finishes, like aerospace and automotive.

Limitations: High-Tensile Steels and Thick Stainless Steel

You should know the limits of d2 steel shear blades. They work best on mild and medium-hard metals. If you try to cut very hard or thick stainless steel, the blades may wear out faster. For these jobs, you may need a different type of cold work tool steel. Always check the material before you start cutting.

Tip: For special jobs or unique materials, you can order custom blades. Visit our custom blade page to find the right tool for your needs.

D2 and Blade Geometry: Selecting the Correct Rake Angle

The shape of your blade matters. The rake angle is the tilt of the blade’s edge. You must pick the right angle for your job. Cold work tool steel with the right geometry gives you better results.

Impact of Rake Angle on Edge Load and Shear Force

A small rake angle makes the blade stronger. You use this for hard metals. A large rake angle makes cutting easier but can wear the blade faster. You must balance edge holding and cutting force. If you cut soft metals, use a larger angle. For hard metals, use a smaller angle. This helps your d2 steel shear blades last longer and cut better.

| Neigungswinkel | Am besten für | Wirkung auf die Klinge |

|---|---|---|

| Small | Hard metals | More strength, less wear |

| Large | Soft metals | Easier cut, more wear |

You get the most from your blades when you match the rake angle to the material.

The Role of D2 in Fly Shear and Crank Shear Operations

You see d2 steel shear blades in fly shear and crank shear machines. These machines cut metal sheets fast and often. Cold work tool steel stands up to repeated use. You get less downtime because the blades stay sharp. This means more production and less cost.

The table below shows where you use d2 steel shear blades and how you measure success:

| Anwendungsszenarien | Metrics Used to Measure Success |

|---|---|

| Industrial blades | Verschleißresistenz |

| Cutting dies | Edge retention |

| Shears | Frequency of sharpening intervals |

| Slitting tools | |

| Metal stamping applications |

You want blades that last and cut well. D2 steel shear blades give you both. They are suitable for tooling applications and cutting instrument applications. You get optimal knife-making properties and durability. These are the recommended applications for your shop.

Note: You can use d2 steel shear blades for many cutting tools. They work well in both small shops and large factories.

Now you know how to use d2 steel shear blades for the best results. Pick the right material, blade geometry, and machine. You will see better performance and longer blade life.

D2 vs. The Competition: Should You Upgrade or Downgrade?

Picking the right shear blade material can change how well you cut. You want blades that fit your job and last a long time. D2 steel shear blades are known for staying sharp and not wearing out fast. Other steels have their own good points. Let’s see how D2 compares to S7, A8 modified, and low alloy steels.

D2 vs. S7 Steel: Wear Resistance vs. Impact Resistance

D2 steel shear blades are used when you need blades that do not wear out fast. S7 steel is better when you need blades that can take a lot of hits. The table below shows how each steel works:

| Stahlsorte | Verschleißfestigkeit | Schlagfestigkeit |

|---|---|---|

| D2 | Hoch | Mäßig |

| S7 | Mäßig | Hoch |

D2 steel shear blades stay sharp longer. You use them for straight cuts and jobs where you cut again and again. S7 steel blades are good at taking hits. You pick S7 for scrap yards or when you cut thick, hard metals. If your job has lots of heavy hits or surprise loads, S7 is safer.

When to Choose S7 (High Shock Loading/Scrap Yard Applications)

Pick S7 steel blades for these jobs:

- You cut scrap metal that is not all the same thickness.

- You work where blades get hit hard.

- You need blades that do not crack from sudden force.

D2 steel shear blades are best for clean, repeated cuts. S7 steel blades are better for tough jobs with lots of impact.

D2 vs. A8 Modified: The Debate for High-Volume or High-Tensile Cuts

Sometimes you need blades for lots of cutting or for cutting strong metals. D2 steel shear blades stay sharp and do not wear out fast. A8 modified steel is tougher and can cut harder metals.

| Stahlsorte | Vorteile | Nachteile |

|---|---|---|

| D2 Stahl | – Stays sharp for big cutting jobs | – Harder to sharpen |

| – Wears out slowly, good for pro tools | – Not as good at fighting rust | |

| 8Cr13MoV Steel | – Cheap and does not rust easily | – Not as hard as D2 |

| – Easy to sharpen, good for daily use | – Does not stay sharp as long as D2 |

D2 steel shear blades last longer. You do not need to sharpen them as much. A8 modified steel costs more, but it is good for cutting strong steel and hard jobs. If you cut a lot, A8 might be worth the extra money. D2 steel shear blades work well for most cold metal cutting.

