You want the best deal for your work. Picking OEM शीयर ब्लेड or aftermarket ones depends on your needs. It also depends on how much risk you can handle. It matters how important your job is. Total cost of ownership (TCO) means more than the price you pay. It also includes how long the blades last, the warranty, and lost time. Good blades help you do less fixing and work faster. Here is a quick look at how TCO changes how well you work:

| पहलू | Impact on Operational Efficiency |

|---|---|

| ब्लेड की गुणवत्ता | Good blades mean less fixing and better work speed. |

| रखरखाव आवृत्ति | Changing blades less often saves money. |

| काटने की सटीकता | Better cuts help you work faster and stop less. |

OEM shear blades are known for being reliable and lasting a long time.

चाबी छीनना

- Total cost of ownership means more than the price you pay. It also includes money spent on fixing, waiting, and paying workers.

- Picking OEM shear blades helps you trust your tools. These blades last longer and need less fixing. This can save you money and time later.

- Aftermarket blades cost less at first. But they might wear out fast or not fit right. This can make you spend more money later.

- Look at the warranty before you buy blades. A good warranty helps if something is wrong. It can save you money in the future.

- Think about what your job needs. OEM blades work best for important jobs. Aftermarket blades can work for jobs that are not as important.

- Always check if the supplier is trusted and has the right papers. This helps you get good blades that do what you need.

- Try sample blades before you buy a lot. This helps you see if they fit and work well. It can stop you from making expensive mistakes.

- Think about saving money over time, not just at first. Buying good blades can help you save and work better for a long time.

Understanding TCO for Blades

What Is TCO

Total cost of ownership (TCO) means the full amount you spend on shear blades over their lifetime. You pay for more than just the blades themselves. You also pay for maintenance, repairs, downtime, and even labor. TCO helps you see the real cost of your choices. When you look at TCO, you can compare different blade options and see which one gives you the best value.

TCO is not just about the price tag. It covers every expense linked to your blades, from installation to replacement.

Key TCO Factors

You need to know what affects TCO before you choose shear blades. Industry surveys show that several factors play a big role:

- Purchase Price: The cost you pay upfront for the blades.

- रखरखाव लागत: Money spent on sharpening, cleaning, and repairs.

- स्र्कना: Lost production time when machines stop for blade changes or fixes.

- अनुकूलता: Blades that fit many brands can save you money and prevent you from getting stuck with outdated systems.

- Labor Costs: Time and effort needed for installation and upkeep.

- Hidden Costs: Extra expenses like emergency repairs or unexpected delays.

Maintenance and downtime can quickly add up. For example, if your machine costs $25 per hour to run, and you lose 10 hours to downtime, you spend $250 just waiting. Unplanned downtime often costs more than planned stops because you must fix problems right away. You can lower these costs by using preventive maintenance, such as regular checks and scheduled blade changes.

Why TCO Matters

You want your business to stay competitive and efficient. TCO helps you make smart choices about shear blades. When you understand TCO, you see how each blade affects your bottom line. You can pick blades that last longer, need less fixing, and keep your machines running smoothly.

Evaluating TCO lets you reduce waste and save money over time. You avoid surprises and plan for the future.

If you focus only on the purchase price, you might miss hidden costs that hurt your profits. By looking at TCO, you find blades that offer the best long-term value. This approach helps you keep your operations strong and your costs under control.

| TCO Factor | यह क्यों मायने रखती है |

|---|---|

| रखरखाव | Fewer repairs mean lower costs. |

| स्र्कना | Less downtime boosts productivity. |

| अनुकूलता | Flexible blades save money long-term. |

| Labor | Easy installation cuts labor expenses. |

Choosing the right shear blades with TCO in mind helps you reach your goals and keep your business moving forward.

