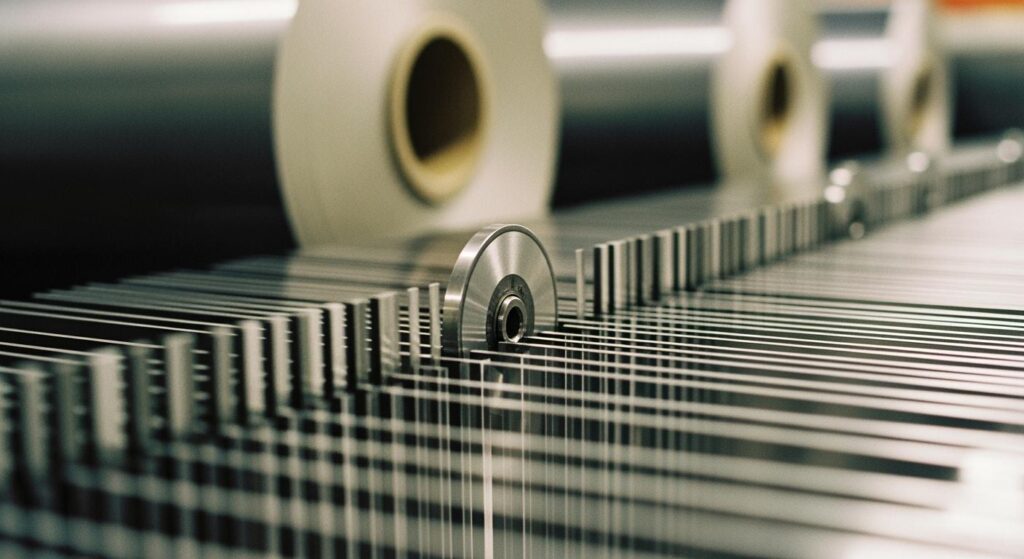

フィルムおよびフォイルスリッティング用の高精度ロータリースリッターブレード

You use high-precision rotary slitter blade for film to achieve smooth and clean edges. These rotary slitter blade for film are essential in your operations, helping you produce neat cuts and reduce errors. Blade quality is especially important for film makers and packaging companies. Nanjing Metal Industrial specializes in manufacturing rotary slitter blade for film that meet strict quality standards. They also offer custom rotary slitter blade for film tailored to your specific requirements. Key Takeaways What Is a Rotary Slitter Blade for Film A rotary slitter blade for film is a special cutting tool. You use it in slitting machines. These machines take big rolls of material and cut them into smaller […]

メタルスリッティングに最適なロータリースリッターブレード

When you pick a rotary slitter blade for metal, you get better accuracy and strength for your work. Nanjing Metal Industrial has rotary slitter blade for metal choices that keep their sharp edge and cut well. You need a rotary slitter blade for metal that fits your metal type, how fast you work, and what size you need. Steel service centers use rotary slitter blade for metal to save time and make cleaner cuts. You get rotary slitter blade for metal made for special jobs and checked for steady results. Key Takeaways Rotary Slitter Blade for Metal: Key Features When you pick a rotary slitter blade for metal, you should check some important […]

