Sicher und effizient Schneidklingen für die Granulierdüse Der Austausch erfordert sorgfältige Sicherheitsvorkehrungen und regelmäßige Wartung. Sie tragen zu einer optimalen Leistung Ihres Pelletierers bei, indem Sie auf Anzeichen wie die folgenden achten: erhöhte Bußgelder, höhere Motorbelastung oder ungewöhnliche GeräuscheDa der Markt für Pelletiergeräte wächst jährlich um 4,51 Tsd.Die Verwendung hochwertiger Sägeblätter gewährleistet, dass Sie den steigenden Anforderungen gerecht werden. Wählen Sie stets ein Sägeblatt mit dem passenden Schnittspalt von 0,2 bis 0,3 mm für saubere Schnitte und minimale Ausfallzeiten.

Die wichtigsten Erkenntnisse

- Tragen Sie vor dem Klingenwechsel stets die richtige Schutzausrüstung wie schnittfeste Handschuhe, Schutzbrille und Sicherheitsschuhe mit Stahlkappen.

- Um den Pelletierer während der Wartung abzuschalten und Unfälle zu vermeiden, befolgen Sie die Sperr- und Kennzeichnungsmaßnahmen.

- Reinigen und prüfen Sie die Matrizenfläche und die Klingen sorgfältig auf Beschädigungen und stellen Sie sicher, dass die neuen Klingen gut passen.

- Verwenden Sie maßgefertigte Pelletierklingen für bessere Ergebnisse, längere Nutzungsdauer und um langfristig Kosten zu sparen.

- Um einen einwandfreien Betrieb der Maschine und die Herstellung guter Pellets zu gewährleisten, sollten Sie die Ausrichtung und den Spalt der Klingen (0,2–0,3 mm) regelmäßig überprüfen.

Sicherheit und Vorbereitung

Persönliche Schutzausrüstung und Werkzeuge

Erforderliche persönliche Schutzausrüstung (PSA)

Bevor Sie beginnen, müssen Sie Ihre Sicherheit gewährleisten. Tragen Sie immer schnittfeste Handschuhe, um Ihre Hände vor scharfen Kanten zu schützen. Tragen Sie eine Schutzbrille, damit nichts in Ihre Augen gelangt. Bei Spritzern oder Staubentwicklung verwenden Sie ein Gesichtsschild. Sicherheitsschuhe mit Stahlkappen schützen Ihre Füße, falls Sie etwas Schweres fallen lassen. Tragen Sie lange Ärmel und Hosen, um Ihre Haut zu bedecken. Bei Lärmbelastung verwenden Sie einen Gehörschutz.

Unverzichtbare Werkzeuge für den Klingenwechsel

Bereiten Sie alle Werkzeuge vor, bevor Sie beginnen. Sie benötigen einen Drehmomentschlüssel, um die Schrauben und Muttern fest anzuziehen. Bringen Sie Inbusschlüssel oder Sechskantschlüssel und einen Schraubendreher mit. Ein Schonhammer hilft Ihnen, vorsichtige Schläge auszuführen. Verwenden Sie eine Reinigungsbürste und fusselfreie Tücher, um Schmutz zu entfernen. Halten Sie einen Behälter für alte Klingen und Befestigungselemente bereit. Stellen Sie sicher, dass Ihre Werkzeuge einwandfrei funktionieren und nicht beschädigt sind.

Maschinenabschaltung

Schrittweise Abschaltprozedur

Um Ihre Sicherheit zu gewährleisten, müssen Sie den Pelletierer ordnungsgemäß ausschalten. Befolgen Sie dazu folgende Schritte:

- Finde alle Energiequellen und Gefahren in der Nähe der Maschine.

- Schalten Sie die Hauptstromversorgung aus und stoppen Sie alle beweglichen Teile.

- Verwenden Sie Sperr- und Kennzeichnungsvorrichtungen, nicht nur Not-Aus-Taster, um die Energiezufuhr zu unterbrechen.

- Bringen Sie die Verriegelungs-/Kennzeichnungsvorrichtungen an den richtigen Stellen an.

- Gespeicherte Energie freisetzen oder speichern, wie beispielsweise in Kondensatoren.