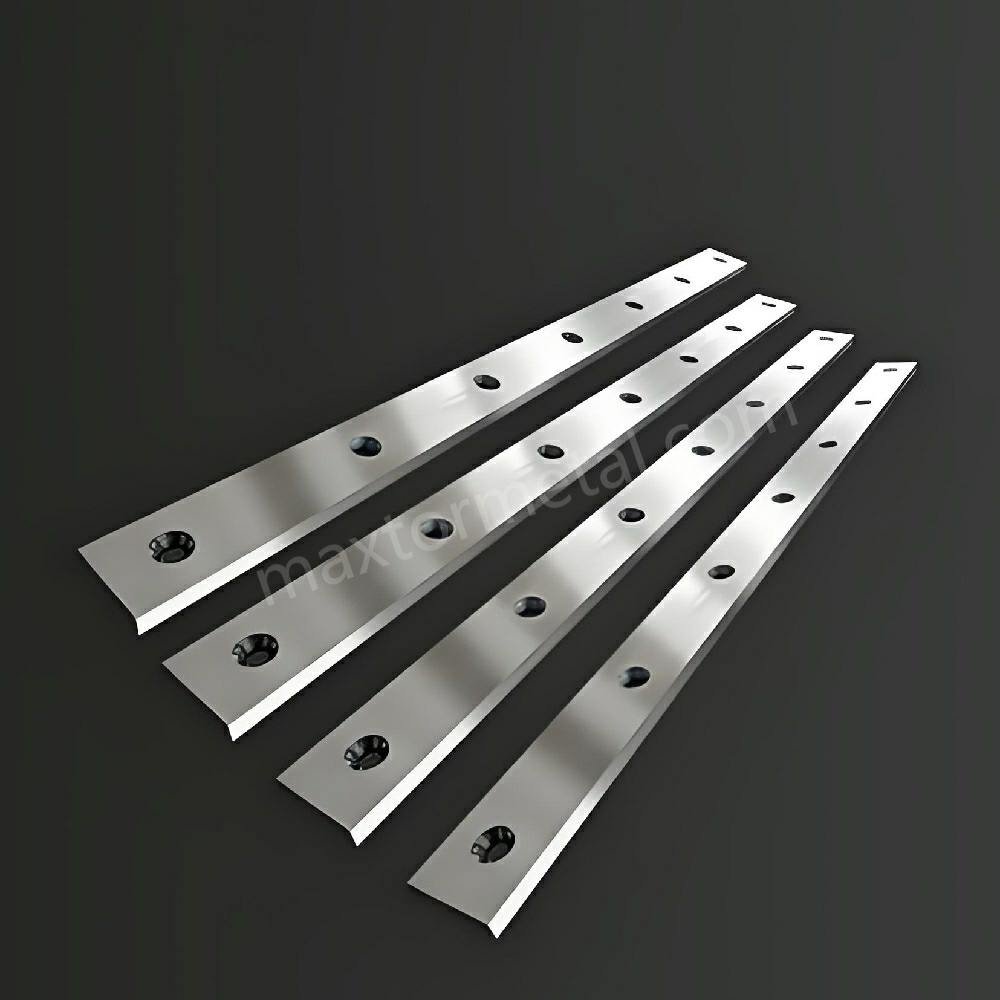

OEM Shear Blades Overview

OEM Parts and Quality

If you pick OEM shear blades, you get parts made to strict rules. The original equipment manufacturer makes these blades to fit just right. They work well every time you use them. OEM blades use strong materials and smart ways to make them. Each blade gets checked and tested before you get it.

You want parts that last a long time. OEM parts give you that trust. They are not just spare parts. They help keep your machines safe. OEM shear blades stop sudden problems and keep things running. You get blades that last and cut well. This means less time fixing and more time working.

Here is a quick look at the quality checks you get with OEM shear blades:

| Quality Assurance Aspect | विवरण |

|---|---|

| एज डिजाइन | Makes sure cuts are good and safe. |

| प्रतिरोध पहन | Uses materials that stay strong and keep their edge. |

| सतह खत्म | Smooth blades stop metal from sticking and help cuts. |

| निरीक्षण और गुणवत्ता नियंत्रण | Checks for flatness, straightness, and smoothness to make sure blades are good. |

| Material Specifications | Picks steel types that last and work for tough jobs. |

| विनिर्माण सहिष्णुता | Tight rules help blades cut well and last longer. |

Material Certification

OEM shear blades come with proof of what they are made of. You know what is in your OEM parts. The manufacturer gives papers that show the steel type and how it was treated. This helps you follow safety rules and standards. Certified blades mean you get good parts every time. You can trust OEM shear blades to work well, even for hard jobs.

OEM Warranty and Liability

When you buy OEM shear blades, you get a strong warranty. The maker covers problems and helps you feel safe. If you use OEM parts, you keep your machine’s warranty and avoid trouble. OEM shear blades protect your money and lower your risk. You know the maker stands by their blades. This matters most when you need blades for important work. OEM parts may cost more at first, but they give you good value with quality, warranty, and lasting use.

OEM Pricing

When you look at OEM shear blades, you see they cost more. The price is higher than many aftermarket blades. You pay more at first, but you get strict quality. The OEM maker uses special processes and certified materials. These blades fit your machines just right and last longer. The higher price shows the quality and support you get with OEM.

You might wonder how OEM blade prices compare to aftermarket. Here is a simple table that shows the main differences:

| पहलू | ओईएम ब्लेड | आफ्टरमार्केट ब्लेड |

|---|---|---|

| कीमत | Generally higher | Typically lower |

| Quality Perception | High-quality and reliable | Varies, broader range of options |

| Consumer Preference | Preferred for new equipment | Preferred for older equipment |

OEM blades cost more, but they work the same every time. You pay for blades that pass tough tests and checks. The OEM price covers research, development, and warranty help. You also get technical support and replacement promises. These things can lower your risk and cut downtime.

