La industria de fabricación de neumáticos es altamente competitiva y exige precisión y durabilidad. La clave para mantener una alta productividad y minimizar costos reside en el uso de las herramientas adecuadas, especialmente las cuchillas y los cuchillos utilizados en todo el proceso de producción. Cuchillas industriales de alto rendimiento Para la fabricación de neumáticos son cruciales para optimizar la eficiencia de la producción y reducir los costos operativos.

En Nanjing MetalComprendemos la importancia de utilizar cuchillas de alta calidad que soporten las rigurosas exigencias de la producción de neumáticos. Con una sólida trayectoria de innovación y artesanía, Nanjing Metal ofrece soluciones de vanguardia para los fabricantes de neumáticos.

En esta guía, exploraremos cómo elegir las cuchillas adecuadas para la fabricación de neumáticos, centrándonos en los materiales de las cuchillas, las aplicaciones y su mantenimiento.

1. Guía de selección de cuchillas para la industria de neumáticos

Para seleccionar las cuchillas adecuadas para la fabricación de neumáticos es necesario comprender varios factores clave:

- Tipo de material

- Durabilidad

- Necesidades específicas de la aplicación

1.1 Selección de materiales: acero al carbono, acero inoxidable y acero aleado

Los distintos materiales ofrecen distintas ventajas según la tarea en cuestión. A continuación, se presenta una comparación de los materiales comunes de las cuchillas utilizadas en la fabricación de neumáticos:

| Tipo de cuchilla | Ventajas | Limitaciones | Aplicaciones Típicas |

| Acero al Carbono | Retención de filo afilado, rentable, alta dureza. | Propenso a la oxidación, menor resistencia a la corrosión. | Mezcla de caucho, corte de caucho blando |

| Acero inoxidable | Resistente a la corrosión, cortes de precisión, duradero. | Más caro que el acero al carbono | Recorte, acabado, aplicaciones higiénicas. |

| Acero Aleado | Alta resistencia al desgaste, larga vida útil, puede soportar altas tensiones. | Caro, necesita manejo especializado | Corte longitudinal, corte de alta resistencia, caucho reforzado |

| Carburo de tungsteno | Extremadamente duradero, excelente para precisión, mantiene el filo por más tiempo. | Alto coste inicial, más frágil que otros aceros. | Corte de precisión, acabado de neumáticos. |

Conclusión claveSi corta caucho blando, el acero al carbono puede ser más rentable, pero para mayor durabilidad y rendimiento a largo plazo, el acero aleado y el acero inoxidable suelen ser superiores. Comprender sus necesidades de producción le ayudará a elegir el material adecuado.

1.2 Aplicaciones de la cuchilla: corte, recorte, ranurado y más

La producción de neumáticos implica varias etapas que requieren diferentes tipos de cuchillas. Analicemos cada aplicación:

- Cuchillas de corteEstas cuchillas están diseñadas para cortar grandes láminas de caucho. Normalmente, se utilizan cuchillas de acero al carbono o de aleación de acero para este propósito.

- Cuchillas de recorteUna vez formada la forma del neumático, es necesario recortar el exceso de caucho. Las cuchillas de acero inoxidable suelen ser las preferidas por su resistencia a la corrosión y sus propiedades de corte limpio.

- Cuchillas de corteSe utilizan para cortar neumáticos a su ancho final. Las hojas de acero aleado son la mejor opción en este caso debido a su durabilidad y capacidad para soportar cortes de alta tensión.

La selección del tipo de cuchilla para cada aplicación garantiza resultados de alta calidad y maximiza la productividad.

2. Cuchillas industriales en la fabricación de neumáticos

Las cuchillas industriales desempeñan un papel esencial para garantizar la precisión, la eficiencia y la reducción del desperdicio de material durante todo el proceso de fabricación de neumáticos. Desde la mezcla del caucho hasta el acabado, las cuchillas garantizan que cada etapa de la producción de neumáticos cumpla con estrictos estándares de calidad y durabilidad. A continuación, se presenta una descripción más detallada del funcionamiento de las diferentes cuchillas en las distintas etapas de fabricación de neumáticos.

2.1 Mezcla de caucho: cuchillas de corte

AplicaciónEn esta etapa, la mezcla de caucho implica combinar materias primas como caucho, negro de humo, aceites y otros aditivos. Se utilizan cuchillas de corte para cortar y trocear el caucho crudo en trozos manejables antes de mezclarlo, un paso crucial para obtener propiedades consistentes del material y una eficiencia óptima de mezclado.

