Perforationsklingen für Vliesstoffe have changed the textile and composite industries. They make very exact and clean cuts. This helps work go faster and makes products better. In hygiene, automotive, and aerospace fields, these blades shape fabric and composite materials for each job. Picking the right blade stops fraying and tearing. New blade types help keep the size and shape correct for every textile and composite product. Makers use these new ideas to work faster, make fewer mistakes, and create fabrics that pass tough tests.

| Aspekt | Impact on Efficiency and Quality |

|---|---|

| Blade Selection | Clean cuts, less waste, higher product quality |

| Tool Head Configuration | Faster cutting, improved accuracy, supports complex textile and composite designs |

| Table Configuration | Stable fabric handling, better throughput |

| Sector Applications | Superior hygiene textiles, durable automotive interiors, advanced aerospace composites |

Die wichtigsten Erkenntnisse

- Perforating blades make exact holes in non-woven fabrics. This helps products be better and made faster.

- There are different blade types like straight, rotary, toothed, and circular. Each type cuts in a special way and keeps fabrics strong.

- Blade materials include tool steel, high-speed steel, stainless steel, and tungsten carbide. These materials change how long blades last and how sharp they are.

- Customization lets makers change blades to fit many machines and fabric types. This gives better results.

- Using advanced materials and careful design makes blades last longer. It also helps blades cut cleanly and the same way every time in textiles and composites.

- Automation makes production faster, lowers mistakes, and keeps fabric holes the same.

- Perforating blades help textiles for hygiene, medical, and protective uses. They control air flow, liquid soaking, and comfort.

- In composites, blades make holes that help with strength, energy soaking, and light weight. This is good for car and airplane parts.

Perforationsklingen für Vliesstoffe

Perforationsklingen für Vliesstoffe help shape how textiles and composites work. These blades make small holes in fabric. This helps the fabric get made faster and better. Picking the right blade, material, and design makes sure the fabric meets tough rules.

Klingentypen

Each blade type works with fabric in a special way. The right blade keeps the fabric strong. It also helps the fabric look and work as needed.