Choosing OEM blades is an investment in your future. You spend more at first, but you might save later. Fewer breakdowns and less replacing help you avoid extra costs. Using OEM parts keeps your equipment warranty safe. This is important for expensive machines.

Think about what you need before you decide. If you need precision and reliability, OEM blades are a good choice. They match your equipment’s needs. You also feel better knowing the maker supports the product.

Some people only look at the price. They pick aftermarket blades to save money. But you should think about the total cost of ownership. The OEM price covers more than just the blade. It includes support, warranty, and proven quality. You should think about all these things before you choose.

Tip: Always look at the long-term value, not just the first price. The OEM blade may cost more, but it can help you avoid big repairs and downtime.

You can ask your supplier for more pricing and warranty details. This helps you plan your budget and know what you get. You should also ask if the OEM has bulk deals or custom options. These can help you save money and keep quality high.

Aftermarket Blades Overview

लागत बचत

You want to spend less money on mower blades. Many companies pick aftermarket blades because they are cheaper than OEM blades. You can save money by choosing these blades for your mower. The lower price helps you use your budget better, especially if you change blades a lot. Aftermarket blades let you buy more for the same money. This matters if you have lots of mowers or a big business.

Aftermarket parts give you more options. Suppliers sell many kinds of mower blades for different machines. You can find blades that fit your mower and do not cost too much. If you own a landscaping company or many mowers, aftermarket blades help you keep costs low. You can keep your mowers working without spending too much.

Tip: Always check the price of aftermarket blades and OEM blades. Think about all costs, like shipping and putting the blades on. This helps you make good choices for your business.

Quality Variability

Aftermarket blades come in many styles. Some blades are as good as OEM blades, but some do not last as long. You should check the blade quality before buying. The blade’s material and shape change how well it cuts and how long it lasts. Some aftermarket blades use strong steel and special heat treatment. These blades work well for hard jobs and big mowers.

Other blades wear out faster or need sharpening more often. You should ask your supplier how the blades are made and what materials they use. Good aftermarket blades can work well and last long. Bad blades may break your mower and need more repairs.

You can try mower blades before buying them. Some suppliers let you test blades for free. This helps you see if the blades fit your mower and work well. Always read reviews and ratings for aftermarket blades. This helps you feel sure about your choice.

आपूर्तिकर्ता चयन

Picking the right supplier for aftermarket blades is important. You want blades that work well and last long. Look for suppliers who sell strong mower blades and give good service. Good suppliers help you avoid problems and keep your mowers running.

Here are things to think about when picking an aftermarket blade supplier:

| मानदंड | विवरण |

|---|---|

| ब्लेड सामग्री | Choose blades made from tough, high-quality materials that are hard and strong. |

| American-Made Products | American makers often have better quality checks and faster help. |

| Flexible Order Volumes | Suppliers should let you buy the number of blades you need. |

| Fast Turnaround Times | Quick making and delivery help you get blades fast for your mowers. |

| Free Test Cutting | Testing blades before buying makes sure they fit and work for your mower. |

Ask your supplier about how fast they make blades and their order rules. Fast making means you get blades quickly when you need them. Flexible orders let you buy only what you need. American-made blades often have better quality and help.

Note: Always ask for papers that show what the blades are made of and details about the warranty. This helps you trust the aftermarket blades you buy for your mower.

If you follow these tips, you can find the best aftermarket blades for your mower. You save money, get good blades, and keep your mowers working well.

Warranty Impact

When you buy aftermarket shear blades, check the warranty first. The warranty can change how much you spend later. Some suppliers give strong warranties. Others only offer a little protection. You need to know what the warranty covers before you choose.

A good warranty helps if your blades break or wear out early. If your shear blades fail too soon, you can get new ones or repairs. This lowers your risk and keeps your machines working. Weak warranties can make you pay more if something goes wrong.

Here are some warranty types you might see with aftermarket shear blades:

| वारंटी प्रकार | What It Covers | Typical Duration |

|---|---|---|

| Limited Warranty | Defects in materials or making | 3-12 months |

| Performance Warranty | Promises on blade life or cuts | 6-24 months |

| No Warranty | No coverage for defects | कोई नहीं |

You should always ask your supplier about the warranty rules. Some suppliers only cover problems from making the blades. Others might cover how long the blade lasts or how well it cuts. If you use shear blades for hard jobs, you need a warranty that fits your needs.

Tip: Read the warranty before you buy. Look for coverage for both materials and how well the blade works. Ask if the supplier will replace blades that wear out fast.

Warranty affects your total cost of ownership. A strong warranty means you spend less on new blades and repairs. You also avoid surprise costs if blades break. A weak warranty can mean more downtime and higher bills.

You should compare warranty rules from different suppliers. Some aftermarket brands have warranties almost as good as OEM. Others may not give any coverage. If you want less risk, pick suppliers with clear and fair warranty rules.

