精密ロータリースリッターブレード製造の芸術と科学

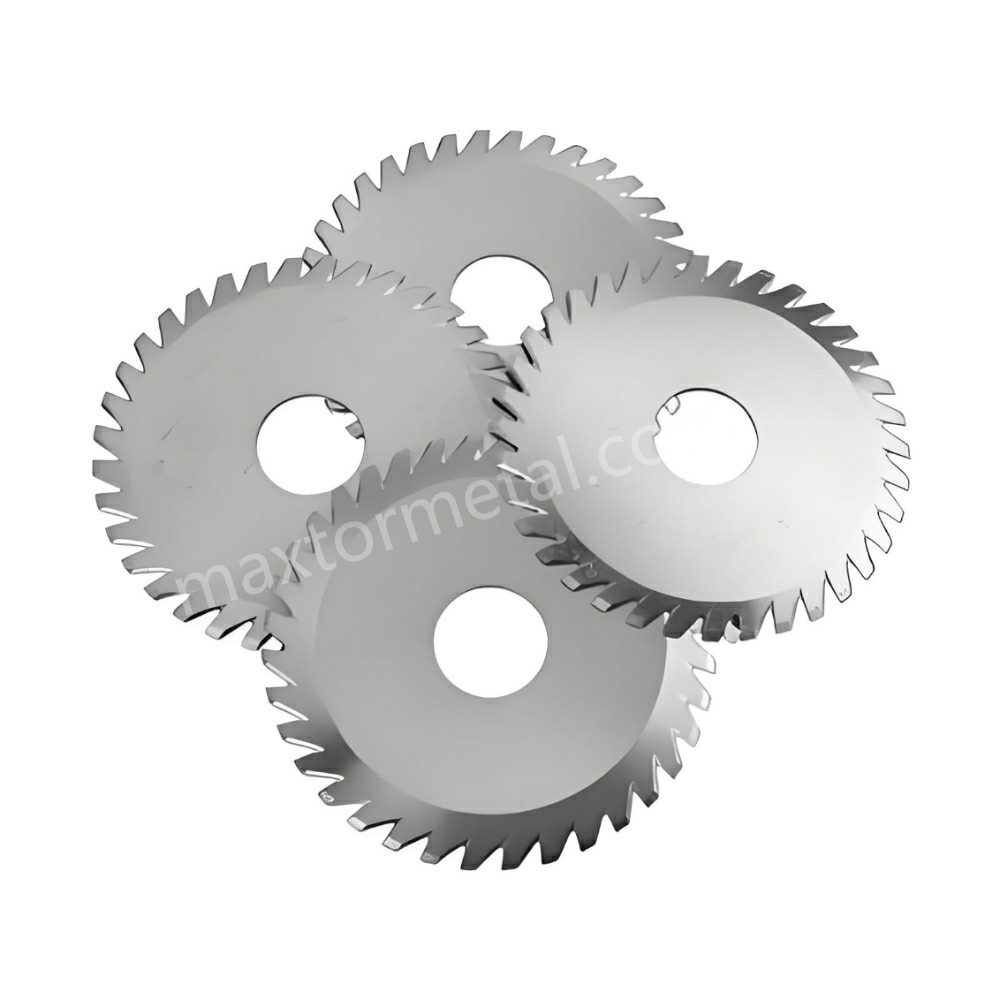

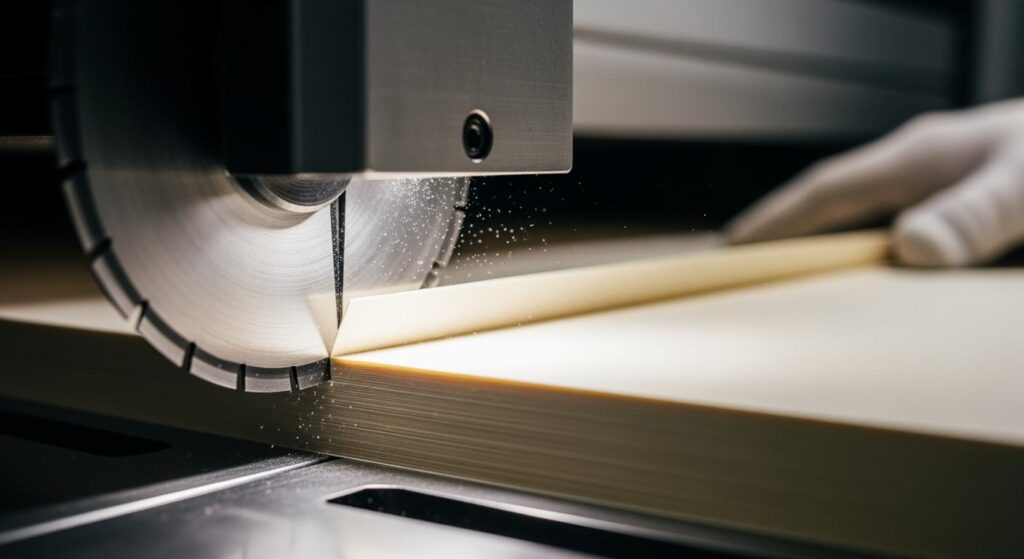

You work with rotary slitter blade manufacturing. This job needs both smart engineering and skilled hands. People want blades that cut very well and very accurately. This need helps the market grow around the world: Nanjing Metal Industrial makes very good blades. They use ISO-certified places to make them. They use many kinds of materials and sizes. This helps meet your specific needs. You may ask: Why is rotary slitter blade manufacturing special? How do you make sure the blades are always good and accurate? What problems and new ideas change your industry? Key Takeaways Rotary Slitter Blade Manufacturing Essentials What Are Circular Slitter Blades? Circular slitter blades cut big rolls into […]

