シャー刃をプロのように研磨する:一般的な研削ミスを回避し、TCO を延長

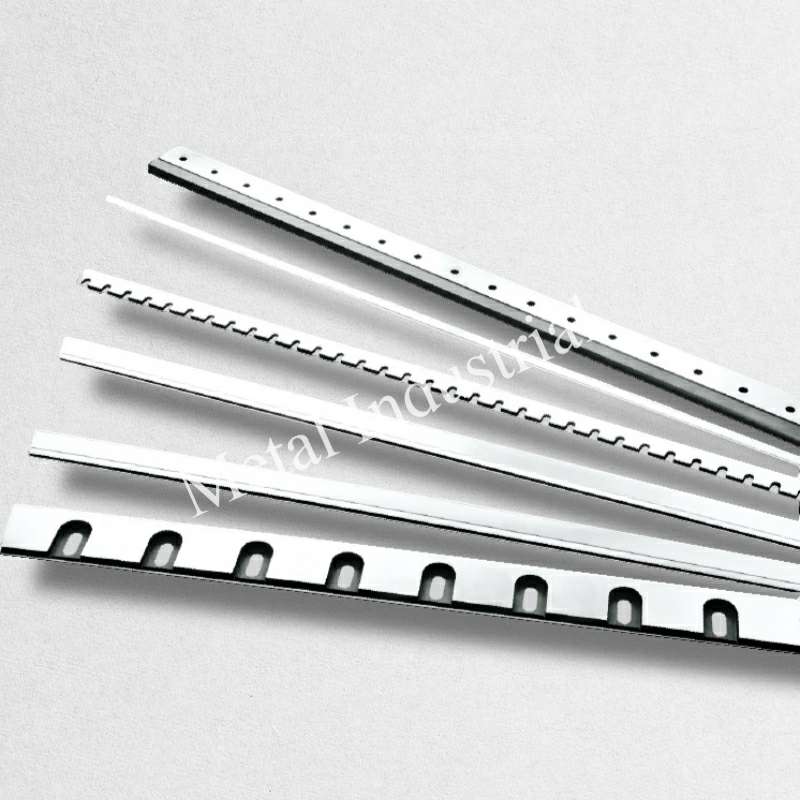

You get great results when you sharpen shear blades. Keep the blade shape correct and use the right angle. Keep the blade’s original shape. Take off only a little bit of material. Metal Industrial Shear Blades have special edge design and strong materials. Careful sharpening helps them cut better and last longer. Use the right way to sharpen to avoid mistakes. This helps you save money over time. Key Takeaways Why Sharpen Shear Blades Properly Performance and Longevity Sharpening shear blades the right way helps them work well. It also makes them last longer. Metal Industrial Shear Blades use strong materials and special edges. These blades are tough and can do many […]

