Nella produzione di fibre e PCB il lavoro è duro. Ogni giorno hai bisogno di prodotti precisi e resistenti. lamette in carburo Ti aiuta a realizzare tagli lisci e lavorare velocemente. Il carburo di tungsteno è molto duro e dura a lungo. Guarda come si confronta con altri materiali:

| Materiale | Durezza di Mohs | Durezza Vickers (Hv) |

|---|---|---|

| Carburo di tungsteno (WC) | 9 | 2400 |

| Carburo di silicio (SiC) | 9-9.5 | 2400-2800 |

| Diboruro di titanio (TiB2) | 9-9.5 | 3000-3500 |

| Carburo di boro (B4C) | 9-9.5 | 3000 |

Le lame in carburo di tungsteno durano a lungo e ti fanno risparmiare denaro ogni volta che tagli.

Punti chiave

- Le lame in carburo sono molto resistenti e durano più a lungo delle lame in acciaio. Questo consente di risparmiare tempo e denaro. Queste lame eseguono tagli estremamente precisi con pochi errori. Questo garantisce prodotti di alta qualità nella produzione di fibre e PCB. Le lame in carburo di tungsteno non si danneggiano con il calore né si usurano facilmente. Questo le rende ideali per linee di produzione veloci con tempi di fermo ridotti. È possibile realizzare lame in carburo personalizzate per esigenze di taglio speciali. Questo contribuisce a rendere il lavoro più veloce e preciso. Pulire e affilare spesso le lame in carburo può prolungarne notevolmente la durata. L'utilizzo di lame in carburo riduce gli sprechi e garantisce una migliore qualità del prodotto. Eseguono tagli puliti e lisci. Scegliere il tipo e le caratteristiche della lama giusti è molto importante. Aiuta a ottenere i migliori risultati nei lavori di taglio. Acquistare lame in carburo aiuta a lavorare meglio e a risparmiare denaro nella produzione.

Lame di rasoio in carburo: importanza per l'industria

Soddisfare le esigenze di precisione

Chi produce fibre e PCB ha bisogno di strumenti precisi. Le lame in carburo aiutano a ottenere risultati estremamente precisi. Queste lame possono tagliare con minimi errori. meno di ±0,01 mmCiò significa che ogni taglio avrà lo stesso aspetto. I tuoi prodotti rimarranno uniformi e puliti. Le lame in carburo mantengono i bordi lisci e puliti. Puoi usarle per tagliare migliaia di pezzi ogni giorno.

Le lame in carburo di tungsteno utilizzano carburo C2 resistente. Questo materiale non si consuma rapidamente. Le lame rimangono affilate più a lungo rispetto ad altri tipi. Alcune lame hanno rivestimenti come il nitruro di titanio. Questi rivestimenti aiutano a prevenire l'usura e a ridurre l'attrito. Le lame durano più a lungo e funzionano meglio. Il peso di queste lame è bilanciato. Questo impedisce loro di vibrare. Otterrai tagli dritti ogni volta.

Se hai bisogno di lame speciali, puoi ottenerne di personalizzate. Puoi andare al pagina lama personalizzata per trovare ciò di cui hai bisogno. Le lame personalizzate ti aiutano a lavorare in modo più preciso e veloce.

Superare i limiti delle lame tradizionali

Produrre fibre e PCB può essere difficile. Le vecchie lame in acciaio si smussano rapidamente. Bisogna sostituirle spesso. Questo sottrae tempo alla produzione. Le lamette in carburo risolvono questo problema. Il loro filo affilato dura a lungo. Non è necessario sostituirle spesso. Si risparmia denaro e le macchine funzionano più a lungo.

Il carburo di tungsteno rende queste lame molto difficileNon si danneggiano con il calore. Puoi tagliare materiali resistenti senza preoccupazioni. Le lame in carburo sono adatte alle linee di produzione veloci. Si ottengono meno fermate e risultati migliori.

Vuoi lame che ti aiutino a lavorare in modo rapido e intelligente. Le lame in carburo sono resistenti, affilate e fanno risparmiare. Ottieni di più da ogni lama e da ogni taglio.

Proprietà uniche delle lame in carburo di tungsteno

Affilatura del bordo sub-micron

Sono necessarie lame con bordi molto affilati. I bordi affilati aiutano a effettuare tagli puliti. Le lame in carburo di tungsteno possono essere super sottili e lisce. Questo aiuta a tagliare meglio fibre e materiali PCB. Il bordo rimane affilato a lungo. Non è necessario cambiare lame spesso.

Ecco una tabella che mostra come il carburo di tungsteno si confronta con altri materiali per lame:

| Materiale della lama | Durezza (HRC) | Raggio del bordo consigliato |

|---|---|---|

| Carburo di tungsteno | 85–90 HRC | 20–50 µm |

| Lame in Ceramica | 90+ HRC | 5–15 µm |

Taglio della fibra ad alta velocità

Tagli le fibre velocemente ogni giorno. L'affilatura submicronica ti aiuta a lavorare più velocemente. La lama taglia le fibre con meno forza. Vedi meno bordi irregolari e più pezzi uniformi. La tua linea si muove più velocemente perché correggi meno errori.