- Testen Sie die Maschine, um sicherzustellen, dass sie wirklich ausgeschaltet ist.

- Informieren Sie Ihr Team, damit alle wissen, dass die Maschine abgeschaltet ist.

Sicherheitsprotokoll für die Verriegelung/Kennzeichnung (LOTO)

Die Sperr- und Kennzeichnungsmethode (LOTO) sorgt für Ihre Sicherheit beim Klingenwechsel. Verwenden Sie stets LOTO-Vorrichtungen, um die Maschine abzuschalten. Bringen Sie Kennzeichnungsschilder an, um anzuzeigen, dass Arbeiten durchgeführt werden. Verlassen Sie sich nicht allein auf die Verriegelungen. Nur geschultes Personal darf die LOTO-Vorrichtungen nach Abschluss der Arbeiten entfernen.

Bereichsvorbereitung

Arbeitsbereich freiräumen und reinigen

Ein sauberer Arbeitsbereich beugt Unfällen vor. Entfernen Sie alle Kunststoffgranulate, Staub und Abfälle vom Boden und von der Maschine. Verstauen Sie Werkzeuge und Materialien ordentlich. Ordnung am Arbeitsplatz verhindert Ausrutschen, Stolpern und Brände.

Erkennen und Vermeiden häufiger Gefahren

Branchenberichten zufolge können Brände und Explosionen bei Wartungsarbeiten an Pelletieranlagen auftreten.Die folgende Tabelle zeigt die wichtigsten Gefahrenarten:

| Kategorie | Details |

|---|---|

| Verwendete Materialien | Grüne und trockene Holzfasern, Holzpellets, Brenngase |

| Beteiligte Ausrüstung | Pelletieranlagen, Trockner, Hammermühlen, Silos, Förderbänder, Entstauber, Kühler |

| Zündquellen | Heißarbeiten, mechanische Funken, elektrische Geräte, Glimmen, Selbsterhitzung, Reibung |

| Vorfallarten | Brände (Pelletieranlage, Silo, Trockner), Verpuffungen, Explosionen, Geräteausfälle |

Diese Gefahren lassen sich durch Staubbekämpfung, regelmäßige Geräteprüfung und Schulung Ihres Teams vermeiden. Installieren Sie Brandmelder und halten Sie den Arbeitsbereich frei von brennbaren Gegenständen. Befolgen Sie beim Klingenwechsel stets die Sicherheitsvorkehrungen.

Schritte zum Austausch der Düsenkeile einer Pelletierpresse

Klingenentfernung

Schrittweiser Entfernungsprozess

Vor dem Einsetzen neuer Messer müssen die alten Messer entfernt werden. So entfernen Sie die Messer sicher und schnell: 1. Stellen Sie sicher, dass der Pelletierer ausgeschaltet und verriegelt ist. 2. Lassen Sie die Matrizenfläche und die Messer abkühlen, falls sie heiß waren. 3. Lösen Sie die Schrauben mit einem Drehmomentschlüssel oder Inbusschlüsseln. Drehen Sie jede Schraube langsam und gleichmäßig. 4. Halten Sie das Messer mit einer Hand fest, während Sie die letzte Schraube entfernen. So verhindern Sie, dass das Messer herunterfällt. 5. Heben Sie das Messer von der Matrizenfläche ab. Legen Sie es in einen sicheren Behälter zur Entsorgung oder Überprüfung.

Tipp: Halten Sie Ihre Hände von scharfen Kanten fern. Tragen Sie schnittfeste Handschuhe, um sich zu schützen.