高速テキスタイル切断に最適なロータリースリッターブレード

When you choose the best rotary slitter blades for textiles, you enhance the speed and quality of your cutting process. Poor-quality rotary slitter blades can lead to several issues, such as: Nanjing Metal Industrial offers a wide selection of rotary slitter blades for textiles, crafted from premium materials. You can select blades with specialized edges, exceptional durability, and tailored options to meet your specific requirements. Key Takeaways Key Features of the Best Rotary Slitter Blade Blade Materials for Textile Cutting Picking the right material for rotary slitter blades is important. Every material has its own benefits for different textile jobs. You should think about how the material changes blade life, sharpness, and […]

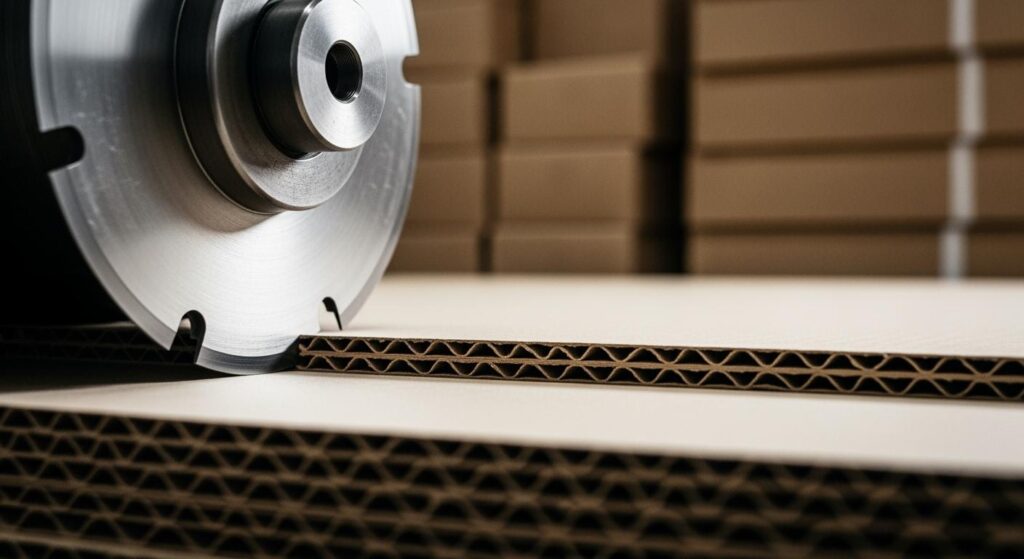

段ボール用ロータリースリッターブレードが完璧なパッケージングの鍵である理由

You want every box to look neat and strong, right? Picking the right rotary slitter blade for corrugated board is very important. Good blades help you make clean and exact cuts. This means you waste less material and have fewer mistakes. You also save time because these blades stop your machines from breaking down. Your machines work better and faster. If you choose the right blade type and material, you work more efficiently. Every package will look great. Key Takeaways Rotary Slitter Blades: Essential for Corrugated Board What Are Rotary Slitter Blades? Rotary slitter blades are used in many factories. These blades cut big rolls of corrugated board into smaller strips. You […]

カスタムロータリースリッターナイフがあなたのビジネスにとって賢明な投資である理由

Custom rotary slitter knives help you cut better. They last longer and work faster. When you pick a custom knife, it fits your business needs. You can get special sizes and strong materials. This helps you cut with less waste. Your machines can run more without stopping. These knives are used in many industries. Here are some examples: Industry Application Description Metal Processing Cutting coils and sheets with precision Packaging Making rolls and sheets from plastic and paper Food Processing Slicing and portioning products for efficiency Timber Processing Shaping and trimming veneer and plywood Textiles Used in fabric processing for different jobs Printing Used to make printed materials Buying custom rotary slitter […]

あなたの究極のチェックリスト:ロータリースリッターブレードの購入方法

When buying rotary slitter blades, you need to check every step to get the best results. Choosing the right blade prevents costly mistakes. Tooling issues, like using the wrong blade, cause about 25% of all manufacturing downtime. You can avoid this by using a careful checklist. You should always compare prices and look for trusted suppliers to protect your investment. Key Takeaways Buying Rotary Slitter Blades: Define Your Needs When you want to buy rotary slitter blades, you should know what you need first. This helps you pick the right blade and avoid problems. It also makes sure your equipment works well. Material Type Common Materials You need to know what […]

