You need to be accurate and fast when working with plastics. Granulatorklingen für Kunststoff help make even pieces for recycling and molding. Good blades, smart designs, and regular care help you do your best. The table below shows how taking care of blades and using new designs helps you every day.

| What You Do | Warum es wichtig ist |

|---|---|

| Keep blades sharp and clean | Even granulate size |

| Use modern blade designs | Less stopping, better work speed |

| Keep granule size the same | Easy to feed and mix |

Die wichtigsten Erkenntnisse

- Granulator blades help cut plastic waste into small pieces. This makes recycling and molding easier.

- Blades need regular care like sharpening and cleaning. This helps them work well and make even granules.

- Picking the best blade design, such as staggered or teeth cutters, helps blades cut better. It also saves energy.

- Blades made from high-grade steel last longer and cut better. This means the tools work for more time.

- Changing the blade gap and feed rate helps granulation work well. This gives better granules and less waste.

- Teaching workers about safety rules and blade use lowers accidents. It also makes the workplace safer.

- Watching blade performance with data helps know when to change blades. This keeps the quality steady.

- Choosing the right granulator for the material and job helps work faster. It also helps reach production goals.

Granulatorklingen für Kunststoff

Granulatorklingen für Kunststoff are very important in recycling and injection molding. These blades cut plastic waste into small, even pieces. This step helps you get materials ready for new products. It also keeps your work fast and smooth. Picking the right blade design and material is important for good results.

Designmerkmale der Klinge

There are many blade designs to pick from. Each one has its own benefits. The best design helps you cut plastic easily and neatly.

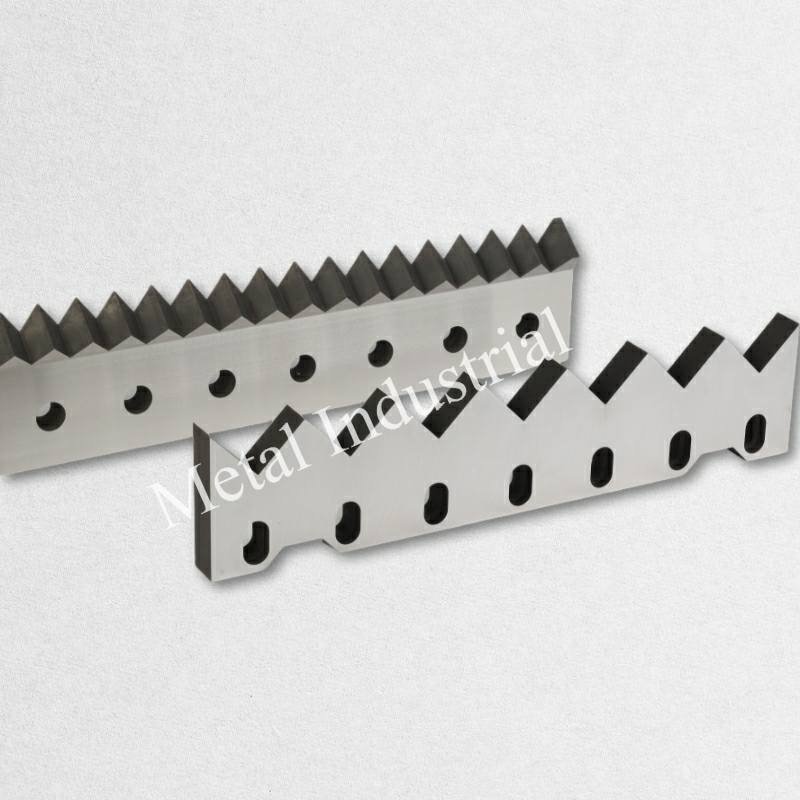

Staggered and Teeth Cutters

Staggered cutters have blades set in a special pattern. Each blade takes turns cutting. This means no blade works too hard. You get steady cutting, which keeps heat and wear low. This design is good for thick or tough plastics. Teeth cutters have jagged edges. These edges grab and slice plastic. They make the granules more even and create less dust. Both designs are used in recycling and making feedstock for injection molding. They work well with PET, HDPE, and engineering plastics.