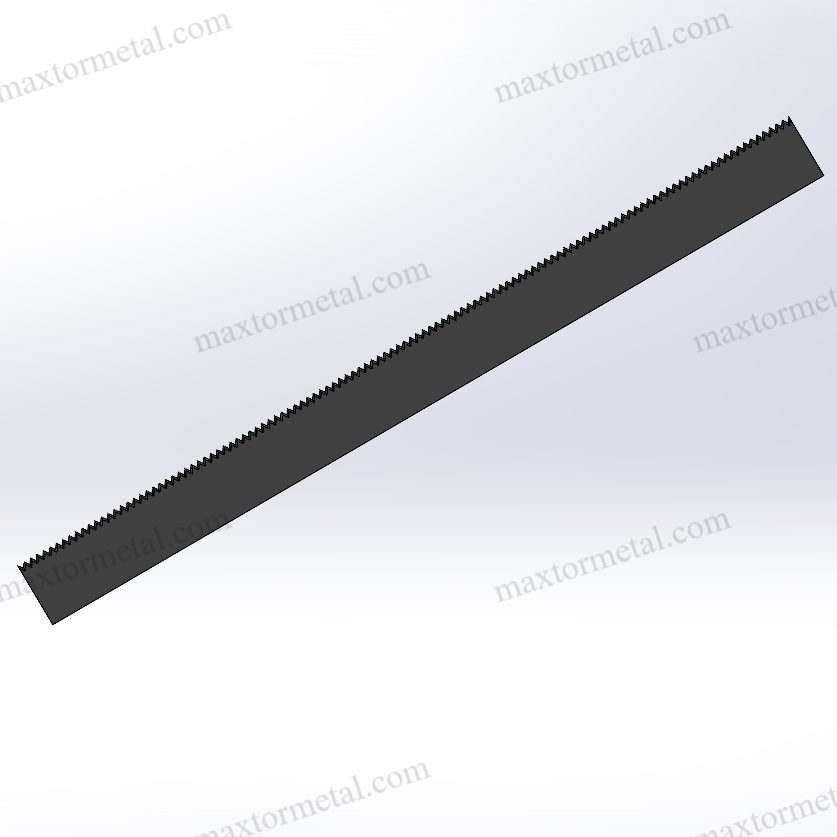

Gerade

Straight blades make long, straight holes in fabric. They are used in guillotine cutters and die-cutting tools. The teeth on these blades make a pattern of cuts and ties. This pattern controls how the fabric tears. A sharp straight blade keeps the fabric neat and stops fraying.

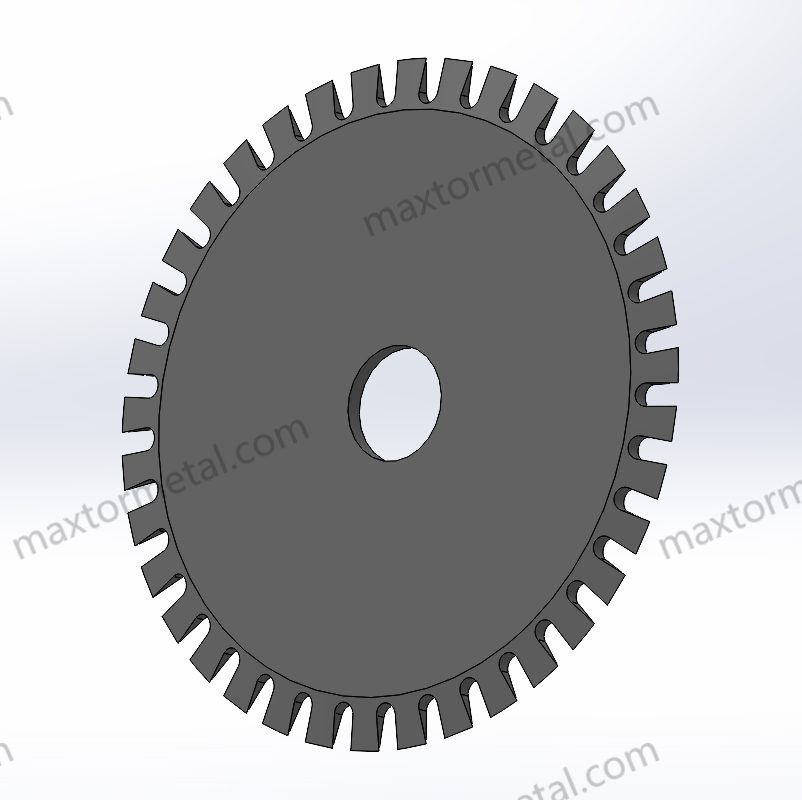

Rotary

Rotary blades are also called circular blades. They spin while cutting. This spinning makes fast and clean cuts. Rotary blades are good for machines that work quickly. The shape and teeth of the blade change how fast and well it cuts. Rotary blades help keep the fabric strong in big factories.

