妥協を止めましょう:カスタム工業用シャー刃が既製品の代替品よりも優れている理由

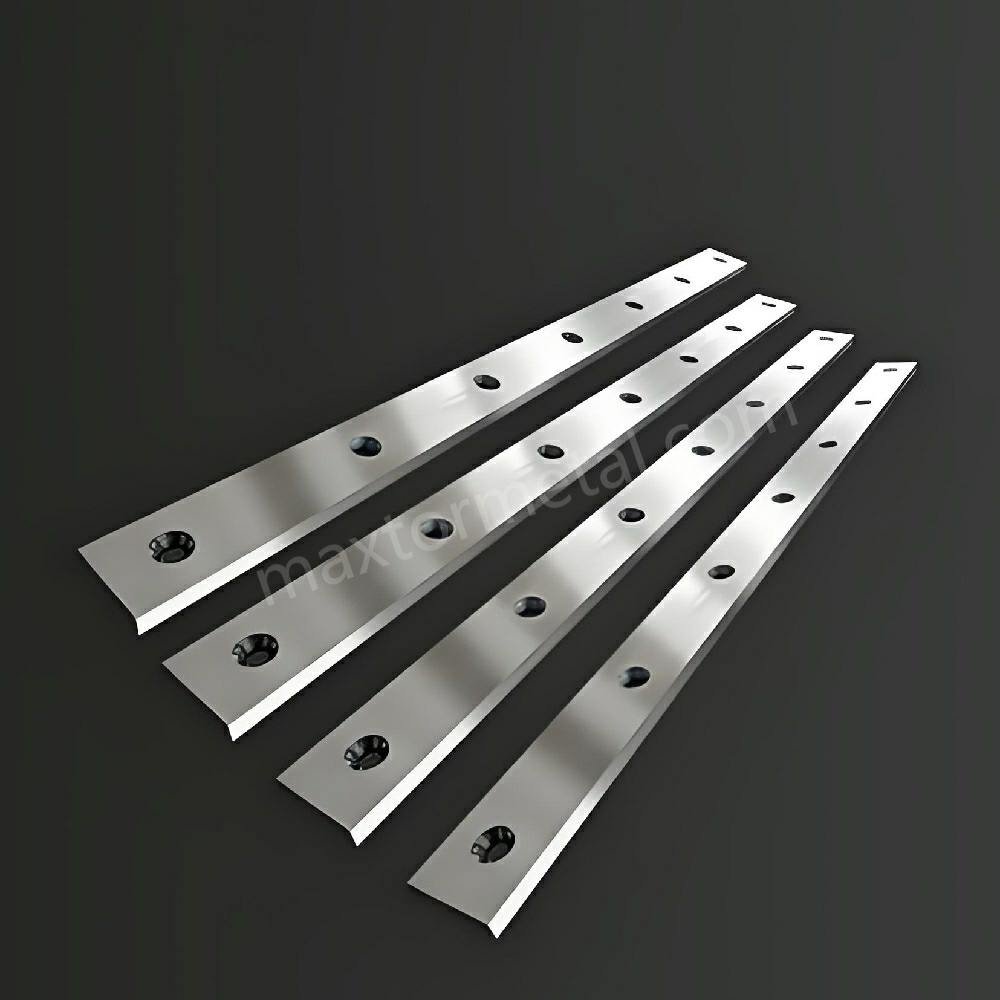

基本的な機能以上の機能を備えた切削工具が必要です。カスタムメイドの工業用せん断刃は、通常のものよりも強度と精度に優れています。既製品の刃では、その品質に匹敵するものはありません。カスタムメイドの刃は、特殊な刃先形状、優れた素材、そして熟練の職人技によって作られています。Metal Industrialの米国製切削工具は、カスタムメイドの刃先を採用することで、より長く鋭い切れ味を保ちます。カスタムメイドの刃は最大50%長持ちし、交換頻度も30%少なくなります。カスタムメイドのソリューションを選ぶことで、信頼できる工具を手に入れ、修理費用を削減できます。重要なポイント:カスタムメイドの工業用せん断刃と既製品の性能の違い 自分に合った工具が必要です。カスタムメイドの工業用せん断刃は[…]

ステンレス鋼用シャー刃の決定版ガイド:高品質な切断のための材料と形状

ステンレス鋼用のせん断ブレードを選ぶ際には、特別な問題に直面します。ステンレス鋼はすぐに硬化し、工具を摩耗させます。かじりや強度の高い金属は切断を困難にします。バリ、ブレードの摩耗、材料の曲がりが頻繁に発生することがあります。良質なブレード素材と正確な形状は、食い込みや裂傷を防ぎます。Metal Industrialは、きれいで安定した切断を実現するブレードを製造するための新しい方法を採用しています。重要なポイントステンレス鋼用せん断ブレード:主要な性能要因ステンレス鋼用のせん断ブレードを選ぶ際には、いくつかの点が非常に重要です。これらの点は、きれいな切断を実現するのに役立ちます。また、ブレードの寿命を延ばし、ダウンタイムを削減することにも役立ちます。では、最も重要な点を見ていきましょう。[…]