- Tipo de cuchilla: Hojas de acero al carbono (a menudo preferidas)

- Características claveLas hojas de acero al carbono son afiladas y mantienen el filo, lo que garantiza un corte rápido y eficiente de compuestos de caucho resistentes. Se utilizan por su rentabilidad, especialmente al cortar mezclas de caucho de blandas a moderadamente duras.

- Rendimiento de la cuchillaLa eficiencia de corte también depende de factores como la geometría de la cuchilla y el tipo de caucho procesado. Por ejemplo, las cuchillas con perfiles de filo específicos son más adecuadas para cortar láminas de caucho de diferentes espesores, lo que reduce el desgaste de las cuchillas durante el funcionamiento.

2.2 Moldeo de neumáticos: cuchillas de recorte

AplicaciónDespués de moldear el neumático, es necesario recortar el exceso de caucho. Se utilizan cuchillas de recorte para eliminar cualquier rebaba (exceso de caucho) y garantizar que el neumático tenga la forma exacta.

- Tipo de cuchilla:Cuchillas de acero inoxidable (las más utilizadas)

- Características claveLas cuchillas de acero inoxidable son altamente resistentes a la corrosión, lo que las hace ideales para tareas de alta precisión como el recorte de neumáticos moldeados. Estas cuchillas pueden trabajar a altas velocidades sin perder filo, ofreciendo cortes limpios y una formación de filo precisa.

- Métricas de rendimientoLas cuchillas de corte de acero inoxidable también ayudan a reducir defectos posteriores al moldeo, como el grosor desigual de los neumáticos. Al mejorar la precisión del corte, estas cuchillas contribuyen directamente a la reducción del desperdicio de material y a la mejora de la calidad de los neumáticos.

2.3 Corte de neumáticos: Cuchillas de corte

AplicaciónLas cuchillas de corte son cruciales para dividir rollos de neumáticos grandes en el ancho y la forma finales. Este paso es necesario para crear neumáticos con dimensiones y características precisas que se ajusten a los requisitos de rendimiento específicos.

- Tipo de cuchilla: Hojas de acero aleado (preferibles para tareas de corte)

- Características claveLas cuchillas de acero aleado ofrecen una durabilidad superior y resistencia al calor. Su robustez garantiza que puedan soportar la alta presión y fuerza necesarias para cortar caucho reforzado y materiales de neumáticos con cinturón de acero sin sufrir un desgaste excesivo.

- Consideraciones claveLa eficacia de las cuchillas de corte también depende de su geometría, como el ángulo del filo y su grosor. Optimizar estos factores puede mejorar aún más la precisión y la velocidad de corte.

2.4 Acabado de neumáticos: cuchillas de corte de precisión

AplicaciónLa etapa de acabado consiste en el refinamiento de los bordes del neumático, especialmente a lo largo de los flancos, para garantizar una apariencia uniforme y lisa. Se utilizan cuchillas de corte de precisión para recortar estos bordes y eliminar el exceso de caucho sin dañar la estructura del neumático.

- Tipo de cuchilla: Hojas de carburo de tungsteno (o hojas de acero revestidas)

- Características claveLas hojas de carburo de tungsteno son extremadamente duras y resistentes al desgaste, lo que las hace ideales para cortes precisos en la etapa de acabado. Estas hojas mantienen su filo durante largos periodos, incluso con un uso frecuente en procesos de producción de alta velocidad.

- Métricas de rendimientoLas hojas de carburo de tungsteno también mejoran la calidad del filo, garantizando que no queden irregularidades ni rebabas indeseadas en el neumático. Los neumáticos con flancos lisos y uniformes ofrecen una mejor estética y un mejor rendimiento en términos de aerodinámica y equilibrio.

3. Cuchillas industriales de alto rendimiento: ventajas

3.1 Mayor eficiencia de producción

Las cuchillas de alto rendimiento están diseñadas para mejorar la velocidad y la precisión de corte, lo que se traduce directamente en una mayor eficiencia de producción. Esta mejora en la eficiencia no solo se debe a velocidades de corte más rápidas, sino también a la reducción del tiempo de inactividad debido al reemplazo de cuchillas. Un estudio publicado en Revista Internacional de Ingeniería Industrial (2021) Concluyeron que los fabricantes de neumáticos que utilizan cuchillas de alto rendimiento vieron un aumento del 20% en las tasas de producción debido a un menor tiempo de inactividad y menos cambios de cuchillas.

3.2 Mayor vida útil de la cuchilla

Las cuchillas industriales de alta calidad pueden soportar un uso prolongado sin perder filo ni integridad. Por ejemplo, las cuchillas de acero aleado utilizadas para tareas de corte exigentes en la fabricación de neumáticos pueden durar hasta 2,5 veces más que sus equivalentes de acero al carbono. Grupo Internacional de Estudios del Caucho Descubrieron que actualizar a una hoja de acero de aleación de primera calidad puede reducir los costos de reemplazo de hoja en un 40% en el transcurso de un año.

