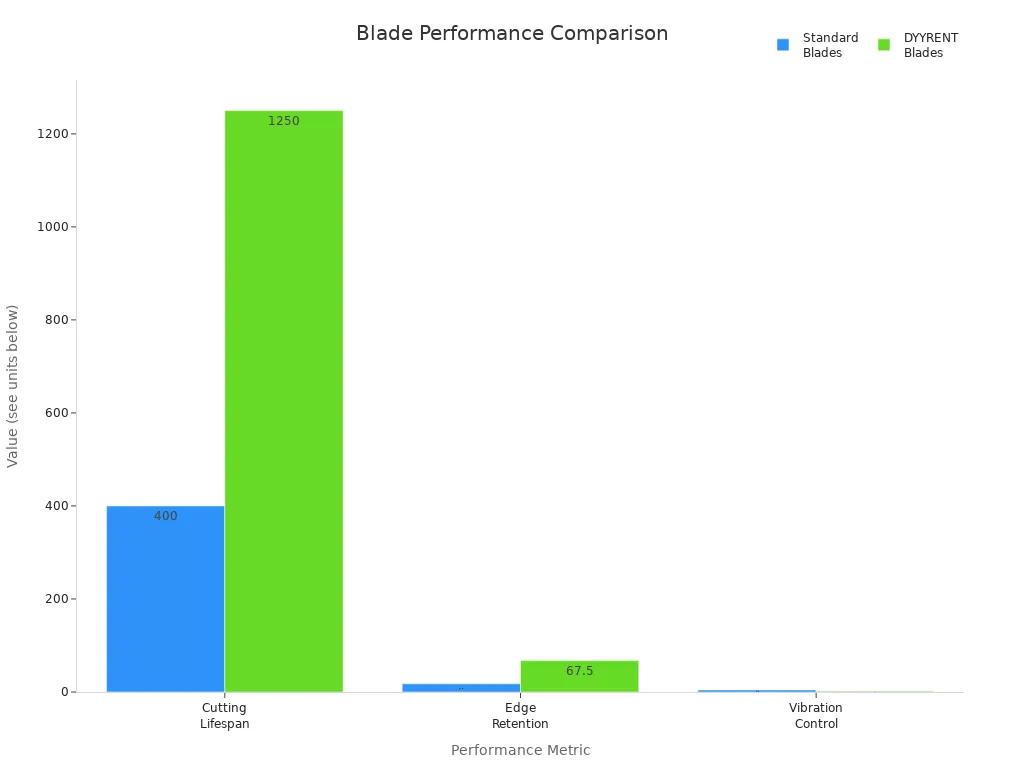

When selecting perforating blade knives, the Geometria da Lâmina Perfuradora plays a crucial role. Factors such as edge angle, tooth profile, thickness, and material compatibility all influence how effectively the blade perforates. Aligning the blade geometry with your specific application allows for faster cutting and cleaner perforations. The table below demonstrates that a multi-angle perforating blade geometry reduces cutting time by nearly half and generates less heat damage compared to conventional blades.

| Parâmetro | Multi-angle Blade | Conventional Blade | Statistical Significance |

|---|---|---|---|

| Cutting Time (seconds) | 46.0 ± 3.4 | 86.6 ± 17.3 | p < 0.001 |

| Max Bone Temp (°C) | 32.3 ± 2.2 | 39.5 ± 4.1 | p < 0.001 |

Optimal results come from using the appropriate perforating blade geometry for your cutting tasks and maintaining your perforating blade knives regularly.

Principais conclusões

- Picking the right blade shape, edge angle, tooth shape, thickness, and material helps you cut faster and cleaner. It also makes your cuts more even.

- Different blade types like straight, rotary, toothed, and circular work best for certain materials and jobs. This gives better results and makes blades last longer.

- Blade materials like carbide, stainless steel, and tool steel change how strong, sharp, and long-lasting a blade is. Choose the material that fits what you need to cut.

- Custom blades made for your material and machine make cutting better. They also help you save time and money.

- Changing blade shape and settings like groove width, perforation radius, and edge angle can help blades work better and last longer.

- Taking care of blades by cleaning, checking for damage, and replacing them on time keeps cuts accurate and machines safe.

- Using smart ways to cut and watching tools closely helps blades last longer. It also lowers the force needed to cut and keeps work steady.

- Following good rules for picking and caring for blades gives you better cuts and longer blade life. This helps you work better overall.

Geometria da Lâmina Perfuradora

Knowing about perforating blade geometry helps you cut better. It also helps you get the same good results every time. You should look at a few important things when picking perforating blade knives. These things are edge angle, tooth profile, thickness, and material compatibility. Each one changes how the blade works with your material. They also decide how good the final perforation looks.

