You can make your perforating blades last longer by doing a few easy things. Clean the blades often. Use the correct lubricant. Keep them in a safe spot. Check your tools a lot to find damage early. Sharpen the blades when they get dull.

Tip: Use these Conseils d'entretien des lames de perforation to get great results every day.

Principaux points à retenir

- Clean and dry your perforating blades after each use. This stops rust and keeps them sharp.

- Use the right lubricant often to lower friction and heat. This helps your blades last longer.

- Store blades in a dry place with good air. Keep them away from chemicals and salty air. This makes them last longer.

- Check blades every day for damage like nicks or rust. Look for dullness too. Sharpen or replace them if needed.

- Pick high-quality blade materials like tungsten carbide. These last longer and cut better.

- Set up your machine the right way. Use the correct pressure and alignment. This stops uneven cuts and blade wear.

- Sharpen blades carefully with the right tools and methods. Do not over-sharpen or damage them.

- Follow a regular maintenance routine. This saves money and reduces waste. You will get cleaner and smoother cuts every time.

Pourquoi l'entretien est important

Avantages

Taking care of your perforating blades helps them work better. Doing things like cleaning, oiling, and checking your blades is important. You can find small problems before they get worse. If you see nicks or cracks early, you can fix them fast. Cleaning after each use gets rid of dirt that can make blades hot. This helps blades stay sharp and last longer. Oiling the blades is also important. It stops too much rubbing and heat. This means your blades do not wear out as fast.

Tip: Clean and check your tools every day to stop accidents and keep them safe.

Here are some ways maintenance helps you:

- Checking early finds damage before it gets bad.

- Cleaning takes off sticky stuff that makes blades dull.

- Oiling helps blades move without sticking.

- Drying after cleaning keeps blades from getting rusty.

- Checking often saves money and keeps blades working well.

Performance

Taking care of blades helps them cut better. Clean and sharp blades make smooth cuts every time. If you do not take care of them, cuts can be rough or not finished. You also waste less material and your machine does not stop as much.

See how different jobs help your results:

| Tâche de maintenance | Fréquence | Reason for Importance |

|---|---|---|

| Nettoyer les lames | Après chaque utilisation | Stops buildup and rust that make cuts worse |

| Lubrifier les lames | Hebdomadaire | Less rubbing and wear, so fewer stops and blade changes |

| Inspect Tips | Tous les jours | Finds damage early, so cuts stay straight and clean |

| Sharpen/Sand Blades | Au besoin | Keeps blades sharp, so you waste less material |

When you take care of your blades, your machine works better. You make fewer mistakes and more good products. Sharp blades help you finish more work the right way.

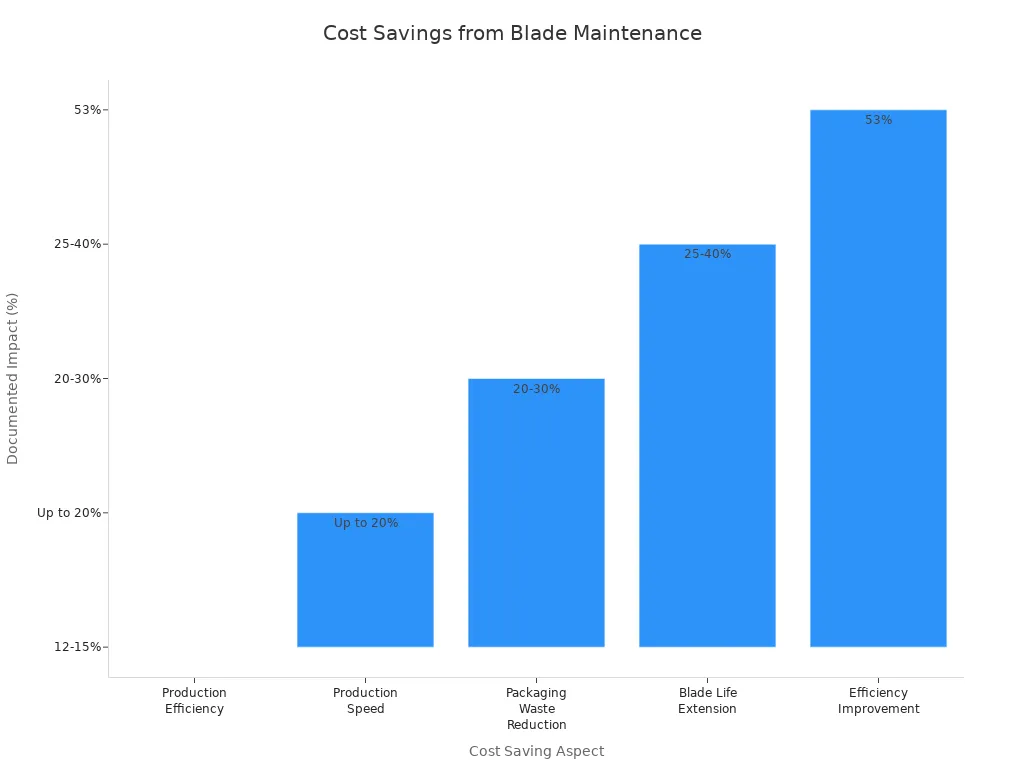

Économies de coûts

Doing regular maintenance saves you money in many ways. You do not have to buy new blades as often. You also waste less material and do not need expensive repairs. Good blades help your machines run faster and smoother.

Here is a chart that shows how taking care of blades saves money:

You can make your machines work up to 20% faster and waste 20-30% less packaging. Coated blades can last up to 40% longer. All these savings add up, so taking care of blades is a smart choice for any business.