3.3 Reducción del tiempo de inactividad

Las cuchillas diseñadas para durar y que requieren menos reemplazos reducen el tiempo de inactividad imprevisto. Las cuchillas de alto rendimiento suelen conservar el filo durante más tiempo y ofrecen resultados de corte consistentes, lo que reduce la necesidad de ajustes frecuentes.

- Datos de la industria:Según un informe de la Asociación Nacional de Fabricantes de Caucho (2022), los fabricantes de neumáticos que utilizan cuchillas duraderas y de alto rendimiento experimentaron menos tiempos de inactividad no planificados (40%) que quienes utilizan cuchillas estándar. La mayor fiabilidad de las cuchillas de alto rendimiento mejoró significativamente la eficiencia de la línea de producción.

3.4 Reducción de costos

Si bien las cuchillas de alto rendimiento pueden tener un costo inicial más alto, su mayor vida útil, mayor eficiencia de corte y menores requisitos de mantenimiento se traducen en ahorros a largo plazo. Los fabricantes que invierten en cuchillas de alta calidad suelen ver una reducción en el costo total por unidad producida.

- Datos económicos: Estudio de análisis de costos de fabricación (2022) descubrieron que los fabricantes que utilizan cuchillas de alto rendimiento podrían ahorrar hasta 18% al año en costos operativos, gracias al aumento de la productividad y la menor necesidad de reemplazo de cuchillas.

Invertir en cuchillas de alta calidad no solo ayuda a los fabricantes de neumáticos a mantener una producción constante, sino que también genera ahorros significativos a largo plazo. Unas cuchillas que mantienen el filo, soportan cortes de alta tensión y requieren un mantenimiento mínimo son cruciales para lograr una rentabilidad sostenida en la industria de producción de neumáticos.

4. Soluciones de cuchillas personalizadas para la fabricación de neumáticos

No todas las operaciones de fabricación de neumáticos son iguales. Dependiendo de su entorno de producción, podría necesitar cuchillas personalizadas que se ajusten a sus necesidades específicas. Nanjing Metal ofrece soluciones de cuchillas a medida para garantizar que sus cuchillas estén optimizadas para sus necesidades específicas.

La fabricación de palas a medida implica trabajar en estrecha colaboración con el cliente para diseñar palas que se adapten a la línea de producción, el tipo de material y el volumen de producción. Nuestro equipo de expertos le guía en cada paso del proceso, desde el diseño hasta la fabricación, garantizando que sus palas se adapten perfectamente a sus necesidades.

5. Mantenimiento y cuidado de la cuchilla

El mantenimiento adecuado de las cuchillas industriales es crucial para garantizar su longevidad, eficiencia y rendimiento. Un cuidado adecuado no solo prolonga la vida útil de las cuchillas, sino que también minimiza el tiempo de inactividad de la producción y mejora la rentabilidad general del proceso de fabricación. A continuación, se detallan prácticas basadas en datos para optimizar el mantenimiento de las cuchillas en la fabricación de neumáticos:

5.1 Afilado regular

Afilar las cuchillas a intervalos adecuados garantiza su eficiencia y eficacia. Con el tiempo, las cuchillas se desgastan debido a la fricción y el impacto con materiales duros. Las cuchillas desafiladas generan un mayor consumo de energía y un corte menos eficiente, lo que afecta al ciclo de producción general.

- Frecuencia de afiladoLa frecuencia de afilado depende del material de la cuchilla y del tipo de corte que realiza. Por ejemplo, hojas de acero al carbono utilizado para cortar caucho puede requerir afilado cada 50 a 100 horas de funcionamiento, mientras que hojas de carburo de tungsteno, que son más duros y duraderos, pueden durar varios cientos de horas antes de necesitar afilarse.

- Métodos de afiladoSe deben utilizar máquinas de afilado de precisión para garantizar que la geometría del filo de la cuchilla se mantenga intacta. Un afilado incorrecto puede resultar en bordes irregulares, lo que puede causar cortes inadecuados y, por lo tanto, defectos de calidad en el proceso de fabricación de neumáticos.

5.2 Almacenamiento adecuado

Las condiciones de almacenamiento son vitales para mantener la calidad de las cuchillas. Almacenar las cuchillas de forma inadecuada, especialmente en entornos con fluctuaciones de humedad o temperaturas extremas, puede provocar oxidación y corrosión, especialmente en hojas de acero al carbonoPara evitar estos problemas, se deben seguir prácticas de almacenamiento adecuadas.