Micro-taglio FPCB

È necessario tagliare i circuiti stampati flessibili con molta attenzione. Una lama affilata consente di effettuare tagli minuscoli senza danneggiare la scheda. Si ottengono linee pulite e bordi lisci. Questo aiuta a rispettare le rigide normative in ambito elettronico.

Ecco una tabella che spiega come l'affilatura del bordo influisce sulla qualità del taglio:

| Tipo di strumento | Nitidezza dei bordi | Impatto sulla qualità del taglio |

|---|---|---|

| MCD | Atomicamente affilato | Rende le superfici lisce e richiede meno forza, ottimo per lavori molto precisi |

| PCD | Limitato dalla granulometria | La superficie potrebbe non essere liscia e affilata come quella dell'MCD |

Durezza e resistenza all'usura

Vuoi lame che durino a lungo. Le lame in carburo di tungsteno sono molto dure e resistenti. La loro struttura compatta le aiuta a rimanere affilate e a non rompersi. Passerai meno tempo a cambiare le lame e più tempo a lavorare.

Osserva i valori di durezza del carburo di tungsteno:

| Scala di durezza | Valore tipico del carburo di tungsteno | Note |

|---|---|---|

| Durezza Vickers (HV) | 1.500 – 3.000 HV | Dipende dalla granulometria e dal contenuto di cobalto |

| Durezza Rockwell A (HRA) | 88 – 95 HRA | Standard per carburo di tungsteno |

| Durezza Rockwell C (HRC) | ~69 – 81 HRC | Equivalente approssimativo per il confronto |

È possibile confrontare il carburo di tungsteno con altri materiali in termini di resistenza all'usura:

| Materiale | Durezza (HV) | Microstruttura | Applicazioni |

|---|---|---|---|

| Carburo di tungsteno | >1600 | Denso, a grana fine | Utensili da taglio, componenti per l'industria mineraria |

| Acciaio ad alta velocità | Inferiore al WC | Struttura più grossolana | Utensili per lavorazioni meccaniche generali |

Consiglio: scegli lame con una durezza maggiore. Durano più a lungo e sono più adatte ai lavori più impegnativi.

Stabilità termica nel taglio

Hai bisogno di lame che funzionino bene a caldo. Le lame in carburo di tungsteno mantengono la loro durezza anche a temperature elevate. Puoi usarle per un taglio veloce senza preoccuparti di bordi smussati.

- La stabilità termica aiuta le lame a resistere ai danni causati dal calore.

- La lama non si rompe né arrugginisce durante il taglio rapido.

- Si lavora più velocemente e si devono fermare meno persone.

Le lame in carburo offrono affilatura, durezza e resistenza al calore. Tutto questo in un unico strumento per lavori su fibre e PCB.

Applicazioni di produzione di fibre

Taglio di fibre chimiche

Lavori con fibre chimiche ogni giorno. Hai bisogno di lame che taglino in modo netto e riducano al minimo gli sprechi. Le lame in carburo ti aiutano a raggiungere questo obiettivo. Queste lame rimangono affilate e tagliano le fibre con elevata efficienza. Riduci gli sprechi perché le lame effettuano tagli netti e non danneggiano le fibre.

Lunghezze costanti e bordi puliti

Ogni fibra deve avere la stessa lunghezza. I bordi puliti sono importanti per la qualità. Le lame in carburo ti aiutano a ottenere entrambe le cose. Ecco come funzionano:

- Le lame mantengono il filo affilato a lungo, ottenendo tagli puliti ogni volta.

- Il design della lama riduce il calore, impedendo alle fibre di sciogliersi o sfilacciarsi.

- Si vedono meno sprechi perché i tagli sono precisi.

Suggerimento: utilizzare lame con elevata efficienza di taglio per ridurre lo spreco di fibre e migliorare la qualità del prodotto.

Precisione delle fibre sintetiche

Devi tagliare fibre sintetiche come poliestere, nylon e aramide. Queste fibre sono resistenti e tenaci. Le lame in carburo ti offrono la precisione di cui hai bisogno. Otterrai tagli precisi e una lunga durata della lama.

- Le lame funzionano bene con fibre ad alta resistenza.

- Si nota una bassa usura, quindi non è necessario cambiare spesso le lame.

- Le lame gestiscono processi di taglio abbreviati per fibra di vetro e fibra di carbonio.

- È possibile affilare le lame fino a tre volte, prolungandone così la durata.

- La qualità del materiale della lama mantiene i tagli netti e puliti.

| Tipo di fibra | Sfida di taglio | Soluzione per lame in carburo |

|---|---|---|

| Poliestere | Duro, abrasivo | Alta precisione, bassa usura |

| Nylon | Flessibile, forte | Nitidezza costante |

| Aramide | Molto forte | Lunga durata di servizio |

| Fibra di vetro | Fragile | Tagli puliti e precisi |

| Fibra di carbonio | Duro, abrasivo | Mantiene la qualità del bordo |

Produttività della linea automatizzata

Vuoi che la tua linea di produzione funzioni senza intoppi? Le lame in metallo duro ti aiutano a tenere il passo con velocità elevate e volumi elevati. Le lame non si smussano rapidamente, quindi ti fermi meno spesso per sostituirle. Ottieni più prodotti finiti e meno tempi di fermo.