Here is a table that shows how blade types change cutting:

| Klingentyp | Structure Description | Cutting Performance Impact |

|---|---|---|

| Teeth Blade | Complicated structure, works with staggered blades for coarse and fine grinding. | High efficiency in granulating sprues, but small granulating capacity and high initial cost. |

| Staggered Blade | Staggered layout with large cutting angles, fewer cutters for reduced resistance. | Suitable for granulating plates, cheaper and easier to replace than paddle blades. |

| Paddle Blade | V-type cutting technology with increased blade design for gradual granulating. | More effective for large housings, easier material handling, and improved cutting efficiency in larger chambers. |

Staggered and teeth cutters help you get better results. They use less energy. Staggered rotors let you work faster and cut with more force. These features save energy and keep your machines working well.

Open Rotor and Shear Designs

Open rotor designs let air move through the cutting area. This cools the blades and removes dust and small bits. You get cleaner granules and less mess inside the machine. Shear designs use angled blades to slice plastic. This gives a smoother cut and puts less stress on the blades. Both designs help you work with many plastics and have less downtime.

Material and Manufacturing

The material and how you make Granulatorklingen für Kunststoff affect how long they last and how well they cut. You need to choose the right steel and make sure the blades are made carefully.

High-Grade Steel

Most Granulatorklingen für Kunststoff use high-grade steels. D2 steel is a common choice. It can be made very hard, up to 59 HRC. This steel resists wear, but if it is too hard, it can break. Alloy tool steel is another choice. It has extra parts that make it tougher and last longer. Lescowear steel can reach 60 to 62 HRC. It is very hard and tough, like D2 steel.

Here is a table that compares steel types:

| Stahlsorte | Härte (HRC) | Wear Resistance Characteristics |

|---|---|---|

| D2 Stahl | Up to 59 | Good wear resistance but can become brittle if over-hardened. |

| Legierter Werkzeugstahl | N / A | Improved hardness, toughness, and wear resistance due to alloying elements. |

| Lescowear Steel | 60 to 62 | High wear resistance with maintained impact toughness similar to D2 steel. |

Choosing the right steel gives you blades that last longer and work better. If you need something special, you can look at Kundenspezifische Klingen für Ihre Bedürfnisse.

Precision Machining

Precision machining is important for making good Granulatorklingen für Kunststoff. Skilled workers use CNC machines and grinders to shape each blade. They control how hard the blade gets by changing the heat. This careful work removes bad spots and makes the blade strong and long-lasting. If the blade is too hard, it can break. Good makers balance toughness and wear resistance for the best blades.

Precision machining helps your blades stay sharp and cut well. Good materials and skilled workers also make sure you get strong blades every time.

Tipp: Always make sure your Granulatorklingen für Kunststoff come from a trusted company. Good manufacturing means fewer problems and better results in your recycling or molding work.

Plastic Granulators: Equipment and Applications

Plastic granulators break big plastic pieces into small granules. You use these machines in recycling centers and factories. They help you reuse plastic and keep work smooth. When you use plastic granulators, you control the size of each piece. This helps you meet strict rules for new products.

Granulator vs. Shredder Blades

Application Differences

You may wonder how granulator blades and shredder blades are different. Granulator blades cut plastic into small, even granules. These granules meet tight rules, which is important for making new parts. Shredder blades break plastic into rough, uneven pieces. You use shredders for big, tough items that need fast processing. Granulators are best when you want exact size and shape.

Leistungsvergleich

The table below shows how granulator blades and shredder blades are different:

| Besonderheit | Granulatorklingen | Schredderklingen |

|---|---|---|

| Particle Size | Produces small, uniform granules | Reduces materials to irregular-sized pieces |

| Durchsatz | Operates at lower throughput rates | Processes larger volumes quickly |

| Materialeignung | Ideal for plastics, rubber, soft metals | Better for tougher, denser materials |

| Control Over Output Size | Offers precise control with screens | Focused on breaking materials, less uniformity |

You use granulator blades when you need exact sizes. Shredder blades help you handle big waste fast.

