| Andere Namen | Kerbschneider, Quetschschneider, Kerbmesser, Nachschneidermesser, Quetschschneider, gewölbte Messer |

|---|---|

| Herkunftsort | China |

| Anwendung | Kunststoff, Papier, Karton, Vlies, Film, Folie, Etiketten, Klebeband, Textil, Verpackung, Teppich, Taschen, Rohre, Kerne, Gummi |

| Material | 65Mn,9CrSi,Cr12MoV,SKD-11,HSSl |

| Modell-Nr | CV-CK |

| OEM-Service | Verfügbar |

| Zahlungsbedingungen | L/C, T/T, Western Union |

| Paket | Kartonschachtel, in Holzkisten |

| Lieferzeit | 7-20 Tage |

Teilen mit:

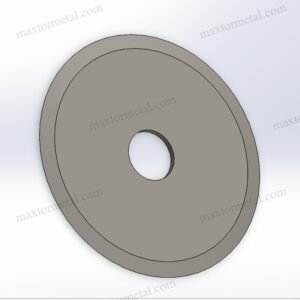

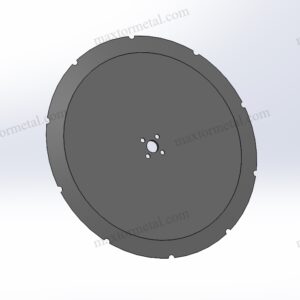

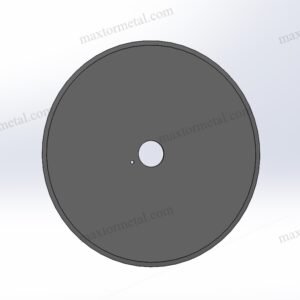

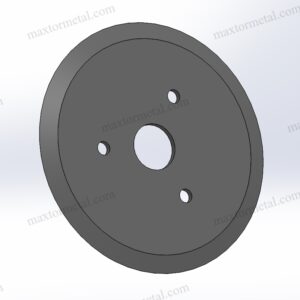

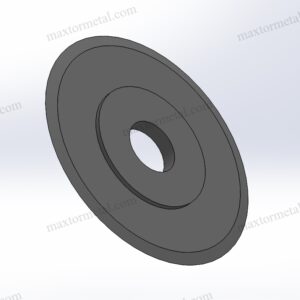

Kreismesser, also known as rotary blades or disc knives, are cutting tools with a circular shape and a sharpened outer edge. They are designed to cut materials through a rotary motion, often against a counter blade or anvil. The term “circular knives” is broad and encompasses a wide variety of disc-shaped cutting tools used across numerous industries for slicing, slitting, perforating, and scoring various materials. Their rotating action allows for continuous and efficient cutting, making them ideal for high-speed production processes.

Kreismesser find extensive applications across a multitude of industries due to their efficiency and versatility in cutting various materials. Some key uses include:

The choice of material for circular knives depends heavily on the material being cut, the speed of operation, and the required lifespan of the blade. Common materials include:

Coatings such as titanium nitride (TiN), chromium nitride (CrN), or diamond-like carbon (DLC) can be applied to enhance surface hardness, reduce friction, and extend the life of circular knives, especially when dealing with abrasive or sticky materials.

Kreismesser come in a wide array of shapes and edge configurations to optimize cutting performance for specific applications. Common shapes include:

The working principle of circular knives involves rotary motion combined with controlled pressure against the material being cut. The sharpness and geometry of the cutting edge, along with the speed of rotation and the material properties, determine the quality and efficiency of the cut. In many applications, circular knives work in conjunction with anvils, counter blades, or other rollers to provide support and ensure a clean cut.

Willkommen zu Anfragen!

If you don’t find the shear blade you are looking for, we can also customize it, see our “Kundenspezifische Klingen“, um zu erfahren wie!

Genießen Sie den Komfort des Imports. Vom Transport bis zur Zollabfertigung kümmern wir uns um den gesamten Prozess. Sie müssen nur die Mehrwertsteuer zahlen und warten, bis die Waren beim Unternehmen eintreffen.

Wir haben gesehen, wie seine Klingen in unzähligen Anwendungen eingesetzt wurden, und sind bereit, jedes Projekt zu bewältigen, das Sie uns stellen – mit Genauigkeit, Haltbarkeit und unübertroffen wettbewerbsfähigen Preisen.

Ob Sie Zeichnungen, Skizzen oder Muster liefern, wir können für Sie zeichnen und fertigen. Wir können Ihnen auch dabei helfen, bestehende Designs und Spezifikationen zu ändern, um nahezu jede industrielle Werkzeuganwendung zu verbessern. Bitte kontaktieren Sie unser engagiertes Vertriebsteam, um Ihre spezifischen Anforderungen zu besprechen.

Zur Kontrolle der Qualität werden eine Reihe von Tests und Kontrollen durchgeführt, darunter die Erstmusterprüfung, die Prüfung eingehender Materialien und zertifizierter Materialien, die Qualitätskontrolle während des Prozesses und die Endqualitätsprüfung.

Egal, ob Sie Importeur, Händler, Großhändler oder Endverbraucher sind, Sie sind bei uns herzlich willkommen – mit minimaler Mindestbestellmenge, ohne lästige Anfragen und mit mehr Freiheit beim Einkauf.

Werden Sie Ihr exklusiver Monitor und übertragen Sie regelmäßig alle wichtigen Knoten in der Produktionslinie, egal wie weit sie entfernt sind. So haben Sie den Produktfortschritt so weit wie möglich im Blick!

Nanjing Metal Industrial CO., Limited

Mingjue-Industriepark, Lishui, Nanjing, Jiangsu, China

Bleiben Sie mit unseren neuesten Nachrichten auf dem Laufenden.