- Condiciones ambientalesAlmacene las cuchillas en un ambiente limpio y seco con temperaturas estables entre 15 y 25 °C (59 y 77 °F). La humedad debe mantenerse por debajo de 50 °C (50 °F) para evitar la oxidación y la herrumbre. Si las cuchillas se almacenan en zonas con alta humedad, deben inspeccionarse periódicamente y recubrirse con aceites protectores o recubrimientos antioxidantes.

- Sistemas de almacenamiento:La implementación de sistemas de almacenamiento de hojas, como estantes de herramientas personalizados o cajas con revestimientos anticorrosivos, ayuda a mantener la integridad de los bordes de las hojas y minimiza el riesgo de daño físico durante el almacenamiento y la manipulación.

5.3 Inspecciones de rutina

Las inspecciones periódicas son clave para identificar indicios tempranos de desgaste, daños u otros problemas que puedan comprometer el rendimiento de la cuchilla. La detección oportuna de problemas como filos desafilados, astillas, grietas o dobleces puede prevenir fallos repentinos durante la producción y mejorar la seguridad.

- Frecuencia de inspecciónLas cuchillas deben inspeccionarse al menos una vez por turno, especialmente en entornos de producción de alto volumen. En el caso de las cuchillas utilizadas en procesos críticos, podrían requerirse inspecciones antes de cada operación. Las herramientas de inspección digital o las cámaras pueden ayudar a detectar pequeños defectos y grietas en la superficie de la cuchilla que podrían no ser visibles a simple vista.

- Indicadores clave del desgaste de la cuchilla:

- Bordes opacos:Esto conduce a un corte ineficiente, un mayor consumo de energía y una calidad inconsistente del producto.

- Astillas y grietasSuelen ocurrir debido a impactos o tensiones. Si no se tratan, pueden provocar la falla de la cuchilla.

- Doblado o deformación:Común en cuchillas expuestas a altas temperaturas o manipulación inadecuada.

5.4 Cómo abordar fallas comunes de las cuchillas

Las cuchillas pueden fallar debido a diversos factores, como un mantenimiento inadecuado, materiales de baja calidad o un desgaste excesivo. Detectar estos problemas a tiempo y tomar medidas correctivas puede evitar costosos tiempos de inactividad y una producción deficiente.

- Bordes opacosLas hojas desafiladas aumentan la resistencia al corte, lo que genera más calor y un desgaste prematuro. Se recomienda afilarlas regularmente antes de que los filos se desafilen demasiado y no funcionen eficazmente. Hojas fabricadas con acero aleado o carburo de tungsteno Por lo general, mantienen su filo por más tiempo, pero será necesario afilarlos a medida que se desgastan.

- GrietasLas grietas suelen deberse a tensión mecánica o a un tratamiento térmico inadecuado. Una vez que aparecen, es fundamental reemplazar la cuchilla inmediatamente, ya que una cuchilla agrietada podría romperse durante el uso, causando daños o lesiones.

- Doblado o deformaciónLas hojas deformadas son resultado de un calentamiento desigual durante la fabricación o de un esfuerzo operativo excesivo. La flexión puede afectar la precisión de corte de la hoja y causar cortes desiguales. Las inspecciones periódicas para detectar estos problemas pueden prevenir este problema.

6. Innovación en cuchillas en la industria de fabricación de neumáticos

A medida que la industria de fabricación de neumáticos continúa evolucionando, también lo hace la tecnología detrás de las palas utilizadas en la producción. Estas innovaciones mejoran el rendimiento de las palas, optimizan la eficiencia de la producción de neumáticos y reducen los costos generales. A continuación, se presentan algunas de las últimas tendencias y avances tecnológicos en el diseño de palas:

6.1 Recubrimientos avanzados para una vida útil más prolongada

El uso de recubrimientos avanzados como diamante, cerámico, y nitruro de titanio (TiN) Ha mejorado drásticamente la durabilidad de las cuchillas industriales.

- Recubrimientos de diamanteLos recubrimientos de diamante se aplican a las hojas para mejorar su dureza y resistencia al desgaste. Estos recubrimientos reducen la fricción durante el corte, lo que resulta en filos más afilados y una mayor vida útil de la hoja. Las hojas con recubrimiento de diamante son ideales para cortar materiales altamente abrasivos, como compuestos de caucho con alambres de acero incrustados.

- Recubrimientos cerámicosLas cuchillas con recubrimiento cerámico ofrecen alta resistencia al calor y la corrosión. Estos recubrimientos permiten que las cuchillas mantengan su filo incluso en condiciones intensas, mejorando la eficiencia y reduciendo la necesidad de mantenimiento frecuente. Investigación de la industria de los neumáticos (2021) descubrió que las hojas revestidas de cerámica en entornos de alto estrés superan a las hojas de acero tradicionales en términos de longevidad y precisión de corte.