- Le lame mantengono il filo anche durante le corse più lunghe.

- Si riducono le soste per la sostituzione delle lame.

- La tua linea si muove più velocemente e rimane produttiva.

Nota: le lame affidabili ti aiutano a raggiungere gli obiettivi di produzione e a mantenere bassi i costi.

Puoi affidarti alle lame in carburo per ottenere tagli puliti, lunghezze costanti ed elevata produttività nella produzione di fibre.

Soluzioni di taglio PCB e FPCB

I circuiti stampati (PCB) e i circuiti stampati flessibili (FPCB) richiedono un taglio preciso. È necessario che ogni scheda abbia bordi puliti e forme precise. Le lame in carburo di tungsteno aiutano a raggiungere questi obiettivi. È possibile utilizzare queste lame per micro-taglio, pannellizzazione e molti altri processi di PCB.

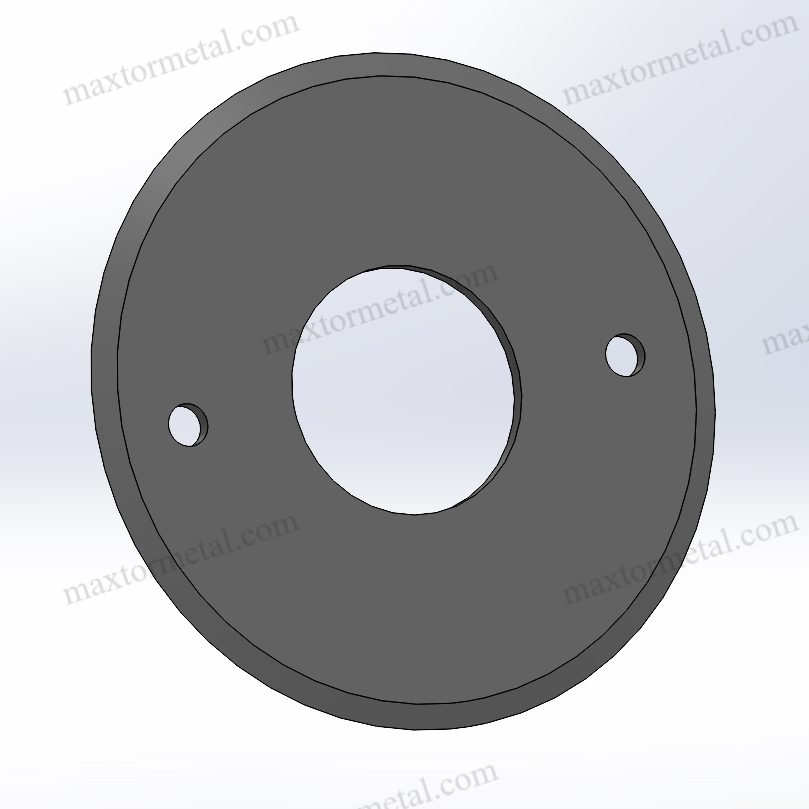

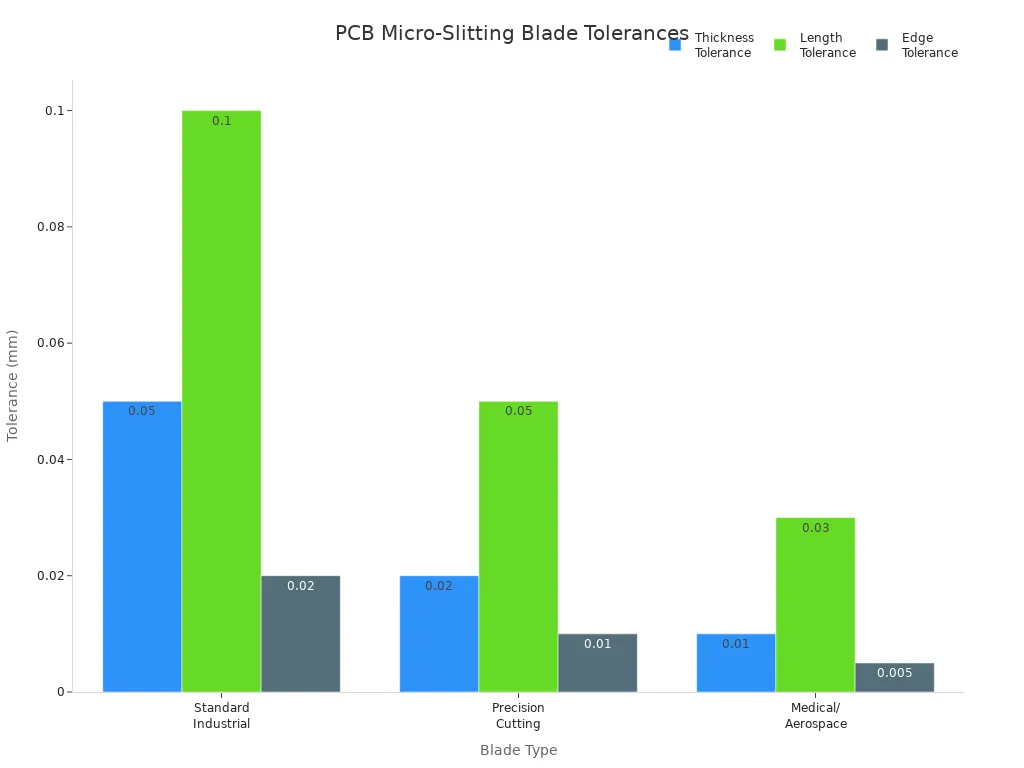

Micro-taglio PCB

Il micro-taglio consiste nel tagliare linee molto sottili nei PCB. Per questo lavoro è richiesta un'elevata precisione. Le lame in carburo garantiscono tolleranze ridotte. È possibile mantenere spessori, lunghezze e bordi prossimi al target.

| Tipo di lama | Tolleranza di spessore (mm) | Tolleranza di lunghezza (mm) | Tolleranza del bordo (mm) |

|---|---|---|---|

| Standard Industrial | ±0,05 | ±0,10 | ±0,02 |

| Taglio di precisione | ±0,02 | ±0,05 | ±0,01 |

| Medico/Aerospaziale | ±0,01 | ±0,03 | ±0,005 |

Come puoi vedere, le lame di precisione offrono tolleranze molto più strette rispetto alle lame standard. Questo significa che i tuoi PCB avranno forme e dimensioni più uniformi.

Burr-Free Edges

You want smooth edges on every PCB. Burrs are tiny pieces left after cutting. Burrs can cause problems in electronics. Carbide Razor Blades help you avoid burrs. The sharp edge slices cleanly through the board. You get smooth, flat edges every time.

Tip: Use blades with sub-micron sharpness to reduce burrs and improve product quality.

Carbide Razor Blades in PCB Panelization

Panelization means you group many PCBs together before cutting them apart. You need blades that can handle many cuts in a row. Carbide Razor Blades stay sharp for a long time. You can cut hundreds or thousands of boards before changing the blade.

- You get even cuts across the whole panel.

- The blade does not bend or break during fast cutting.

- You save time because you do not stop often for blade changes.

Note: Reliable blades help you keep your production line moving and meet your delivery deadlines.

Blade Types for PCB

You have many blade choices for PCB work. Tungsten carbide blades are the most common. These blades use ultrafine tungsten carbide. They reach a hardness of 93.5 HRA. You can use them for V-CUT knives and Gong blades. These tools help you cut straight lines and separate panels.