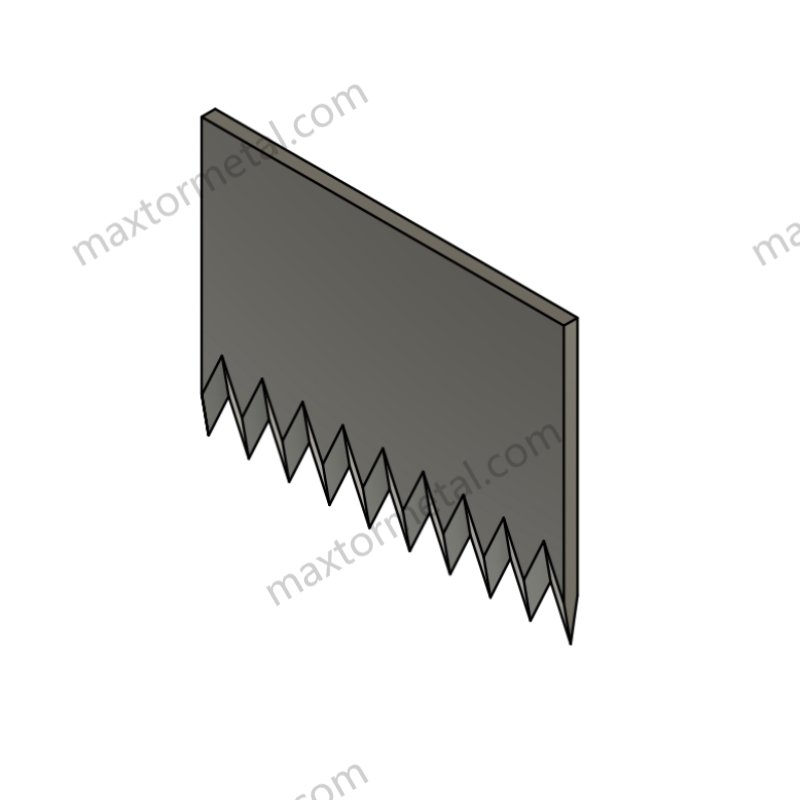

Toothed

Toothed blades have teeth with special shapes and spaces. The cut and tie ratio makes different hole patterns. Some teeth are serrated or scalloped. These shapes help the blade cut the fabric in different ways. The teeth control how easy the fabric tears and how strong it stays.

Kreisförmig

Circular blades are a kind of rotary blade. They make smooth, even holes in fabric. These blades are best for jobs that need even holes and fast work. The round shape gives even pressure and steady results. This helps keep delicate or special fabrics in good shape.

Table: Blade Types and Their Influence on Fabric Structure

| Type of Perforating Blade | Beschreibung | Influence on Fabric Structure |

|---|---|---|

| Rotary (Circular) Blades | Spin while cutting, used for fast, precise, and clean cuts in fabric and textile industries, especially non-woven fabrics. | Continuous rotation ensures consistent perforation; blade shape and tooth geometry affect cut quality and speed; suitable for automation and high-speed machines. |

| Gerade Klingen | Linear blades used for straight perforation lines, often in guillotine cutters or die-cutting tools. | Tooth design creates intermittent cuts; blade stability and sharpness influence accuracy and clean cuts. |

| Gezahnte Klingen | Blades with teeth of specific shapes and spacing (cut and tie ratio) to create desired perforation patterns. | Tooth geometry and spacing control ease of tearing and strength of perforated material; different tooth forms (serrated, scalloped) tailor cutting action. |

| Benutzerdefinierte Formen | Blades manufactured in unique shapes for specialized perforation patterns. | Customization allows precise control over perforation design, affecting fabric appearance and tear properties. |

Materialien

The material of Perforationsklingen für Vliesstoffe changes how long they last and how sharp they stay. Each material is good for different fabrics and jobs.

Werkzeugstahl

Tool steel, like D2 or M2, is very hard and tough. Blades made from tool steel cut well and stay sharp. This helps stop fraying and keeps holes neat.

HSS

High-Speed Steel (HSS) blades are strong and do not get dull fast. HSS works well when machines cut fabric all day. The fabric stays strong, even when cut many times.

Edelstahl

Stainless steel blades do not rust and are both hard and bendy. These blades are good for clean jobs, like medical or hygiene fabrics. Stainless steel keeps the fabric clean and safe.

Wolframkarbid

Tungsten carbide is super hard and lasts a long time. Blades made from this material stay sharp, even when cutting fast. This stops fraying and makes the blade last longer. Tungsten carbide is great for tough jobs and keeps the fabric strong.