Cost-Benefit Analysis: The Higher Initial Investment of A8

A8 modified steel blades cost more at first. They are tougher and work better in hard jobs. D2 steel shear blades cost less and last a long time for normal jobs. If you cut strong steel or thick stuff, A8 might save you money because you change blades less. For most shops, D2 steel shear blades give you the best mix of price and how long they last.

D2 vs. Low Alloy Steels (e.g., 4140, 52100)

You might wonder if you should get D2 steel shear blades or use cheaper steels like 4140 or 52100. Low alloy steels cost less, but you have to sharpen and replace them more often.

TCO Analysis: Comparing Regrinding Frequency and Downtime

You want blades that keep working without stopping all the time. D2 steel shear blades stay sharp longer, so you do not need to sharpen them as much. Low alloy steels wear out faster. You lose time and money when you stop to fix or change blades.

Think about these things before you pick your blade:

- What kind of metal you cut

- How thick the metal is

- How fast you cut

- How well the blade fights wear

- What your job needs

D2 steel shear blades help you work longer without stopping. You get more cuts from each blade and less time fixing things.

Tip: If you want blades that last and need less fixing, D2 steel shear blades are a smart choice for your shop.

Now you know how D2 steel shear blades compare to other steels. You can pick the right blade for your job and get the best results for your work.

Maintenance and Troubleshooting D2 Shear Blade Failures

Taking care of your D2 steel shear blades helps them last longer. You get better cuts when your blades are in good shape. Most problems can be stopped with the right care and by checking for trouble early. Let’s see how you can stop chipping, keep blades sharp, and handle cracks.

Preventing Chipping and Edge Breakdown

D2 steel shear blades are strong, but they can still chip or break. This happens if you do not use them the right way. You want to stop these problems so your blades last longer.

Some things that cause chipping and edge breakdown are:

- Using the wrong blade for your job

- Cutting metal that is too hard for the blade

- Using too much force when cutting

- Setting the blade gap wrong

- Not doing regular maintenance

You can stop these problems by doing a few things:

- Always pick the right blade for your job

- Check your blades for cracks before you use them

- Set the cutting force and blade gap for your material

- Put oil on the blade to lower friction and wear

- Make sure your machine settings are correct

The Importance of Accurate Blade Clearance (Misalignment is the Enemy)

Blade clearance is the small space between the top and bottom blades. If you set this space wrong, your blade can chip or break. If the blades are not lined up, you get rough cuts and shaking.

Tip: Always check the blade gap before you start. Even a small mistake can cause big trouble.

Here is a table to help you fix common problems:

| Problem | Schritte zur Fehlerbehebung |

|---|---|

| Dullness | Sharpen or change blade; clean every day |

| Hacken | Use right blade; set force; add oil |

| Fehlausrichtung | Check blade spot; tighten bolts the same |

| Vibration | Look for wear; check if blades line up |

Regrinding Guidelines for D2 Steel

You need to sharpen your D2 steel shear blades to keep them working well. Sharpening often helps you avoid bad cuts and stops your work from slowing down.

Good ways to sharpen D2 steel shear blades:

- Sharpen blades often to keep them cutting well

- Set the blade gap right before each job

- Check blades a lot to find wear early

- Do not cut metal that is too hard for your machine

- Clean blades after you use them to stop buildup

- Keep blades in a dry, cool place to stop rust

Watch for these signs that your blade needs sharpening:

- The cut edge has bigger burrs

- The cutting sound changes or gets louder

- You see a shiny line on the blade edge

Good workers can spot these signs early. Do not wait until the blade is very dull. Blade sharpening shops can make your blade sharp again and keep its shape. Special grinding machines help keep the edge straight and the angle right.

Maintaining Bevel and Surface Finish

When you sharpen D2 steel shear blades, you must keep the angle and surface smooth. If you grind too fast or use the wrong way, the blade can get too hot. Too much heat makes the edge soft and the blade will not last.

Note: Always use the right grinding tools and methods. This helps your D2 steel shear blades stay hard and sharp longer.

Recognizing and Managing Fatigue Cracks in D2 Blades

Fatigue cracks can show up in D2 steel shear blades after lots of use. You need to find these cracks early to stop bigger problems.

Look for these signs of cracks:

- Small lines or marks on the blade

- The blade cuts differently than before

- Strange sounds when cutting

To fix and handle cracks, you can:

- Use welding to repair cracks

- Pick the right tools and way to fix the blade

- Check the blade after fixing to make sure the crack is gone

- Try ways like weld toe burr machining, shot or needle peening, high-frequency impact, or TIG dressing

- Cut out the cracked part before welding and use improvement steps

Callout: Checking your blades often and fixing them early helps them last longer. You get more cuts and better work from each blade.