Nanjing Metal Industriale offers a wide range of tungsten carbide blades for PCB manufacturing.

- V-CUT knives help you make straight grooves in PCBs.

- Gong blades help you separate boards from panels.

- Both blade types give you clean, accurate cuts.

Tip: Choose the right blade type for your PCB process to get the best results.

You can trust carbide blades to deliver high precision, long life, and smooth edges in every PCB and FPCB cutting job.

Impatto su efficienza, costi e qualità

Longer Blade Life, Less Downtime

You want your machines to work longer without stopping. Carbide Razor Blades help you do this. These blades last much longer than steel blades. Tungsten carbide blades can last 50 to 200 times longer than stainless steel blades. You spend less time changing blades and more time making products. Sharp blades keep your production line moving fast. You avoid delays and stay on schedule.

| Tipo di lama | Average Lifespan (hours) | Changeover Frequency | Downtime Impact |

|---|---|---|---|

| Acciaio inossidabile | 10–50 | Alto | fermate frequenti |

| Carburo di tungsteno | 500–10,000 | Basso | Minimal interruptions |

Tip: Pick blades that last longer. This helps you work more and stop less.

Costi di manutenzione inferiori

You want to save money on fixing machines. Tungsten carbide blades help you in many ways:

- Tungsten carbide blades last longer than stainless steel blades.

- Better cuts from carbide blades mean fewer delays and mistakes.

- Using the wrong blade can cost more and be unsafe.

Long-lasting blades mean you buy fewer new ones. Your team spends less time changing and fixing blades. You also lower the chance of accidents from old blades. This keeps your workspace safer and saves money.

Enhanced Product Quality

You want every product to be high quality. Carbide blades help you make clean and exact cuts. Sharp blades give you smooth edges and perfect shapes. Your fiber and PCB products look good and work well. You see fewer mistakes and less waste. Customers trust your products because they are always good.

| Quality Factor | Impact of Carbide Blades |

|---|---|

| Levigatezza dei bordi | High, fewer burrs |

| Cut Accuracy | Precise, tight tolerances |

| Product Consistency | Reliable, repeatable results |

Note: Good cuts make better products and happier customers.

You work faster, spend less, and make better products when you use the right blades.

Confronto dei materiali delle lame

Carbide vs. Steel

When picking blades for fiber or PCB work, you look at carbide razor blades and steel blades. Steel blades have been used for a long time. They are strong and bend easily. But steel blades get dull fast. You have to change them a lot, which slows you down.