Table: Common Blade Materials and Their Advantages

| Materialtyp | Description/Use | Vorteile |

|---|---|---|

| Ground Hardened Tool Steels (D2, M2) | High-grade tool steels used for textile and non-woven cutting blades | High hardness, precision cutting, durability, wear resistance |

| Carbide Grades (C10, C30-C40) | Tungsten carbide grades used for textile knives and cutting blades | Exceptional wear resistance, durability, precision |

| 52100 Steel | Low-alloy, high-carbon steel with chromium | High hardness, strength, suitable for blades |

| Vollhartmetall | Carbide material used for industrial knives | High wear resistance, durability, precision cutting |

Anpassung

Nanjing Metal makes many kinds of Perforationsklingen für Vliesstoffe. They can change the shape, size, and material to fit any job. With OEM and ODM, customers can ask for special logos or sizes. This helps the blade work with many machines and fabrics.

- OEM/ODM lets you add logos and pick special sizes.

- Tungsten carbide blades last five times longer than steel.

- Careful making means no rough edges, so fabric stays safe.

- These blades fit many cutters, so more fabrics can be used.

If you need a specific blade, Nanjing Metal can help. They can change old designs or make new ones from drawings or samples. This makes sure each blade fits the fabric just right.

Quality Control and Inspection Processes

- They checks quality at every step, like first checks, material checks, and final checks.

- They use special tools, like calipers and testers, to make sure blades are perfect.

- Each blade is made, heated, and finished to be hard and last long.

- Inspectors get training and watch every step, following ISO9001 rules.

- Each blade gets a barcode, and the company can sharpen blades again to keep them working well.

They works hard to make sure Perforationsklingen für Vliesstoffe always work well, keep fabric strong, and meet the needs of textile and composite makers.

Technology Innovations

Fortschrittliche Materialien

Manufacturers use new materials to make perforating blades stronger. Superhard materials like CraftAlloy™ Tungsten Carbide and advanced ceramics help blades last longer. These materials keep blades sharp and tough, even when working hard. Teams work to make the knife edge and surface smooth. This makes the blade stronger and helps it last up to 100 times longer. Better blades cost less to use and make work faster. The design helps blades cut well and keeps non-woven fabric strong.

- Superhard materials like tungsten carbide and ceramics make blades tough.

- Smooth surfaces help blades work better and save energy.

- New blade shapes help blades hold more weight and stay strong.

Feinmechanik

Precision engineering helps blades cut fabric the right way. Engineers use special tests to check how strong blades are. They change the blade shape to make it work better. Each way of making holes needs strong blades and good design. This helps make clean and even holes. Tools like vertical die punches, lasers, rotary tools, and heat methods help blades work well. These tools make sure the fabric stays strong and looks good.

| Perforation Method | Precision Engineering Contribution | Impact on Accuracy and Consistency |

|---|---|---|

| Vertical Die Punch | Uses ground plates to cut cleanly; vacuum takes away scraps for neat holes. | Makes round, neat holes; works for soft materials. |

| Laser Perforation | Cuts without touching; focus and depth can change; fits into lines. | Makes exact cuts; lets you change patterns and sizes easily. |

| Rotary Tool + Die | Rotating cylinders cut shapes fast; vacuum removes scraps. | Makes quick, even holes; works with many materials. |

| Thermal/Flame Perforation | Makes lots of tiny, strong holes with extra strength around them. | Makes clean holes; lets you use thinner fabric without losing strength. |

Precision engineering helps blades stay strong and hold up under pressure. This is important for making good non-woven fabric.