Facteurs affectant la durée de vie

Types de matériaux

The kind of material you pick for your perforating blade matters a lot. Some blade materials last longer than others. You should check how each material works before choosing. Here is a table that compares different blade materials:

| Matériau | Lifespan Characteristics | Résistance à l'usure | Notes supplémentaires |

|---|---|---|---|

| carbure monobloc | Lasts the longest and resists wear very well | Le plus élevé | Top quality, less time spent changing blades |

| Acier D2 | Stays strong for a long time and is tough | Bien | Many people use it for perforating blades |

| CPM-10V Steel | Has great wear resistance and lots of vanadium | Better than D2 | Premium, stands up to hard hits |

| High-Carbon & 52100 | Strong and hard, but rusts more easily | Modéré | Not the best for longest-lasting blades |

| Céramique | Very sharp and resists wear, but breaks easily | High but brittle | Not good for jobs with lots of impact |

| Acier inoxydable | Does not rust much, but does not last as long | Inférieur | Not the top choice for long-lasting blades |

If you want your blade to last a long time, pick solid carbide or CPM-10V steel. Tungsten carbide blades are special because they resist wear the best. They keep working well even in tough jobs. These blades let you cut more and change blades less often. When you use tungsten carbide blades, you get more work done and stop less.

Usage

How much you use your blade and what you cut changes how long it lasts. If you use your blade every day on hard stuff, it will wear out faster. Here is a table that shows how using blades a lot affects different materials:

| Matériau de la lame | Impact of Frequency of Use on Wear Rate |

|---|---|

| Acier à haute teneur en carbone | Wears out fast if used a lot; needs sharpening or replacing often |

| Acier inoxydable | Gets dull quickly with heavy use; best for easy jobs |

| Acier allié | Handles lots of use well; lasts longer and needs less fixing |

| Lames en Céramique | Stays sharp for a long time, even with lots of use; good for busy work, but can break if hit |

Tungsten carbide blades work better than most other types when used a lot. You can use them in busy places or for long jobs without worrying about quick wear. To get the most from your blades, match the blade material to your work.

Machine Settings

How you set up your machine is very important for blade lifespan. If you set your machine right, your blade will last longer. Here are the main things to check:

- Set the shaft gap so you only use enough pressure for a clean cut.

- Make sure bushings, bearings, couplings, and shafts are in good shape to stop extra movement.

- Keep counter knives sharp so your blade does not get dull too soon.

- Clean all tool parts to stop wobbling and uneven wear.

- Use good parts with tight fits to lower wear and rust.

Tip: Always check your machine before you start working. Small changes in settings can help your tungsten carbide blades last much longer.

If you pay attention to these things, your blades will make more cuts, work better, and save you money because you will not need to replace them as often.

Environment

Where you use and keep your perforating blades matters a lot. If you want blades to last, watch the temperature and humidity. The air in your workspace can change how long blades last. These things can affect your blades in ways you may not know.

Humidity and temperature can make blades rust faster or slower. If you store blades in a humid place, you might think they will rust fast. But blades can rust even more in places with medium humidity. Sometimes, a workshop with some moisture is worse than a dry or wet place.

Tip: Keep your blades in a dry room with good climate control to help them last longer.

Here are ways the environment can change your blade’s lifespan:

- When temperature goes up and down, metal can stretch and shrink. This makes blades weaker over time.

- Humid air can cause steel blades to rust.

- Chemicals in the air, like salt near the ocean, can make blades rust faster.

- Dust and dirt can stick to blades and hold water, which causes rust.

If you work near the ocean or chemicals, you need to be extra careful. Salt, water, and changing temperatures can make blades wear out much faster. Always clean blades after you use them. Store them in a closed box or cabinet. You can use silica gel packs or dehumidifiers to keep blades dry.

Think about the temperature where you keep your blades. High heat can make some blades softer and wear out faster. Cold air can make blades break more easily. Try to keep your storage area at a steady, mild temperature.

If you want blades to last as long as possible, you should:

- Keep blades dry and clean.

- Do not store blades near chemicals or salty air.

- Use coatings to protect blades in tough places.

- Check your storage area often for water or rust.

If you control the environment, your blades will stay sharp and strong longer. Good storage and care help you get the most life from every blade.