Carbide razor blades are much harder. They stay sharp much longer than steel blades. You spend less time swapping blades and more time making good products. Carbide blades do not wear out or get hot as quickly as steel. You can use them for hard jobs without worrying about breaking them.

| Caratteristica | Carbide Razor Blades | Lame in acciaio |

|---|---|---|

| Durezza | Very high (85–90 HRC) | Moderate (55–65 HRC) |

| Mantenimento del bordo | Eccellente | Giusto |

| Resistenza all'usura | Outstanding | Moderare |

| Durata | 50–500x longer | Più corto |

| Manutenzione | Basso | Alto |

| Costo nel tempo | Saves money | Higher replacement cost |

Tip: If you want to change blades less and get smoother cuts, carbide razor blades are the best pick.

Carbide vs. Ceramic

You might also think about using ceramic blades for cutting. Ceramic blades are very hard. They stay sharp for a long time and are good for careful jobs. But ceramic blades can break or chip if you use them for tough work or if something bumps them.

Carbide razor blades are both hard and tough. You can use them for careful and heavy jobs. Carbide blades handle bumps and shaking better than ceramic blades. You get steady results on busy lines.

Here is a table to help you see the differences between carbide and ceramic blades:

| Caratteristica | Carbide Razor Blades | Lame in Ceramica |

|---|---|---|

| Robustezza | High, suitable for heavy-duty use | Low, more brittle |

| Durata | Excellent, long lifespan | Good, but prone to chipping |

| Precisione di taglio | Good, can handle tough materials | Excellent, ideal for precision tasks |

| Mantenimento del bordo | Very good, can be resharpened | Exceptional, remains sharp longer |

| Peso | Heavier than steel | Lightweight, reduces hand fatigue |

| Applicazioni | Industrial, construction, heavy-duty | Food prep, electronics, crafting |

- Ceramic blades are harder than 2,500 HV. They work best for fast jobs that do not need much force.

- Carbide blades are between 1,500–2,000 HV. They do not break easily and are good for hard, bumpy cuts.

- Ceramic blades are great at not wearing out. Carbide blades are better when you need both careful cuts and strength.

Note: Pick carbide razor blades if you need a blade that can handle shaking and tough stuff. Choose ceramic blades for gentle, careful jobs with less chance of breaking.

Cost-Benefit for Industry

Switching to carbide razor blades helps your business in many ways. You get blades that last longer, make better cuts, and stop less often. Carbide blades can last 50 to 500 times longer than steel blades. You change blades less, so your machines keep working and your team stays busy.

- Longer wear means you buy fewer blades.

- Better cuts mean your products look nicer and you waste less.

- Less stopping helps you finish work on time and save money.

Using carbide razor blades helps you work faster and make better things. You spend less on fixing and changing blades. Over time, you save more money. Your line runs better, and your products are always high quality.

👍 Picking carbide razor blades helps you work smarter, save money, and get better results.

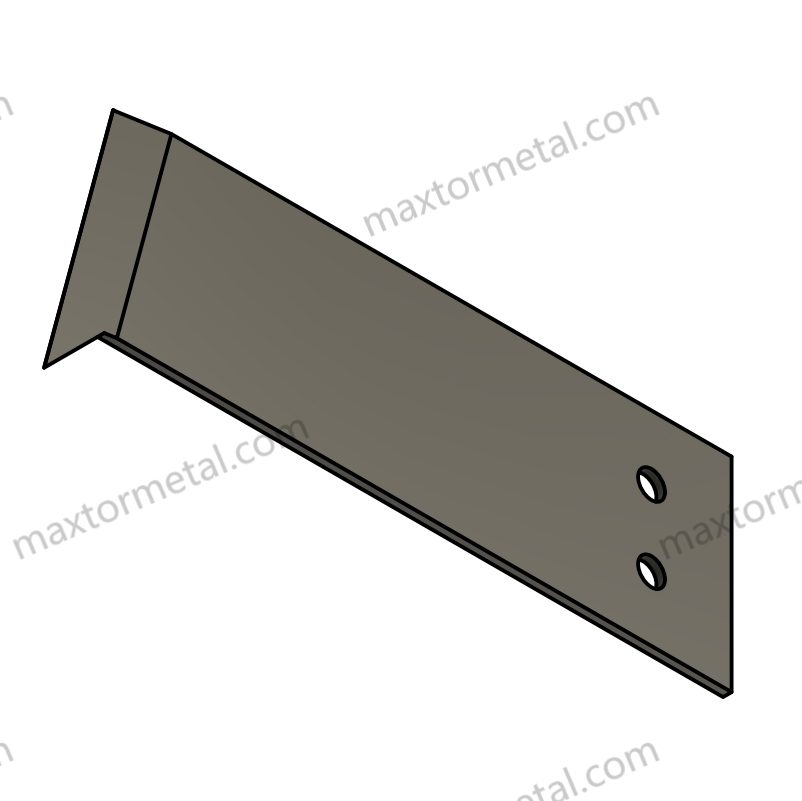

Scegliere la giusta lama di rasoio in carburo

Criteri di selezione

You want to pick the best carbide razor blade for your work. First, look at the blade type, what it is made of, and what it does best. The table below helps you see the choices:

| Tipo di lama | Materiale | Vantaggio chiave | Miglior caso d'uso |

|---|---|---|---|

| Carburo di tungsteno | Lega di carburo ultra-dura | Maggiore durata, basso attrito | Linee di produzione ad alta velocità e lunga durata |

Think about these things when you choose a blade: The blade angle is usually between 12° and 20°. The right angle depends on how thick your material is. Blade sharpness and shape matter too. A blade with 2 or 3 sides can cut smoother and with less rubbing. Web tension and speed are important. If the tension is balanced, your material will not stretch or change shape. Blade thickness, edge angle, and tip shape also matter. These things help you get clean and exact cuts.