Häufige Probleme und Lösungen bei der Entfernung

Beim Herausnehmen der Klinge können Probleme auftreten. Hier sind einige häufige Probleme und deren Behebung:

| Ausgabe | Ursache | Lösung |

|---|---|---|

| Klinge steckte fest und starb | Rückstandsbildung oder Korrosion | Mit einem weichen Gummihammer vorsichtig klopfen; bei Bedarf etwas Kriechöl verwenden. |

| Abgerissene Schraubenköpfe | Zu festes Anziehen oder verschlissene Werkzeuge | Verwenden Sie einen Bolzenausdreher oder besorgen Sie sich neues Werkzeug. |

| Die Klinge fällt plötzlich zu Boden | Die Klinge wurde beim letzten Bolzen nicht festgehalten. | Halten Sie die Klinge immer mit der Hand fest oder verwenden Sie eine Klemme. |

Inspektion und Reinigung

Inspektionscheckliste und Reinigungsschritte

Nach dem Entnehmen des Messers prüfen und reinigen Sie die Schneidfläche und den Montagebereich. Nutzen Sie diese Checkliste: – Achten Sie auf Risse, Absplitterungen oder ungleichmäßigen Verschleiß an der Schneidfläche. – Prüfen Sie die Befestigungslöcher auf Gewindeschäden oder Verschmutzungen. – Prüfen Sie das alte Messer auf starken Verschleiß oder Brüche. – Achten Sie auf Rückstände, Kunststoffablagerungen oder Rost auf allen Oberflächen.

Zur Reinigung des Bereichs: 1. Staub und Schmutz mit einem fusselfreien Tuch abwischen. 2. Hartnäckige Rückstände mit einer Reinigungsbürste entfernen. 3. Bei Bedarf ein vom Hersteller als unbedenklich eingestuftes, mildes Lösungsmittel verwenden. 4. Vor dem Einsetzen der neuen Klinge alles gründlich trocknen.

Notiz: Saubere Oberflächen sorgen für einen korrekten Sitz der Klinge und verhindern Ausrichtungsprobleme.

Häufige Probleme und Lösungen bei Inspektion/Reinigung

Probleme können beim Überprüfen und Reinigen des Bereichs auftreten. Hier einige Beispiele:

| Ausgabe | Ursache | Lösung |

|---|---|---|

| Schwer zu entfernende Rückstände | Geschmolzener Kunststoff oder altes Fett | Verwenden Sie einen Kunststoffschaber oder ein unbedenkliches Lösungsmittel. |

| Fäden voller Schmutz | Nach dem letzten Wechsel nicht gereinigt | Gewinde mit einer kleinen Drahtbürste reinigen. |

| Oberflächenrost | Wassereinwirkung | Mit feinem Schleifpapier vorsichtig anschleifen; Rostschutzmittel verwenden. |

Klingenmontage

Schrittweiser Installationsprozess

Jetzt können Sie das neue einsetzen. Granulierdüsen-SchaufelnGehen Sie wie folgt vor: 1. Richten Sie die neue Klinge an den Löchern der Matrize aus. 2. Drehen Sie die Schrauben von Hand ein, um ein Verkanten zu vermeiden. 3. Ziehen Sie jede Schraube über Kreuz leicht an. 4. Verwenden Sie einen Drehmomentschlüssel, um die Schrauben mit dem richtigen Drehmoment festzuziehen. 5. Stellen Sie sicher, dass die Klinge plan und lückenlos an der Matrize anliegt.

Sicherheitscheck: Stellen Sie sicher, dass alle Schrauben fest angezogen sind und sich die Klinge bei Bedarf bewegen lässt.

Häufige Probleme und Lösungen während der Installation

Beim Einsetzen der Klinge können folgende Probleme auftreten:

| Ausgabe | Ursache | Lösung |

|---|---|---|

| Die Klinge passt nicht. | Falsche Klingengröße oder nicht ausgerichtet | Prüfen Sie die Teilenummer und vergewissern Sie sich, dass es sich um die richtige Klinge handelt. |

| Die Schrauben lassen sich nicht festziehen | Verkantetes Gewinde oder Schmutz | Schrauben herausnehmen, Gewinde reinigen und es erneut versuchen. |

| Die Klinge sitzt uneben. | Verschmutzungen oder Beschädigungen an der Montagefläche | Reinigen Sie die Oberfläche erneut und prüfen Sie sie auf Beschädigungen. |