シャー刃クリアランス設定の決定版ガイド:公式、間違い、およびバリゼロの結果

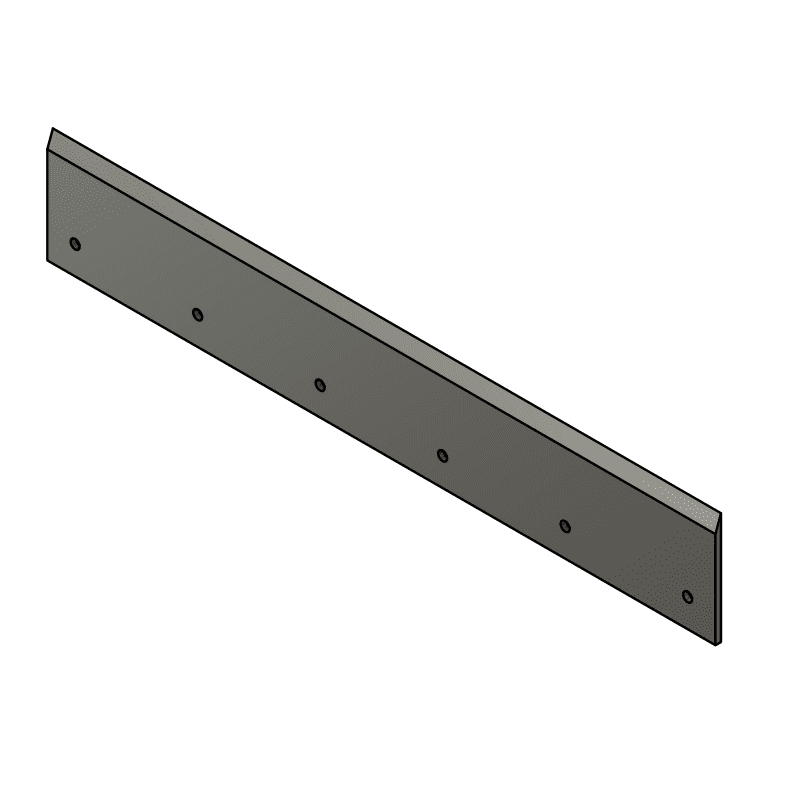

Imagine you cut a metal sheet and see rough burrs on the edge. Sometimes, you might even find chips on your cutting blade. You can stop these problems by ensuring proper shear blade clearance adjustment. If you set the clearance just right, you achieve smooth cuts and fewer burrs. Your blades will also last longer and avoid damage. Many workers make mistakes like using dull blades. Some use plates that are too thick. Others set the gap unevenly. You can avoid these issues by checking if your blade is sharp. Make sure the machine matches the plate thickness. Adjust the gap carefully. High-quality blades from Metal Industrial help you get excellent results […]

H13 熱間シャー刃:高温金属切断とビレット剪断をマスターする

You need cutting tools that can handle very high heat. These tools must stay sharp for a long time. Hot work shear blades made from H13 steel are tough and dependable. They work well for hard jobs. H13 steel is special because it does not get tired from heat. It does not wear out fast. It can be shaped into many forms. Here is how these benefits compare: Advantage Description Resistance to thermal fatigue Handles heating and cooling many times. It does not crack or get soft. Good wear resistance Stays sharp and strong for a long time. Ability to be machined Can be shaped exactly for many uses. Metal Industrial works […]

精密ギロチンシャー刃によるバリゼロの切断を実現する方法

You can get zero-burr cuts by using good blades. You also need to set up the machine right. Skilled workers help a lot too. Precision Guillotine Shear Blades from Metal Industrial give you great results. These blades help you work faster and better. Blades with special edges and strong materials work best. Taking care of your blades keeps cuts smooth. Studies show blade quality matters most. Cutting speed and setup also change burr size and cutting results. Key Takeaways Achieving Zero-Burr Cuts with Precision Guillotine Shear Blades What Are Zero-Burr Cuts? Zero-burr cuts give you a smooth edge after cutting. There are no rough spots or extra metal sticking out. You want […]

D2 シャー刃:なぜ D2 鋼が冷間金属切断の王様なのか

D2 steel shear blades are great for cutting cold metal. These blades stay sharp for a long time. They do not wear out quickly. You get the same good results every time. Many workers pick D2 steel because it is very hard. It keeps its shape well and does not rust easily. Metal Industrial works hard to make good and new products. This means you can trust their blades to work well. Learn why experts say Nanjing Metal Industrial is the best place for cutting tools. Key Takeaways Why D2 is the Standard for Cold Metal Shearing Defining “Cold Metal Cutting” and the Role of the Shear Blade You use cold metal cutting […]

ギロチン刃 vs. シャー刃:違いは何?あなたの仕事に最適なのは?

Imagine you have to cut thick metal sheets for a big job. You need to pick between guillotine vs shear blades. Guillotine shears move straight down and are best for long, straight cuts. Shear blades, like the ones from Metal Industrial, are strong and accurate, working on many materials and shapes. Picking the right tool changes how good your cuts are and affects how much work you do to keep tools functioning. Your choice can help your project succeed. Studies show that this choice can change how fast you work and can also help you control costs. Key Takeaways Guillotine vs Shear Blades: Key Differences When you look at guillotine vs […]

シャーブレード材料ガイド:D2 vs. A2 vs. 5160 vs. 超硬合金 — 最適な選択は?