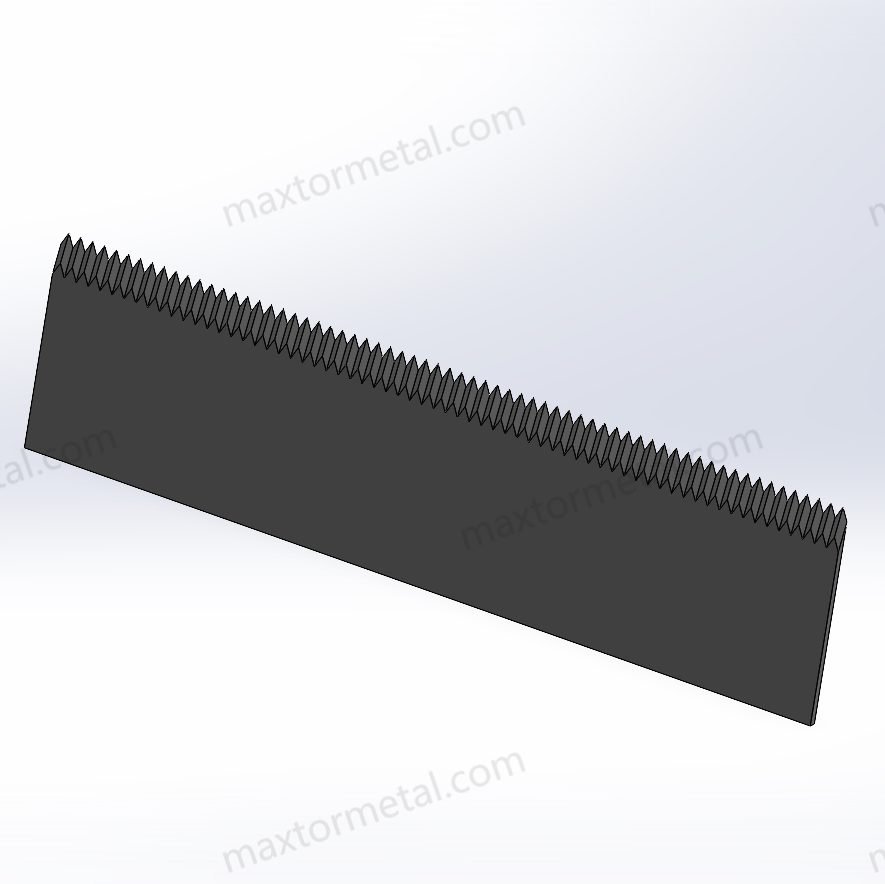

Conseils d'entretien des lames de perforation

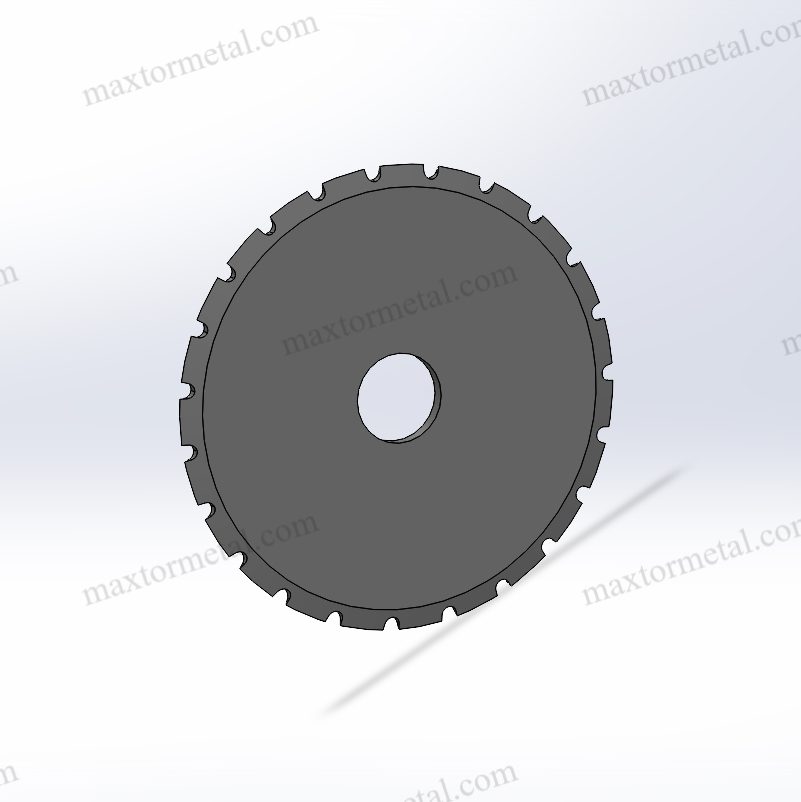

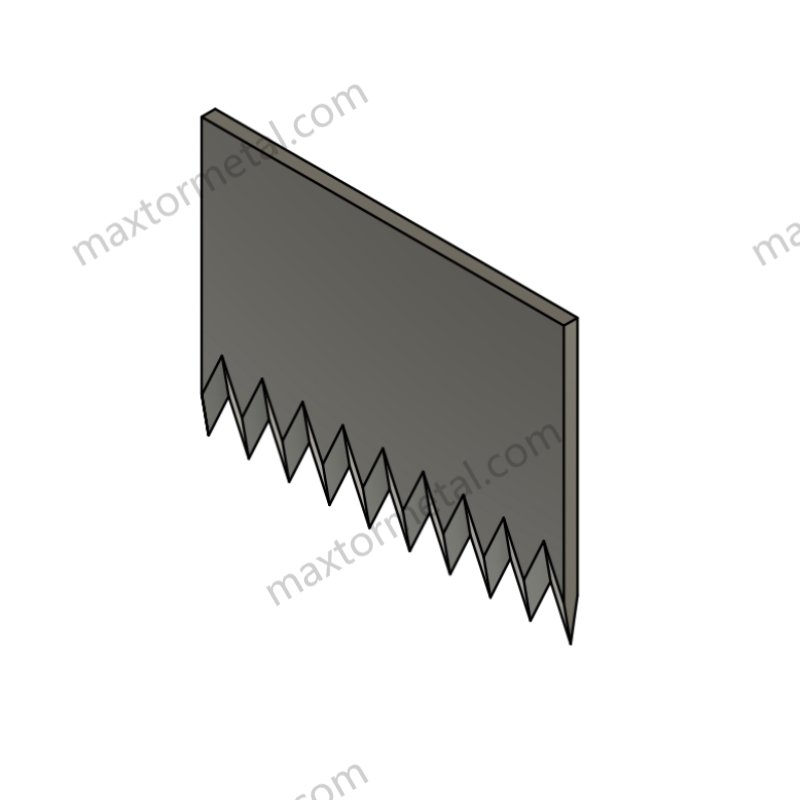

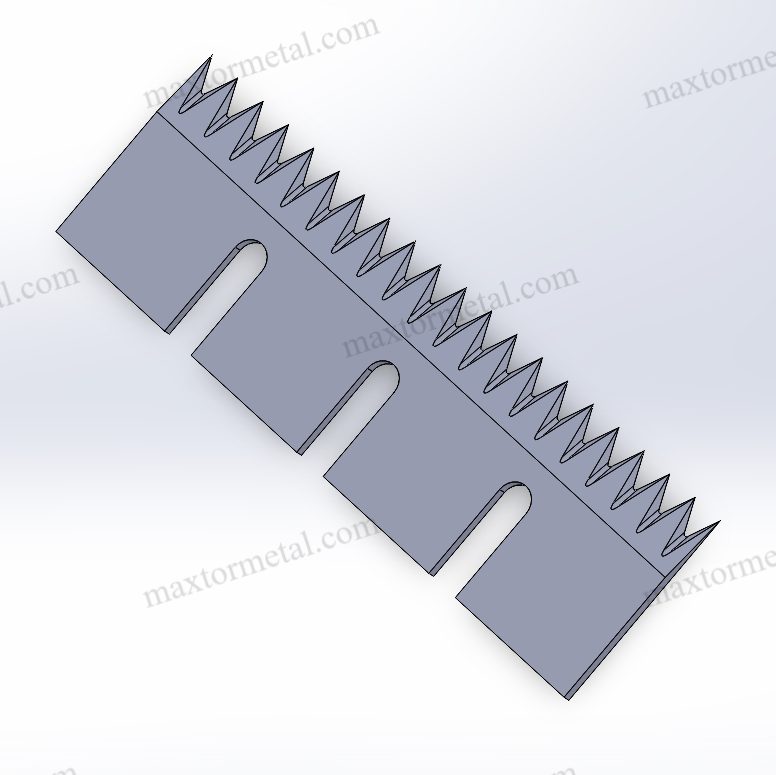

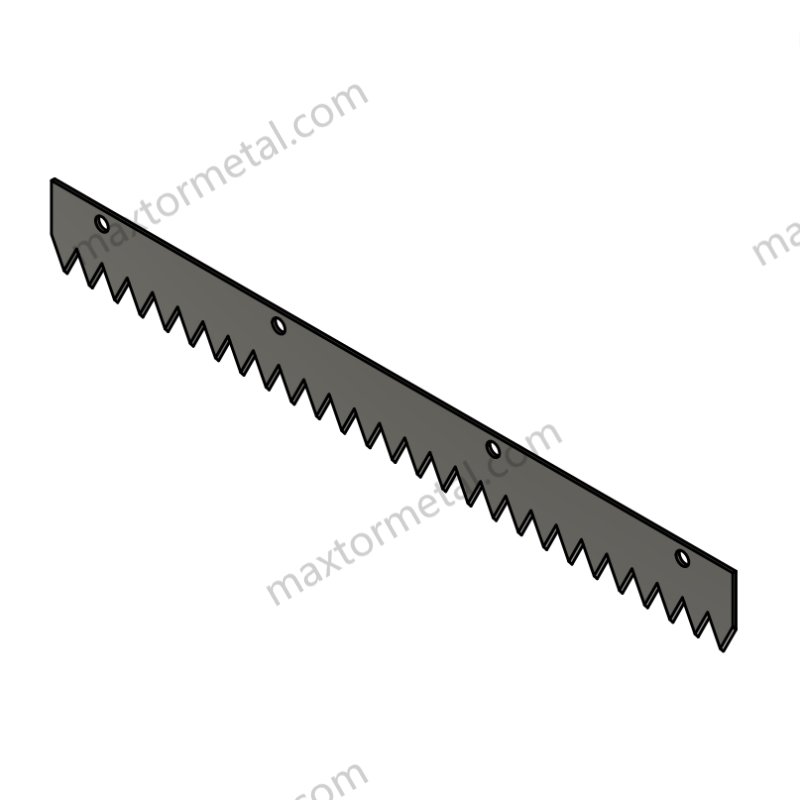

You can help your blades last longer by following these perforating blade maintenance tips. Nanjing Metal’s Perforating Blade Knives are made from strong materials like tungsten carbide blades, tool steel, and stainless steel. These blades are used in packaging, textiles, paper, and other industries. You need to take care of your blades to get the best results.

Nettoyage

Outils

You need the right tools to clean your blades. Use soft brushes, lint-free cloths, and gentle cleaners. If there is tough dirt, use a plastic scraper. Do not use metal brushes because they can scratch the blade. You can use compressed air to blow away dust and small pieces. Always wear gloves to keep your hands and the blade safe.

| Outil | But | Idéal pour |

|---|---|---|

| Soft Brush | Takes off dust and dirt | Cleaning and drying every day |

| Lint-Free Cloth | Wipes away leftover stuff | Blade care after each use |

| Mild Cleaner | Gets rid of glue and sticky bits | Entretien régulier |

| Plastic Scraper | Removes hard buildup | Lames en carbure de tungstène |

| Compressed Air | Blows away tiny particles | Cleaning hard-to-reach places |

Pas

Here are the steps for cleaning:

- Unplug your machine before you start.

- Take out the blade carefully. Hold the sides, not the edge.

- Use a soft brush to sweep away dust and loose dirt.

- Wipe the blade with a lint-free cloth and gentle cleaner. Clean both sides.

- For sticky glue, use a plastic scraper gently. Do not push too hard.

- Dry the blade with a clean cloth. Cleaning and drying every day stops rust and keeps blades sharp.

- Look for nicks or cracks. If you see damage, put the blade aside for fixing.

- Put the blade back in the machine or store it safely.

Tip: Clean your blades after every shift. Daily cleaning and drying helps tungsten carbide blades last longer.