Ausrichtung und Testlauf

Ausrichtungsverfahren und Testlaufschritte

Eine korrekte Ausrichtung trägt zu einem reibungslosen Maschinenbetrieb bei und verlängert die Lebensdauer der Klingen. So richten Sie die neue Klinge aus und testen sie: 1. Drehen Sie die Matrizenfläche von Hand, um den Klingenspalt zu prüfen. 2. Messen Sie den Abstand zwischen Klinge und Matrizenfläche. Stellen Sie ihn auf 0,2–0,3 mm ein. 3. Achten Sie darauf, dass die Klinge die Matrizenfläche nicht berührt oder daran schleift. 4. Entfernen Sie alle Werkzeuge und Reinigungsmittel aus dem Arbeitsbereich. 5. Entfernen Sie die Sperr- und Kennzeichnungsvorrichtungen und schalten Sie die Stromzufuhr wieder ein. 6. Starten Sie den Pelletierer mit niedriger Drehzahl. Achten Sie auf ungewöhnliche Geräusche oder Vibrationen. 7. Erhöhen Sie die Drehzahl langsam und beobachten Sie die Pellets.

Profi-Tipp: Stoppen Sie die Maschine sofort, wenn Sie kratzende Geräusche hören oder ungleichmäßige Pellets sehen. Überprüfen Sie die Ausrichtung und den Spalt erneut.

Häufige Probleme und Lösungen während der Ausrichtung/des Testlaufs

Während der Ausrichtung oder des Testlaufs können Probleme auftreten. So beheben Sie diese:

| Ausgabe | Ursache | Lösung |

|---|---|---|

| Seltsame Geräusche oder Erschütterungen | Fehlende Ausrichtung oder lockere Schrauben | Maschine anhalten, Ausrichtung prüfen und Schrauben festziehen. |

| Pellets sind nicht einmal | Falscher Klingenabstand | Der Spalt sollte auf 0,2–0,3 mm eingestellt werden. |

| Klinge berührt Würfelgesicht | Der Spalt ist zu klein | Schrauben lösen, Klinge bewegen und wieder festziehen. |

Befolgen Sie stets die Anweisungen des Herstellers zum Austausch von Matrize und Klinge. Sorgfältiges Ausführen jedes einzelnen Schrittes trägt zu Ihrer Sicherheit bei und gewährleistet optimale Ergebnisse.