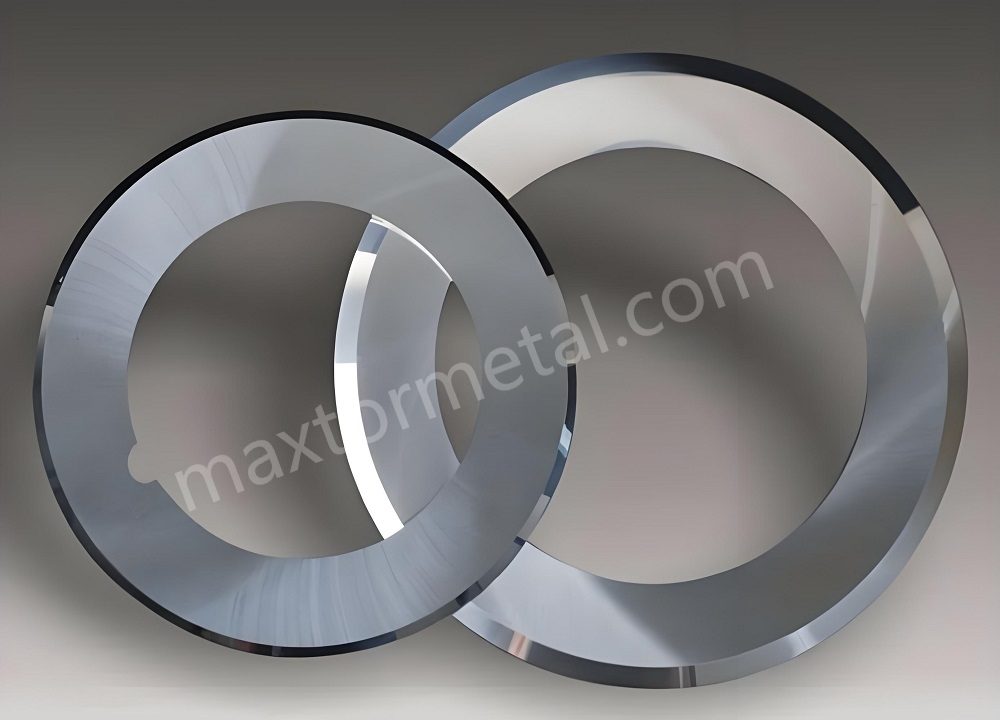

Choosing the right shear blade material depends on what you cut. It also depends on how often you use your blades. You need blades that can handle hard jobs. You want blades that last a long time. Special heat treatments like quenching and tempering make blades harder. These treatments also make blades stronger. The table below shows common problems with blade durability for popular materials: Material Properties Durability Concern D2 Tool Steel High chromium, great wear resistance Has trouble with very hard metals Tungsten Carbide Up to 1,500 Vickers, strong metals Costs more at first Nanjing Metal Industrial gives you good choices. They also offer custom solutions. These help you pick blades that fit your […]

ステンレス鋼は錆びるのか?— 一般的な産業用ブレード鋼種の腐食比較

Stainless steel can rust, contrary to popular belief that it never does. It’s important to understand how each grade works before selecting a blade, as not all stainless steel types prevent stainless steel rust in the same manner. The environment where you work and the composition of your blade both play significant roles. Recent research indicates that stainless steel maintains its strength longer than carbon steel, which tends to develop rusty layers over time. Key Takeaways Why Does Stainless Steel Rust? The Science of Stainless Steel Rust Chromium’s Protective Role Some people think stainless steel never rusts, but that is wrong. Stainless steel rust can happen if its protective layer gets damaged. […]

ステンレス鋼ブレードの黒ずみ:発生する理由と予防方法

You may see your stainless steel blade turn black. You might think it should stay shiny. Stainless steel blade blackening means dark spots show up. These spots or patches can appear on the surface. This usually happens because of oxidation. Oxidation is also called rouging. Many things can cause this change. Some common causes are: Touching non-stainless metals can also cause blackening. Using strong cleaning agents can do this too. Key Takeaways What Is Stainless Steel Blade Blackening Definition and Appearance Stainless steel blade blackening means your blade gets dark spots or turns black. Sometimes, the blade looks matte black on top. This happens because of a chemical reaction. The iron in the […]

タングステンナイフ:その価値は?業界における利点、欠点、および用途

長持ちして、頻繁に切れなくなることが少ないナイフをお探しなら、タングステンナイフは良い選択肢かもしれません。タングステンカーバイドは摩耗しにくいため、業界では特別な素材です。鋼よりもはるかに長く鋭い切れ味を保ちます。タングステンカーバイド製品には、世界中のタングステンの約65%が使用されています。そのため、タングステンカーバイドは過酷な作業に最適です。選ぶ前に、良い点と悪い点を知っておく必要があります。簡単に見てみましょう。メリット デメリット 耐摩耗性が高い 靭性が低い ナイフと刃の交換頻度が少ない カーバイドの価格 刃先保持による効率性 研ぎにくい 適切な素材を選ぶことで、より速く、より良い作業が可能になります。タングステン[…]