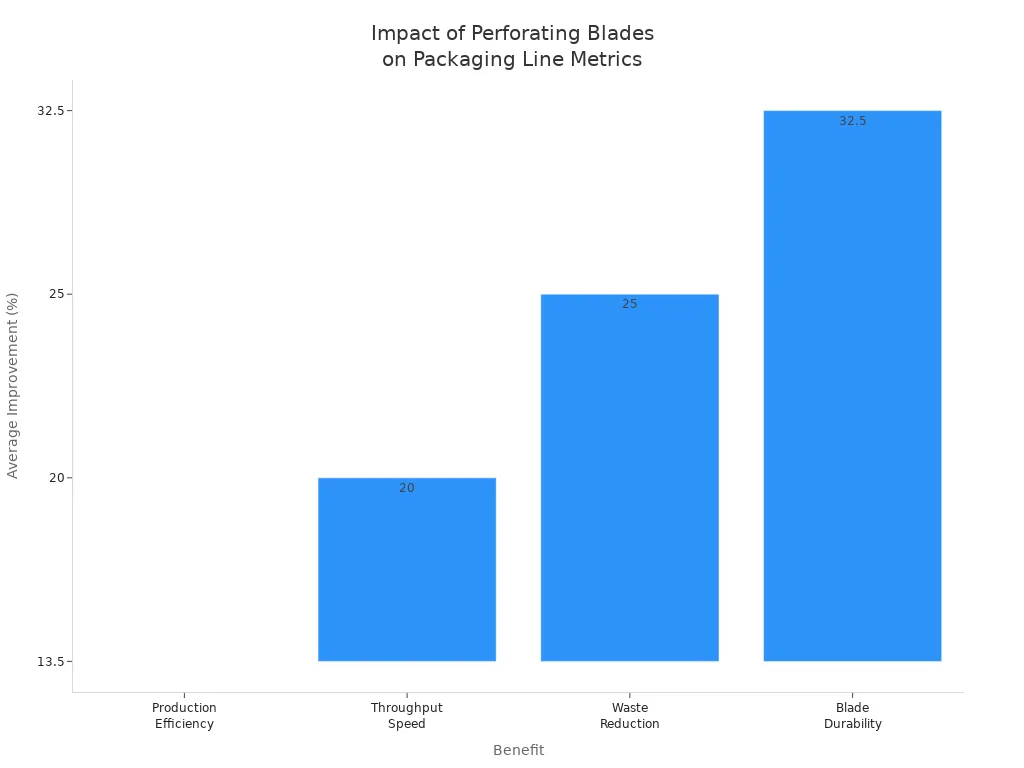

選ぶ際には重要な選択があります パッケージング用ミシン目ブレード2022年の調査では、 68%の包装ラインの問題 間違った刃を選ぶと、作業効率が悪くなることがあります。材料とニーズに合った適切な刃を選ぶことで、作業が速くなり、製品の品質が向上します。刃の選択は、速度、廃棄物、そして修理費用に影響します。下の表は、高度な穿孔刃がどのようにより良い結果をもたらすかを示しています。

| 利点 | 影響の説明 |

|---|---|

| 生産効率 | 高度な穿孔ブレードにより、ライン作業 12-15% が毎年向上します。 |

| スループット速度 | 最高のブレードを使用すると、ラインの実行速度を最大 20% まで高速化できます。 |

| 廃棄物の削減 | これらのブレードにより、梱包廃棄物が 20 ~ 30% 削減され、コストが節約され、地球環境にも貢献します。 |

| ブレードの耐久性 | TiN や DLC などのコーティングにより、ブレードの寿命が長くなるため、作業の中断が減り、ブレードの購入回数も減ります。 |

| 製品の品質 | 優れたミシン目により、切り取りシート、ラベル、シールに必要なきれいな切り取り線が作成できます。 |

| カスタマイズ | お客様のニーズに合わせて作られた特別なブレードにより、ラインの速度が上がり、製品の品質が向上します。 |

専門家に相談し、信頼できるサプライヤーと協力することで、高額なミスや遅延を防ぐことができます。 マックストア Metal。 穴あけナイフに関するこの概要は、賢い選択がいかに重要であるかを理解するのに役立ちます。

重要なポイント

- 包装材に合った穿孔刃を選びましょう。これにより、きれいな切断面が得られ、廃棄物を削減できます。 – タングステンカーバイドや高速度鋼などの刃材を選びましょう。これらは耐久性が高く、生産速度も速くなります。 – サンプルの刃を実際の包装材で試してみましょう。これにより、最適な切断品質と破裂強度を見つけることができます。 – 信頼できるサプライヤーや専門家に相談し、アドバイスやカスタム刃の選定を依頼しましょう。必要なときにサポートを受けることもできます。 – 刃は大切に扱い、頻繁に点検しましょう。これにより、包装ラインの稼働率を維持し、コストを削減できます。