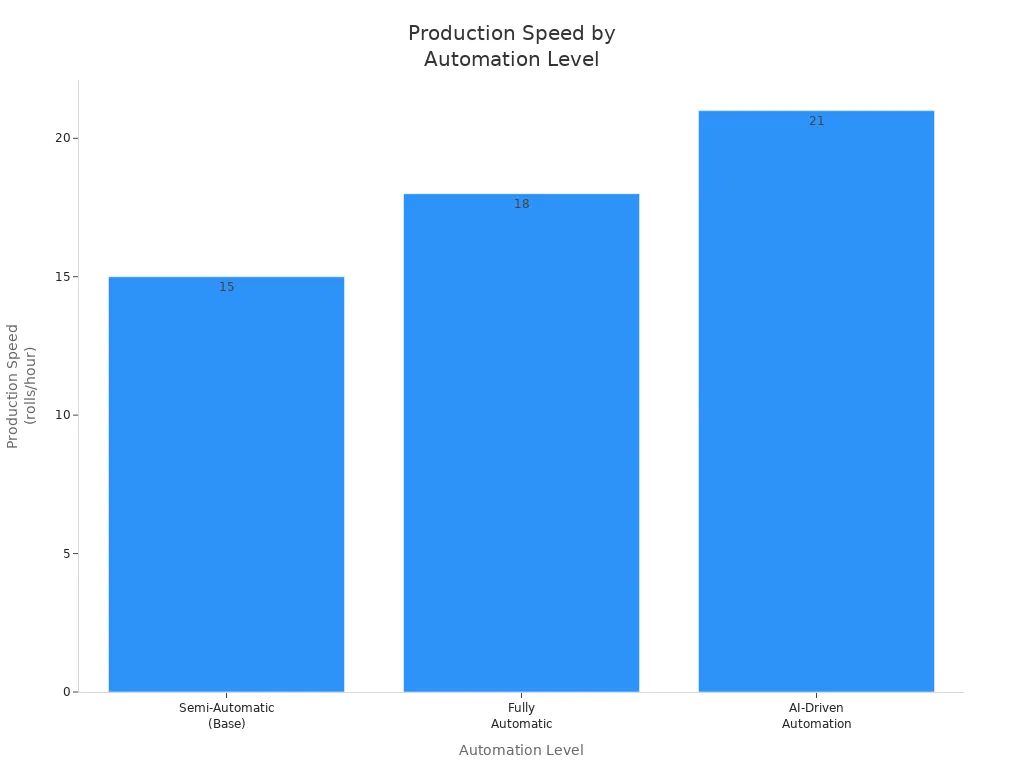

Automation Integration

Automation changes how blades work in factories. Machines feed, cut, punch, and stack fabric by themselves. This saves energy and makes blades work better. Automation means fewer mistakes and stronger products. It also lowers labor costs and cuts down on waste. Machines help keep blades strong and make sure every product is the same.

- Automation makes work faster and blades stronger.

- Machines help keep products the same every time.

- Automated systems let you use new designs and stronger blades.

| Automatisierungsgrad | Production Speed (rolls/hour) | Anpassungsmöglichkeit |

|---|---|---|

| Semi-Automatic (Base) | 15 | Simple size and pattern changes |

| Fully Automatic | 18 (+20%) | Mixes different materials |

| AI-Driven Automation | 21 (+40%) | Makes many layers and designs |

Automation makes non-woven fabric stronger and helps blades hold up better. These systems save energy and help make products fast. Perforating blades for non-woven fabric now work better than ever. They meet the needs of today’s textile and composite industries.

Textile Applications

Perforationsklingen für Vliesstoffe are very important in textiles. These blades make special holes in fabric. The holes help air move through and make the fabric absorb better. This makes the fabric more comfortable to wear. How well each textile works depends on how exact the holes are. Makers use these blades to pick the size and pattern of holes. This changes how the fabric feels and works. With this control, they can make textiles that meet tough rules for hygiene, medical, and safety uses.

Hygiene Products

Hygiene products need fabric with special features. The non-woven fabric must let air in, soak up liquid, and feel soft. Perforationsklingen für Vliesstoffe help makers add tiny holes. These holes make the fabric work better.

Diapers

Diapers use non-woven fabric with a special design. Perforierklingen make tiny holes for air to pass through. The fabric still soaks up liquid well. This keeps skin dry and stops rashes. The holes help liquid move away fast. This stops leaks and makes diapers comfy. The fabric also absorbs energy from quick moves.