Lubrification

Types

Lubrication is important for perforating blade maintenance tips. Pick the right lubricant for your blades. Heavy-duty oils with EP additives work best for hard jobs. These oils protect tungsten carbide blades from wearing out and getting hot. Macroemulsions and chemical solutions are good for lighter work. Vanishing oils leave no leftover oil and are good when you do not want oil left behind. Water-based lubricants like Lubriks-05 make a slippery layer and help with soft rolls or cores.

| Type de lubrifiant | Effectiveness in Reducing Friction and Wear | Application Method(s) |

|---|---|---|

| Compounded Oils (EP) | Best for protecting tools, especially with EP additives | Roller coater, airless spray, drip |

| Macroemulsions | Work okay, lighter than heavy oils | Used for less tough jobs |

| Chemical Solutions | Easy to clean, for lighter work | Good for extra steps |

| Vanishing Oils | Dry up and leave no oil, least protective | Used when you do not want residue |

| Water-Based Lubricants | Lower friction, stop glue from sticking | Spray, wipe, safe for food use |

Methods

Put lubricant on the blade before and after using it. Use a roller coater, spray, or drip to put it on. For tungsten carbide blades, use thick EP-type oil. Make sure the blade is covered all over. Put lubricant on the bottom of the strip for punch return stroke. This lowers friction and wear. Nanofluid lubricants with tiny particles like MoS2 or Al2O3 help cool the blade and move heat away. These ways help your blades stay sharp and last longer.

Note: Lubrication and cooling are important for blade care. Use the right lubricant for your blade and job.

Stockage

Environment

Good storage is part of perforating blade maintenance tips. Keep blades in a dry, climate-controlled room. Humidity can cause rust and make blades weak. Keep the temperature the same. Do not keep blades near chemicals or salty air. Use silica gel packs or dehumidifiers to keep out moisture. Tungsten carbide blades last longer in a clean, dry place.

- Store blades in their original boxes.

- Keep blades in a toolbox, drawer, or cabinet.

- Use blade covers for extra safety.

Protection

Protect your blades from damage and rust. Clean blades before putting them away. Put a little oil or silicone spray on moving parts. Organize blades in toolboxes, rolls, or on pegboards. Keep blades away from kids and pets. Take blades out of razors made from lower-grade stainless steel after using them. This stops rust from spreading. Regular care and good storage keep your blades sharp and safe.

Tip: Always check your storage area for water or rust. Good storage and blade care help tungsten carbide blades stay strong and sharp.

These perforating blade maintenance tips help you get the most from your blades. Clean and dry your blades every day, use the right lubricant, and store them safely to keep them working well. These care steps save you money and time.

Inspections

Que vérifier

You need to check your perforating blade often to keep it working well. Checking and changing blades helps you find problems before they get worse. When you look at your blade, watch for these signs:

| Signes d'usure ou de dommages | Description / Symptoms | Common Causes | Actions préventives |

|---|---|---|---|

| Blade Wear and Dulling | The edge gets dull, cuts are rough, or the machine shakes or makes noise | Using the blade a lot, not cleaning enough, using the wrong blade | Clean and check blades often, sharpen when needed, pick the right blade |

| Corrosion or Rust | Brown spots or pits show up, blade feels weak | Water, not drying or cleaning well | Dry blades after cleaning, use oil to protect them |

| Chipping and Nicks | Small pieces break off the edge, cuts are rough or uneven | Hitting things, blade gets old | Check edges often, handle blades carefully |

| Gauchissement | Blade bends or twists, cuts are not even | Too much heat, storing or using blades wrong | Use oil, store blades right, check and change blades often |

| Material Build-up | Dirt or stuff sticks to the blade, cuts get bad | Not cleaning after using | Clean blades after every shift to get rid of dirt |

| Incorrect Alignment | Cuts are crooked or not finished, material tears | Blade is not put in straight or moves | Use guides, check if blade is straight before using |

Check if your blade is straight. If it is not, cuts may look crooked or not finish. Always make sure the blade is in the right spot before you start the machine. Look for chips, cracks, or round edges. These mean you need to sharpen or change the blade. If you see rust or brown spots, dry and oil the blade right away.

Fréquence

You need a plan to check and change blades often. Experts say you should do these things:

- Clean your blade and machine every day so cuts stay smooth.

- Check if the blade is straight before each shift.

- Look for dullness, chips, cracks, or round edges every day. Change the blade if you see any of these.

- Change cutting pressure and tension to fit what you are cutting.

- Use a checklist each shift so you do not forget any steps.

- Test the blade by making a sample cut and see if it works right. This helps you find problems early.

- Watch your machine with sensors or cameras if you can. This helps you see if the blade is dull or if rollers slip.

- Plan to do some jobs every day, week, month, and year. This includes sharpening, oiling, safety checks, and checking the machine.

- Write down all checks, changes, and repairs. This helps you keep track of everything.

- Teach your team how to check, fix, and take care of the blades.

Tip: Checking and changing blades often keeps them sharp and your products looking good. You save money and stop problems when you follow a good plan.

Sharpen your blade as soon as you see it is dull or cuts are rough. Do not wait for the blade to break. Sharpening and oiling often help your blade last longer and keep your machine working well.

Sharpening Blades

Quand affûter

You need to sharpen your blades when you notice certain signs. If your blade starts making rough or uneven cuts, it is time for sharpening. You may also hear strange noises from your machine or see that the blade leaves jagged edges. These are clear signs that your blade has become dull. If you see more dust or debris than usual, your blade may not be cutting cleanly.

You should check your blades every day. Regular sharpening and oil application help keep your tools in top shape. If you use your blades for heavy-duty jobs, you may need to sharpen them more often. Always follow safety steps. Wear gloves and safety glasses before you start sharpening. Turn off your machine and unplug it. Remove the blade carefully.