Here are steps to check warranty impact:

- Ask for written warranty details from your supplier.

- Check what the warranty covers and how long it lasts.

- Find out how to make a claim if your shear blades fail.

- Compare warranty rules with other suppliers.

- Choose blades with the best price and warranty.

A strong warranty helps you feel safe. You know your shear blades are protected. Your machines keep working and you avoid costly stops. Always think about warranty impact when you look at TCO for aftermarket shear blades.

OEM vs. Aftermarket: Key Differences

Specification Match

ओईएम ब्लेड

OEM blades are made to fit your machine exactly. The manufacturer designs each blade for your equipment. You do not have to worry about loose parts or gaps. The blade fits every time you put it on. This perfect fit helps you get good cuts and fewer problems.

- OEM blades use exact measurements.

- Each blade is checked for size and shape.

- You can trust the blade to fit without extra work.

Metal Industrial’s OEM shear blades are a good example. Their blades use smart engineering for a perfect fit. This helps you avoid downtime and keeps your machines working. If you need a special fit, you can look at कस्टम ब्लेड for your needs.

आफ्टरमार्केट ब्लेड

Aftermarket blades come in many sizes and shapes. Some blades fit almost as well as OEM blades. Others use more basic sizes and may not fit perfectly. You might need extra time to install or adjust them.

- Some aftermarket blades fit well, but some need extra work.

- You may see small changes in size or shape.

- A bad fit can cause shaking or uneven cuts.

When you look at oem vs. aftermarket, check the fit before buying. Always ask your supplier about the blade’s size. Try a sample blade to avoid problems later.

Material Consistency

ओईएम ब्लेड

OEM blades use tested materials. The manufacturer picks steel and metals that meet strict rules. Every blade goes through the same steps, so you get the same quality each time. This helps you trust the blade’s strength.

- The manufacturer tests each batch of material.

- You get blades with the same hardness and toughness.

- Consistent materials mean fewer surprises.

Metal Industrial’s OEM blades show how good materials help your work. Their blades use special heat treatment and forging. This gives you a strong product for hard jobs.

आफ्टरमार्केट ब्लेड

Aftermarket blades can be made from different materials. Some suppliers use strong steel, but others use cheaper metals. This changes how long the blade lasts and how well it cuts. Some blades may wear out faster or break more easily.

- Material quality depends on the supplier.

- Some blades use strong steel, others do not.

- Bad materials can cause blade failures.

When you compare oem vs. aftermarket, ask for proof of material quality. Good suppliers will show test results or papers. This helps you pick a blade that lasts longer.

प्रदर्शन और विश्वसनीयता

ओईएम ब्लेड

OEM blades work well in tough jobs. The manufacturer tests each blade to make sure it works under stress. You can count on the blade to cut cleanly and last a long time. This helps you avoid costly stops.

- OEM blades go through strict testing.

- You get the same results every time.

- The blade’s design and materials help it work well.

If your job is important, you need a blade you can trust. OEM blades give you peace of mind because they fit and work as expected.

आफ्टरमार्केट ब्लेड

Aftermarket blades have different levels of performance. Some blades work almost as well as OEM blades. Others may not last as long. How well aftermarket blades work depends on the supplier and materials. You might need to replace or fix them more often if they do not fit or use weak steel.

- Performance changes from one supplier to another.

- Some blades cut well, but others dull quickly.

- Reliability depends on fit and material quality.

When you compare oem vs. aftermarket, think about how much risk you want. If your job is not critical, an aftermarket blade may save money. For important work, you may want the proven results of an OEM blade.

Tip: Always match the blade to your job. The right fit and material can save you time and money.

आवेदन उपयुक्तता

ओईएम ब्लेड

You want shear blades that work well every time. OEM blades are best for jobs where safety and accuracy matter. You use these blades in places like car factories, airplane making, recycling, and building work. OEM blades follow strict rules, so you do not get surprise stops or big repairs.

- You pick OEM shear blades for important jobs.

- You trust them when your machines must keep running.

- You need blades that fit your machine’s design.

- You get blades made from certified materials and tested by the maker.

Metal Industrial’s shear blades are a good example in tough jobs. Their blades fit well and use strong materials. You use them when you cannot risk mistakes or delays.

| आवेदन का प्रकार | Why OEM Blades Work Best |

|---|---|

| उच्च मात्रा में उत्पादन | Reliable performance, less downtime |

| Safety-critical tasks | Certified materials, strict tolerances |

| Expensive machinery | Protects warranty, reduces risk |

| Regulatory compliance | Meets industry standards |

Tip: If your job has strict rules or lots of work, OEM shear blades help you stay safe and keep working.