Sanitary Napkins

Sanitary napkins need fabric that soaks up liquid and lets air flow. Perforationsklingen für Vliesstoffe make tiny holes that help with this. The holes give more space for liquid to move. The fabric moves liquid away from skin quickly. This keeps users dry and comfy. Layers inside the fabric help keep its shape. They also absorb energy when used.

Incontinence Products

Incontinence products need fabric that soaks up liquid and lets air in. The non-woven fabric gets its shape from perforating blades. The holes help liquid move and dry fast. The special holes stop leaks and keep users comfy. Extra layers in the fabric make it strong and supportive. This helps the product work well for a long time.

Notiz: Special holes and layers in hygiene fabrics help air move, soak up liquid, and keep users comfy. The way each fabric is made fits the job it needs to do.

Medical Non-Wovens

Medical textiles need fabric that controls liquid and blocks germs. Perforationsklingen für Vliesstoffe help make fabric with exact holes and patterns.

Surgical Drapes

Surgical drapes use non-woven fabric made for safety. New ways to make holes, like hydroentangling, let makers pick the size and shape of holes. This gives fabric that soaks up liquid and blocks germs. Studies show that even holes help keep things clean during surgery. The fabric stays in place and keeps the area safe.

Wound Care

Wound care needs fabric with even holes for liquid and germ control. Perforationsklingen für Vliesstoffe work with hydroentangling and heat to make strong, light fabric. These fabrics soak up liquid well. Special tools can make the holes even better. This helps cells and nutrients move through. Even holes in wound dressings keep things clean and safe, as nurses and doctors say.

Tipp: The way medical fabrics are made with advanced perforating blades helps them soak up liquid, block germs, and stay clean.

Protective Clothing

Protective clothing uses non-woven fabric that keeps people safe and comfy. Perforationsklingen für Vliesstoffe make air zones and channels for sweat to move. This helps the fabric breathe and absorb energy, which is important in risky jobs.

| Anwendungsbereich | Protective Garment Type | Material/Structure | Protection Features | Comfort Features | Notes on Balance |

|---|---|---|---|---|---|

| Medical (Surgical) | Disposable gowns and drapes | Nonwoven spunbond, wet-laid, SMS composites | Liquid repellency, antibacterial, strength, flame resistance | Fabric stiffness optimized for tactile softness and comfort | Optimal fabric stiffness critical to balance barrier performance and wearer comfort |

| Firefighting | Multi-layered garments | Hydroentangled aramids, modacrylic blends, Nomex, Kevlar, PBI fibers | Heat, flame, chemical, mechanical protection | Breathability, sweat evaporation, ventilation | Technologies combine comfort with flame resistance |

| Military/Body Armor | Hard and soft armor; needle-punched ballistic-resistant nylon nonwovens | Ceramics, reinforced plastics, metals, Kevlar, Spectra, Twaron | Bullet and fragment protection, high tensile strength | Reduced weight, improved comfort | Hybrid woven/nonwoven designs optimize protection and comfort |

Protective fabrics often have extra layers for energy and air flow. The way these clothes are made keeps people safe and comfy. Makers use perforating blades to make fabric for medical, firefighting, and military jobs.

Aufbieten, ausrufen, zurufen: Extra layers and special holes in protective fabrics help absorb energy and let air move, keeping people safe and comfy.

Perforationsklingen für Vliesstoffe have changed textiles. They help make fabric with new features for every job. The way each fabric is made with exact holes helps it soak up liquid, absorb energy, and feel good. These new ideas help make better textiles for many uses.

Composite Applications

Perforationsklingen für Vliesstoffe are very important in making composites. These blades make exact holes and patterns in composite materials. The holes help resin move better and make the material stronger. Makers use these blades to build strong and tough composites for cars and planes.

Automobilindustrie

Car engineers use composites to make vehicles lighter and safer. Perforationsklingen für Vliesstoffe help shape these materials for special uses.