Tungsten carbide blades are special because they are very hard. They last a long time and do not wear out fast. Different grades and ways of making the blade can change how long it lasts. Pick a blade that fits your job for the best results.

Tip: Always choose a blade with features that match your fiber or PCB job. This helps you get better cuts every time.

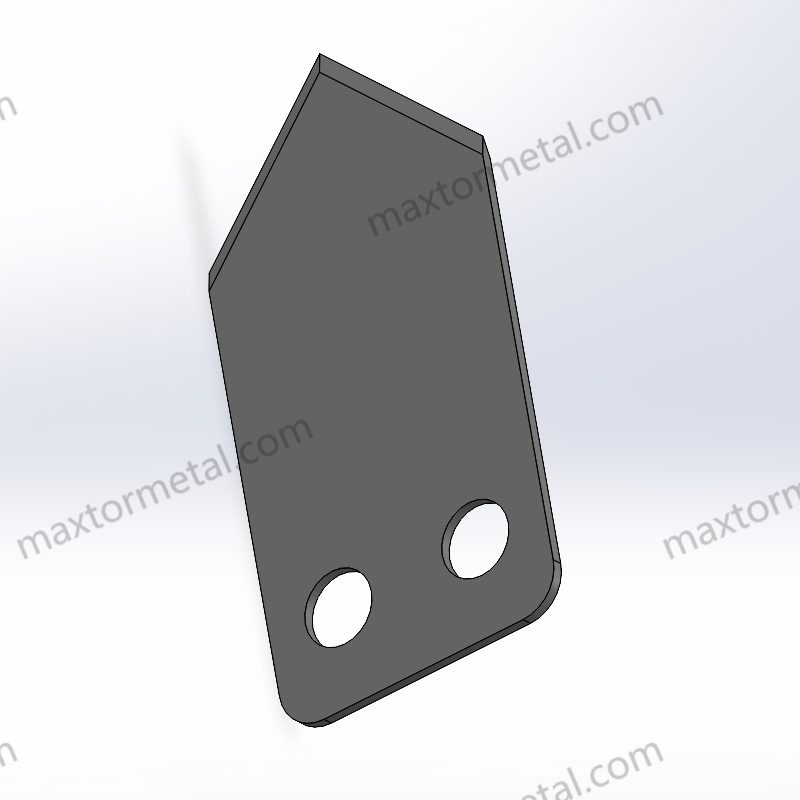

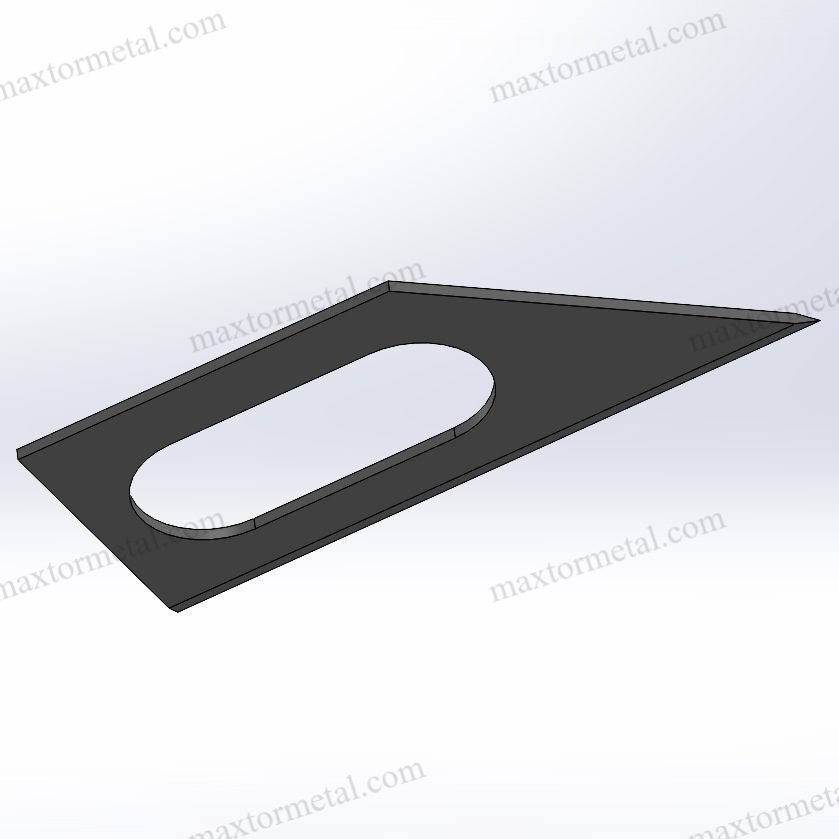

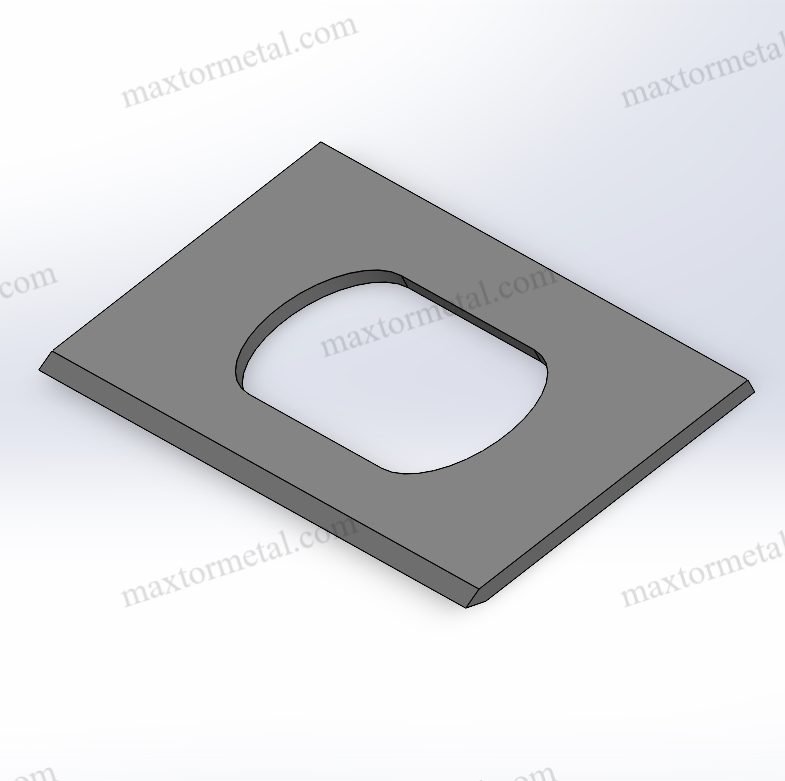

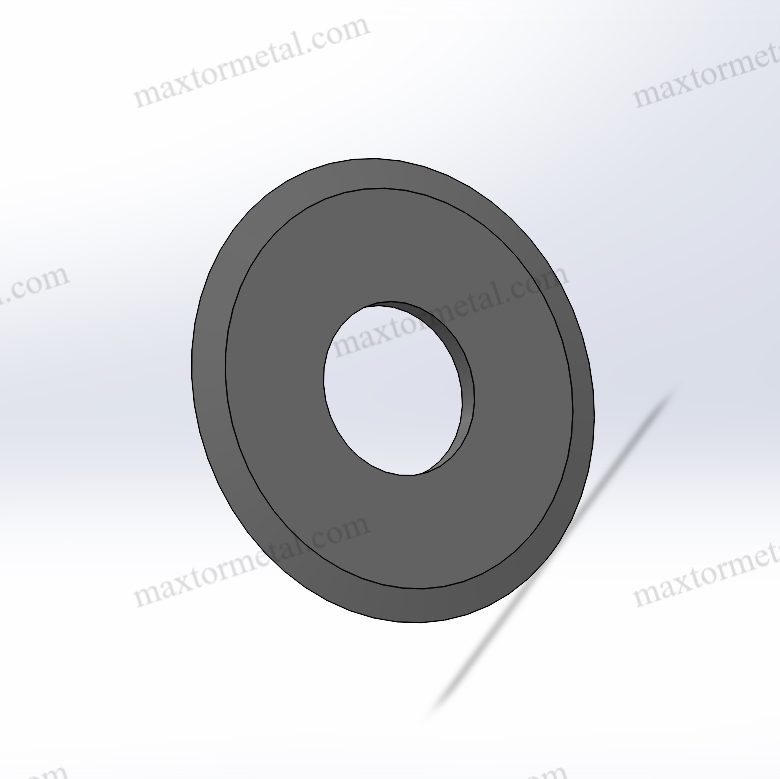

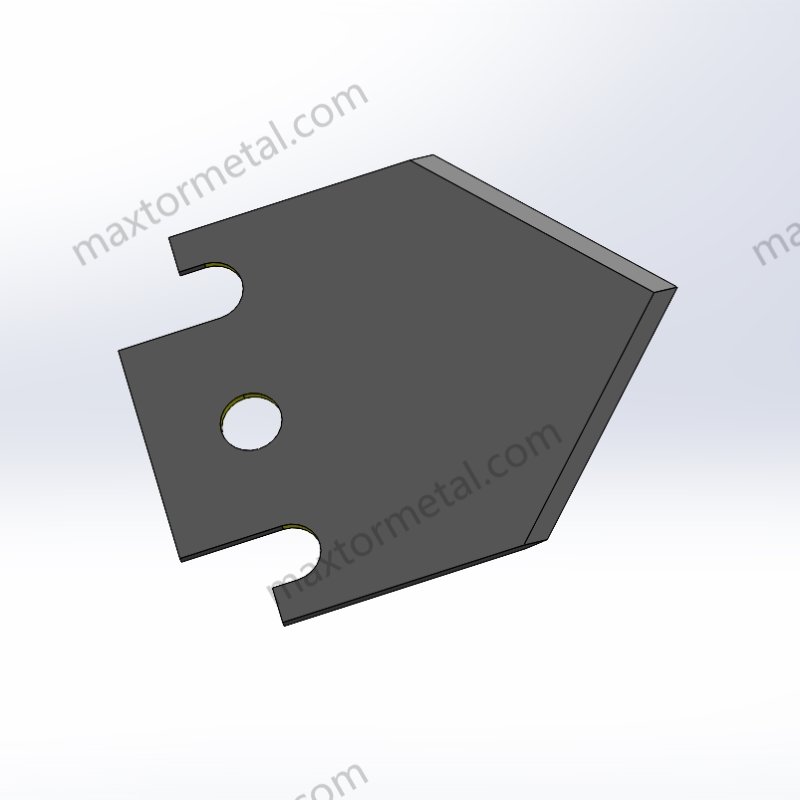

Opzioni di personalizzazione

Sometimes you need a carbide razor blade made just for your job. There are many ways to customize your blade. The table below shows what you can pick:

| Customization Feature | Dettagli |

|---|---|

| Forme delle lame | Straight, curved, wavy, toothed, serrated, scalloped, notched, pointed tip, multiple-edged |

| Materiali | High speed steel, tungsten carbide, solid ceramic, and others |

| Rivestimenti | TiN, TiC, TiCN, PTFE, Ceramic, Diamond |

| Packaging Options | Bulk, individual, or premium packaging |

| Part Identification | Logos or unique identifiers |

| Quality Documentation | COC, FAI, SPC, Cpk, etc. |

| Expediting Options | Options for expedited delivery available |

You can also ask for: OEM and ODM services if you have specific needs. Custom designs made just for you. Help with CAD drawings or samples if you need them.

Note: Custom blades help you fix special cutting problems and make your work better.

Migliori pratiche di manutenzione