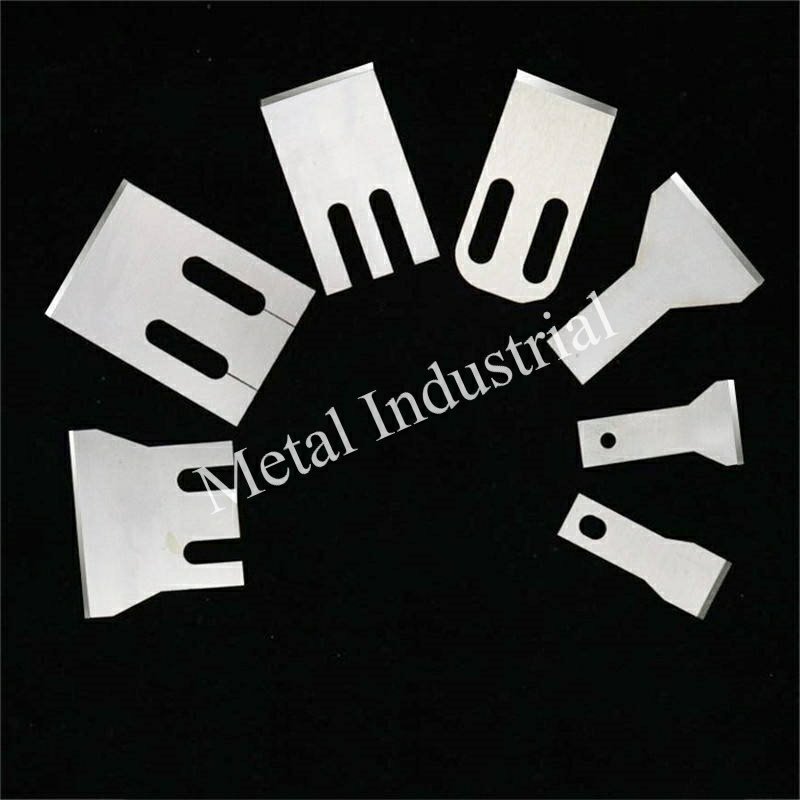

Kundenspezifische Pelletierdüsen-Schneidflächen

Vorteile der Anpassung

Verbesserte Leistung und Effizienz

Maßgefertigte Pelletiermesser helfen Ihnen, mehr Pellets herzustellen. Sie tragen außerdem zu einer besseren Pelletqualität bei. Sie können die Messerform und das Material passend zu Ihren Anforderungen auswählen. So erhalten Sie Pellets mit einheitlichem Aussehen und reduzieren den Materialverlust. Studien zeigen, dass… Steuerung von Faktoren wie Partikelgröße und MaschinengeschwindigkeitSie erhalten festere Pellets und eine größere Menge davon. Individuell anpassbare Klingen ermöglichen es Ihnen, die optimale Lösung für Ihre Rohstoffe und Ihre Ziele auszuwählen.

Erhöhte Haltbarkeit und Lebensdauer

Speziell angefertigte Sägeblätter sind langlebiger, da sie aus besonderen Materialien und Beschichtungen bestehen. Einige verfügen über Wolframkarbid- oder Keramikbeschichtungen, die den Verschleiß deutlich reduzieren. Diese Sägeblätter bleiben länger scharf und müssen seltener gewechselt werden. Das spart Ihnen Zeit und Geld für Reparaturen.

Passgenau für bestimmte Maschinen

Maßgefertigte Messer passen perfekt zu Ihrem Pelletierer. Das sorgt für einen ruhigen Lauf der Maschine und reduziert Vibrationen. Eine optimale Passform verhindert außerdem Probleme wie ungleichmäßige Schnitte oder nicht fluchtende Messer.

Kosteneffizienz im Laufe der Zeit

Maßgefertigte Klingen sind zwar in der Anschaffung teurer, sparen Ihnen aber langfristig Geld, da sie deutlich länger halten. Sie können bis zu dreimal länger halten als Standardklingen. Außerdem reduzieren Sie den Reparaturaufwand Ihrer Maschine. Die folgende Tabelle zeigt die Vorteile maßgefertigter Klingen gegenüber Standardklingen:

| Leistungsaspekt | Kundenspezifische Pelletierklingen | Standardklingen |

|---|---|---|

| Klingenlebensdauer | Bis zu 3-mal länger aufgrund fortschrittlicher Materialien/Beschichtungen | Standardstahl, kürzere Lebensdauer |

| Schnittkonsistenz | Höherer Wert, was zu einer besseren Pelletgleichmäßigkeit führt | Geringere Konsistenz |

| Durchsatz | Höherer Durchsatz; Beispiel: 200 Tonnen Recyclingpellets/Monat | Geringerer Durchsatz |

| Rohstoffeinsparungen | Ein Möbelunternehmen in China meldet Einsparungen von bis zu 351 TP4T. | Weniger effizient, mehr Abfall |

| Auswirkungen auf den Umsatz | $1,2 Millionen zusätzlicher Jahresumsatz (Fallbeispiel) | Kein vergleichbarer Anstieg |

| Wartungshäufigkeit | Weniger häufig aufgrund von Langlebigkeit und besserer Passform | Häufigere Klingenwechsel und Reparaturen |

| Kosteneffizienz | Besser aufgrund längerer Lebensdauer und weniger Ausfallzeiten | Höhere Betriebskosten |

Verbesserte Wartung und Sicherheit

Speziell angefertigte Messer lassen sich leichter einsetzen und entnehmen. Das erhöht die Sicherheit für die Arbeiter und trägt zu einem reibungslosen Betrieb des Pelletierers bei.

Nanjing Metal-Lösungen

Nanjing Metal Industrial CO., Limited ist ein führender Hersteller von Düsenschaufeln für Pelletierpressen. Das Unternehmen fertigt seit über 20 Jahren Schaufeln. Die ISO-Zertifizierung garantiert höchste Produktqualität. Das Team besteht aus erfahrenen und jungen Ingenieuren, die mit großem Engagement erstklassige Schaufeln entwickeln. Nanjing Metal bietet Ihnen die Möglichkeit, maßgefertigte Schaufeln nach Ihren individuellen Anforderungen zu bestellen.