Tip: Sharpen your blade as soon as you see dullness. Do not wait for the blade to get damaged.

Outils

You need the right tools for sharpening. Using the correct tool helps you get a sharp edge without harming the blade. Here are some common tools you can use:

| Type d'outil | Idéal pour | Remarques |

|---|---|---|

| Grinding Machine | Most industrial blades | Use with abrasive aluminum oxide wheels |

| Dremel or Rotary Tool | Manual sharpening, wide blades | Use steady hands for best results |

| Sharpening Stone | Small or fine blades | Good for touch-ups and minor dullness |

| Specialized Grinder | Band saw and perforating blades | Keeps blade shape and tooth pattern |

Grinding machines work well for most industrial blades. You should use abrasive aluminum oxide wheels and set the speed correctly. For manual sharpening, a Dremel or rotary tool gives you control. Use a sharpening stone for small blades or quick fixes. Specialized grinders help keep the blade’s tooth pattern and shape.

Note: Always use tools that match your blade’s material and size. This keeps the quality high and prevents damage.

Techniques

You need proper sharpening techniques to keep your blades in good condition. Start by swaging the blade. This step widens the tooth tip beyond the blade thickness. Swaging helps prevent overheating and damage during cutting.

Use a grinding machine with an abrasive aluminum oxide wheel. Set the wheel speed to the right level. If the wheel spins too fast, it can burn the blade. The wheel thickness should be about half the tooth pitch length. This gives you a sharp edge without harming the blade.

For manual sharpening, use a Dremel or rotary tool. Hold the tool steady and move slowly along the edge. Wide blades need extra care to avoid uneven sharpening.

If you work in an industrial setting, use a specialized grinding machine. These machines keep the blade’s shape and tooth pattern. They also help you maintain the quality of each blade.

Tip: Always cool the blade during sharpening. This stops heat from building up and keeps the blade strong.

Nanjing Metal uses strict quality control during production. Their blades have high material durability. This means you can sharpen them many times without losing quality.

Proper sharpening techniques help you get the most from your blades. You keep your tools sharp, safe, and ready for any job.

Over-Sharpening

Over-sharpening happens when you try to make your blade too sharp. You might think a sharper blade always works better. This is not true. If you sharpen a blade too much, you can make the edge weak. The blade can chip, break, or wear out faster. You waste time and money when you need to replace blades more often.

You need to know the signs of over-sharpening. Look for these problems:

- The blade edge looks very thin or uneven.

- Small chips or cracks appear along the edge.

- The blade does not last as long as before.

- You see more dust or tiny metal pieces after cutting.

Note: A blade that is too sharp can cut well at first, but it will not stay sharp for long. You will need to stop and change blades more often.

You can avoid over-sharpening by following a few simple steps:

- Check the blade edge before each sharpening. Only sharpen when you see clear signs of dullness.

- Use the right tool and technique. Do not grind away too much metal.

- Follow the manufacturer’s guidelines for blade thickness and angle.

- Keep a record of how often you sharpen each blade.

Here is a table to help you compare normal sharpening and over-sharpening:

| Fonctionnalité | Normal Sharpening | Over-Sharpening |

|---|---|---|

| Edge Thickness | Even and strong | Too thin or fragile |

| Durée de vie de la lame | Long | Court |

| Qualité de coupe | Cohérent | Good at first, then poor |

| Risk of Chipping | Faible | Haut |

These blades can handle many sharpening cycles. You still need to avoid over-sharpening to get the best results. Always use care and check your blades often. This helps you keep your tools working well and saves you money.

Prolong Blade Lifespan

Technique de coupe

You can make blades last longer by cutting the right way. Pick the best blade for your job. Circular blades and cutoff blades work for different cuts. Using the right blade style helps you cut better and keeps blades from wearing out fast. Change the blade shape, like the bevel and pitch, to lower stress on the edge. These changes can cut edge stress by up to 27%. This means blades stay sharp and cut cleaner.

Special coatings like Titanium Nitride (TiN), Diamond-Like Carbon (DLC), and Titanium Carbonitride (TiCN) help blades fight friction and heat. These coatings make blades tougher and keep them sharp for more cuts. DLC-coated blades can last over 50% longer and stop sticky stuff from building up. You get better cutting and save time.

Setting your machine right is important too. If you line up your machine well, blades work together and wear out less. Cleaning and checking your blades often gets rid of dirt that can cause rust or bad cuts. Only sharpen blades when you need to. Sharpening too much makes the edge weak and blades wear out faster. Lubrication and cooling help lower friction and heat, which are big reasons blades wear out.

Tip: Always check if your machine is lined up and set to the right pressure before cutting. Small changes can help blades work better.

Edge Protection

Taking care of the blade edge helps you get better cuts and use blades longer. Be gentle when you handle blades. Do not drop them or hit them on hard things. Use blade covers or guards when you store or move blades. This stops chips and cracks.

Keep blades in a dry and clean place. Humidity and chemicals can make blades rusty and weak. Use silica gel packs or dehumidifiers to keep blades dry. Clean blades before you put them away and add a thin layer of oil to protect the edge. Put blades in toolboxes or cabinets so they do not touch each other.

Picking the right blade material and tooth design helps too. Solid carbide steel and special tooth patterns lower cutting force and strain. This keeps the edge strong and sharp for more cuts.

Professional Service

Sometimes you need an expert to keep blades working well. If you see dull or round edges, chips, cracks, or nicks, ask for help. If it gets harder to cut or you hear squeaks or grinding, your blade needs attention. Uneven cuts mean the blade is wearing out. Rust or dirt buildup also makes blades work worse.