包装用穿孔刃:重要な要素

材料の適合性

ミシン目カッターを選ぶ際は、何を切るかを考えましょう。包装材の種類によって、適切なカッターの種類が異なります。適切なカッターを使用しないと、切り口が粗くなったり、切り口が悪くなったりすることがあります。製品を傷つけてしまう可能性もあります。包装材には様々な種類がありますが、一般的なものは以下のとおりです。

- プラスチック:軽くて曲がりやすいので、フィルムを溶かしたり引っ張ったりすることなくきれいに切れる刃が必要です。

- ガラス:ガラスは強度があり、物と反応しません。欠けたり割れたりしない刃を使用してください。

- Metal: Metal には、鋭い切れ味を保ち、すぐに摩耗しないブレードが必要です。

- 生分解性素材: 刃先が破れたりほつれたりしない刃が必要です。

- ラミネート:ラミネートには層があります。すべての層を切断し、線をまっすぐに保つ刃が必要です。

ゴム、粘着性のあるもの、高耐熱プラスチックなど、特殊な素材を扱う場合もあります。これらの素材には、特殊なコーティングや形状の刃が必要です。素材に合った刃を選ぶことで、よりきれいに切れ、トラブルも少なくなります。

ヒント:刃を選ぶ前に、パッケージが熱や化学物質にどう反応するかを必ず確認してください。そうすることで、損傷や悪影響を防ぐことができます。

ブレードの材質と耐久性

適切なナイフ素材を選ぶことで、穿孔刃の性能が向上します。Maxtor Metalは、工具鋼、高速度鋼(HSS)、ステンレス鋼、タングステンカーバイドなどの高強度素材を使用しています。素材によって耐久性や強度が異なります。

| ブレード材質 | 耐久性と寿命特性 | 代表的な用途と注意事項 |

|---|---|---|

| 工具鋼 | 硬くて丈夫ですが、長持ちしません。安価で、研ぎやすいですが、他のものほど強くありません。 | 包装、紙、プラスチックに使用されます。お金を節約したい場合や、長期間使用する必要がない場合に適しています。 |

| 高速度鋼(HSS) | 工具鋼よりも長持ちし、耐熱性に優れており、高速切断に適しており、研ぎやすいです。 | 紙やフィルムに使用され、価格、強度、手入れのしやすさのバランスが取れています。 |

| タングステンカーバイド | 最も硬く、最も長持ちします。鋭い刃先を保ち、熱にも強く、厳しい作業に最適です。 | 重い梱包、ゴム、硬いものに最適です。コストは高くなりますが、長期的には節約になります。落とすと壊れることがあります。 |

| ステンレス鋼 | 中程度の持続時間があり、錆びないので、清潔に保つ必要がある場所に適しています。 | 食品、医療、清潔な包装に使用され、洗浄が容易で、中程度の期間持続します。 |

刃の持ちが良く、研ぎ直しの手間が少ない刃をお探しなら、HSSまたはタングステンカーバイドをお選びください。ステンレス鋼は錆びないので、食品や医療品の包装に適しています。コストを抑えたい場合や、耐久性を必要としない場合は、工具鋼が最適です。適切なナイフの素材を選ぶことで、刃を止めずに、より滑らかな切れ味を実現できます。

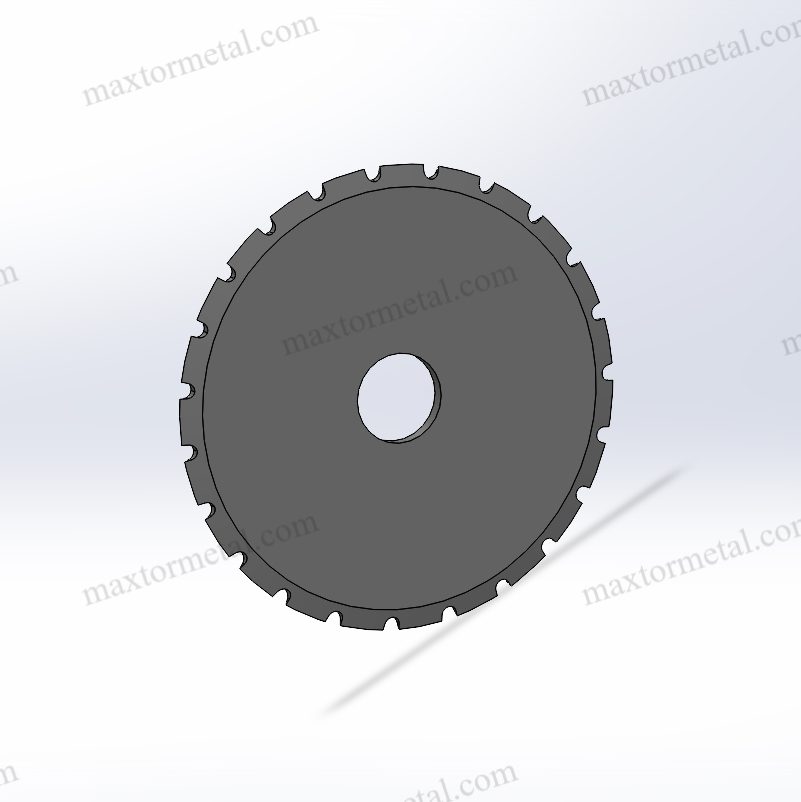

生産速度と量

作業速度は使用する刃によって変わります。ラインが速い場合は、摩耗しにくい刃が必要です。回転式ミシン目入れ刃は、ラインが速く、ロールが長い場合に最適です。これらの刃は材料への負担が少なく、作業速度が向上します。

