Risoluzione dei problemi delle lame per taglierina rotativa mistakes can cause big problems. If you avoid these mistakes, your blades work better. This keeps workers safe and helps things run faster. You should watch blade selection, installation, and maintenance. Doing this gives you many good results:

- Machines stop less often

- You waste less material

- Cuts look better

- Machines and blades last longer

- Work stays safe

Read this guide for fast fixes and long-term help.

Punti chiave

- Check rotary slitter blades often for wear or damage. This helps stop bigger problems.

- Pick the right blade type for your material. This gives clean cuts and less wear.

- Make sure blades are lined up right. This stops uneven cuts and too much wear.

- Keep a log for maintenance. Write down inspections, repairs, and blade changes.

- Clean blades after you use them. This stops them from getting dull and keeps them working well.

- Sharpen blades often. This helps them cut better and makes less waste.

- Teach operators well. They should know how to spot problems and follow safety rules.

- Fix vibration or noise fast. This helps stop damage to the machine.

Rotary Slitter Blade Troubleshooting Basics

Identifying Common Problems

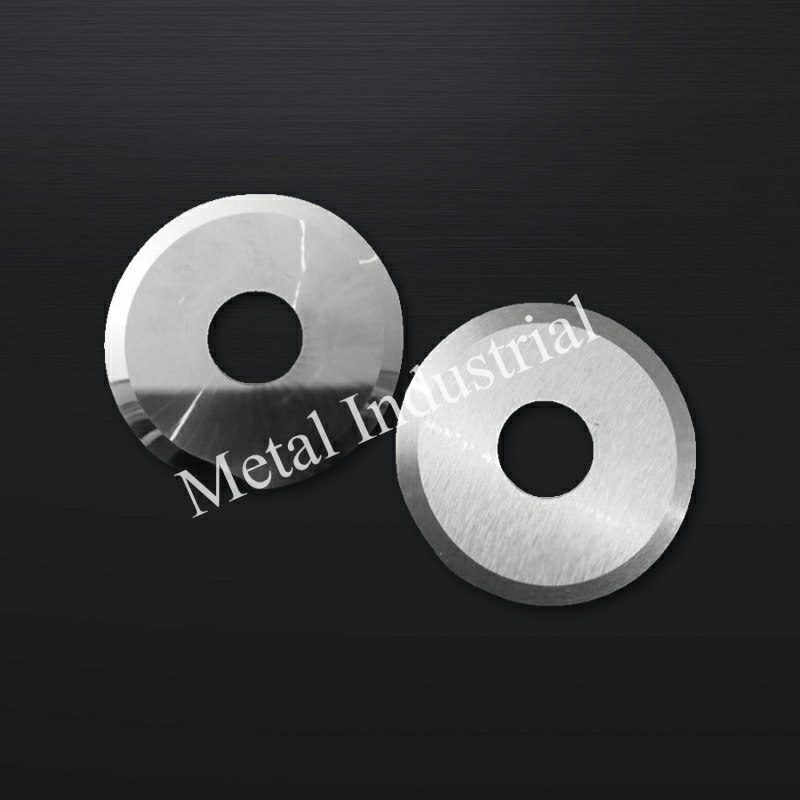

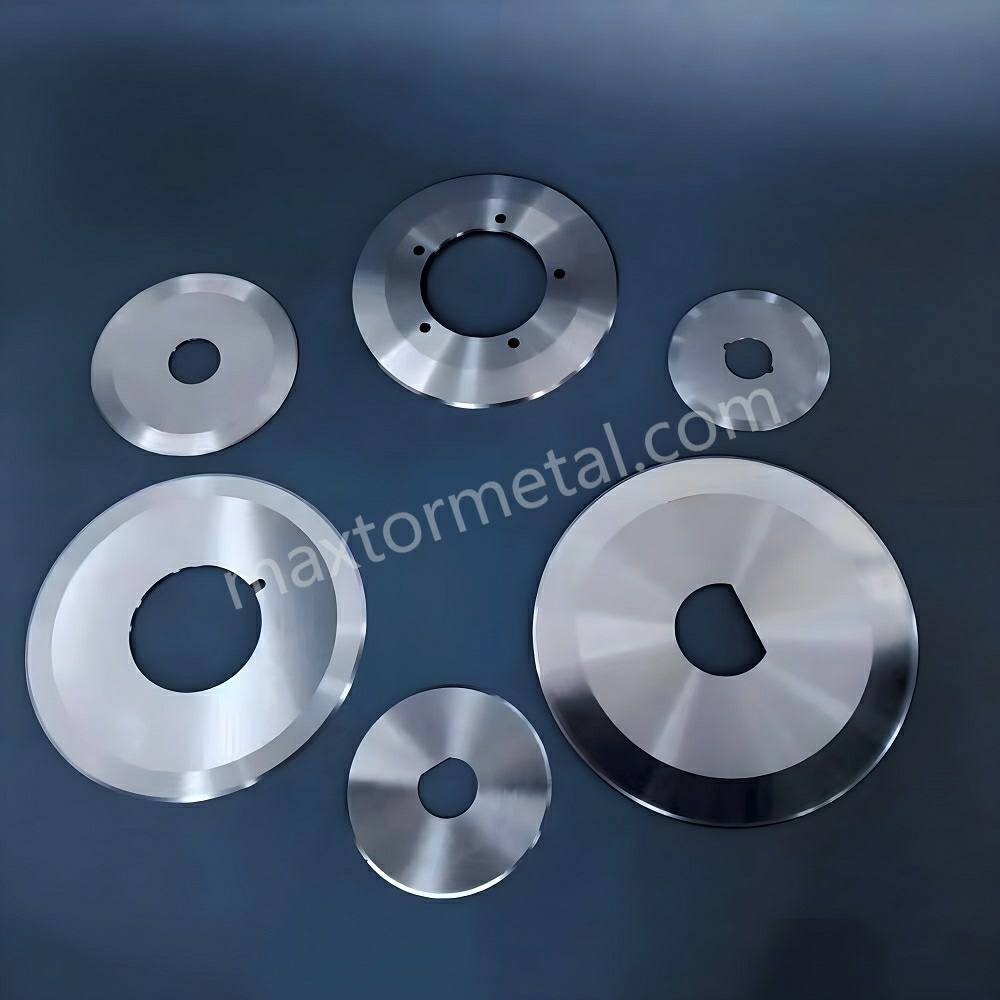

You use round slitter blades every day at work. These blades are very important in slitting machines. They help cut big rolls into smaller strips. Good blades from Nanjing Metal Industriale give you nice, clean cuts. But even the best blades can have problems, so rotary slitter blade troubleshooting matters.

You might see some problems when you check your blades. Here are the most common ones:

- The cut material has rough edges or burrs. This usually means the blade is worn out and needs fixing.

- You see chips or cracks on the blade. These show damage and can make the blade work badly.

- If the blade is dull, it is hard to cut cleanly. You may need to sharpen or change the blade.

- If the machine shakes more than usual, the blade might be worn or not lined up right.

- Strange sounds like grinding or squealing mean the blade is not working well.

If you see any of these problems, act fast. Finding problems early stops bigger issues and keeps your machines working well.