आफ्टरमार्केट ब्लेड

You might pick aftermarket shear blades for jobs that are not as important. These blades are good if you want to save money or need more choices. You use aftermarket blades in extra machines, test projects, or short-term setups. Some aftermarket blades work almost as well as OEM, but you should check suppliers first.

- You choose aftermarket blades for machines that are not critical.

- You use them when saving money is more important than top reliability.

- You find them useful for short jobs or buying many blades at once.

- You get lower prices and blades that fit many machines.

| आवेदन का प्रकार | Why Aftermarket Blades Make Sense |

|---|---|

| Auxiliary equipment | Lower cost, adequate performance |

| Pilot or temporary use | Budget-friendly, easy replacement |

| Low-risk operations | Sufficient quality, flexible sourcing |

| Older machinery | Broad fit, cost-effective solution |

Note: Always try aftermarket shear blades before using them everywhere. This helps you make sure they work well and avoid problems.

You pick blades based on what your job needs. OEM blades are best for important work. Aftermarket blades are good for less risky jobs. You think about risk, price, and how well the blades work to choose what is best for your business.

TCO Analysis for Shear Blades

Upfront Cost vs. Long-Term Value

When you pick shear blades, you might look at price first. The price matters, but it is not the whole story. You should think about how much value you get over time. A cheap blade may not last very long. You could spend more money fixing or replacing it. If you choose a blade that is strong, you do not need to change it as often. This saves you money and keeps your machines working.

You want blades that last a long time. A blade that stays sharp and strong gives you better value. You spend less time fixing problems and more time working. If you use blades that last, you avoid surprise stops. This helps your team work faster and safer.

Here are some things to help you compare price and value:

- A cheap blade can cost more later if it wears out fast.

- Blades that last longer help you save money.

- You get more value when your blades work well and last.

Tip: Always ask how long a blade will last before you buy. A higher price can mean better value over time.

Hidden Costs

You may not see every cost when you buy shear blades. Some costs show up after you start using the blades. Aftermarket blades can bring extra costs. If a blade does not fit well, you spend more time putting it on. You might lose time if the blade wears out fast. A bad fit can make noise, rough cuts, or even hurt your machine.

Check this table to see common hidden costs with aftermarket blades:

| Hidden Costs/Issues | विवरण |

|---|---|

| बढ़ा हुआ डाउनटाइम | Aftermarket blades wear out faster, leading to more frequent machine stops and loss of productivity. |

| संगतता संबंधी समस्याएं | Non-OEM blades may not fit properly, causing alignment problems, increased noise, and setup difficulties. |

| परिचालन जोखिम | Potential for rough edges, uneven cuts, and faster machine wear, which can lead to additional costs later. |

You want to avoid these hidden costs. If you pick blades that last longer, you lower the risk of extra spending. You get more value when your blades fit and work well. Always check for hidden costs before you buy.

Note: Hidden costs can hurt your budget and slow down your work. You protect your value by picking blades that last and fit your needs.

TCO Calculation Framework

You need a clear way to measure total cost of ownership. TCO helps you see the real value of your blade choice. You look at more than just the price. You add up all the costs and subtract the value left after use. This helps you compare choices and pick the best one for your business.

Here is a simple way to figure out TCO:

| अवयव | विवरण |

|---|---|

| Initial cost (I) | The upfront price of the equipment, which is often less than 10% of the TCO. |

| Operation (O) | Costs related to installation, testing, training, and energy consumption. |

| Maintenance (M) | Regular and reactive maintenance costs to keep the equipment in optimal condition. |

| Downtime (D) | Costs associated with production delays due to equipment failure, including labor and lost output. |

| Production (P) | Variability in output quality and quantity from different equipment. |

| Remaining value (R) | The estimated value of the equipment after a certain period, accounting for depreciation. |

| TCO | The total cost of ownership calculated as I + M + D – R. |

You use this formula to compare blades. You want blades that give you the most value for your money. Blades that last longer help you spend less on fixing and downtime. You get better value when your blades keep working and hold their value.

Callout: Always use a TCO framework before you buy. This helps you see the true value and avoid surprises.

You make better choices when you look at everything. You get more value, save money, and keep your machines working with blades that last longer.

When to Choose OEM Shear Blades

Picking OEM shear blades is smart when you need top safety and accuracy. These blades help you avoid problems and protect your machines. OEM shear blades give you the strong performance you want.

Critical Applications

You should use OEM shear blades for jobs that must not fail. These blades follow strict rules and pass tough tests. They help you get good results in places where mistakes cost a lot.