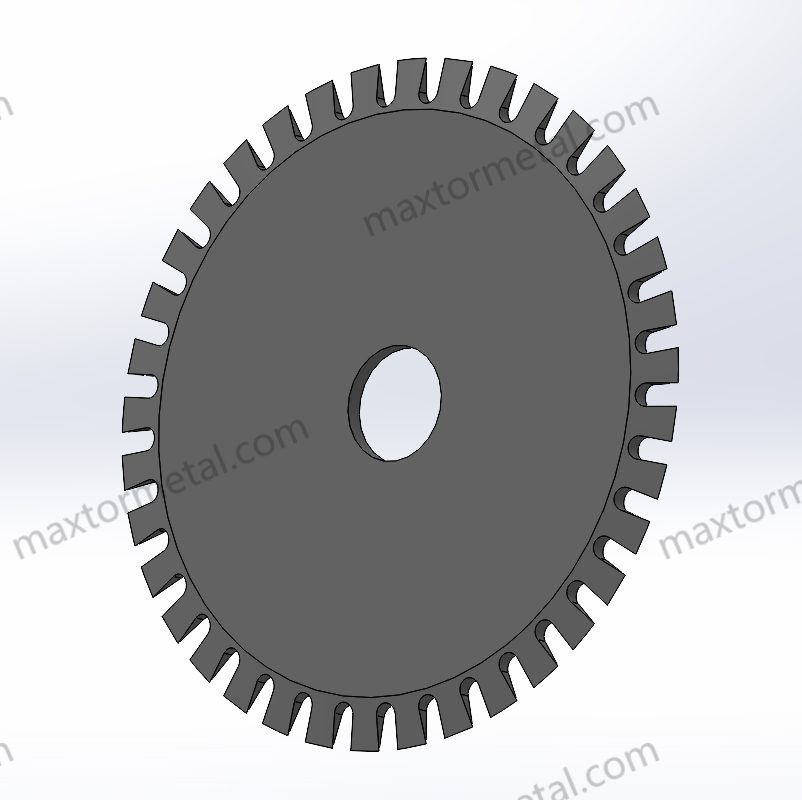

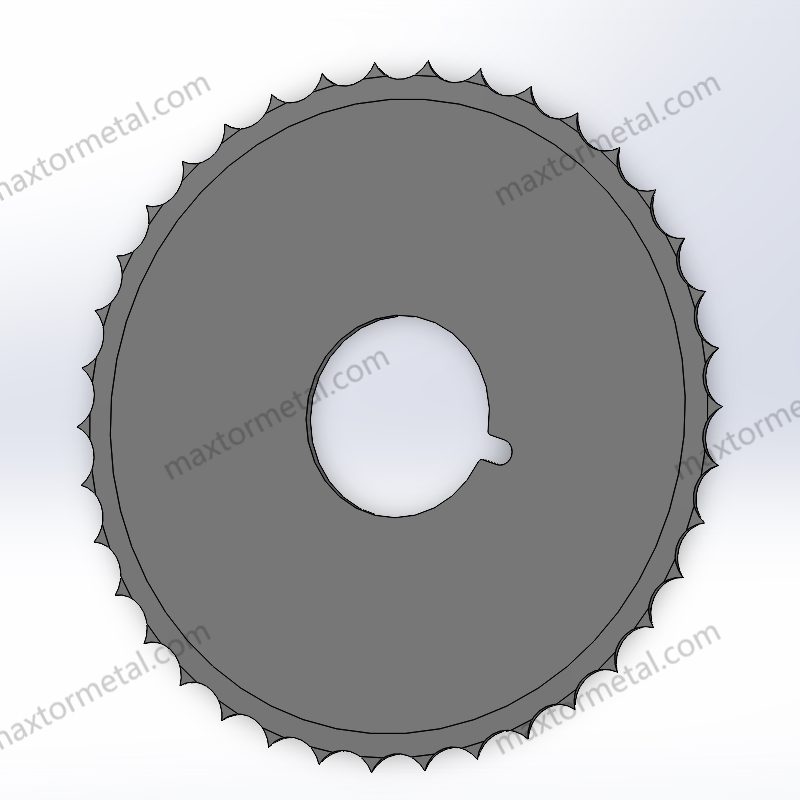

- 丸い穴あき刃は、素早く大きな作業に最適です。切れ味も良く、長持ちします。

- 直刃はまっすぐな切れ味を実現。完璧なラインを描きたいときにお使いください。

- タングステンカーバイドとHSSブレードは、大きな作業に最適です。熱や摩耗に強いので、作業の中断が少なくなります。

作業に適したブレードを選べば、より良い仕上がりと作業停止回数の削減が実現します。また、廃棄物を減らし、製品の処理速度を速めることでコスト削減にもつながります。

穿孔パターンと強度

ミシン目刃のパターンと破裂強度によって、製品の性能は大きく変わります。破裂強度とは、線に沿って破裂させるのに必要な力のことです。開封しやすいパッケージが必要な場合は、破裂強度を低くする必要があります。一方、しっかりと密封したい場合は、破裂強度を高くする必要があります。

歯の形状、結束と切断の比率、間隔を変えることで、パターンを変更できます。例:

- 細かい歯のパターンにより、きれいな引き裂きと低い破裂強度が得られます。

- 幅広の歯のパターンによりパッケージが強化され、必要な時まで閉じた状態を保ちます。

- 結束材と切断材の比率は、切断と切断の間にどれだけの材料が残るかを示します。結束材が多いほど、パッケージはより強力になります。

様々なパターンをテストすることで、開けやすさと強力な保護力の最適な組み合わせを見つけることができます。Maxtor Metalは、適切な破裂強度と切断品質を実現するためのカスタムブレードを製作できます。