Professional care is important for big jobs or heavy use. Experts can sharpen blades, fix damage, and check for safety problems. If your blade cannot stay sharp after sharpening, you should replace it or get it sharpened by a pro. Checking and fixing blades on time helps you keep cutting quality and stops machine damage or accidents.

Note: Getting help from a pro keeps blades safe and helps you get the best results every time.

Lames de haute qualité

Picking high-quality blades helps you do better work. Blades made from advanced materials like tungsten carbide stay sharp longer. These materials make blades harder and tougher. You can cut more things before you need to stop. You do not have to change or sharpen blades as much.

Here is how high-quality blades compare to regular ones:

| Type de lame | Material Examples | Lifespan & Wear Resistance | Performance & Maintenance | Implications financières |

|---|---|---|---|---|

| High-Quality Perforating Blades | Tungsten Carbide, CPM 10-V Steel | Superior hardness, longer sharpness, cryogenic treatment can double lifespan | Less frequent replacement, reduced downtime, coatings improve performance | Coût initial plus élevé, coût à long terme plus faible |

| Lames standard | High-Speed Steel, Stainless Steel | Lower hardness, shorter lifespan, no advanced treatments | More frequent replacement, higher downtime, less consistent | Lower initial cost, higher total cost over time |

High-quality blades last much longer than regular blades. You do not need to fix or change them as often. This lets you spend more time working. Special coatings like Titanium Nitride or Diamond-Like Carbon make blades even stronger. These coatings help keep sticky stuff off the blade and keep the edge sharp.

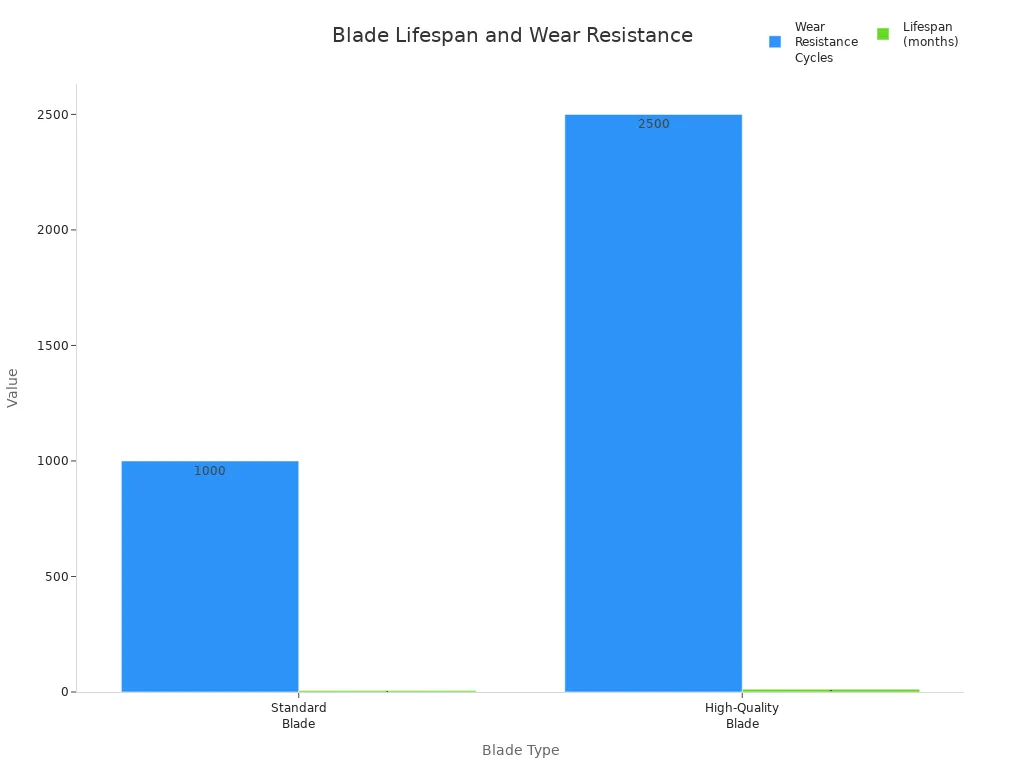

High-quality blades can last twice as long as regular blades. Cryogenic treatment can make blades last from 6 months to 12 months. The number of wear resistance cycles can go from 1,000 to 2,500. You do not have to buy new blades as often, so you save money.

You also get cleaner cuts with high-quality blades. The edges look smoother and you waste less material. If you cut tough or rough stuff, these blades do not wear out fast.

Tip: High-quality blades cost more at first, but you save money later because you do not need to replace them as much.

When you pick high-quality blades, your work gets easier. You get sharper cuts, less stopping, and better value over time.

Saw Blade Maintenance vs. Perforating Blades

Similarities

You might think taking care of saw blades and perforating blades is not the same. But they actually have a lot in common. Both need regular care to work well. Here are some ways they are alike:

- Clean both blades often. This gets rid of sticky stuff and dirt.

- Sharpening is important for both. Sharp blades make clean cuts.

- Store blades in a dry, neat place. This stops rust and damage.

- Check blades often. Look for dull spots or cracks.

Doing these things helps blades last longer. Clean and sharp blades also keep you safe and help you work better. If you follow these steps, you protect your tools and yourself.

Tip: Make a checklist for saw blade and perforating blade care. It helps you remember what to do and keeps blades working well.