Types of Plastic Granulators

You can choose from different types of plastic granulators. Each type helps you reach your goals for size, speed, and rules.

Einwellen

Single-shaft plastic granulators have one shaft with blades. You get high output, especially with hard plastics. These granulators are easy to fix because they are simple. You can keep tight rules with less work. Single-shaft granulators work well for most recycling jobs.

Multi-Shaft

Multi-shaft plastic granulators have two or more shafts. You use them for big or tough scrap. These granulators handle more material at once. They need more care because they have extra moving parts. Multi-shaft granulators help you meet rules for bigger or mixed plastic waste.

The table below shows how single-shaft and dual-shaft granulators are different:

| Type of Shredder | Processing Efficiency | Wartungsanforderungen |

|---|---|---|

| Einwellen-Häcksler | High productivity, especially with rigid plastics | Easier maintenance due to simpler design |

| Dual-Shaft Shredder | More efficient for bulky scrap | More complex, prone to damage, requires more maintenance due to two sets of knives |

When you pick plastic granulators, think about your material, the rules you need, and how much you want to process. You can find granulators for every job, from small units to big machines for large parts. Each type helps you control size, shape, and rules for your recycled plastic.

Tipp: Always check the rules your process needs before picking a granulator. The right machine helps you save time and get better results.

Granulator Blades: Precision and Maintenance

Taking care of your granulator blades helps you get good results. You need to keep blades sharp and lined up right. Regular checks help you keep high quality. These steps help you meet strict blade rules and make sure every cut is precise.

Sharpening and Alignment

Knife Sharpeners

You have to sharpen blades often to keep them working well. How often depends on your work. If you do heavy jobs, sharpen every 8 to 12 hours. For lighter work, sharpen once a week or every two weeks. Look for dull blades, rough cuts, or more energy use. These signs mean it is time to sharpen.

| Usage Type | Empfohlene Häufigkeit |

|---|---|

| Heavy Jobs | Every 8–12 hours of use |

| Lighter Tasks | Once a week or every two weeks |

When sharpening, follow these steps:

- Clean blades before you start.

- Use coolants to stop blades from getting too hot.

- Keep the same edge angle as before.

- Only take off a little bit of metal.

Some mistakes can make blades wear out faster. Not cleaning leaves dirt that makes edges uneven. Not using coolants makes blades too hot and soft. If you do not sharpen the right way, the edge angle changes. This makes blades cut badly. These mistakes make blades dull faster and lower their quality.

Tipp: Sharpening blades the right way helps them last longer and keeps your work going.

Installationstipps

Blades work best when you install them the right way. Always check if blades are lined up and the gap is set right. Use the torque the maker says for bolts. Make sure all safety guards are on after you finish. These steps help you keep blade rules and keep your machine safe.

Best Practices für die Wartung

Doing regular checks helps blades last longer and keeps granules the same size. You need a plan and a checklist to help you.

Inspection Schedules

Follow a weekly checklist:

- Check if blades are sharp or chipped. This keeps cuts even and stops machine overload.

- Look at blade gap and if they line up. The right gap stops too much wear and keeps granules even.

- Check bolts and fasteners to see if they are tight. Loose bolts can make blades move or break.

- Listen for strange sounds or shaking when the machine runs. Finding problems early can save money on repairs.

- Clean the chamber and take out any dirt. This keeps the machine working well and stops dirt from getting in.

Write down what you do and teach workers to spot blade problems. Train more than one person to care for blades. Make rules for how to handle blades and set limits for blade thickness and signs of wear.

Ersatzschilder

Change blades if you see cracks, chips, or lots of wear. If blades will not stay sharp after sharpening, get new ones. If you see more fines or uneven granules, even with the right settings, it is time to replace blades.

| Auswirkungen | Beschreibung |

|---|---|

| Höherer Energieverbrauch | Dull blades use 15–25% more energy each cycle, which costs more. |

| Zusätzliche Maschinenbelastung | Worn blades make the machine work harder and can break other parts sooner. |

| Increased maintenance costs | Using bad blades can cause emergency repairs, which cost more than planned checks. |

Notiz: Changing blades on time saves money and keeps your machine safe.