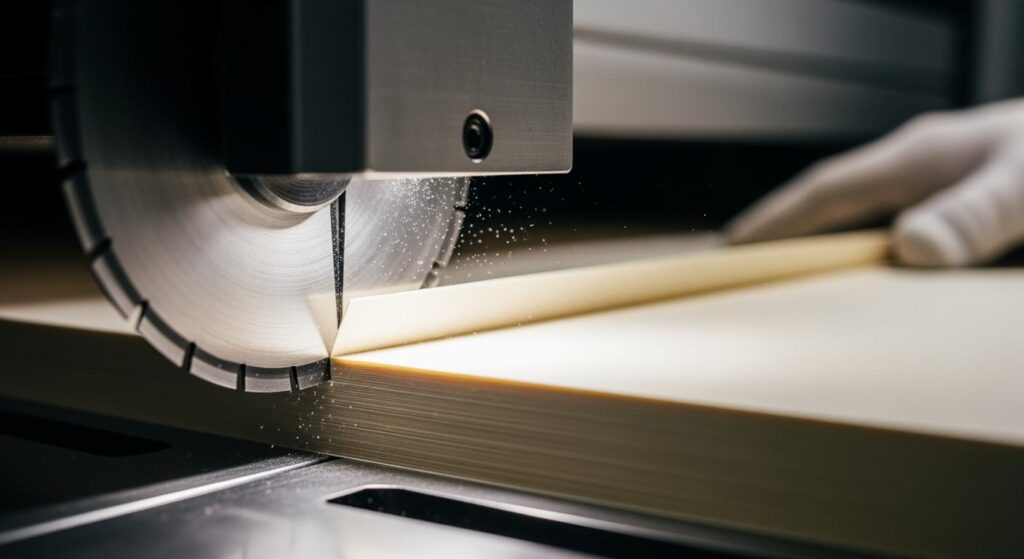

紙用ロータリースリッターブレードで完璧な切断を達成する方法

You need neat cuts when you work with paper in factories. The rotary slitter blade for paper is very important. It helps each sheet look neat and nice. The blade you pick, how you set up the machine, and how you care for your tools all matter. Watching these things helps you get the best cuts every time. Key Takeaways Blade Selection for Rotary Slitter Blade for Paper Picking the right rotary slitter blade for paper is the first thing you should do for neat cuts. You have to think about what the blade is made of, what kind of blade it is, and what kind of paper you want to cut. Nanjing […]

シアースリッティング vs. クラッシュスリッティング:あなたに適した切断方法は?

When you look at shear vs. crush slitting, you see distinct differences. Shear slitting is best for thin and delicate materials, providing clean and precise cuts. On the other hand, crush slitting works better for thick, soft, or fibrous materials. Choosing the right cutting method is crucial for achieving optimal results, as it depends on your material and what you need to produce. Nanjing Metal Industrial offers exceptional slitter blades tailored for your specific needs. As you consider your options, think about what is most important to you: cost, cut quality, material, or your industry? Key Takeaways Shear vs. Crush Slitting Overview Shear Slitting Shear slitting gives you clean and exact cuts. It […]

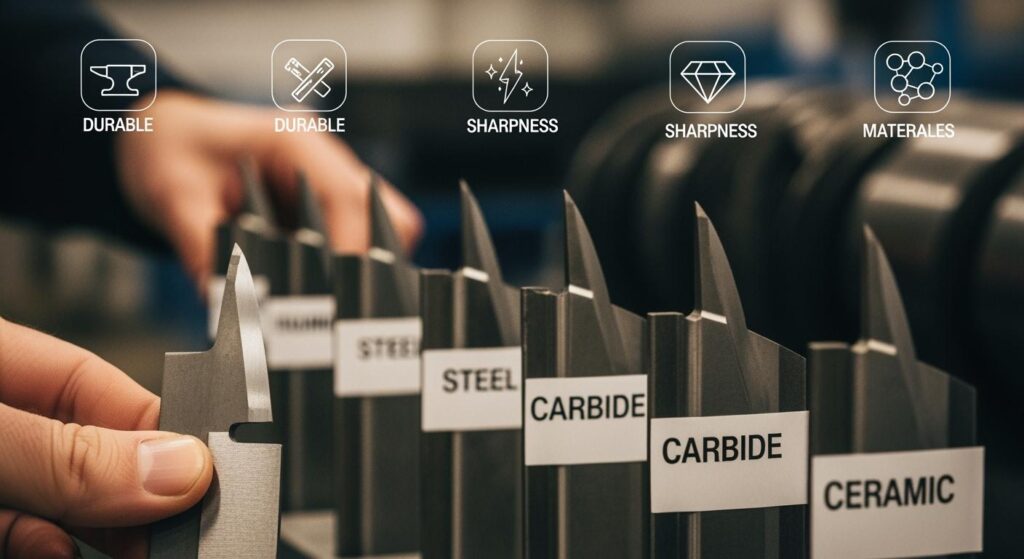

ロータリースリッターブレード材料選択の決定版ガイド

Choosing the right rotary slitter blade material helps you get cleaner cuts and work faster. You must pick a blade material that fits your substrate and process. This choice changes how often you need to fix things and how much money you use. Key Takeaways Key Factors Slitting Process You should know how slitting works before picking a blade. Different ways of slitting work better for certain materials and speeds. Here are some slitting methods you might use: You can look at how slitting methods are different: Slitting Technique Description Blade Requirements Conventional Slitting Uses round blades to slice coils into strips. Sharp round blades for many steel types. High-Speed Slitting Uses […]

リサイクルにおけるテキスタイルシュレッダーブレードの役割

Textile shredder blades are very important in recycling. They cut waste textiles into small pieces. This helps people get fibers back from old clothes. Using these blades helps keep trash out of landfills. It also helps make new things from old textiles. Did you know less than 0.5% of all textile waste is recycled? Most old textiles go to landfills or are burned. Textile shredder blades help recycling plants work with mixed fabrics. They help get useful fibers from these fabrics. Function Benefit Adaptability Handles different fibers High-capacity processing Works with large volumes Energy efficiency Saves power Robust construction Operates all the time Key Takeaways Textile shredder blades in recycling Breaking down […]