Fatores-chave

Ângulo da aresta

Edge angle shows how sharp and strong your perforating blade is. A sharper edge angle lets you cut soft materials and make small holes. If you need to cut tough materials, a bigger edge angle makes the blade last longer. Think about how hard your material is and how deep you want to cut. Also, think about what you are cutting. For example, if you make the bevel angle 5° smaller, the blade gets 38% sharper. But it will not last as long and loses 45% of its edge. You can pick a sharper edge for a better first cut. But you might need a less sharp edge if you want the blade to last longer.

Perfil do dente

Tooth profile means the shape, space, and layout of the teeth on the blade. This changes the pattern of the holes and how easy the material tears. Fine serrated teeth make less tearing on the surface by 43%. Coarse hook-tooth blades cut rubber 15% faster and last 20% longer. You should pick the tooth profile that matches the holes you want and how thick your material is. Custom profiles help you get the best blade for special jobs. This makes cutting faster and more even.

Grossura

Blade thickness changes how stiff the blade is and how good the holes look. Thin blades (0.4 mm) cut fast at 180 m/min but can waste more material and cause more downtime. Thick blades cut slower but waste less and stop less often. This helps your work stay steady. Use thin blades for neat cuts in light materials. Use thick blades for heavy or big jobs. The machine you use and how exact you need to cut also matter when picking blade thickness.

Material

The material of your perforating blade knives decides how strong they are and how long they last. It also decides what materials you can cut. Tool steel, high-speed steel (HSS), stainless steel, and carbide are common choices. Pick high-speed steel or carbide for jobs that wear out blades fast. Pick stainless steel if you need to stop rust, like in food or medical work. Where you use the blade, how often, and how rough the material is all matter. Picking the right blade material helps your blade work well and last longer.

Impacto no desempenho

You can check how well your perforating blade geometry works by looking at some performance numbers. These numbers show how good, fast, and steady your cuts are. The table below lists the most used geometric parameters in blade design:

| Geometric Parameter | Descrição |

|---|---|

| Airfoil data points | 2D points that show the airfoil cross-section shape |

| Twist | Angle between the airfoil base and a circle in the rotor plane |

| Rake | How much blade sections move along the rotor axis |

| Skew | How much blade sections move sideways from the rotor axis |

| Coning distribution | How the blade bends or cones along its length |

| Leading edge | The front edge of the airfoil, important for air performance |

| Trailing edge | The back edge of the airfoil, usually sharp |

| B-spline curves and surfaces | Math shapes for exact blade surface modeling |

Small changes in blade geometry make perforations more even. The table below shows how edge angle, tooth profile, thickness, and material compatibility change perforation quality:

| Blade Geometry Factor | Quantitative Effect on Perforation Consistency | Explicação |

|---|---|---|

| Ângulo da aresta | 5° smaller bevel angle makes blade 38% sharper but 45% less lasting | Sharper edges cut better at first but wear out faster, so cuts get less even over time |

| Tooth Profile & Pitch | Fine serrated teeth cut surface tearing by 43%; coarse hook-tooth blades cut rubber 15% faster and last 20% longer | Tooth shape changes how the blade grabs the material, making fewer mistakes and faster, longer cuts |

| Espessura da lâmina | Thin blades (0.4 mm) cut at 180 m/min but waste 1.8% more material and add 2 hours of downtime each week; thick blades cut slower but waste less and stop less | Thickness changes speed and cut quality, which affects waste and how steady your work is |

| Compatibilidade de materiais | Plastics: wide pitch, high bevel angle to stop friction and melting; Metals: thick carbide blades with steep bevels for strength | Matching blade geometry to the material stops friction, wear, and makes cuts more exact |

You can also use performance numbers to see how well your perforating blade knives work:

| Métrica de Desempenho | Description / Impact |

|---|---|

| Consumo de energia | Sharp bore holes use 30–40% of energy and blades use 60–70%, both affect cutting efficiency. |

| Volume Flow Rate | Number and size of bore holes change flow rate; higher flow means less heat. |

| Sharpness of Blades and Bore Holes | These are big reasons for energy use and product quality. |

| Temperature Increase During Cutting | Lower in perforated plate-knife sets than in just knife sets; this is because of less friction heat. |

| Transmission Ratio of Perforated Plates | Best ratio is 1:6–1:4 for good mixing and smaller pieces. |

| Product Structural and Sensory Attributes | Checked based on knife geometry and how you use the blade. |

| Real-time Monitoring Parameters | Includes wear, cutting force, and material resistance using smart sensors (new ways to measure). |

Nanjing Metal’s perforating blade knives meet high standards for accuracy and strength. Their blades give you steady cuts and last a long time. You get better blade design, strict checks, and custom blades for your needs.