ロータリースリッターブレードのトラブルシューティングにおける最大の誤りとその修正方法

Rotary slitter blade troubleshooting mistakes can cause big problems. If you avoid these mistakes, your blades work better. This keeps workers safe and helps things run faster. You should watch blade selection, installation, and maintenance. Doing this gives you many good results: Read this guide for fast fixes and long-term help. Key Takeaways Rotary Slitter Blade Troubleshooting Basics Identifying Common Problems You use round slitter blades every day at work. These blades are very important in slitting machines. They help cut big rolls into smaller strips. Good blades from Nanjing Metal Industrial give you nice, clean cuts. But even the best blades can have problems, so rotary slitter blade troubleshooting matters. You might […]

刃の寿命を延ばす:ロータリースリッター刃の研磨完全ガイド

You want your blades to last a long time. You also want to keep costs low. Rotary slitter blade sharpening helps with both things. Using good slitting blades gives you clean cuts. It also makes machines run smoothly. Regular care and expert sharpening help every day. Look at how you care for your blades now. Even small changes can save money and make things better. Key Takeaways Why Rotary Slitter Blade Sharpening Matters Role in Industrial Cutting Slitting blades are used every day in factories. These blades cut big rolls into smaller strips. Sharp blades make clean and straight cuts. Rotary slitter blade sharpening keeps machines working well. When blades are sharp, […]

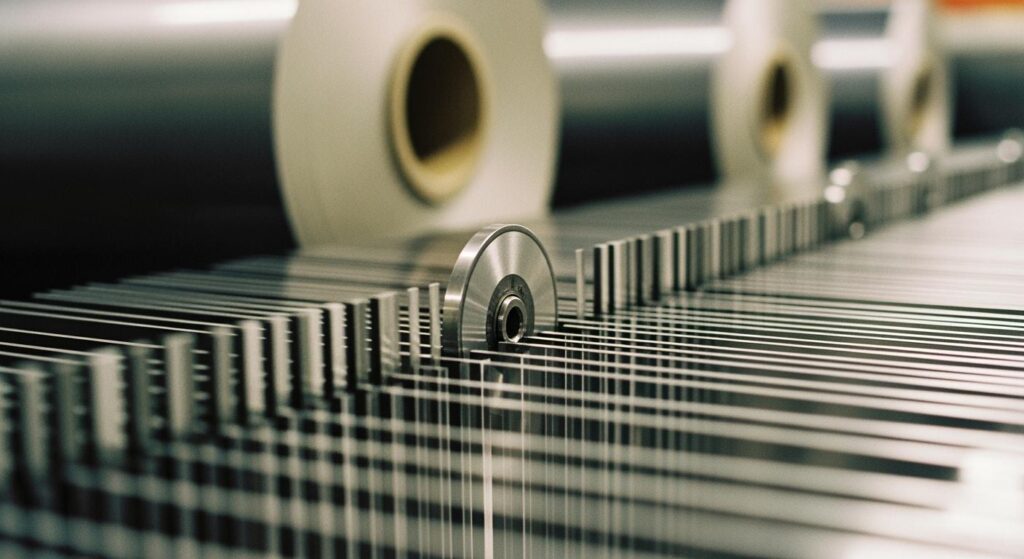

フィルムおよびフォイルスリッティング用の高精度ロータリースリッターブレード

You use high-precision rotary slitter blade for film to achieve smooth and clean edges. These rotary slitter blade for film are essential in your operations, helping you produce neat cuts and reduce errors. Blade quality is especially important for film makers and packaging companies. Nanjing Metal Industrial specializes in manufacturing rotary slitter blade for film that meet strict quality standards. They also offer custom rotary slitter blade for film tailored to your specific requirements. Key Takeaways What Is a Rotary Slitter Blade for Film A rotary slitter blade for film is a special cutting tool. You use it in slitting machines. These machines take big rolls of material and cut them into smaller […]

メタルスリッティングに最適なロータリースリッターブレード

When you pick a rotary slitter blade for metal, you get better accuracy and strength for your work. Nanjing Metal Industrial has rotary slitter blade for metal choices that keep their sharp edge and cut well. You need a rotary slitter blade for metal that fits your metal type, how fast you work, and what size you need. Steel service centers use rotary slitter blade for metal to save time and make cleaner cuts. You get rotary slitter blade for metal made for special jobs and checked for steady results. Key Takeaways Rotary Slitter Blade for Metal: Key Features When you pick a rotary slitter blade for metal, you should check some important […]

紙用ロータリースリッターブレードで完璧な切断を達成する方法

You need neat cuts when you work with paper in factories. The rotary slitter blade for paper is very important. It helps each sheet look neat and nice. The blade you pick, how you set up the machine, and how you care for your tools all matter. Watching these things helps you get the best cuts every time. Key Takeaways Blade Selection for Rotary Slitter Blade for Paper Picking the right rotary slitter blade for paper is the first thing you should do for neat cuts. You have to think about what the blade is made of, what kind of blade it is, and what kind of paper you want to cut. Nanjing […]