高性能木材シュレッダーナイフで木材廃棄物収益を最大化する

Upgrade to high-performance wood shredder knives to make more money from wood waste. New shredding technology breaks down wood fast. It makes less waste and lowers storage costs. You can fit more wood in each load. This saves fuel and labor. Shredding also makes it easier to move and handle wood. This helps your business run better and make more money. Key Takeaways Wood Waste Processing and Revenue Value of Wood in Biomass Markets Wood waste can be useful and worth money. Many companies use wood waste for biomass fuel and wood chips. These things help make energy and help landscaping and farming. The market for biomass fuel and wood chips gets bigger […]

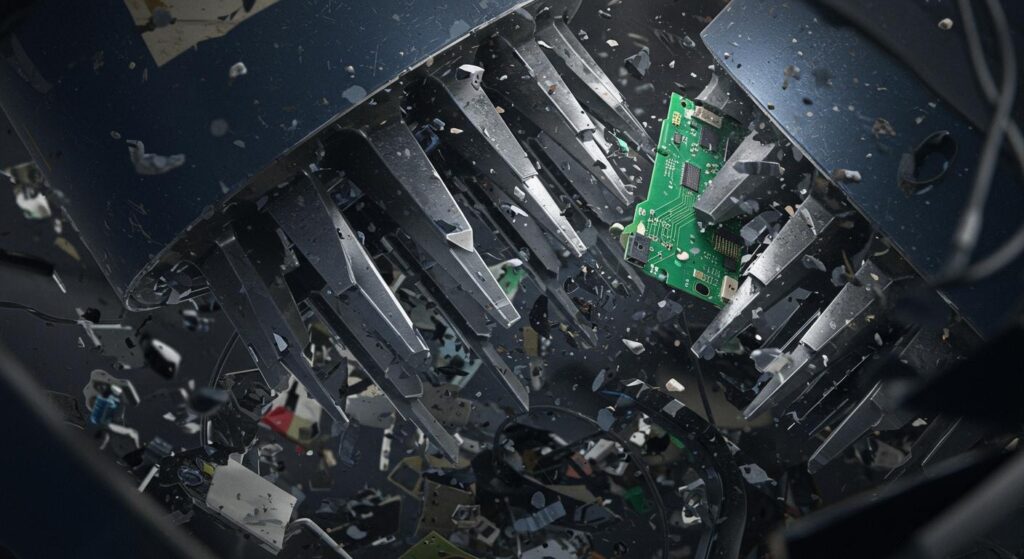

安全な破壊のための E-waste シュレッダーブレードの必須機能

You have more problems when you try to handle e-waste safely. If you throw away e-waste the wrong way, it can leak private data. It can also hurt the earth. Good E-waste shredder blades help you follow safety rules. They also help you meet laws about e-waste. In 2021, people made 57.4 million tons of e-waste. Only 17.4% of it got recycled. Look at the recycling rates below: Region Recycling Rate Global 17.4% Europe 42.5% Asia 11.7% Africa 0.9% Key Takeaways E-waste Shredders and Secure Destruction Why E-waste Security Matters If you do not destroy e-waste the right way, you face many dangers. Old computers and phones can still have private data inside. Someone […]

効率的なリサイクルのためのプラスチックシュレッダーブレードの選び方

適切なプラスチックシュレッダーブレードを選ぶことで、リサイクル効率が向上します。不適切なブレードを選ぶと、すぐに鈍くなったり、破損したりする可能性があります。これは、硬質プラスチックや繊維入りプラスチックで起こりやすいです。そうなると、作業を中断し、追加の費用を支払うことになります。ハイス鋼やタングステンカーバイドなどの高品質なブレードは、より長持ちします。作業がスムーズに進みます。Nanjing Metal Industrialは、様々な用途に対応するシュレッダーブレードを豊富に取り揃えています。ブレードと素材は、プラスチックの種類とリサイクルの目的に合わせて選ぶ必要があります。ブレードを選ぶ際には、技術面、作業面、費用面の3つの要素を常に考慮してください。ヒント:適切なブレードはコストを節約し、リサイクル効率を向上させます。重要なポイント:ブレード選びが重要な理由:効率とスループット[…]