Maintenance Differences for Various Plastics

Different plastics need different care. Glass-filled nylon makes blades dull fast, so sharpen more often. PET wears blades in its own way, so you need to check them differently. HDPE wears blades in a special way and needs its own care.

| Materialtyp | Maintenance Requirement |

|---|---|

| Glass-filled Nylon | Sharpen more often because blades dull quickly |

| HAUSTIER | Needs different care because it wears blades differently |

| HDPE | Needs special care because it wears blades in its own way |

Rough plastics like glass-filled types wear blades out faster. Check blades more often and use harder blade types. Soft plastics like LDPE and PP can stick to blades, so clean them more to stop buildup. Plastics that do not like water, like PET, can rust blades. Use blades that do not rust and dry them well after cleaning. Plastics that get hot may need you to check the gap more because they expand.

Sharpening blades well and doing regular checks helps you get the best results and keeps your granulator blades working well, no matter what plastic you use.

Efficiency in Plastic Granulation

You can make your plastic granulation better by checking blade gap, feed rate, and machine settings. These things help you get more good granules and use less energy. If you set up your granulator the right way, you get even pieces and less waste.

Blade Gap and Feed Rate

Adjusting for Material Type

Always check the blade gap before you start. The gap should fit the widest knife in your machine. If knives are not the same size, you get uneven cuts and more blade wear. Sharp and well-fitted knives make granules the same size. This also helps stop dust and fines. Dull or loose blades make mixed sizes and more dust.

Feed rate is also important for your work. You need to match feed rate with rotor speed. Too much material can jam the machine. Too little wastes energy. The best feed rate gives you up to 90% efficiency. A steady feed rate keeps your work smooth and gives you more output.

Reducing Fines and Dust

You can lower dust and fines by keeping your granulator in good shape. Worn blades make uneven granules and more dust. Change blades on time and keep your machine clean. This helps you get better granules and less waste.

Some ways to cut dust and fines are:

- Use special dust collectors, like pulse bag systems.

- Do regular maintenance and change old blades.

- Clean your machine often.

- Use water sprays to keep dust down.

- Make your crushing process better.

Tip: Check your granulator often and wear safety gear to keep your area safe and clean.

Productivity and Output

Throughput Optimization

You can get more output by looking at different parts of your granulator. The cutting chamber, rotor type, knife setup, and screen size all matter. Feeding systems and automation help you reach your goals. The kind of plastic, the size you want, and your space also matter.

A good granulator with the right settings gives you high performance and steady output. Pick the right machine for your plastic and make sure all parts work together.

Energieeffizienz

Blade design changes how much energy you use. Blades that cut well make even granules and better quality. Hard blades last longer and mean less downtime, so you can make 15–30% more. If you use blades made for your plastic, you lower the motor load and save power.

| Faktor | Impact on Energy Efficiency |

|---|---|

| Schnittpräzision | Same granule size, better quality |

| Verschleißresistenz | Less downtime, more production |

| Blade optimization | Lower motor load, less electricity |

New blade designs, like teeth, paddle, and staggered blades, help you cut tough or thin plastics with less energy. These blades spread the work and hold the plastic better, so you get better results.

Remember: The right blade settings and regular care help you get the best efficiency and output from your granulator.

User Recommendations

Training and Safety

Staff Education

You need workers who know what they are doing. Training helps everyone use granulator blades safely. It also helps stop accidents from happening. The table below lists some top training programs for plastic work:

| Training Program | Beschreibung | Required Courses |

|---|---|---|

| 36-hour OSH Train-the-Trainer | Gets staff ready to teach safety classes | Safety Management, Hazard Analysis, Ergonomics, Training Development |

| 36-hour Safety Committee Chair | Teaches leaders how to run safety meetings | Safety Management, Accident Investigation, Emergency Action Plans |

| 32-hour Safety Committee Member | Trains members to help with safety | Safety Management, Committee Operations, Hazard Control, Emergency Action Plans |

These programs show your team how to find dangers and handle emergencies. They also help keep the workplace safe. You should keep learning so everyone knows the latest rules.