Sie prüfen die Qualität in jedem Produktionsschritt, von der Materialprüfung bis zum fertigen Produkt. Dabei kommen robuste Werkstoffe wie SK2, HSS, M2 und SKD11 zum Einsatz. Spezielle Wärmebehandlungen wie Härten, Anlassen und Tiefkühlen sorgen für eine hohe Härte der Klingen von HRC 52 bis 65. Dadurch erreichen die Klingen eine längere Lebensdauer als die von 60%. Optional sind Beschichtungen wie Verchromung oder Titannitrid erhältlich, die die Klingen zusätzlich leistungsfähiger machen.

Die Spezialklingen von Nanjing Metal eignen sich für viele Anwendungen, wie z. B. Kunststoffrecycling und Masterbatch-Herstellung. Sie können auf deren Fachwissen vertrauen und erhalten regelmäßig Updates zu Ihrer Bestellung. Wenn Sie mehr erfahren möchten oder eine spezielle Klinge benötigen, können Sie sich an uns wenden. Kontakt ihren Vertriebsingenieuren.

Werkzeugwartung und bewährte Verfahren

Routineinspektion

Wichtige Prüfpunkte für den Klingenmontagebereich

Bei der Werkzeugwartung sollten Sie zahlreiche Teile überprüfen. Achten Sie besonders auf Schaufelfuß, Plattform, Hinterkante, Schaufelspitze, Vorderkante, Schaufelprofil und Plattformradius. Saubere Schaufeln erleichtern das Erkennen von Problemen. Studien belegen, dass saubere Schaufeln die Fehlersuche erleichtern. dreimal häufiger als verschmutzte. Wischen Sie Staub und Rückstände immer ab, bevor Sie die Maschine überprüfen. So erkennen Sie Risse, Kerben oder andere Beschädigungen, die die Funktion der Maschine beeinträchtigen könnten.

Anzeichen von Verschleiß, Rissen oder Lockerung in den Klingensitzen

Prüfen Sie die Klingensitze auf Rillen, Ausbrüche oder ungleichmäßigen Verschleiß. Achten Sie auf Risse oder darauf, ob die Klinge nicht fest sitzt. Sollten Sie lose Schrauben oder bewegliche Teile entdecken, unterbrechen Sie den Vorgang und beheben Sie diese umgehend. Werden diese Probleme übersehen, können größere Ausfälle entstehen, die Zeit und Geld kosten. Die regelmäßige Überprüfung der Matrize hilft Ihnen, diese Probleme frühzeitig zu erkennen.

Reinigung und Schmierung

Reinigungsverfahren für Klingen- und Werkzeugkontaktflächen

Reinigen Sie nach jedem Gebrauch die Kontaktflächen von Matrize und Messer. Verwenden Sie ein fusselfreies Tuch, um Staub und Kunststoffreste zu entfernen. Prüfen Sie vor dem nächsten Start der Maschine, ob Materialreste vorhanden sind. Gründliche Reinigung verhindert Verunreinigungen und gewährleistet die einwandfreie Funktion Ihrer Maschine.

Schmiertipps für die Klingenmontage und bewegliche Teile

Verwenden Sie das richtige Schmiermittel für bewegliche Teile und Messerhalterungen. Verwenden Sie niemals Flaschen ohne Etikett. Achten Sie bei laufender Maschine stets auf Lecks oder Tropfen. Legen Sie einen Schmierplan fest, der sich nach der Nutzungshäufigkeit der Maschine richtet.

Vermeidung von Verunreinigungen während der Wartung

Halten Sie Ihren Arbeitsbereich sauber. Tragen Sie saubere Kleidung und schließen Sie die Türen, um Staub und Insekten fernzuhalten. Bewahren Sie Schmierstoffe in beschrifteten Behältern auf. Unzureichende Reinigung kann zu Verunreinigungen führen, die Ihre Klingen und Düsen beschädigen können. Regelmäßige Wartung hilft Ihnen, diese Probleme zu vermeiden.