Differences

Even though both blades need care, there are some big differences. Each blade has its own problems because of how you use it and what it cuts.

| Fonctionnalité | Saw Blade Maintenance | Perforating Blade Maintenance |

|---|---|---|

| Main Use | Cutting through solid materials | Creating lines of small cuts or holes |

| Sharpening Needs | Focus on tooth shape and set | Focus on edge and perforation pattern |

| Cleaning Challenges | Resin and pitch buildup common | Adhesive and fine debris buildup common |

| Stockage | Often larger, need blade guards | Smaller, need edge protection |

| Inspection Focus | Tooth damage, missing teeth | Chipped edges, uneven perforations |

Saw blades cut wood, metal, or plastic. Sticky stuff like resin can get stuck on the teeth. You need to clean this off and check for bent or missing teeth. Keeping the tooth shape right helps you get smooth cuts.

Perforating blades are used for making small cuts in paper or packaging. You need to watch for glue and dust building up. Make sure the perforation line stays even. Protecting the edge is very important because small chips can mess up the cuts.

Saw blades are usually bigger and need blade guards when you store them. Perforating blades are smaller, so you need to keep the edge safe from chips and rust.

Note: Knowing these differences helps you take care of each blade the right way. This lets you get better results and use your tools longer.

Conseils de dépannage

Coupes inégales

Uneven cuts can make your finished product look messy. You want every cut to be straight and clean. If you notice jagged or crooked lines, you need to check your perforating blade and machine right away. Here are some steps you can follow to fix uneven cuts:

- Clean your blades after each use. Glue, ink, or dust can stick to the blade and cause rough cuts.

- Inspect the blade for damage. Look for nicks, burrs, or scratches. If you see any, repair small spots or replace the blade if the damage is on the cutting edge.

- Make sure the blade sits tight and straight in the machine. A loose or tilted blade will not cut evenly.

- Test the sharpness every week. Dull blades often make uneven cuts. Use the right sharpening tools and keep the blade cool while sharpening.

- Check the mounting area for dirt or damage. Clean and fix any problems you find.

- Measure the blade thickness and balance the blade every month. A thin or warped blade will not cut well.

- Replace blades that are too thin, cracked, or bent. Do not use a blade that cannot hold a sharp edge.

- Use the correct blade type and coating for your material. Some jobs need special blades to prevent uneven wear.

- Check for sideways play or bending in the shafts. Movement in the shafts can cause the blade to trim unevenly.

- Make sure gripper rollers are clean and worn evenly. Dirty or uneven rollers can pull the material wrong and cause bad cuts.

Tip: Always check the folds in your material before you cut. Poor folds can make even a sharp blade cut unevenly.

If you follow these perforating blade maintenance tips, you will get smoother, straighter cuts every time.

Platitude

Dull blades make your work harder. You may see rough edges or need to push harder to cut. Dullness can also cause more dust and waste. You should check your blade for dullness every day. If you see the edge looks round or shiny, it is time to sharpen. Use a sharpening stone or grinding machine for best results. Always cool the blade while sharpening to keep it strong. Replace the blade if it cannot hold a sharp edge after sharpening.

Noise

Strange noises from your machine can mean trouble. Squeaks, grinding, or rattling sounds often point to a problem with the blade or machine setup. First, stop the machine and check the blade for chips or cracks. Make sure the blade is tight and not wobbling. Clean the blade and the mounting area. Lubricate the blade if it feels dry. If the noise continues, check the shafts and rollers for wear or dirt. Replace any worn parts right away. Quiet machines usually mean your perforating blade maintenance tips are working well.

Rouiller

Rust can ruin your perforating blades and make your cuts rough. You need to watch for rust, especially if you work in places with moisture or chemicals. Rust starts as small brown or orange spots on the blade. If you see these spots, act quickly to stop the damage.

You can prevent rust by cleaning and drying your blades after every use. Wipe the blade with a dry cloth and store it in a dry place. Use silica gel packs or a dehumidifier in your storage area. These steps help keep moisture away from your blades.

Stainless steel blades work well for preventing corrosion. Stainless steel contains chromium, which protects the blade from rust and staining. If you work in food processing or other wet environments, stainless steel blades give you extra protection. You spend less time worrying about rust and more time getting clean cuts.

Cryogenic treatment also helps your blades fight rust. This process cools the blade to very low temperatures. It stops oxidation, which is the chemical reaction that causes rust. Cryogenic treatment makes your blades stronger and helps them last longer. You do not need to sharpen or replace blades as often. You also avoid discoloration and wear from oxidation.

Here are some steps you can follow to stop rust:

- Clean blades after each use.

- Dry blades completely before storing.

- Use silica gel packs in your toolbox or cabinet.

- Choose stainless steel blades for wet jobs.

- Ask for cryogenic treatment if you want blades that last longer.

- Oil the blade lightly before storage.

Tip: If you see rust, use a soft brush or cloth to remove it. Do not use harsh chemicals or metal brushes. These can scratch the blade and make rust worse.

You can use a simple table to check your rust prevention routine:

| Étape | À quelle fréquence | Pourquoi c'est important |

|---|---|---|

| Clean blade | Après chaque utilisation | Removes moisture and dirt |

| Dry blade | À chaque fois | Stops water from causing rust |

| Utiliser du gel de silice | In storage | Keeps air dry |

| Pick stainless steel | For wet jobs | Resists rust and staining |

| Cryogenic treatment | When possible | Makes blades stronger |

If you follow these steps, you keep your blades sharp and safe. Rust does not have to be a problem. You can keep your perforating blades working well for a long time.

You can help your blades last longer if you follow these perforating blade maintenance tips. Clean and dry your blades every time you use them. Use the right oil to keep blades working well. Put blades away in a dry and safe spot. Check your blades often and sharpen them when they get dull.

If you take care of your blades, you get sharper cuts. You waste less material and save money. Start your care routine now to get the best results.

Do you need help? Contact our sales engineers if you want more advice about perforating blade maintenance tips.