Importance of Correct Troubleshooting

You want your slitting machines to work their best. Good rotary slitter blade troubleshooting helps you do this. If you check your blades the right way, you stop problems and keep your line moving.

First, look at your round slitter blades for damage or wear. Use a flashlight to check for chips, cracks, or dull spots. Listen for odd sounds and feel for shaking. If you find something wrong, write it in your maintenance log. This helps you remember problems and plan repairs.

Think about what kind of blade you need. Different jobs need different blades. For example, single-layer small edge blades are good for hard stuff. Double-layer large edge blades are better for thin things that need careful cuts. If you need a special blade, check the pagina delle lame personalizzate per avere più scelte.

Checking your blades the right way saves time and money. You waste less material and lower the chance of machine damage. You also keep your team safe by finding problems early. Using round slitter blades from trusted brand helps you do a good job.

Rotary slitter blade troubleshooting is not just about fixing things. It is about making a habit that keeps your machines and blades working well. You get better cuts, your blades last longer, and your work gets better.

Common Wear Issues in Slitter Blades

Signs of Blade Wear

Visual and Performance Indicators

It is important to find wear problems early. This helps your slitting machines work well. When you check round slitter blades, look for these signs:

- Cutting does not work as well as before

- The machine shakes or makes loud sounds

- The blade edge looks worn or damaged

- The machine uses more energy than normal

- La macchina smette di funzionare più spesso

- The products do not look the same each time

- The equipment gets too hot

- It takes longer to cut things

- You need to fix the blade a lot

- Workers may not be as safe

If you see these problems, your blades might be dull or broken. You should fix them soon to stop bigger problems.

Causes of Premature Wear

How you use and care for your blades can cause them to wear out fast. Here are some main reasons round slitter blades do not last long:

- If the blade is not lined up right, cuts are uneven and the blade gets dull faster.