- Nitruro de titanio (TiN)Los recubrimientos de TiN ofrecen mayor resistencia al desgaste y la corrosión, a la vez que reducen la fricción. Esto se traduce en cortes más suaves y un mejor rendimiento general de la cuchilla, esencial para la fabricación de neumáticos a gran escala. Los recubrimientos de TiN son especialmente beneficiosos para las cuchillas utilizadas en tareas de corte longitudinal y longitudinal a alta velocidad.

6.2 Tratamiento térmico para la durabilidad de la hoja

Las innovaciones en las técnicas de tratamiento térmico han permitido que las hojas mantengan su filo y resistencia durante más tiempo, incluso en condiciones de funcionamiento intensas.

- Nuevas técnicas de tratamiento térmico:Avances en procesos de tratamiento térmico como tratamiento térmico al vacío y endurecimiento por inducción Permiten un control más preciso de la dureza y tenacidad de las cuchillas. Estos tratamientos garantizan que las cuchillas soporten las tensiones extremas a las que se ven sometidas durante la producción de neumáticos, como el corte de materiales reforzados y cauchos de alta resistencia.

6.3 Geometría de hoja personalizada

La geometría de la hoja, como los ángulos del filo, el espesor y el acabado de la superficie, pueden afectar significativamente la eficiencia de corte y la calidad del proceso.

- Ángulo del filo y geometría de la hojaLos fabricantes diseñan cuchillas con geometrías personalizadas, adaptadas a las necesidades específicas de producción. Por ejemplo, las cuchillas con ángulos más agudos son ideales para cortes finos en el acabado de neumáticos, mientras que los filos más gruesos se utilizan para tareas de corte más robustas en corte longitudinal o moldeado.

- Recubrimientos de bordes especializadosAlgunas cuchillas cuentan con recubrimientos especializados para reducir el desgaste y mejorar la precisión de corte a velocidades más altas. Esto incluye recubrimientos de aleación de cobalto que puede mantener la eficiencia de corte a las temperaturas elevadas que se encuentran comúnmente en el proceso de producción de neumáticos.

- Diseños innovadores:Empresas como Nanjing Metal están invirtiendo en el desarrollo de geometrías patentadas que optimizan los ángulos de corte y reducen la fricción. Según un informe de Tecnología de neumáticos internacional (2022), las hojas diseñadas a medida han dado lugar a un aumento de 10 a 151 TP4T en la eficiencia de corte general, lo que reduce los costos operativos y mejora la calidad del producto.

Estas innovaciones tecnológicas en materiales, recubrimientos, tratamiento térmico y geometría de las cuchillas han mejorado significativamente la durabilidad y el rendimiento de las cuchillas utilizadas en la fabricación de neumáticos. Los fabricantes que se mantienen al día con estos avances pueden beneficiarse de menores tiempos de inactividad, mayor precisión de corte y menores costos de mantenimiento.

7. Comparación de diferentes tipos de cuchillas para la fabricación de neumáticos

Seleccionar el tipo de cuchilla adecuado para cada tarea es crucial para optimizar el proceso de fabricación de neumáticos. Cada tipo de cuchilla está diseñado con características únicas que la hacen adecuada para tareas específicas. A continuación, se presenta una comparación más detallada de las cuchillas más utilizadas en la producción de neumáticos, con información adicional sobre las propiedades de los materiales y las métricas de rendimiento.