Here is a table that shows where OEM shear blades are important:

| उद्योग | आवेदन विवरण |

|---|---|

| Metal प्रसंस्करण | Cutting steel, stainless steel, aluminum alloys, and non-ferrous metals with high precision and efficiency. |

| मोटर वाहन उद्योग | Producing circular parts, interior components, and upholstery fabrics for vehicle manufacturing. |

| पैकेजिंग उद्योग | Processing corrugated cardboard, plastic films, and flexible packaging materials. |

| Textile Manufacturing | Precision cutting of fabrics and technical textiles for garment production. |

| प्लास्टिक रीसाइक्लिंग | Granulator blades and size reduction equipment for plastic processing. |

| HVAC Industry | Manufacturing circular components for heating and ventilation systems. |

| एयरोस्पेस | Specialized cutting solutions for demanding applications. |

| निर्माण | High-volume production requirements for construction materials. |

| खाद्य प्रसंस्करण | Cutting solutions tailored for food industry applications. |

| Consumer Goods | Specialized shear cutting solutions for consumer products. |

You see OEM shear blades in metal plants and car factories. These places need blades that cut tough stuff and stay sharp. For example, Metal Industrial’s OEM shear blades work well in busy metal shops. Their blades stay sharp and do not wear out fast. This keeps your machines working and stops surprise breakdowns.

You also find special OEM blades, like scissor blades for clothes or strong blades for recycling. These blades help you with hard jobs in your business.

Warranty Needs

Warranty is important when you pick OEM shear blades. Using OEM parts keeps your machine’s warranty safe. This helps you avoid big repair bills and worry less.

- OEM shear blades help you keep your warranty.

- You do not risk losing money if a part breaks.

- You have less downtime from warranty problems.

If you use other blades, you might lose your warranty. This can mean more costs and longer stops if things break. In important jobs, you cannot risk these problems. OEM shear blades help you protect your money and your machines.

Tip: Always read your warranty before using non-OEM blades. OEM shear blades usually keep your warranty safe and your business strong.

Reliability Demands

You want blades that work the same every time. OEM shear blades give you steady results because they use good materials and strict checks. You get blades that fit your machine just right, so you do not get surprises.

- OEM blades work well in tough places.

- You have fewer breakdowns and change blades less often.

- Your machines run better and faster.

In jobs like aerospace or cars, even small problems can be big. You need blades you can trust every day. Metal Industrial’s OEM shear blades are known for being strong. Their special making process keeps blades sharp and stops chips, even with hard work.

If you want to know more about OEM shear blades for tough jobs, visit नानजिंग Metal औद्योगिक.

Note: If your work needs steady uptime and good quality, OEM shear blades help you reach your goals.

Choosing OEM shear blades is smart when you want strong performance, warranty safety, and trusted results. You keep your business running and avoid costly problems.

When Aftermarket Blades Make Sense

Aftermarket shear blades can help many businesses. These blades work well if you want more choices or lower costs. They are good for jobs that are not very risky. Let’s see when aftermarket blades are the best pick for your work.

Cost-Driven Choices

You pick aftermarket blades to save money. These blades help you spend less and keep things running.

बजट बाधाएं

If you need to spend less, aftermarket blades give you choices. You can find blades that fit your budget and still work well. Many companies use these blades to save money and avoid spending too much.

Picking the right blade material helps your machines work longer and saves money on repairs.

You can look at different materials and pick what works best. The right blade helps you fix less and keeps your machines working.

Large-Scale Procurement

If you need blades for lots of machines, aftermarket blades help you save. You can buy many blades at once and get better prices. This is good for big factories or places with lots of cutting jobs.

| सामग्री का प्रकार | प्रदर्शन | Cost Impact |

|---|---|---|

| औजारों का स्टील | उच्च | मध्यम |

| अलॉय स्टील | मध्यम | कम |

| करबैड | बहुत ऊँचा | उच्च |

Picking the right material matters. Each type has good and bad points. You need to think about cost and how well the blade works. If you want to save money, look at these things before you buy.

Short-Term Projects

For short jobs or test projects, aftermarket blades are smart. You do not need to buy expensive blades for quick work. You can pick blades that fit your job and budget.

- Strong aftermarket blades last longer and need fewer changes.

- Good materials help blades stand up to wear and keep working.

Using aftermarket blades can cut down on fixing costs. These blades are made to be easy to take care of, which helps save money for jobs that need it.

- Better blades waste less material.

- Good blades help you spend less on running machines.

- All of this helps you save money.

If you need special blades for a project, you can check out custom blades for your needs.

Non-Critical Use

You do not need the best blades for every job. Aftermarket blades work fine for jobs that are not very important.

Auxiliary Equipment

You use extra machines for small jobs. These machines do not run all day or cut tough stuff. Aftermarket blades work well for these jobs and help you save money.

Low-Risk Operations

Some jobs are not risky. You can use aftermarket blades for soft materials or jobs where stopping does not hurt your business. You use OEM blades for main machines and aftermarket blades for smaller jobs.

Temporary or Pilot Applications

If you have a test job or short project, aftermarket blades are flexible. You can try new things without spending a lot. You can change blades fast and set up your machines as needed.

Tip: Always pick the blade that matches your job and how hard it will work.