Interiors

Car interiors have panels and liners made from composites. Dashboards, doors, and seats use these panels. Perforierklingen make tiny holes in the panels. The holes let air and energy move through. This makes the car more comfy and quiet. The holes also help resin fill the panels during making. This makes the panels stronger and able to hold more weight. The panels stay light but work well.

Filtration

Car filters use composite materials to clean air. Perforationsklingen für Vliesstoffe make special hole patterns in these filters. The holes control how air moves and catch dirt. This helps the filter work better. The strong filter lasts longer in tough car conditions.

Insulation

Car insulation panels use fiber composites with layers. Perforierklingen make channels and holes in these panels. The holes help absorb energy and block sound. The panels get stronger and can hold more weight. The holes also help control moisture. This keeps the panels safe from damage and helps them last longer.

Luft- und Raumfahrt

Planes need composites that are strong and light. Perforationsklingen für Vliesstoffe help engineers meet these needs.

Lightweight Panels

Plane parts use light composite panels. Perforierklingen make tiny or big holes in these panels. The holes let air and resin move easily. This helps the panels stick together and get stronger. The panels can take hits and hold weight. The holes also help keep the panels light but strong.

Fire Retardant Materials

Planes need materials that do not burn easily. Perforationsklingen für Vliesstoffe help make panels with safe airflow and energy control. The holes let steam out and spread heat fast in a fire. This makes the panels stronger and safer for planes.

Technical Composites

Technical composites are used in many jobs and vehicles. Perforationsklingen für Vliesstoffe help make advanced composite materials.

- Pinned or needle rollers make different holes in panels and films.

- The holes control how air, water, and liquids move. This makes the material stronger and better at absorbing energy.

- Makers can pick the size, shape, and type of holes for each job.

- Holes can also make it easy to tear or look nice, saving time and money.

- Fast-change systems and special rollers help make holes quickly and accurately.

Notiz: Verwenden von Perforationsklingen für Vliesstoffe in technical composites keeps quality high for cars, planes, and factories.

| Composite Application | Role of Perforating Blades | Impact on Structure and Performance |

|---|---|---|

| Automotive Interiors | Micro-perforations for air and resin flow | Improved comfort, strength, and load-carrying capacity |

| Filtration | Controlled hole patterns | Enhanced filtration, mechanical strength, and energy absorption |

| Insulation | Channels and holes in spacer layers | Better sound dampening, moisture control, and load-bearing capacity |

| Aerospace Panels | Nano/micro/macro holes in prepregs | Increased strength, energy absorption, and lightweight structure |

| Fire Retardant Materials | Perforations for airflow and energy dissipation | Higher impact resistance and safety |

| Technical Composites | Customizable perforations | Optimized mechanical properties, energy absorption, and performance |

Perforationsklingen für Vliesstoffe have changed how composites are made. They help engineers build materials that are strong and absorb energy well. These new ideas help make better composites for cars, planes, and factories. Being able to control the holes and patterns makes sure each composite works well and lasts a long time.

Process Benefits

Effizienz

Perforationsklingen für Vliesstoffe help factories work faster. These blades cut fabric and composite layers very quickly. They keep up with fast machines in big factories. Machines can switch hole patterns fast, so workers do not stop for long. This keeps the work moving without big breaks. The blades make neat holes in fabric and panels. This helps each layer stay strong and work well. Spacer materials in composites get quick, exact holes. This helps them absorb energy and be stronger. Factories can cut big rolls of fabric and sheets without slowing down. This means they can make lots of products and keep them the same every time.

Tipp: Fast perforation stops slowdowns and helps factories keep making things, which is important for textile and composite industries.

Kosteneinsparungen

Factories save money by using Perforationsklingen für Vliesstoffe. These blades work as fast as the rest of the machines. There is no need to stop or slow down. Special blade shapes help keep fabric and layers tight. This means less waste and better material. Machines can change hole patterns quickly, so there is less waiting. Factories can collect the punched-out pieces and use them again. This saves money and helps the planet. Adding perforation units to old lines makes it easy to keep working fast.