注:必ず実際の包装材で穿孔刃のテストを行ってください。これにより、破裂強度を確認し、製品の性能が十分であるかどうかを確認できます。

穿孔刃の種類

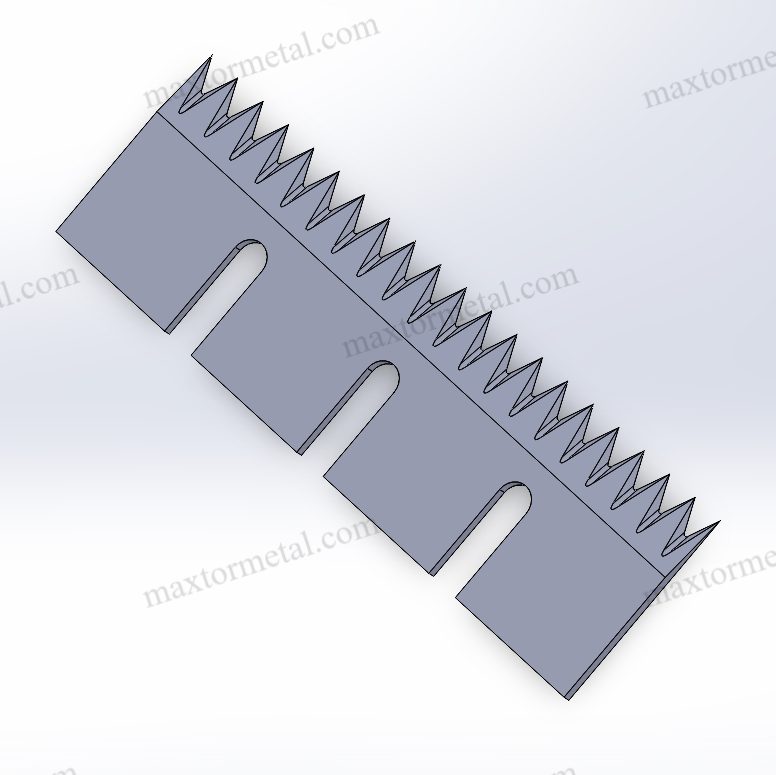

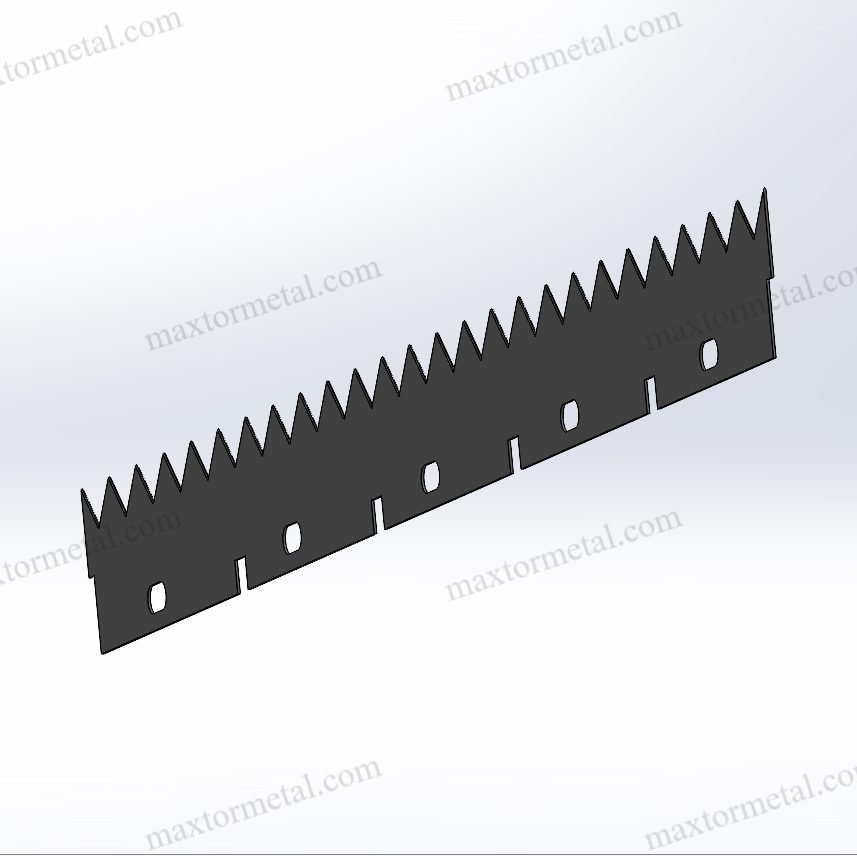

ストレートブレードとロータリーブレード

適切な材料

紙、プラスチックフィルム、ラミネート、軽金属には、ストレート刃とロータリー刃を使用できます。これらの刃は、平らなシートやロールに適しています。

代表的な用途

ストレート刃は、食品ラップ、フレキシブル包装、ティアオフストリップ、ラベルなどに使用されます。ロータリー刃は、高速包装ラインやノンストップカットが必要な作業に適しています。

主な利点と欠点

| ブレードタイプ | 利点 | デメリット |

|---|---|---|

| ストレート・ブレード | きれいにまっすぐに切る。正確 | 直線のみカット |

| ロータリーブレード | 早く切れて長持ち | 時々特別な機械が必要になる |

ストレート刃はきれいな線を描き、切れ味をコントロールするのに役立ちます。ロータリー刃は大きな作業に最適で、線を素早く動かすことができます。

構造上の特徴

直刃は刃先がまっすぐで、まっすぐな切断が可能です。回転刃は円形で、軸の上で回転し、ノンストップで切断できます。

選択のヒント

- 平らな材料をまっすぐに切る場合は、直線刃を使用します。

- 高速でノンストップの作業には回転刃を選択してください。

- 刃のサンプルを試してみて、どれくらい簡単に切れるか、どれくらいきれいに切れるかを確認します。

- Maxtor Metalに問い合わせる ブレードのコーティングと材料に関するヘルプ。

業界の事例

あるスナック菓子会社はチタンコーティングされた回転刃を使い始めました。彼らは刃を交換しました 35% 削減し、20% 増加した製品別の工場ではタングステンカーバイドの回転刃を使用し、毎年$15,000を節約しました。

歯付き刃と円形刃

適切な材料

歯付き刃と円形刃は、紙、フィルム、箔、繊維、不織布に使用できます。

代表的な用途

これらのブレードは、ミシン目付きラベル、切り取りチケット、包装フィルム、繊維ロールなどに使用されます。

主な利点と欠点