シュレッダーブレードの寿命を延ばすための予防保全計画

You want your industrial shredder blades to last a long time, right? That is why you need preventative maintenance for shredder blades. Regular inspection, cleaning, and lubrication help you save money. These steps also help you avoid stopping work and keep your machines working well. When you use high-quality blades, like those from Nanjing Metal Industrial, you get even more good results. Being proactive keeps your shredding operation strong and dependable. Key Takeaways Preventative Maintenance for Shredder Blades You want your industrial shredder blades to work well every day. Taking care of shredder blades helps you reach this goal. When you follow good maintenance steps, your machines run better. You also avoid […]

シュレッダーブレードメーカーを選ぶ前に尋ねるべき 10 の質問

When you pick a shredder blade manufacturer, you want someone you can trust. They should have a good name for making strong and reliable products. Companies like Nanjing Metal Industrial are good examples in this field. You should check if their products work with your machines. See if they can make special options just for you. Also, find out how much help they give to customers. Use these tips to help you choose the best company for your needs. Key Takeaways Manufacturer Reputation Picking a shredder blade manufacturer with a good reputation helps you avoid trouble. You want to get products that work well and last long. It is smart to choose companies […]

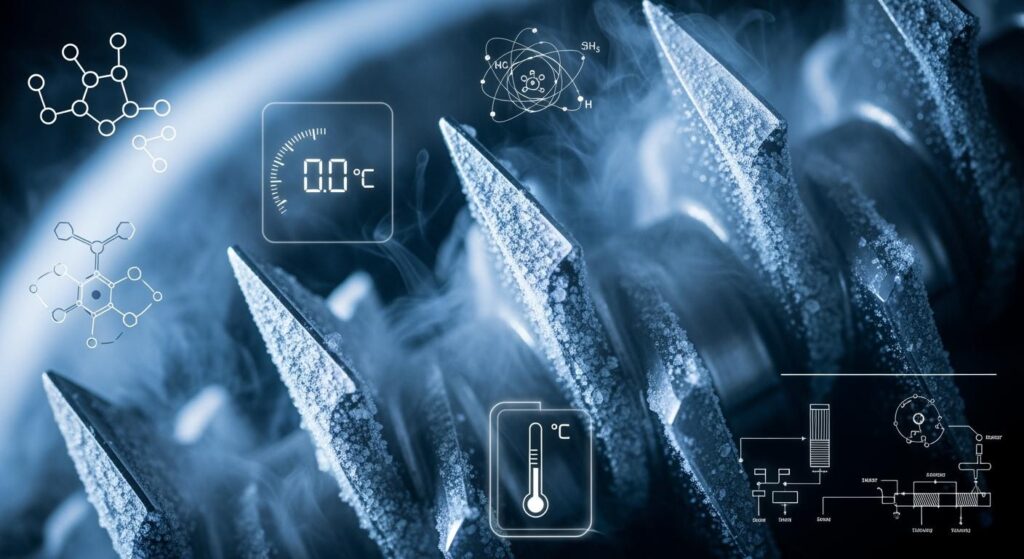

極低温処理されたシュレッダーブレードの背後にある科学

産業用シュレッダーは毎日過酷な作業を行っています。作業員は、刃がすぐに鈍くなったり、簡単に破損したりする問題にしばしば直面します。これは、高額な停止費用と何度も刃の交換を必要とします。極低温処理された刃は、この問題を解決します。これらの刃は長持ちし、通常の刃ほど摩耗しません。Nanjing Metal Industrialは、重作業に耐える強固な刃の製造で知られています。重要なポイント 極低温処理の概要 極低温処理された刃とは 極低温処理された刃は、非常に低温の処理を受けます。この処理では、極低温を利用して金属を変化させます。刃は極低温チャンバーに入れられ、-185℃以下に冷却されます。冷気が金属の奥深くまで浸透し、[…]

当社のプラスチック用グラニュレーターブレードによる精度と効率

You need to be accurate and fast when working with plastics. Granulator blades for plastic help make even pieces for recycling and molding. Good blades, smart designs, and regular care help you do your best. The table below shows how taking care of blades and using new designs helps you every day. What You Do Why It Matters Keep blades sharp and clean Even granulate size Use modern blade designs Less stopping, better work speed Keep granule size the same Easy to feed and mix Key Takeaways Granulator Blades for Plastic Granulator blades for plastic are very important in recycling and injection molding. These blades cut plastic waste into small, even pieces. This step […]