- If the tension is wrong, the blade gets extra stress.

- If you cut rough materials, like recycled stuff, the blade wears out quicker.

- Wet air can make the blade rust and get dull.

- If you run the machine too fast, the blade gets hot and dulls faster.

You can stop many of these problems by checking your machine and what you cut.

Solutions for Wear Problems

You can fix wear problems and help your round slitter blades last longer by following good care steps. Here is an easy plan:

- Pulizia: Clean off dirt and leftover bits after each use with a safe cleaner. This keeps the blade from getting dull.

- Ispezione: Look for small chips or uneven spots every day. Finding problems early lets you fix them before they get worse.

- Lubrificazione: Use the right oil to stop rust and make the blade move smoothly.

- Optimizing Operating Conditions: Change speed and pressure so the blade does not wear out fast.

- Sharpening and Resurfacing: Sharpen the blade after 500 to 1,000 cuts to keep it sharp and working well.

Mancia: Write down blade checks and repairs in a log. This helps you see problems early and plan when to change blades.

Using strong blade materials helps a lot. Blades from Nanjing Metal Industrial use tough metals like high-carbon steel and tungsten carbide. These materials help blades last longer and work better. Custom blades let you pick the right type and edge for your job, which helps stop wear problems.

When you follow these steps, your round slitter blades stay sharp and your machines work well. You also make your products better and keep workers safe.

Chipping Rotary Slitter Knives

Causes of Chipping

You might see chipping on rotary slitter knives during checks. Chipping means small pieces break off the blade’s edge. This can make your cuts look bad and slow down your work. Many things can cause chipping or cracking. Here are some common reasons:

- Cutting clearance is not right, either too small or too big.

- Too much vertical overlap can hurt the blade.

- Stress can bend the blade and cause damage.

- If you use too much force, the blade can break.

- Waiting too long to regrind makes the blade weak.

- Using the wrong knife material can cause problems.

- Knife hardness should match your job.

- If you wait to regrind, chipping can happen.

The material you pick for your blade matters a lot. Tungsten carbide blades last longer than tool steel blades. They are very hard and help you make clean cuts. This makes your work faster and better. Tungsten carbide does not wear out fast, but it can chip if you are rough with it. Tool steel is softer, but it can take more stress without chipping. Picking the right blade material helps stop chipping and keeps your blades working well.

Preventing Knife Chipping

You can stop chipping by following some easy steps. Handle and install your blades with care to keep them safe. Here are some ways to help:

- Keep the knife holder in good shape. This keeps the blade steady and stops uneven wear.

- Use coatings like Physical Vapor Deposition (PVD) to protect blades from wear and rust.

- Pick the right blade material for your job. Tungsten carbide is good for hard cuts. Tool steel is better if you need more toughness.

- Do not use too much force on the blade. Forcing it through thick or hard stuff can break it.

- Sharpen and regrind your blades often. This keeps the edge sharp and stops dulling.

- Be careful when you put in new blades. Dropping or hitting them can cause chips.

Tip: Check your blade for wear before every shift. Finding problems early helps you fix them fast and keeps your machines running well.

Repair and Replacement Steps

If you find chipping on rotary slitter knives, act quickly. Fixing round slitter blades right away stops bigger problems and keeps your line safe. Here is a simple plan to fix them:

- Take the damaged blade out of the machine.

- Look at the blade for dull spots, chips, or other damage.

- Decide if sharpening or regrinding can fix it. If the chips are small, sharpening may work. If the chips are deep, regrinding is better.

- If you cannot fix the blade, put in a new one that fits your job.

- Write down all repairs and changes in your maintenance log.

Fixing round slitter blades fast helps you avoid stopping work and keeps your cuts neat. Using these repair steps will help your blades last longer. Regular care and careful handling stop chipping and dulling, so your machines stay safe and work well.

Blade Misalignment and Installation Errors

Effects of Misalignment

When you put in round slitter blades, you need to line them up right. If you do not, you will have problems. Misalignment makes cuts uneven and wears out blades faster. You might see these problems:

- The blade edge wears down unevenly.

- The blade gets too hot when you use it.

- The blade edge fails sooner than it should.

- The cuts do not look good.

- The blade does not last as long.

If you ignore these signs, you will have to fix or change blades more often. Misalignment also puts more pressure on your machine. This can make your machine stop working and cost more money. Always check for these problems if your cuts get worse or blades wear out fast.