| ブレードタイプ | 利点 | デメリット |

|---|---|---|

| 歯付きブレード | さまざまなパターン。歯は変化する可能性がある | より粗いエッジを残すことができます |

| 円形ブレード | 作業が速く、カスタマイズ可能 | 正しく設定する必要がある |

歯付き刃は、切り裂きやすさをコントロールできます。円形刃は、ロールツーロール作業や素早い作業に適しています。

構造上の特徴

歯付き刃は、様々な模様を描くためにギザギザの刃先を持っています。円形刃は丸く、歯付きまたは滑らかな刃先を持っています。

選択のヒント

- 希望する裂傷に適した歯のサイズとスペースを選択します。

- 連続した穿孔には円形の歯付き刃を使用します。

- サンプルをテストして、梱包規則を満たしていることを確認します。

- 特殊なブレード形状に対応します。

業界の事例

ラベル工場ではマイクロ歯刃を採用し、ダウンタイムを28%削減しました。繊維工場では、切り離し性能の向上と廃棄物の削減のため、円形刃を使用しています。

カスタムおよび特殊オプション

適切な材料

カスタムブレードは、特殊フィルム、多層ラミネート、その他の扱いにくい梱包材向けに作られています。

代表的な用途

カスタムブレードは、医療用パッケージ、セキュリティラベル、特殊な切り取りデザインに使用されます。

主な利点と欠点

| 特徴 | 利点 | デメリット |

|---|---|---|

| カスタムブレード | あなたのニーズに合わせて作られ、難しい仕事を解決します | コストが高く、入手に時間がかかる |

カスタムブレードを使用すると、製品の切り口や外観を一致させることができます。

構造上の特徴

カスタムブレードには、独自の作業に適した特別な形状、歯のパターン、コーティングが施されています。

選択のヒント

- Maxtor Metalにご相談ください カスタムブレード サンプル。

- ブレードをテストして、パッケージとルールに適合していることを確認します。

- 不正開封防止パッケージや通気性パッケージには、専用のブレードを使用してください。

業界の事例

ある箱工場では、カスタムのマイクロ歯ブレードを使用することで、ダウンタイムを 14 時間から 5 時間に短縮しました。食品会社は、不正開封防止シールや簡単に開けられるパッケージに特殊なブレードを使用しています。