- Perforierklingen help cut fabric and composites quickly.

- Special blade shapes keep fabric and layers strong.

- Machines help stop waste and waiting.

- Reusing punched-out pieces saves money.

- Adding new units to old lines makes work better.

Nanjing Metal gives good prices and helps with shipping. This makes it easy for factories to get strong perforating blades. Their fast service helps companies save money and stay ahead.

Strenge Qualitätskontrolle

Quality control is very important in making textiles and composites. Perforationsklingen für Vliesstoffe must always work the same way. This keeps each product strong and working right. Factories use sharp blades with special teeth and smooth edges. These blades make clean, even holes in every layer. Good materials like tool steel, high-speed steel, and tungsten carbide make blades last longer. This helps spacer materials stay strong and absorb energy.

To get good results, workers follow these steps:

- Keep fabric and layers tight so they do not wrinkle or break.

- Check and change blades often to keep cuts neat.

- Line up knives and set the right depth for even holes.

- Set blade pressure so fabric and layers do not get hurt.

- Check machines often to keep everything working well.

These steps help factories make products that are always strong and work the same way. Even holes help each batch have the right features. Good quality control is very important for modern factories.

Zukunftstrends

Digitalization

Digitalization is changing how factories use perforating blades for non-woven fabric in textiles and composites. Smart machines now have sensors that watch every cut. These sensors check the quality of each spacer and composite layer. Machines can change blade pressure and speed right away. This keeps the material strong and even. Factories use digital twins to test new blade designs before making them. This helps engineers make each composite work better. Automated lines can change spacer patterns with just one command. Digitalization helps stop mistakes and waste. It also helps companies follow strict rules for composite products.

Tipp: Digital tools help factories use perforating blades for non-woven fabric better. They keep each spacer and composite layer strong and high quality.

Nachhaltigkeit

Sustainability brings new ideas for using perforating blades for non-woven fabric. Factories now pick eco-friendly materials for blades and spacers. Many companies recycle old spacers and use them in new composites. Perforating blades help make light panels that use less material. This cuts down on waste and saves energy. Engineers design blades to last longer, so they need fewer replacements. This is better for the environment. Each composite now lets air move better and absorbs energy well. This makes products safer and more comfy. Green practices also make the final composite stronger.

- Factories recycle spacer materials for new composite panels.

- Blades that last longer help cut waste and support green goals.

- Light composite structures save energy and resources.

New Markets

New markets are growing as perforating blades for non-woven fabric get better. Car makers use advanced spacers to make lighter and stronger vehicles. Airplane companies want panels with special features for safety and strength. Medical fields need spacers with exact shapes for wound care and safety gear. Sports brands use composites with special features for better gear. The need for smart textiles is rising. These textiles have spacers with sensors inside. Every new market wants composites that are strong and last long. Perforating blades for non-woven fabric help by shaping each spacer and layer just right.

| Market | Key Application | Benefit from Perforating Blades |

|---|---|---|

| Automobilindustrie | Lightweight composite spacers | Improved structure and properties |

| Luft- und Raumfahrt | Fire-resistant composite panels | Enhanced mechanical properties |

| Medizinische Industrie | Breathable non-woven spacers | Better structure and comfort |

| Sports | High-performance composites | Custom properties and durability |

New markets need to control the structure and features of each composite and spacer. Perforating blades for non-woven fabric make this possible.

Perforating blades for non-woven fabric help make textiles and composites better. Some new ideas include:

- Special blades that cut more exactly and make less waste

- New coatings and materials that help blades last longer and work better

- Machines and careful design that make things faster and improve quality

People keep working together and using new tools, like smart slitting systems, to help factories keep up with what customers want. If you need a special blade or have questions, you can talk to Nanjing Metal’s sales engineers Hier.

Siehe auch

Warum Verpackungsperforationsmesser in der Verpackungsindustrie weit verbreitet sind