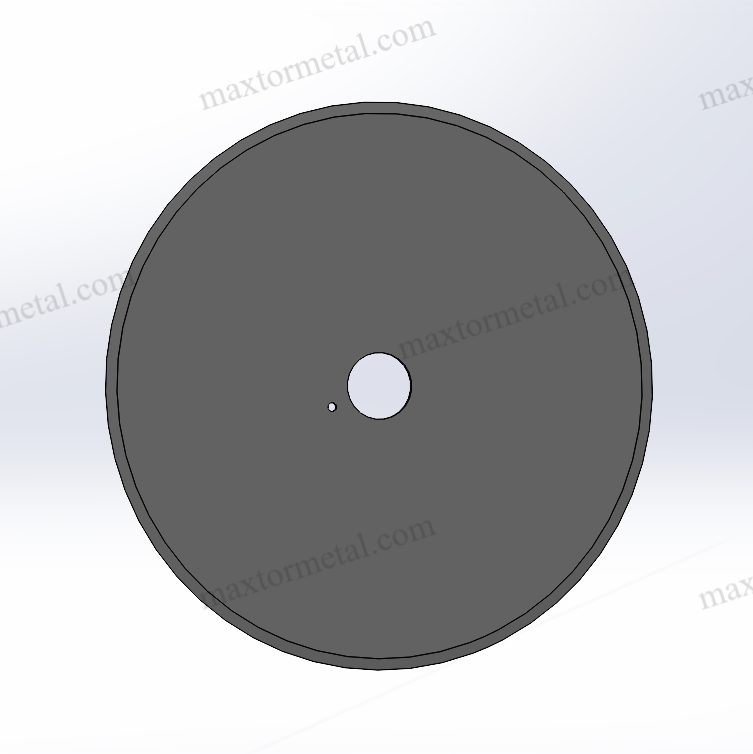

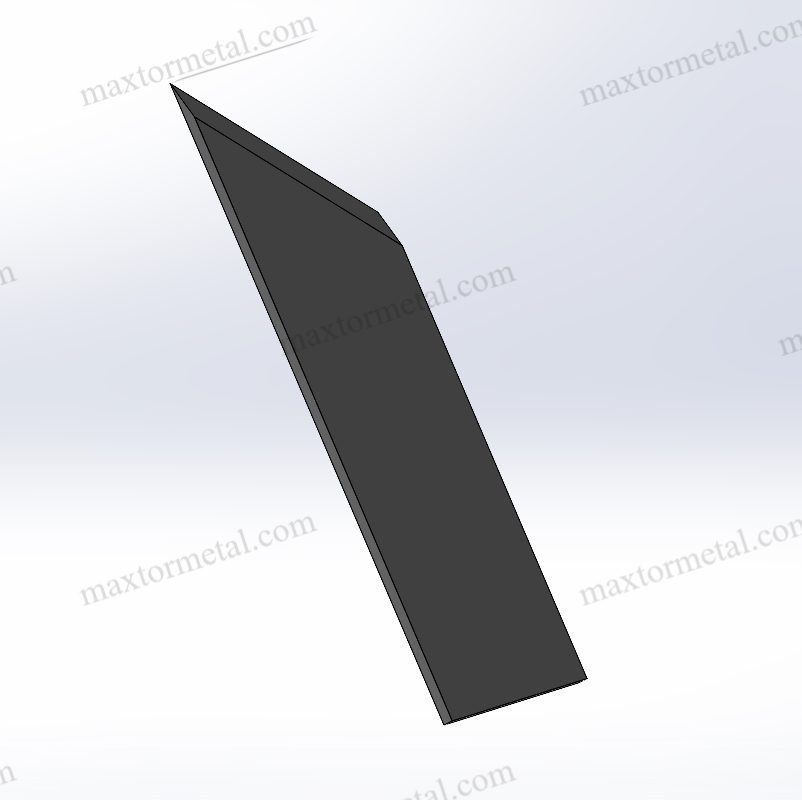

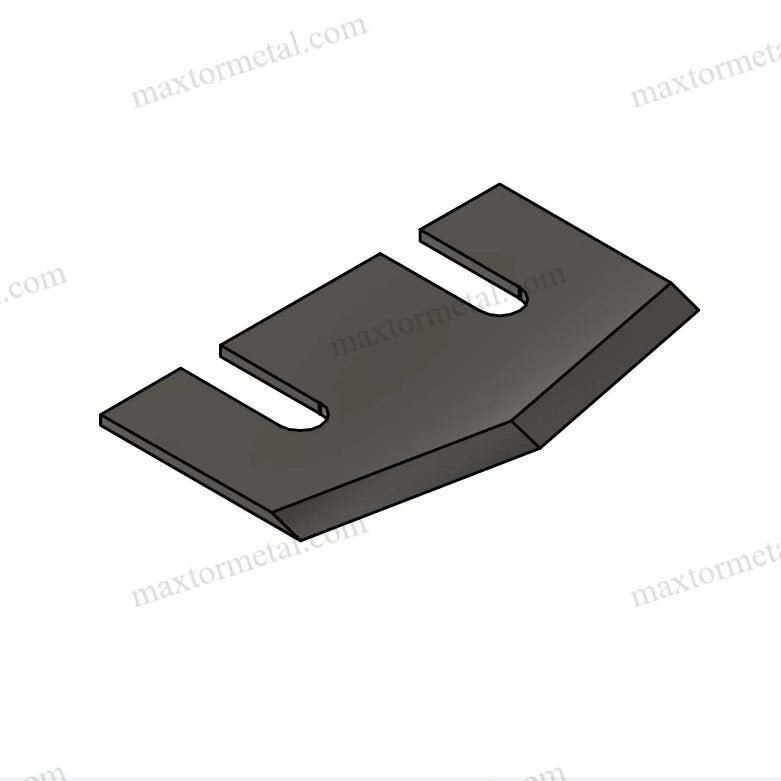

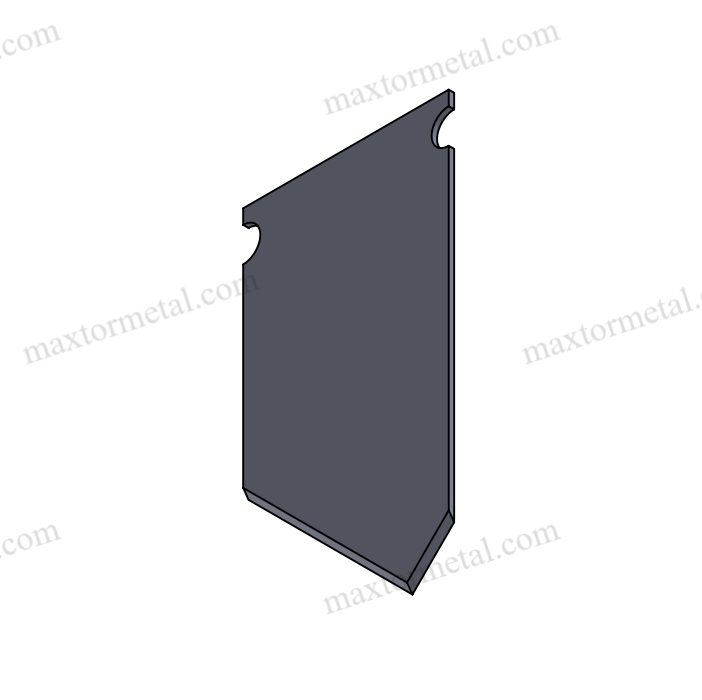

| Tipo de cuchilla | Función | Material | Uso recomendado | Información detallada |

| Cuchillas circulares | Corte continuo de láminas de caucho | Acero al carbono, acero aleado, carburo de tungsteno | Ideal para cortes a granel | Las cuchillas circulares se eligen a menudo por su capacidad de corte uniforme y precisión al cortar grandes volúmenes de láminas de caucho o componentes de neumáticos. El uso de carburo de tungsteno En estas hojas, conocidas por su dureza y resistencia al desgaste, se consigue una mayor vida útil, especialmente al cortar materiales de alta abrasión. |

| Cuchillas de recorte | Cómo retirar el exceso de caucho después del moldeo | Acero inoxidable, aleación de cobalto | Cortes limpios en el modelado y recorte de neumáticos | Las cuchillas de corte deben tener un filo afilado y ser resistentes a la corrosión, ya que están expuestas a altas temperaturas y humedad. Las cuchillas de acero inoxidable son ideales para este propósito, ya que resisten la corrosión y mantienen el filo afilado. aleación de cobalto Las cuchillas de recorte son más resistentes al desgaste cuando se exponen a altas temperaturas durante el proceso final de modelado del neumático. |

| Cuchillas de corte | Corte de neumáticos en anchos y formas precisas | Acero aleado, acero de alta velocidad | Corte de caucho a medida | Las cuchillas de corte están diseñadas para brindar precisión y exactitud al dividir secciones de neumáticos en anchos específicos. Acero de alta velocidad (HSS) Se prefiere aquí debido a su excelente resistencia al calor y su capacidad para mantener