Vetting Suppliers

You need to pick your aftermarket blade supplier with care. How good the blades are depends on the supplier.

Supplier Reputation and Track Record

Find suppliers with a good history. You want companies that send blades on time and make good products. Read reviews and ask other buyers for advice.

Material and Quality Certifications

Quality is important. Good suppliers have papers like ISO 9001 and show proof of what their blades are made of.

| मानदंड | विवरण |

|---|---|

| Quality Assurance and Certification | Pick suppliers with ISO 9001 and proof of material testing. |

| उत्पादन क्षमता | Check factory size and workers to see if they can handle big orders. |

| Communication Efficiency | See how fast they answer questions to help your project go smoothly. |

Warranty and After-Sales Support

A strong warranty protects your money. Ask what the warranty covers and how long it lasts. Good help after you buy makes fixing problems easier and keeps your machines working.

Sample Testing and Evaluation

Try blades before you buy a lot. Many suppliers give samples to test. You can check if the blades fit and work well in your machines. This helps you avoid problems and get the right blades.

Note: Picking good suppliers helps you avoid surprise costs and makes sure you get blades you can trust.

You can make smart choices by matching the blade to your job and picking good suppliers. Aftermarket blades give you more choices, help you save money, and work well for jobs that are not risky.

Sourcing and Quality Assurance

You want the best shear blades for your work. You need to make sure your supplier is good. You should check what the blades are made of. You also need to know about the warranty. This section helps you make smart choices and avoid mistakes that cost money.

Supplier Vetting Tips

You must pick a supplier you can trust. Good suppliers give you blades you can count on. Bad suppliers can slow you down and send poor blades. Use these tips to find the right supplier:

- Check Supplier Reputation

Look for suppliers with good reviews and a long history. Ask other companies what they think. Reliable suppliers have many repeat buyers. - Review Certifications

Ask for ISO 9001 or other quality papers. These show the supplier follows strict rules for making shear blades. - Visit the Factory (if possible)

If you can, go see the supplier’s factory. You watch how they make blades and check their machines. You can meet the workers and ask questions. - Evaluate Communication

Good suppliers answer your questions fast. They explain their process and give clear details about their blades. - Request References

Ask for names of other customers. Talk to them about delivery, blade quality, and help after you buy.

Tip: Make a checklist before you pick a supplier. This helps you compare choices and choose the best one for your needs.

| Vetting Step | किसकी तलाश है | यह क्यों मायने रखती है |

|---|---|---|

| प्रतिष्ठा | Good reviews, repeat buyers | Shows you can trust them |

| प्रमाणीकरण | ISO 9001, material papers | Proves they follow rules |

| Factory Visit | Clean, modern machines | Shows they make good blades |

| संचार | Fast, clear answers | Stops confusion |

| संदर्भ | Happy customers | Proves supplier is reliable |

Material Testing

You need to know what your shear blades are made of. Good materials help blades last longer and work better. Bad materials can make blades break and cost you more. Use these steps to check blade quality:

- Ask for Material Certificates

Suppliers should give you papers that show steel type and heat treatment. These prove the blades meet your standards. - Request Sample Blades

Test a few blades before you buy a lot. Use them in your machines and check sharpness, wear, and fit. - Use Hardness Testing

You can use a tester to check blade strength. Most shear blades need a certain hardness to cut metal and last longer. - Inspect Surface Finish

Look at the blade’s surface. Smooth blades cut better and reduce friction. Rough blades can cause problems and wear out faster. - Check for Consistency

Compare several blades from the same batch. They should look and feel the same. Consistent blades mean the supplier makes blades the right way.

Note: Always keep records of your tests. This helps you track blade performance and find problems early.

| Material Test | What You Learn | यह कैसे मदद करता है |

|---|---|---|

| Certificate Review | Steel type, heat treatment | Proves blade quality |

| Sample Testing | Sharpness, fit, wear resistance | Shows how blades work |

| Hardness Check | Blade strength | Makes sure blades last |

| Surface Inspection | Smoothness, finish | Helps blades cut better |

| Consistency Check | Same look and feel | Lowers risk of bad blades |

Negotiating Warranty

You need a strong warranty to protect your money. A good warranty covers defects and early wear. Always ask about warranty rules before you buy.

- Read the Warranty Document

Ask for a written warranty. Read what it covers, how long it lasts, and what you do if you need to make a claim. - Ask About Coverage

Some warranties cover only defects. Others include blade performance and early wear. Pick the warranty that fits your needs. - Negotiate Terms

You can ask for longer coverage or better rules. Suppliers may offer better warranties if you buy a lot or sign a long contract. - Understand the Claim Process

Ask how you make a claim. Find out if you need to send photos, samples, or fill out forms. Fast claims help you get new blades quickly. - Compare Warranties

Look at warranties from different suppliers. Pick the one that gives you the most protection and fits your budget.