Correct Alignment Steps

You can stop many problems by lining up the blades the right way. First, make sure the in-feed roller lines up with the blades. If the roller is not lined up, it pushes the material to the side. This puts extra force on the blades. Thin blades need even better alignment because they can break easily.

Here are some steps to help you line up the blades:

- Line up the knife carefully to stop waste and keep cuts good.

- Check the tension on the material before you cut.

- Change the speed and feed rate to fit the blade and material.

Make sure the rollers guide the material at a 90° angle. If the rollers are not lined up, the material can move or wrinkle. Use laser or optical tools to check if things are lined up, especially on old machines. These steps help you stop many problems with round slitter blades.

Tip: Write down every time you check alignment in your log. This helps you see problems early and plan repairs before they get worse.

Installation Best Practices

Good ways to install blades help you stop wear and repairs. Always handle round slitter blades with care. Make sure each blade fits your machine just right. Nanjing Metal Industrial gives you many ways to customize blades for a good fit. You can pick the material, add your logo, or send a sample or drawing for a lama personalizzata.

| Opzione di personalizzazione | Descrizione |

|---|---|

| Selezione dei materiali | Pick the best material for your job |

| Personalizzazione minore | Add your logo, pictures, or special packaging |

| Customization Based on Samples | Send a sample or drawing for a perfect fit |

When you put in new blades, look for any damage or wear. Clean the area before you put the blade in. Tighten all bolts to the right level. If you see a problem while installing, stop and fix it before you use the machine. Careful installation keeps blades sharp and cuts clean.

If you do these things, you will have less wear, fewer repairs, and your round slitter blades will last longer.

Rotary Slitter Blade Repair and Maintenance

Scheduled Maintenance Tasks

You keep round slitter blades working well by sticking to a regular plan. Checking the blades often helps you find problems early. Cleaning the machine and blades stops dust and dirt from piling up. Lubrication helps the moving parts work smoothly and stops damage. You also need to look at the knife shafts and the whole system for any trouble. Here is a table that shows the best regular maintenance jobs:

| Attività di manutenzione | Descrizione |

|---|---|

| Blade Inspection and Replacement | Check if the blade is sharp. Replace or sharpen it if you see uneven wear, nicks, or chips. Look at the whole blade system and holders. Change blades that are getting old. |

| Cleaning of Machine Components | Clean the cutting and rewinding areas well. Remove dust, dirt, and sticky stuff with safe cleaners. Clean inside and outside parts deeply. |

| Lubrication Parts | Make sure there is enough oil. Oil the moving parts. Change or add oil and check for leaks or old oil in the system. |

| Rewind / Knife Shaft Maintenance | Check if the rewind shaft is sealed tight. Make sure the top and bottom knife shafts are straight for good cuts. |

| Full System Inspections | Look at all belts, gears, and motors for damage. Have a pro check the machine and test how well it works. |

Follow the maker’s rules for keeping things in good shape. Every week, check the oil and air systems, roller alignment, and blade space. Each month, change the oil, watch the slitting knives, and oil the machine parts again. How often you sharpen blades depends on how much you use them and what you cut.

| Frequenza di manutenzione | Compiti |

|---|---|

| Settimanale | Check oil and air systems, make sure rollers are straight, check blade space |

| Mensile | Change oil, watch slitting knives, oil machine parts again |

| Additional | Sharpen blades based on what you cut and how much you use them |

Repair vs. Replacement

You have to choose if you should fix round slitter blades or get new ones. Checking the blades often helps you see wear, nicks, or chips. Sharpening keeps blades cutting well. Dull blades make rough cuts and waste material. Here are some signs to help you decide:

- Bad cuts mean you need to fix the blade.

- If you see big chips or cracks, get a new blade.

- Ask a knife expert if you are not sure if the blade or another part is the problem.

- If sharpening does not help, replace the blade.

- Fixing works for small chips or dull spots. Get a new blade if it is very worn or damaged.

Tip: Always check the blade after you fix it. Make sure it is sharp and fits right before you use it again.

Maintenance Log Tips

You help blades work better and last longer by keeping a good log. Write down every time you clean, check, sharpen, or fix the blades. Checking often helps you find problems early. You stop machine stops by looking for parts that are not lined up or dull blades. Here are some tips for your log:

- Write down every cleaning of the machine and blades.

- Note each check and what you find.

- Keep track of sharpening and fixing round slitter blades.

- Write down any problems and how you solved them.

- Check the knife holder often to stop wear.

Note: A good log helps you plan repairs and blade changes. You save time and keep round slitter blades working longer.