ヒント: 穿孔ナイフ ガイドを参照して、パッケージング ラインに最適なブレードを選択してください。

アプリケーションに適したパフォーマンスの選択

包装ニーズの評価

梱包材の種類を識別する

まず、包装に使用している素材を確認しましょう。フィルム、紙、ゴム、金属など、それぞれの素材には専用の刃が必要です。薄いプラスチックフィルムには、端が溶けずにきれいに切れる刃が必要です。厚いゴムや金属には、厳しい作業に耐えられる強力な刃が必要です。素材に合った刃を選ぶことで、破裂強度や引裂強度が向上します。これにより、端が荒れたり、製品が無駄になったりすることを防ぐことができます。

製品保護要件を決定する

製品にどの程度の保護が必要か考えてみてください。パッケージによっては、お客様が開封するまで密封状態を維持する必要があります。また、簡単に開けられることも必要です。強力な密封が必要な場合は、破裂強度の高いブレードを選びましょう。簡単に開けられるパッケージには、破裂強度の低いブレードを選びましょう。保護と開けやすさのバランスを取ることが重要です。適切なブレードは、製品を安全に保ち、お客様が簡単に開けられるようにします。

パッケージデザインと機能性を考慮する

パッケージデザインをよく考え、何が必要か考えてみましょう。パッケージの切り口はまっすぐに切るべきですか、それとも特殊な形状にする必要がありますか?ミシン目のあるストリップにしますか、それともカスタムパターンにしますか?デザインに合ったブレードを選ぶ必要があります。回転式ブレードは長く直線的な線を描きます。歯付きブレードは様々なパターンを描きます。カスタムブレードは特殊な形状や特徴を作り出すのに役立ちます。優れたデザインは、製品を際立たせ、より効果的に機能させます。

規制と業界標準を評価する

業界の包装に関する規則に従う必要があります。食品や医薬品など、一部の製品では、錆びたり鋭利な刃先を残したりしない刃が必要です。破裂強度や切断品質に関する規則を満たす必要がある場合もあります。刃を選ぶ前に、必ず規則を確認してください。規格に従うことで、製品の安全性が確保され、品質検査に合格しやすくなります。

段階的な選考プロセス

業界の専門家は、適切な穿孔刃を選ぶための明確な手順を推奨しています。以下の手順で賢く選んでください。

- フィルム、布、ゴム、金属など、切断する必要がある材料を確認します。

- 滑らかなカット、鋸歯状のカット、または穴あきのカットのいずれにするかを決めます。

- ブレードが何をしなければならないかを知るために、材料の厚さと密度を測定します。

- スリッター、クラッシュカット、鋸歯状、ロータリーなど、作業に適したブレードタイプを選択します。

- ラインの稼働速度と、許容できるダウンタイムの長さを考慮してください。速度と耐久性のバランスが取れたブレードの素材と設計をお選びください。

- 刃がマシンに合っていることを確認してください。サイズ、形状、刃先を確認してください。

- サンプルブレードを実際の素材でテストし、切れ味と破裂強度を確認してください。

- テスト後に、圧力、速度、位置合わせなどのナイフの設定を変更します。

- ブレードサプライヤーまたは専門家にアドバイスやカスタムヘルプを依頼してください。

- 刃の使い心地をじっくり観察しましょう。切れ味を良く保ち、修理の手間を減らすために、小さな調整を積み重ねましょう。

ヒント:本番生産の前に必ずサンプルブレードをテストしてください。これにより、パッケージに最適な破裂強度と切断品質を見つけることができます。

コンサルティング専門家とサプライヤー

技術コンサルタントによる指導を受ける

ブレードとパッケージングに精通した技術コンサルタントがサポートいたします。お客様の素材やデザインに最適なブレードの選定をお手伝いいたします。難しい作業の場合は、カスタムソリューションもご提案いたします。的確なアドバイスは時間とコストの節約につながります。

サプライヤーの経験を活用

サプライヤーは穿孔刃の豊富な経験を有しています。お客様のニーズに合わせて刃の材質や形状を選定する方法を熟知しています。作業に最適なナイフの材質選びについて、サプライヤーにご相談ください。刃のサイズや刃先の選択ミスといったミスを防ぐお手伝いをいたします。