If you follow these tips, your D2 steel shear blades will work better. You save time, spend less money, and get cleaner cuts every time.

Leveraging D2 for Profitability and Performance

Final Selection Checklist for Your Next D2 Blade Purchase

Picking the right D2 steel shear blades helps your shop do better work. You want blades that fit your jobs and are worth the money. Use this checklist to help you buy the right blade:

| Kriterien | Considerations |

|---|---|

| Betriebsumgebung | Will you use the blade fast or slow? Are you cutting rough materials? |

| Verschleißfestigkeit | D2 is good for jobs that need blades to last. |

| Production Cost | D2 costs more at first, but saves money later. |

| Maintenance and Environment | Think about rust and how often you will fix or change the blade. |

| Heat-treatment & Metallurgy | Make sure the blade was heated right for D2 steel. |

| Tool Design & Geometry | The blade’s shape and angle help it cut better. |

Tip: Always pick a blade that matches your machine and the metal you want to cut. The right blade gives you better cuts and lasts longer.

Moving Forward: The Future of High-Chromium Tool Steels

D2 steel shear blades help you cut metal easily and with more control. You get smooth, steady cuts on many kinds of metal. These blades work well in busy factories and fit many big machines.

Here is how D2 steel shear blades help your shop do better:

| Besonderheit | Nutzen |

|---|---|

| Haltbarkeit | Blades last longer, so you change them less |

| Ausfallzeit | Less fixing means your machines keep working |

| Produktivität | Faster cutting helps you finish more jobs |

You will see these changes in your daily work: You do not change blades as much. Your machines work longer without stopping. You get smoother cuts and waste less metal.

- Blades last longer, so you do not need new ones often.

- Less time fixing blades keeps your shop busy.

- Better cuts help you finish jobs faster.

Note: High-chromium tool steels like D2 keep getting better. New ways to heat and design blades will make them even stronger and more trusted.

D2 steel shear blades are the top choice for cold metal cutting. As new ideas come out, these blades will get even better. Keep learning about new changes to help your shop stay ahead.

D2 steel shear blades stand out as the top choice for cold metal cutting. You get blades with high hardness and wear resistance, so they last longer in tough jobs. You also save money because D2 steel offers great edge retention at a fair price.

- D2 steel blades work well in abrasive environments and keep their edge longer than many other steels.

- They resist rust and corrosion, making them reliable for many uses.

- You can trust these blades to cut through tough materials without breaking or chipping.

If you want to upgrade your cutting tools, learn more about D2 steel shear blades and how to care for them. For expert advice or to find the right blade for your needs, Kontaktieren Sie unser Team. D2 steel remains the king for cold metal cutting.

Häufig gestellte Fragen

What makes D2 steel shear blades different from regular steel blades?

D2 steel shear blades use high carbon and chromium. You get better wear resistance and edge retention. These blades last longer than regular steel blades. You spend less time sharpening and more time cutting.

Can you use D2 steel shear blades for stainless steel?

You can use D2 steel shear blades for thin or mild stainless steel. For thick or very hard stainless, you may need a tougher blade. Always check the material before you cut.

How often should you sharpen D2 steel shear blades?

You should sharpen D2 steel shear blades when you notice dull cuts or more burrs. Regular checks help you keep the edge sharp. Most users sharpen less often than with low alloy blades.

Do D2 steel shear blades resist rust?

Yes, D2 steel shear blades resist rust better than many other tool steels. The high chromium content helps stop corrosion. You still need to keep blades clean and dry for best results.

What is the best hardness for D2 steel shear blades?

The best hardness for D2 steel shear blades is 60–62 HRC. This range gives you a strong edge that stays sharp. It also helps prevent chipping during use.

Can you use D2 steel shear blades for aluminum?

You can use D2 steel shear blades for aluminum and other non-ferrous metals. The blades give you clean cuts and last a long time. You get less wear and fewer burrs.

How do you prevent chipping in D2 steel shear blades?

You prevent chipping by setting the correct blade clearance and using the right cutting force. Always match the blade to the material. Regular maintenance helps you avoid edge breakdown.

Are D2 steel shear blades good for recycling operations?

Yes, D2 steel shear blades work well in recycling. You get long blade life and less downtime. The blades handle many types of scrap metal and keep their edge through repeated use.

Siehe auch

So wählen Sie die richtige Guillotine-Klinge für Ihre Anforderungen aus

Wahl zwischen Tafelscheren und Schwingschnittscheren: Eine Umfassende Vergleichende Analyse

Schritt-für-Schritt-Anleitung zum Wechseln von Hydraulikschermessern