la agudeza bajo tensión. Acero aleado, a menudo utilizado para cortar hojas, proporciona un equilibrio entre dureza y rentabilidad. El velocidad de corte y la resistencia a la acumulación de calor hacen que el acero de aleación sea particularmente adecuado para aplicaciones de corte a alta velocidad. |

La elección del material influye significativamente en el rendimiento de la hoja, la resistencia al desgaste y la calidad de corte. El carburo de tungsteno es ideal para tareas de alta abrasión, mientras que el acero inoxidable destaca en cortes y recortes de precisión. El acero aleado y el acero de alta velocidad ofrecen una combinación equilibrada de durabilidad y rendimiento para operaciones de corte.

8. Optimización de la eficiencia de corte

Para maximizar la eficiencia y minimizar los costos de producción, es esencial comprender la relación entre geometría de la hoja y rendimiento de corteEl diseño del filo, el ángulo y las propiedades de la superficie de la hoja pueden influir en la velocidad de corte, la precisión y la calidad del producto final. Analicemos algunos factores clave que influyen de forma crucial en la eficiencia de la hoja:

8.1 Factores clave en la geometría de la hoja:

8.1 Ángulo de la hoja

El ángulo en el que la hoja se encuentra con el material durante el corte, conocido como ángulo de corte—desempeña un papel crucial en la reducción de la resistencia al corte. Un ángulo de corte más agudo (un ángulo de cuchilla menor) puede reducir la fricción y facilitar el corte, lo que resulta en tiempos de producción más rápidos. Sin embargo, existe una desventaja: los ángulos más agudos pueden acelerar el desgaste de las cuchillas, ya que el filo se vuelve más vulnerable a los impactos y la acumulación de calor.