カスタマイズとプロトタイピングのオプションを調べる

特殊なブレードが必要な場合は、サプライヤーと協力してカスタムオプションの設計とテストを行うことができます。サプライヤーは迅速な試作と技術チェックを提供します。テスト用に小ロットを注文することもできます。これにより、新しいデザインを試用し、パッケージに最適な破裂強度を見つけることができます。カスタムブレードは、困難な問題を解決し、製品の品質向上に役立ちます。

継続的なサポートと品質保証を確立する

サプライヤーと強固なパートナーシップを築くことが重要です。サプライヤーは、トレーニング、機械のサービス、ブレードのメンテナンスなど、お客様をサポートしてくれます。サプライヤーはブレードのパフォーマンスを追跡し、効率の測定方法を指導してくれます。 継続的なサポートにより、ブレードの動作が良好に保たれます ラインがスムーズに稼働します。品質保証により、常に良質の刃をお届けします。

注:信頼できるサプライヤーと提携することで、技術サポート、品質管理、カスタムサポートが受けられます。これにより、梱包ラインの効率化と製品の安全性が維持されます。

紙やフレキシブル素材の穿孔

材料固有の考慮事項

紙や軟包装材を切る際には、材質を考慮する必要があります。包装材によって、切ったりミシン目を入れたりする際の動作は異なります。 低密度ポリエチレン LDPEは曲げやすく、防水性があり、コストも低いため、よく選ばれています。LDPEは大きな穴にも小さな穴にも使用できます。食品の鮮度を保ち、輸送にも十分な強度があります。PET/PEフィルムの場合は、厚さと切断時の耐熱性を確認する必要があります。AmcorやMondiなどの企業は、食品の鮮度を保ち、地球環境にも配慮した新しい穴あきフィルムや紙を開発しています。

| 材質タイプ | 重要な考慮事項とプロパティ |

|---|---|

| 低密度ポリエチレン | 簡単に曲げられ、水の浸入を防ぎ、安価で、大きな穴にも小さな穴にも適しており、食品を新鮮に保ち、輸送にも強い |

| PET/PEフィルム | 適切なレーザーが必要 厚さきれいな穴と良好な空気の流れのための層 |

| 紙ベースの包装 | 小さな穴は食品の保存期間を延ばし、環境にも優しい |

カットギャップ比の最適化

カットと隙間の比率とは、穴の列にいくつの切れ目と隙間があるかを表します。このパターンによって、パッケージの開封しやすさと開封前の強度が決まります。開けやすいパッケージにしたい場合は、切れ目を多くし、隙間を小さくします。より強力な密閉性が必要な場合は、切れ目を少なくし、隙間を大きくします。刃の形状と刃の間隔も、穴の開けやすさに影響します。製品に合った刃のパターンを選ぶ必要があります。

ヒント:大量生産する前に、必ずパッケージのカットと隙間の比率をテストしてください。これにより、密封性が弱くなったり、開けにくくなったりするパッケージを防ぐことができます。

テストと調整

大量に切る前に、必ず刃のテストを行ってください。まずは試し切りをいくつかして、刃の使い心地を確認しましょう。必要に応じて、圧力、速度、刃の配置などを調整してください。切れ味を継続的に確認し、より良い仕上がりになるように少しずつ調整を加えていきましょう。ご不明な点がある場合は、刃のメーカーにご相談ください。

- 穴を確認するためにテストカットを数回行います。

- 必要に応じて圧力、速度、またはブレードの位置を変更します。

- 結果を見て、さらに改善し続けてください。

- 質問がある場合は専門家にご相談ください。

プロセスをテストして変更することで、優れた結果が得られ、パッケージング ラインを正常に稼働させることができます。

避けるべきよくある間違い

物質的な違いを無視する

すべての刃は同じように機能すると考えている人がいますが、素材ごとに刃の使い分けが必要です。注意を怠ると、刃や製品を傷つけてしまう可能性があります。よくある間違いを以下に示します。

- 素材に合わない刃を使う金属にコンクリートの刃が当たるような感じ。

- 材質が硬いか柔らかいかは考えない。

- コンクリートを切る前に、コンクリートの中に何が入っているか確認し忘れる。

- 作業に適さないダイヤモンドの粒度または結合剤を選択する。

- 硬い材料に広い溝を使用すると、刃が熱くなりすぎる可能性があります。

これらのミスをすると、刃はすぐに折れて摩耗してしまいます。刃が熱くなりすぎて長持ちしません。切れ味が悪くなったり、刃が揺れたり、刃先が乱れたりします。これらの問題は、無駄が増え、コストが上昇し、安全上の問題につながります。必ず材料に適した刃を選び、作業を始める前に仕様を確認してください。