You keep your slitting machines working well by following these steps. Checking, cleaning, sharpening, and fixing blades stops problems before they get worse. You get better cuts, waste less, and your blades last longer.

Troubleshooting Poor Cut Quality

You want your rotary slitter blades to make clean cuts. Bad cuts slow you down and waste material. You can fix most problems by checking the blade type and how you use it. Look at the edge shape too.

Dull or Nicked Blades

Dull or nicked blades make bad cuts. You might see rough edges or uneven strips. This happens if you skip sharpening or ignore dull blades. If you change blades a lot, your blades may wear out unevenly. Knife holders that are not cared for can also dull blades. Check blades before each shift for nicks or dull spots. Sharpen blades on time to keep them working well. This stops dull blades from ruining your products.

Tip: Better knives can help you get cleaner cuts. Try blades made from high carbon steel, tool steel, or tungsten carbide. These last longer and do not dull as fast.

Incorrect Blade Clearance

Blade clearance is the space between the top and bottom blades. If you set this wrong, you get bad cuts. Wrong LAP and GAP settings can dull the blade faster. You might see uneven strips or damage to the blade edge. Damaged spacers also hurt the blade edge. Bad installation can cause more dulling and wear. Always check blade clearance before you start. Use good tools to measure the gap and line up the blades.

- Common causes of poor cut quality:

- Wrong LAP and GAP settings

- Broken spacers

- Bad blade installation

- Uneven strip width

- Strip steel not flat

Fixing these problems helps your blades last longer. It also makes cutting faster and better.

Material Compatibility Issues

The material you cut changes how blades work. Using the wrong blade can dull the edge and make dust. Thin films like BOPP and PET need sharp, polished blades. Thick steel coils need strong blades with the right angle. The table below shows how picking the right blade helps:

| Sfida | Soluzione | Risultato |

|---|---|---|

| Dust and bad edges when cutting thin films | Use fine-grain tungsten carbide blades with polished edges | Less dust, better edges, blades last longer |

| Uneven edges in thick steel coils | Use D2 steel blades with special treatment and good spacers | No edge problems, better cuts, less scrap |

Nanjing Metal Industrial has many blade types. They offer high carbon steel, high speed steel, tool steel, alloy steel, and stainless steel blades. You can also get special grades like SKD-11, SKH-51, and SUS440C.

Note: Picking the right blade and edge shape for your material stops dulling. It also helps you cut better and keeps blades sharp.

You can fix bad cuts by checking for dull blades, setting the clearance right, and using the right blade for your material. Sharpen blades often and pick carefully to keep your machines running well.

Addressing Vibration and Noise

Causes of Excessive Vibration

You might notice vibration and noise when the machine runs. Vibration can mean there is a bigger problem. It may be from how the blade was put in or if the blade is worn. If you ignore these signs, your machine can get damaged. Your cuts may not look good.

Some main causes of vibration in rotary slitter blade systems are:

- Imbalance: If the parts do not weigh the same, the machine shakes.

- Disallineamento: If shafts or blades are not lined up, vibration happens.

- Loose or worn-out components: Old or loose bolts and bearings make the machine shake.

- Resonance: If the machine’s natural frequency matches how it works, vibration gets worse.

- Mechanical looseness: Extra space or loose parts add more shaking.

- Bearing problems: Bad bearings make the machine shake even more.

- Operating conditions: Running fast or with heavy loads can cause vibration.

Mancia: If you hear weird sounds or feel shaking, check your rotary slitter blade system right away. Fixing problems early stops bigger issues.

Solutions for Reducing Vibration

You can lower vibration and noise by doing simple things. First, check if all parts are lined up. Make sure blades and shafts match up. Tighten bolts and change old bearings. Use the biggest diameter and shortest length for your tooling assembly. This makes the system stronger and less shaky.

Here are more ways to help stop vibration:

- Make sure metal parts touch tightly and do not move.

- Use tools that are strong and do not bend easily.

- Pick stiff materials like carbide for tool shanks.

- Set the cutting-edge angle close to 90° for better balance.

- Use a sharper edge and a smaller nose radius.

- Cut less deep and feed faster.

- Change the cutting speed to find what works best.

- Get a better tool clamping system.

Nota: If your machine has long tooling assemblies, use vibration damping parts. These parts soak up vibration and help your rotary slitter blade system work smoothly.

Impatto sulle prestazioni della lama

Vibration changes how rotary slitter blades work. Blades that do not shake cut better and last longer. Less vibration means smoother cuts and better products. High concentricity in slitter blades keeps things steady and safe.