シングルシャフトシュレッダーブレードデザインの究極ガイド

Single shaft shredder blades are important in shredding work. Blade design helps machines work better and last longer. These blades are used for tough jobs. When you shred big things like metal or plastic, hook-shaped blades grab and rip them apart. This makes shredding work well. The blade material helps blades stay sharp and strong. They do not break easily under pressure. Many companies want custom blades to fit their needs. They choose OEM or ODM options. Good quality control gives steady results. It helps with recycling and waste management goals. Key Takeaways Single Shaft Shredder Blades Overview Blade Function Single shaft shredder blades help break down many kinds of waste. These blades […]

最新のプレスブレーキ用途における金型用 DXF ファイルの役割

You use dxf files for tooling when you need exact results in modern press brake work. Dxf files work like a digital link between your design software and your factory process. You can see how dxf adds smart steps to your work. When you use dxf, you make each step faster and more correct. Dxf lets you test bends and setups before you start making things. This helps you get better parts and make fewer errors. Key Takeaways DXF Files for Tooling Digital Workflow Shift You see a big change in how factories work when you use dxf. You move from paper drawings and manual setups to a digital process. You start […]

ロータリー曲げ金型:傷ゼロで完璧な曲げを実現

Rotary bending tooling lets you make smooth bends. Your tubes will not have any marks. You can get great results if you pick the right bender. You should use the correct materials. You must control the bending process. Advanced tooling helps stop problems. These tools include non-marking inserts and synthetic die surfaces. They help prevent ovality, wrinkling, thinning, and springback. Here are ways to fix these problems: Surface Imperfection Common Causes Advanced Tooling Solutions Ovality Too much force, not enough support, poor lube Use mandrels, correct die, add booster Inner Wall Wrinkling Bad wiper setup, wrong mandrel, thick wall Use wiper die, adjust mandrel, thin-wall tech Outer Wall Thinning Tight radius, low […]

曲げ加工のABC:プレスブレーキパンチとダイの初心者向けガイド

When you work with metal, you need tools that help you bend it into the right shape. The press brake punch and die act like a mold and a hammer, shaping sheet metal with care. These tools matter because they give you: Key Takeaways Press Brake Punch and Die What Are They When you work with metal, you need to change its shape. The press brake punch and die help you do this job. The punch is like a strong finger that pushes down. The die sits under the metal and helps guide it. You put the sheet metal between the punch and die. When the press brake moves, the punch pushes […]

プレスブレーキツールのトップブランド:市場をリードしているのは誰か?

When you want good press brake brands, these ten are popular: These press brake tooling brands are leaders. They focus on making high-quality tools. They also work on new ideas and help customers well. You need a brand that gives you good results every time. Here is what makes these brands special: Factor Description Quality Control Good brands check every press brake tool carefully. Communication Top brands talk to you and answer fast. Pricing Structure Simple prices help you know what you will pay. Technological Advancements New technology helps you work faster and better. Picking the right brand helps you do your best work in your shop. Key Takeaways Press Brake Tooling […]

カスタムプレスブレーキ金型を購入する前に尋ねるべきトップ 10 の質問

Are you sure your press brake tooling fits your needs? If you ask good questions before buying, you can save money and avoid costly mistakes. When you choose custom tooling manufacturers you receive expert assistance and solutions tailored specifically for you. Use this checklist to help you make informed decisions. Consider quality, compatibility, safety, and value for your shop. Think about what will benefit your shop for the long term. Key Takeaways Top 10 Things To Consider Workpiece Requirements Dimensions Before you buy custom press brake tooling, know your workpiece size. The length, width, and thickness of your metal sheets matter. These measurements help you pick the right tooling for your job. […]

工具の価格が決定の唯一の要因ではない理由:費用対効果分析

You might think press brake tooling price is most important. Press brake tooling price can change your budget in many ways. If you only look at press brake tooling price, you might miss hidden costs. These hidden costs can hurt your financial plans. Press brake tooling price can look cheap, but low quality can cause problems. You might need repairs or have downtime. You should use cost-benefit analysis to help your choices. Press brake tooling price is just one part. Financial managers need to check the value too. Nanjing Metal’s press brake tooling shows how results get better when you look at more than price. Key Takeaways Press Brake Tooling Price: More Than […]