シャー刃のチッピング分析:トップ 5 の根本原因と予防・修復のための専門戦略

せん断ブレードの欠け解析は、ブレードの損傷原因を突き止めるのに役立ちます。また、油圧切断プロセスにおけるシステムの故障原因も明らかにします。ブレードは疲労したり、負荷がかかったりすると欠けてしまいます。これは時間と良好な切断面を失う原因となります。不適切なメンテナンスや油圧の問題による損傷は、作業の中断やコストの増加につながる可能性があります。ブレードの故障を防ぐには、問題を早期に点検し、解決する必要があります。良質なブレードは長持ちし、良好な切断面を維持し、コスト削減にもつながります。機械を頻繁に点検・修理することで、ストレスや疲労から守ることができます。油圧せん断機の問題を解決することで、ブレードの損傷を防ぐことができます。また、毎回良好な切断面を得ることにも役立ちます。重要なポイント:せん断ブレードの理解 […]

熱処理を超えて:深冷処理シャー刃で優れた長寿命を実現

硬い場所でもしっかりと機能し、長持ちする刃が欲しいですよね。極低温処理されたせん断刃は、通常の熱処理された刃よりも優れています。重要なポイント 極低温処理されたせん断刃:プロセスと原理 極低温処理とは 極低温処理は、せん断刃をより強く、長持ちさせる特別な方法です。まず、刃を高温に加熱します。これにより、刃内部の仕組みが変化します。次に、刃は室温まで冷却されます。その後、刃はさらにマイナス300度まで冷やされます。この極低温処理により、刃内部の鋼が変化し、刃はより硬く、より安定します。その後、刃は再び加熱されます […]