You want your carbide razor blade to last a long time. Taking care of your blade is important. Here are some good tips: Clean your blades often so nothing builds up on them. If you clean them every day, they can last 25–35% longer. Check the cutting edge after each use to see if it is worn or broken. Use the right coolant when you cut to stop the blade from wearing out too soon. Keep your blades in a dry place so they do not rust or get damaged. Sharpen your blades with a stone or diamond wheel when they get dull.

Here are three big reasons to take care of your blades: 1. Cleaning stops rust by getting rid of water and chemicals. 2. Keeping the blade sharp helps it cut better and with less rubbing. 3. Good care makes your blade work up to 20% better.

🛠️ If you take care of your carbide razor blade, it will stay sharp, safe, and ready for every job.

Carbide razor blades let you make exact cuts in fiber and PCB work. You use them for a long time before changing. This means your machines stop less often. Your products look better and work well. These blades are tough and work fast. You do not need to buy new blades as much. You save money because you replace blades less.

- Pick tungsten carbide blades if you want blades that work well.

- Get better cutting tools so they last longer.

Vuoi migliorare il tuo lavoro? Talk to our sales engineers for help with carbide razor blades.

Domande frequenti

What makes carbide razor blades better for fiber and PCB cutting?

Carbide razor blades have very sharp edges. They stay sharp for a long time. These blades do not wear out fast. You get clean cuts every time. Your machines stop less often.