Fehlerbehebung

Häufige Probleme nach dem Klingenwechsel (z. B. unsachgemäße Installation, ungewöhnliche Geräusche, ungleichmäßiger Schnitt)

Nach dem Klingenwechsel können ungewöhnliche Geräusche auftreten, ungleichmäßige Pellets sichtbar sein oder ein Rütteln spürbar sein. Diese Probleme entstehen meist durch eine fehlerhafte Montage, lockere Schrauben oder einen falschen Klingenspalt.

Lösungen und Präventivmaßnahmen für Probleme im Zusammenhang mit Klingen

Prüfen Sie, ob alles korrekt ausgerichtet ist, und ziehen Sie alle Schrauben fest. Stellen Sie den Klingenspalt auf das richtige Maß ein. Befolgen Sie bei jedem Schritt die Anweisungen des Herstellers. Führen Sie eine Checkliste für die Werkzeugwartung. Studien belegen, dass eine gute Werkzeugwartung die Lebensdauer der Werkzeuge verlängern und die Kosten um bis zu 901 TP4T senken kann. Regelmäßige Kontrollen und Pflege gewährleisten die einwandfreie Funktion Ihrer Maschine.

Benötigen Sie fachkundige Beratung oder individuelle Lösungen? Wenden Sie sich an die Vertriebsingenieure von Nanjing Metal, um Unterstützung zu erhalten.

Wenn Sie jeden Schritt befolgen, können Sie die Düsenaufsatzmesser von Pelletierpressen sicher und schnell wechseln. Regelmäßige Wartung und die Verwendung von Spezialmessern tragen zu einem reibungslosen Maschinenbetrieb bei und reduzieren Ausfallzeiten. Experten empfehlen folgende Vorgehensweise:

- Überprüfen Sie die Klingen und andere Teile auf Beschädigungen oder Verschleiß.

- Beschädigte oder alte Teile sollten umgehend ausgetauscht werden, damit die Maschine einwandfrei funktioniert.

- Beachten Sie stets die Sicherheitsregeln und die Anweisungen des Herstellers.

- Weisen Sie Ihr Team in die Vorgehensweise ein und halten Sie Ersatzteile bereit.

- Wenn die Aufgabe schwierig ist, holen Sie sich Hilfe von Experten.

Häufig gestellte Fragen

Wie oft sollten die Düsenmesser einer Pelletierpresse ausgetauscht werden?

Überprüfen Sie die Klingen nach jedem Produktionslauf. Tauschen Sie sie aus, wenn Sie Absplitterungen, Risse oder ungleichmäßigen Verschleiß feststellen. Regelmäßige Kontrollen beugen Maschinenproblemen vor und erhalten die Qualität der Pellets.

Welcher Schaufelspalt ist für eine effiziente Pelletierung optimal?

Stellen Sie den Sägeblattspalt auf 0,2 bis 0,3 mm ein. Dieser Spalt sorgt für saubere Schnitte und reduziert Feinschnitte. Überprüfen Sie den Spalt immer vor dem Starten der Maschine.

Können Standardmesser auf allen Pelletiermaschinen verwendet werden?

Nein, Sie benötigen speziell für Ihre Maschine angefertigte Messer. Maßgefertigte Messer passen besser und haben eine längere Lebensdauer. Die Verwendung ungeeigneter Messer kann zu ungleichmäßigen Pellets führen und die Maschine beschädigen.

Wie lässt sich eine Kontamination beim Klingenwechsel verhindern?

Halten Sie Ihren Arbeitsbereich sauber und ordentlich. Verwenden Sie fusselfreie Tücher und füllen Sie Schmierstoffe in beschriftete Behälter. Tragen Sie stets saubere Handschuhe und schließen Sie die Türen, um Staub fernzuhalten.

Siehe auch

Finden Sie die perfekten Granuliermesser für Ihre Kunststoffverarbeitungsanforderungen

Granuliermesser im Vergleich: Finden Sie leicht die richtige Passform

Was sind Granuliermesser und wie funktionieren sie in der Industrie?

So wählen Sie das richtige Pelletiermesser für Ihre Branche aus

Umfassender Leitfaden zur Auswahl des besten Granuliermessers für Ihre Maschine