- Ángulos de cuchilla óptimos para la fabricación de neumáticos:

- Cuchillas circularesSe suele utilizar un ángulo de entre 20° y 30°, lo que permite un equilibrio entre la velocidad de corte y la durabilidad de la hoja. Esto garantiza cortes suaves y continuos de láminas de caucho sin desgaste excesivo.

- Cuchillas de recorte:Un ángulo más agudo de alrededor 15° a 20° Se utiliza a menudo para cortes más limpios, especialmente durante el proceso final de modelado de neumáticos, donde la precisión es primordial.

- Cuchillas de corte:Por lo general, tienen un ángulo de corte ligeramente más grande (30° a 45°) para soportar el aumento de estrés que se produce al cortar materiales de caucho más gruesos y resistentes.

8.2 Diseño de bordes

El diseño del filo de la hoja, ya sea liso, dentado o afilado, puede afectar significativamente la precisión del corte, los niveles de fricción y la generación de calor. borde liso tiende a reducir la fricción, lo que resulta en una menor generación de calor y una mayor vida útil de la cuchilla. Por otro lado, un borde dentado Es más adecuado para cortar materiales más fibrosos o abrasivos.

- Bordes suavesProporciona cortes limpios y precisos con mínimo desgaste. Esto es especialmente importante para cuchillas de corte que requieren afilado y precisión durante todo el proceso de producción.

- Bordes dentados: Se utiliza a menudo en aplicaciones donde el material a cortar es más resistente, como el caucho con banda de acero. Los bordes dentados proporcionan un mejor agarre y eficiencia de corte, especialmente para cuchillas de corte Se utiliza para segmentos de neumáticos más duros.

8.3 Acabado de la superficie

El acabado de la superficie de la hoja, ya sea pulido, recubierto o tratado, afecta su rendimiento. Hojas con... pulido o superficie recubierta Experimentan menos fricción, lo que conduce a un menor desgaste y cortes más suaves.

- Cuchillas recubiertas:Muchas cuchillas de fabricación de neumáticos están recubiertas con Estaño (Nitruro de titanio) o Carbono tipo diamante (DLC) Recubrimientos que reducen la fricción y mejoran la resistencia al desgaste. Estos recubrimientos mejoran la eficiencia de corte, especialmente en operaciones a alta temperatura, y reducen la frecuencia de afilado.

8.2 Relación entre geometría y eficiencia de corte

La geometría de la hoja no solo afecta a la velocidad de corte pero también determina cómo limpiamente Se corta el material y como mínimamente La cuchilla se desgasta. Al optimizar la geometría de la cuchilla, los fabricantes de neumáticos pueden lograr un aumento sustancial de la eficiencia y reducir los costos operativos.

- Eficiencia energética:Una hoja con geometría optimizada (ángulo y diseño de filo correctos) requiere menos fuerza para cortar caucho, lo que reduce el consumo de energía.

- Precisión y desperdicioEl corte de precisión garantiza la producción de neumáticos de alta calidad con un mínimo desperdicio de material. Unos cortes más limpios mejoran el rendimiento y la estética de los neumáticos, algo fundamental en la competitiva industria de los neumáticos.

- Ahorro de costos operativosMinimizar el desgaste, reducir la fricción y prolongar la vida útil de las cuchillas resulta en menos reemplazos y menos tiempo de inactividad para su mantenimiento. Esto se traduce en ahorros de costos y mayor tiempo de producción.

9. El papel fundamental de las cuchillas en la fabricación de neumáticos

Las cuchillas son fundamentales para garantizar la eficiencia, precisión y rentabilidad de la producción de neumáticos. Al comprender los diferentes materiales, tipos y aplicaciones de las cuchillas, podrá optimizar su línea de producción para maximizar la producción y minimizar el tiempo de inactividad.

En Nanjing Metal, nos especializamos en proporcionar cuchillas duraderas y de alta calidad que satisfacen las exigentes necesidades de los fabricantes de neumáticos. Ya sea que necesite cuchillas estándar o soluciones a medida, contamos con la experiencia para impulsar el crecimiento y el éxito de su negocio.

Para obtener más información sobre cómo las cuchillas de Nanjing Metal pueden mejorar su proceso de fabricación de neumáticos, contáctenos hoy.