Callout: A strong warranty lowers your risk and helps you avoid surprise costs. Always ask for the best terms before you buy shear blades.

| Warranty Feature | What to Ask For | यह क्यों मायने रखती है |

|---|---|---|

| Coverage Scope | Defects, wear, performance | Protects your money |

| Duration | 6-24 months or longer | Gives longer protection |

| Claim Process | Easy, fast, clear steps | Cuts downtime |

| Negotiation | Bulk deals, custom rules | Gets you better value |

You make better choices when you check suppliers, test materials, and ask about warranties. These steps help you get good shear blades and keep your machines working well.

Real-World Examples

OEM Blades Case Study

Let’s look at how OEM shear blades work in real life. Metal Industrial is a good example. A big metal plant needed blades for strong steel every day. They picked Metal Industrial’s OEM shear blades for their main cutting machines. The maintenance team saw a big difference. The blades stayed sharp for a longer time. Workers did not have to change blades as often. The machines stopped less often. The plant watched the results for six months. Here is what they learned:

| मीट्रिक | Before (Generic Blades) | After (Metal Industrial OEM) |

|---|---|---|

| Blade Change Frequency | Every 2 weeks | Every 6 weeks |

| Downtime per Month | 12 घंटे | 4 घंटे |

| Scrap Rate | 3% | 1% |

You can see the results. The plant saved money on work and lost time. Less scrap meant less wasted metal. The OEM shear blades fit the machines well, so cuts were clean. The warranty and material papers made the manager feel safe. The team trusted the blades for hard jobs.

Tip: Using OEM shear blades for important work helps you lower risk and save money.

Aftermarket Success Story

You might ask if aftermarket shear blades can help too. A recycling center wanted to spend less on extra machines. They picked a good aftermarket supplier with strong reviews and ISO 9001 papers. The center tried sample blades before buying a lot. The aftermarket blades fit well and worked as promised. The team watched the results for three months. Here is what happened:

- Blade changes went from every week to every three weeks.

- Downtime dropped by 30 percent.

- The supplier gave a six-month warranty that covered one early problem.

The center saved money on buying blades. The lower price let them buy more blades for less money. The team used the savings to buy other upgrades. The aftermarket blades worked well for extra machines. The center kept their main machines on OEM blades for best results.

Note: Aftermarket shear blades are smart for less important jobs. Always test samples and check supplier papers before buying a lot.

These real-life stories show how both OEM and aftermarket shear blades can help your business. You need to pick the blade that fits your job and risk. Use facts and check suppliers to make the best choice.

You face a key choice between OEM and aftermarket shear blades. Focus on total cost of ownership, fit, and warranty. Think about your job’s needs, how much risk you accept, and the trust you place in your supplier. Use the tips and framework in this guide to make a smart decision. For expert advice or to discuss your options, हमारी टीम से संपर्क करें.

सामान्य प्रश्न

What does TCO mean for shear blades?

TCO means total cost of ownership. You count all costs, like buying, fixing, and replacing blades. TCO helps you pick blades that save money over time.

How do OEM shear blades differ from aftermarket options?

OEM shear blades fit your machine’s needs. They use certified materials and work well. Aftermarket blades can be different in fit and quality. You should check the supplier before you buy.

When should you choose OEM shear blades?

You pick OEM shear blades for important jobs. These blades are best for busy work, safety jobs, and when you need a warranty. OEM blades help you stop costly machine downtime.

Are aftermarket shear blades safe for all applications?

You use aftermarket shear blades for less important jobs. These blades fit extra machines, test projects, or old equipment. Always test samples and check certifications before using them everywhere.

What should you check before buying aftermarket shear blades?

You ask for material papers, sample blades, and warranty info. You look at supplier reviews and customer feedback. These steps help you avoid hidden costs and bad blade performance.

How does warranty affect your shear blade choice?

Warranty keeps your money safe. You want coverage for defects and early wear. Good warranties lower risk and help you avoid surprise costs if blades break.

Can you calculate TCO for shear blades easily?

You add up buying, fixing, and downtime costs, then subtract what’s left. This easy formula helps you compare blades and pick the best one for your business.

यह भी देखें

औद्योगिक कतरनी ब्लेड के लिए संपूर्ण खरीदार मार्गदर्शिका: खरीदने से पहले 7 गुणवत्ता जांच

एक प्रो की तरह शीयर ब्लेड को तेज करें: सामान्य ग्राइंडिंग गलतियों से बचना और TCO का विस्तार करना

शीयर ब्लेड क्लीयरेंस सेट करने के लिए निश्चित गाइड: सूत्र, गलतियाँ और शून्य-बर्र परिणाम

H13 हॉट वर्क शीयर ब्लेड: उच्च तापमान धातु कटिंग और बिलेट शीयरिंग में महारत हासिल करना