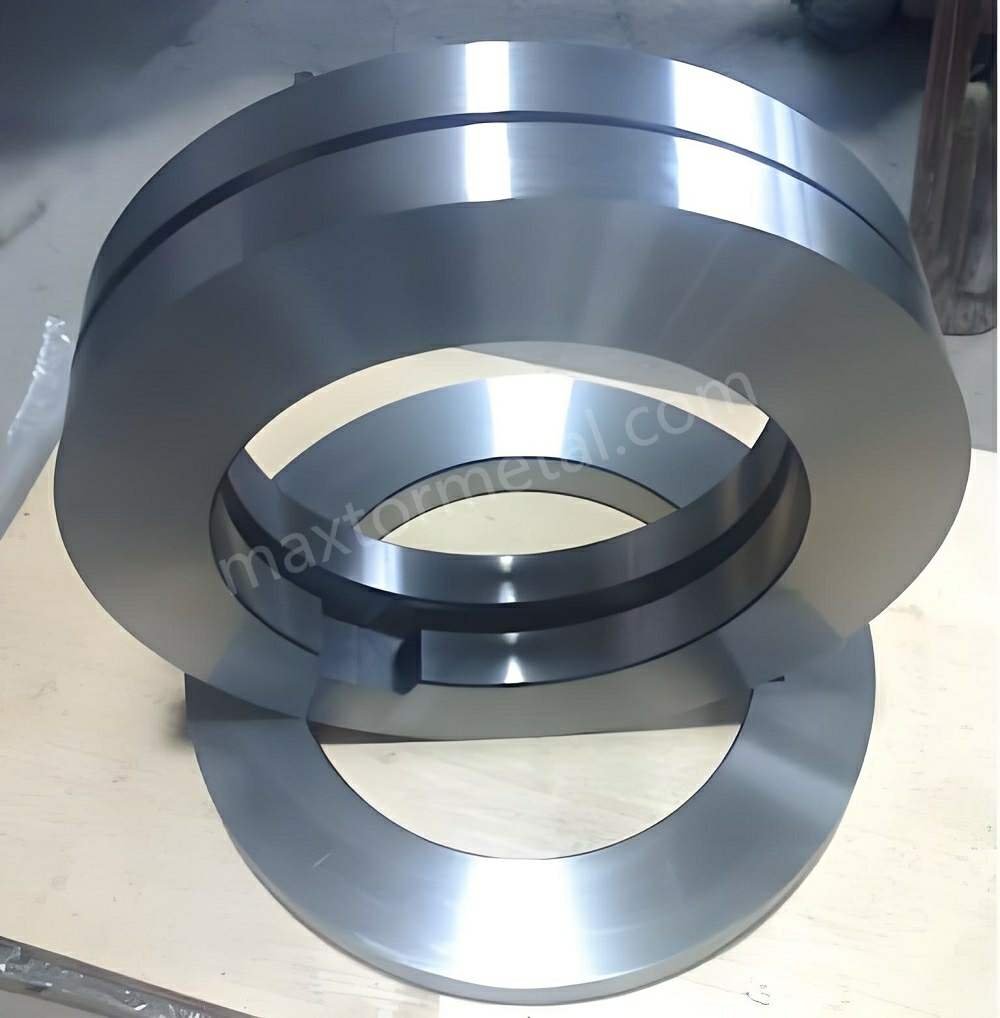

特殊棒材シャー刃:ビレット切断における精度達成と歪みの最小化

ビレットをきれいに切断するには、優れた工具が必要です。適切な形状と材質のバーシャーブレードは、きれいな切断を実現します。また、材料の無駄を減らすことにも役立ちます。材料に適したブレードサイズと刃先形状を選択すれば、より良い結果が得られ、ブレードの寿命も長くなります。多くの作業員は、鋼材の曲がり、時間のロス、表面の荒れなどの問題を抱えています。Metal Industrialの特殊ブレードは、特殊な熱処理と鍛造を施しています。これらのブレードは、これらの問題を解消し、作業を安全かつ迅速に進めます。重要なポイント バーシャーブレード:特殊設計 バーシャーブレードは金属の切断に不可欠です。良好な結果を得るには、適切なブレード設計が必要です。特殊 […]

OEM シャー刃 vs. アフターマーケットのオプション:どちらが最高の TCO (総所有コスト) を提供するか

仕事には最適な条件が求められます。純正のせん断ブレードを選ぶか、アフターマーケットのブレードを選ぶかは、お客様のニーズによって異なります。また、どの程度のリスクを許容できるかも重要です。仕事の重要度も重要です。総所有コスト(TCO)は、支払う価格以上の意味を持ちます。ブレードの耐用年数、保証、そして時間のロスも含まれます。良質なブレードは、修理の手間を減らし、作業をスピードアップさせます。TCOが作業効率に及ぼす影響について、簡単に見ていきましょう。側面 業務効率への影響 ブレードの品質 良質なブレードは、修理の手間を減らし、作業をスピードアップさせます。メンテナンス頻度 ブレードの交換頻度を減らすことで、コストを節約できます。切断精度 より優れた切断 […]

切断をマスターする:産業用剪断における**すくい角(シャー刃のベベル角)**の決定的な役割

すくい角は工業用せん断において非常に重要であることがお分かりいただけるでしょう。この角度によって、切断の質、作業速度、そして刃の寿命が左右されます。以下の表は、すくい角の違いがせん断力と切断品質にどのような影響を与えるかを示しています。すくい角の種類 せん断力への影響 切断品質への影響 正すくい角 せん断力が少なくて済む 切断面の見栄えが良くなる 負すくい角 せん断力が多くて済む 切断面の見栄えが悪くなる可能性がある すくい角を高くすると、刃先がよりきれいで滑らかになります。正すくい角は切断面の鋭さを保つので、切断面の見栄えが良くなります。負すくい角を使用すると […]

アップタイムを最大化:スクラップ金属および厚板加工に最適な重切削シャー刃の選び方

スクラップ金属や厚板を切断する際は、機械を長く稼働させたいものです。耐久性が高く、作業に適した鋼材を使用した高耐久性のせん断ブレードを選びましょう。切断する金属に合わせてブレードの材質を選びましょう。新しい製造方法やカスタムオプションを備えたせん断ブレードを見つけましょう。Metal Industrialはこれらの機能を提供します。メンテナンスなどの総コストを考慮して、作業効率を維持しましょう。重要なポイント 高耐久性せん断ブレード:稼働率における役割 高耐久性せん断ブレードとは? 高耐久性せん断ブレードは、鋼材やスクラップなどの硬いものの切断に役立ちます。これらのブレードは、強度の高い素材を使用し、特殊な熱処理が施されています。これにより、耐久性が高まります[…]

熱間シャー刃 vs. 冷間シャー刃:材料選択と温度限界の決定版ガイド

作業に適さないブレードを選んだと想像してみてください。ブレードはすぐに劣化してしまいます。なぜなら、材料と金属の熱を合わせていなかったからです。高温または低温の金属に適したブレードを知る必要があります。Metalは、高温または低温で切断すると特性が変わります。適切なブレードは、安全性と性能に大きな違いをもたらします。温度がブレードと切断する金属にどのような影響を与えるかを考慮する必要があります。高温の金属の場合は、非常に高温になっても強度を維持するブレードが必要です。低温の金属の場合は、すぐに欠けたり摩耗したりしないブレードが必要です。Metal Industrialは、熱処理と鍛造により[…]

工業用シャー刃の究極の購入ガイド:購入前の 7 つの品質チェック

You should look at seven important things before buying industrial shear blades. These things are blade material, application match, manufacturing tolerances, edge design, equipment compatibility, supplier reputation, and total cost. If you do not check these, your machine may stop working. You could face safety problems and spend more money. Use the Buying guide for Industrial shear blades to help you choose well. Good brands like Metal Industrial give you strong and good blades. Always use this checklist before you buy anything. Key Takeaways Why Quality Checks Matter in Industrial Shears Buying industrial shear blades is a big decision. Your choice can change how your whole team works. Each quality check in […]