How often should you replace carbide razor blades?

Carbide razor blades last longer than steel blades. Change them when the edge gets dull. If cuts are not good, replace the blade. Check your blades often to keep things working well.

Can you use carbide razor blades for both fiber and PCB materials?

You can use carbide razor blades for fiber and PCB. These blades work for hard and soft jobs. You get accurate cuts in both areas.

Do carbide razor blades need special maintenance?

Clean carbide razor blades after you use them. Keep them dry so they do not rust. Sharpen them with a diamond wheel if needed. Taking care of blades helps them last longer.

Are carbide razor blades cost-effective for high-volume production?

Carbide razor blades help you save money. They last longer and need fewer changes. You spend less on fixing and get more products made.

What blade shapes are available for carbide razor blades?

You can pick straight, curved, serrated, or pointed blades. Choose the shape that matches your job. Custom shapes help with special cutting needs.

How do carbide razor blades improve product quality?

Le lame in carburo di tungsteno garantiscono tagli lisci e precisi. I vostri prodotti sono belli e funzionano bene. Le persone si fidano dei vostri prodotti perché sono di qualità.

Vedi anche

Coltello al tungsteno: ne vale la pena? Pro, contro e applicazioni nell'industria

Come Affilare e Mantenere le Lame in Carburo di Tungsteno

Perché i coltelli in carburo di tungsteno si scheggiano: modalità di guasto comuni e come evitarle

Carburo di tungsteno vs acciaio per lame industriali: prestazioni, usura e costi