If you let vibration go on, blades wear out unevenly and cuts look bad. Vibration can also make accidents more likely. You want your rotary slitter blade system to run quietly and smoothly. This keeps your team safe and your products looking good.

Attenzione: Always check for vibration and noise when you do maintenance. Fixing these problems early helps your rotary slitter blades work well and last longer.

Operator Training and Documentation

A skilled operator makes a big difference in rotary slitter blade troubleshooting. You need to know how to use the machine, spot problems, and keep good records. When you focus on training and documentation, you help your team work safely and keep your machines running well.

Training Essentials

You need a strong training program to work with rotary slitter blades. Good training keeps you safe and helps you fix problems fast. Here are the main parts of a good operator training program:

- Foundational Safety Knowledge

You start with classroom lessons. You learn about the machine, how to spot dangers, what to do in an emergency, and what safety gear to wear. - Supervised Hands-On Training

You practice real tasks with a trainer. You learn how to thread material, adjust tension, change blades, and follow troubleshooting steps. You get to see and do each step. - Competency Validation

You show what you know. You take written tests, show your skills in front of a trainer, and practice emergency drills. You also take part in safety checks.

A good training program helps you avoid mistakes. You learn how to spot blade wear, fix alignment, and know when to repair or replace a blade. You also learn how to keep records and follow safety rules.

Troubleshooting Records

Keeping good records helps you solve problems faster. You should write down every time you check, clean, or repair a blade. Use a troubleshooting log to track what you find and what you do. This log helps you see patterns and plan for future repairs.

A simple troubleshooting log might include:

- Date and time of the check

- What you found (like dull blades or misalignment)

- What steps you took to fix the problem

- When you did a repair or changed a blade

- Notes about machine performance

Tip: Review your log often. You can spot problems before they get worse. You also help your team learn from past issues.

Continuous Improvement

You should always look for ways to get better. Ongoing training keeps your skills sharp. You can hold short training sessions or safety meetings. You can also review your troubleshooting logs to find common problems.

Ask your team for ideas. Try new ways to solve problems. Update your training and repair steps as you learn more. When you focus on improvement, you help your machines last longer and keep your work safe.

Note: Good training and records help you avoid downtime. You save money and keep your rotary slitter blades working their best.

You can stop losing time and money by checking rotary slitter blades often. Use the advice in this guide to find problems early. This helps your machines keep working well. Make a short checklist for rotary slitter blade troubleshooting. This way, you will not forget any steps. Doing regular care and putting blades in carefully makes them last longer. If you need more help, talk to a sales engineer Qui.

Domande frequenti

What causes rotary slitter blade wear?

You see rotary slitter blade wear from dull edges, wrong alignment, or cutting tough materials. High speeds and poor cleaning also make blades wear out faster. Check your blades often to spot early signs of wear.

Con quale frequenza è necessario sostituire le lame della taglierina rotante?

You should replace rotary slitter blades when you notice dull edges, chips, or poor cut quality. Most operators check blades daily and replace them as soon as performance drops.

Why do rotary slitter blades chip?

Rotary slitter blades chip if you use too much force, set the clearance wrong, or pick the wrong blade material. Handle blades carefully and check settings before each shift.

How do you align rotary slitter blades correctly?

You align rotary slitter blades by making sure the top and bottom blades match up. Use measuring tools to check the gap. Always follow your machine’s guide for best results.

What is the best way to clean rotary slitter blades?

You clean rotary slitter blades with a soft cloth and a safe cleaner. Remove all dust and debris after each use. Never use harsh chemicals that can damage the blade surface.

Can you sharpen rotary slitter blades yourself?

You can sharpen rotary slitter blades if you have the right tools and training. Use a sharpening stone or machine. If you are unsure, ask a professional to help.

How do you know if a rotary slitter blade is the right type for your material?

You check the blade’s material and edge shape. Harder blades work better for tough materials. Thin films need sharp, polished edges. Ask your supplier for advice if you are not sure.

What should you do if your rotary slitter blade makes loud noise?

You should stop the machine and check for loose parts, misalignment, or blade wear. Tighten bolts and inspect the blade. Replace or repair the blade if needed.

Vedi anche

La Guida Definitiva alla Scelta del Materiale per la Tua Lama per Taglierina Rotativa

Come massimizzare l'affilatura della lama della taglierina per prestazioni di taglio superiori

Come Ottenere Tagli Perfetti con Lame per Taglierina Rotativa per Carta