Safety Protocols

You must follow strict rules when using granulator blades. Here are some important safety steps:

- Always turn off and lock the machine before fixing it.

- Never put your hands in the hopper or cutting area when it is on.

- Wear safety glasses, gloves that protect from cuts, and ear protection.

- Put all guards back before you start the machine again.

- Keep the area around the granulator clean and clear.

Safety comes first! These steps help stop injuries and keep everyone safe.

Leistungsüberwachung

Quality Tracking

You can use special systems to check your plastic granules. These systems help you see and fix problems fast. The table below shows some helpful features:

| Besonderheit | Beschreibung |

|---|---|

| User-friendly interface | Easy to use with many granulators |

| Pre-built dashboards | Shows important numbers for quick checks |

| Historical data access | Lets you look at old results and find patterns |

| Custom alerts | Tells you about problems right away |

| Predictive maintenance | Warns you before parts break, so you have less downtime |

| Continuous quality monitoring | Checks granule size with sieves and lasers for fast fixes |

These tools help you keep your work smooth and make sure everything runs well.

Data Analysis

You can use data to make better choices about your granulator blades. Smart computer programs help you know when to change blades and stop problems. Here are some ways data helps:

- Tells you when blades will wear out and need changing.

- Helps you set up your process for better results.

- Watches granule quality as you work.

- Supports new blade ideas for special jobs.

- Helps you plan and keep track of supplies.

Tip: Work with trusted companies like Nanjing Metal to make a good maintenance plan, pick the best blade materials, and get custom blades for your needs. This teamwork helps you fix problems like jams, too much heat, and bad granule quality.

If you focus on training, safety, and checking your work, you can make your granulator blades work better and keep your business running strong.

Using special granulator blades for plastic helps you save money. These blades also make your products better. The table below shows how different industries get help:

| Industrie | Leistungsbeschreibung |

|---|---|

| uPVC Recycling | You change blades less, so you spend less money. |

| Injection Moulding | Even granules help you work faster and make better products. |

| Herstellung | Custom blades last longer and cost less, so your job is easier. |

If you take care of your machines, they stay safe and work well. You stop breakdowns, use less energy, and keep your workspace safer. If you want more information or need help picking granulator blades for plastic, Kontaktieren Sie unser Team.

Häufig gestellte Fragen

How do you choose the right granulator machine for your needs?

You look at the type of plastic, the size you want, and how much material you process. You also check the blade design and safety features to match your job.

What is a high-efficient granulating process?

You use sharp blades, set the right blade gap, and keep the machine clean. This process helps you get even granules, less waste, and better results.

How do you handle granulating hard plastics?

You pick blades made from tough steel and check them often. You also use staggered or teeth cutters to cut hard plastics with less wear.

Why is high-quality sharpening important?

You keep blades sharp to get smooth cuts and even granules. Good sharpening helps you save energy and keeps your machine working well.

How can you improve production efficiency?

You set the right feed rate, keep blades sharp, and check the machine often. These steps help you get more granules in less time.

What signs show you need to replace your blades?

You see cracks, chips, or dull edges. You notice more dust or uneven granules. You also hear strange sounds from the machine.

How do you track overall output from your granulator?

You use dashboards and sensors to watch granule size and count. You check reports to see how much material you process each day.

Can you use the same blades for all plastics?

You need different blades for soft, hard, or abrasive plastics. You pick the right blade material and design for each type to get the best results.

Tip: Always follow safety rules when working with granulator blades. Wear gloves and eye protection to stay safe.

Siehe auch

Maximierung Ihres Holzabfall-Umsatzes mit Hochleistungs-Holzschredder-Messern

Wesentliche Merkmale von E-Schrott-Shredder-Klingen für sichere Zerstörung

So Wählen Sie Kunststoff-Shredder-Klingen für Effizientes Recycling

Der Ultimative Leitfaden für Einwellen-Shredder-Klingendesigns

Schredderblätter: Analyse der Klassifizierung, Materialauswahl, Lebensdauer und Designtechniken