ヒント: ブレードを選ぶときは 適切な結合と食道のサイズ 素材に合わせて調整できます。これにより、滑らかなカットが可能になり、刃の寿命も長くなります。

生産需要を見落とす

生産ニーズを考慮しなければ、刃は長持ちしません。機械の設定を変更し、刃のメンテナンスを行う必要があります。 下の表は生産需要を忘れた場合に何が起こるかを示しています:

| 原因 | ブレードとラインへの影響 | 予防措置 |

|---|---|---|

| 機械の設定を変更しない | 刃が摩耗し、切り口が不均一になり、ラインが止まる | 速度、圧力、ブレードの深さを変更する |

| ブレードのメンテナンスをしていない | 刃が鈍くなり、熱くなり、切り口が荒くなります | 刃を頻繁に掃除し、研ぎ、油を差す |

| 不適切な取り付けまたは位置合わせ | 切り口が曲がったり、刃が滑ったり、詰まりが起きたり | 手順に従って位置合わせをチェックする |

| 刃の摩耗に注意を払わない | 品質不良、廃棄物増加、ライン停止 | 刃を点検し、交換または研ぐ |

| 材料の蓄積と錆 | 刃が傷つき、錆び、長持ちしない | 刃をきれいにして乾燥させ、オイルを使用してください |

| テストランをしない | セットアップミス、スクラップ、ライン停止 | 変更を加えた後はブレードをテストする |

設定を変更し、ブレードの手入れをすることで、ラインを良好な状態に保つことができます。

テストと品質チェックの省略

品質のテストとチェック 問題を早期に発見するのに役立ちます。これらの手順を省略すると、不良な切断や廃棄物が発生します。刃の状態を確認するには、ビジョンシステム、顕微鏡、切れ味試験機などのツールを活用する必要があります。作業員は問題を発見した場合、迅速に対応し、機械を停止することができます。定期的な点検や走査型電子顕微鏡などの特殊検査は、小さな問題の発見に役立ちます。また、カイゼンやシックスシグマなどの手法を活用することで、より良い結果が得られます。

注:品質テストと品質チェックは、刃の鋭さ、切断面の美しさ、製品の安全性を保つために重要です。検査を業務に組み込むことで、コスト削減とダウンタイムの削減につながります。

適切なミシン目刃を選ぶことで、よりきれいにカットできます。無駄が減り、製品の見た目も良くなります。以下の点に注意してください。

- パッケージに適したブレードのタイプと素材を選択してください。

- ブレードのサンプルを試し、必要に応じてマシンの設定を変更してください。

- 信頼できるサプライヤーからアドバイスやサポートを受ける カスタムブレード.

研究によると、カスタムブレードを使用し、優良サプライヤーと協力することで、切断速度が速くなることが示されています。ブレードの交換頻度が減り、顧客満足度も向上します。品質にこだわり、他者と良好な関係を築くことで、包装ラインの生産性が向上し、製品の認知度も高まります。

よくある質問

穿孔刃で切断できる材料は何ですか?

刃は様々なものを切ることができます。紙、プラスチックフィルム、ラミネート、繊維、ゴム、軽金属など、様々な素材に使用できます。これらの刃は、それぞれの素材にきれいなカットと強力な穿孔効果をもたらします。

包装ラインに適したブレードを選択するにはどうすればよいでしょうか?

素材と作業速度に合った刃を選びましょう。たくさんの製品を作る前に、サンプルの刃で試してみましょう。専門家に相談することもできます。適切な刃の形状と素材を選ぶことで、より良い結果が得られます。

穿孔ブレードはどのくらいの頻度で交換する必要がありますか?

刃が鈍くなっていたり、損傷していないか、頻繁に確認してください。切れ味が悪くなったり、切れ端が増えたりしたら交換してください。刃は長持ちするので、それほど頻繁に交換する必要はありません。

特別な梱包のニーズに合わせてカスタム穿孔ブレードを注文できますか?

はい、Maxtor Metalではカスタムブレードをご注文いただけます。これらのブレードは、お客様の特殊な包装、素材、または引き裂きパターンに合わせて製作されます。カスタムブレードは、困難な問題を解決し、製品の品質向上に役立ちます。

参照

パッケージング用ミシン目ナイフが包装業界で広く使用されている理由

6件のフィードバック

こんにちは、あなたが私のブログを訪問したのを見たので、私は恩返しに来ました。私は自分のウェブサイトを改善するためのものを探しています。あなたのアイデアのいくつかを使用するのは大丈夫だと思います。

またのご来場をお待ちしております。

縁起の良い記事をありがとうそれは実際には娯楽アカウントでしたそれはあなたからはるかに快適に進んで見えますしかし、どのように私たちはコミュニケーションをとることができますか

温かいメッセージとご評価をありがとうございます!記事を気に入っていただけて嬉しいです。メール、WhatsApp、お問い合わせフォーム、コメント欄などでご連絡ください。

あなたのブログは、私にとって常にインスピレーションの源です。テーマに対する情熱が伝わってきて、すべての投稿に心血を注いでいるのが伝わってきます。これからも素晴らしいブログを続けてください!

親切なメッセージと評価をありがとうございます!