You can see that careful blade making and good blade geometry make blades last longer. They also keep their edge better and shake less. These changes help you cut better, make better products, and spend less money.

Note: If you pick perforating blade knives with the right geometry, you work faster and keep your product quality the same every time.

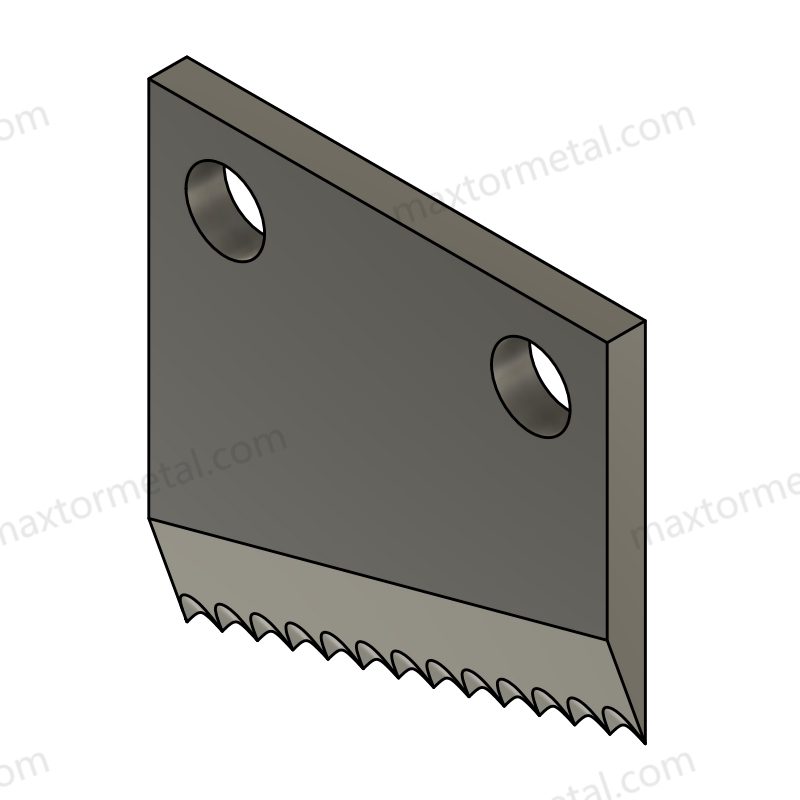

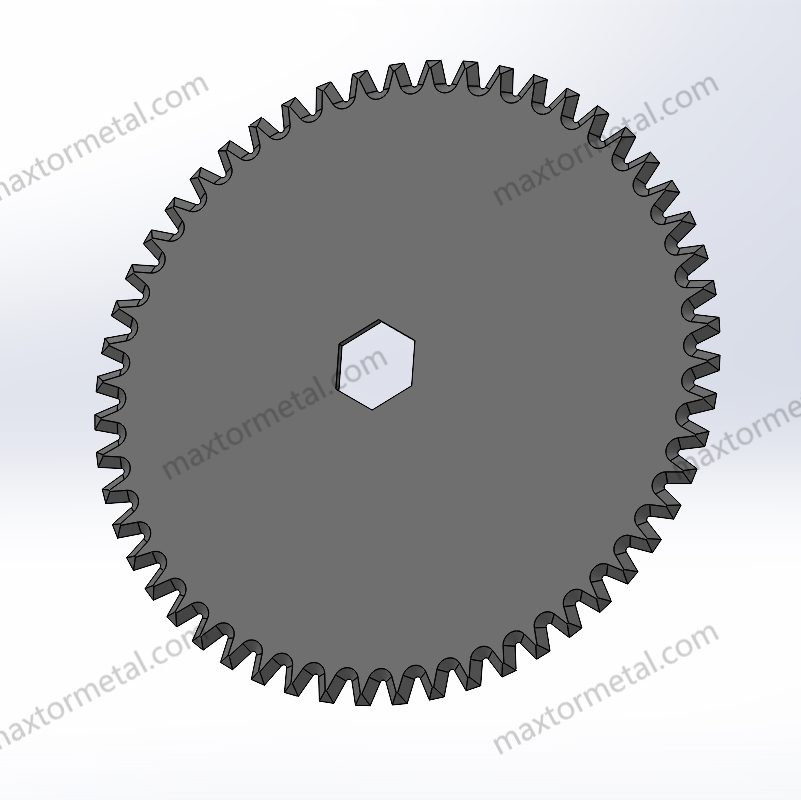

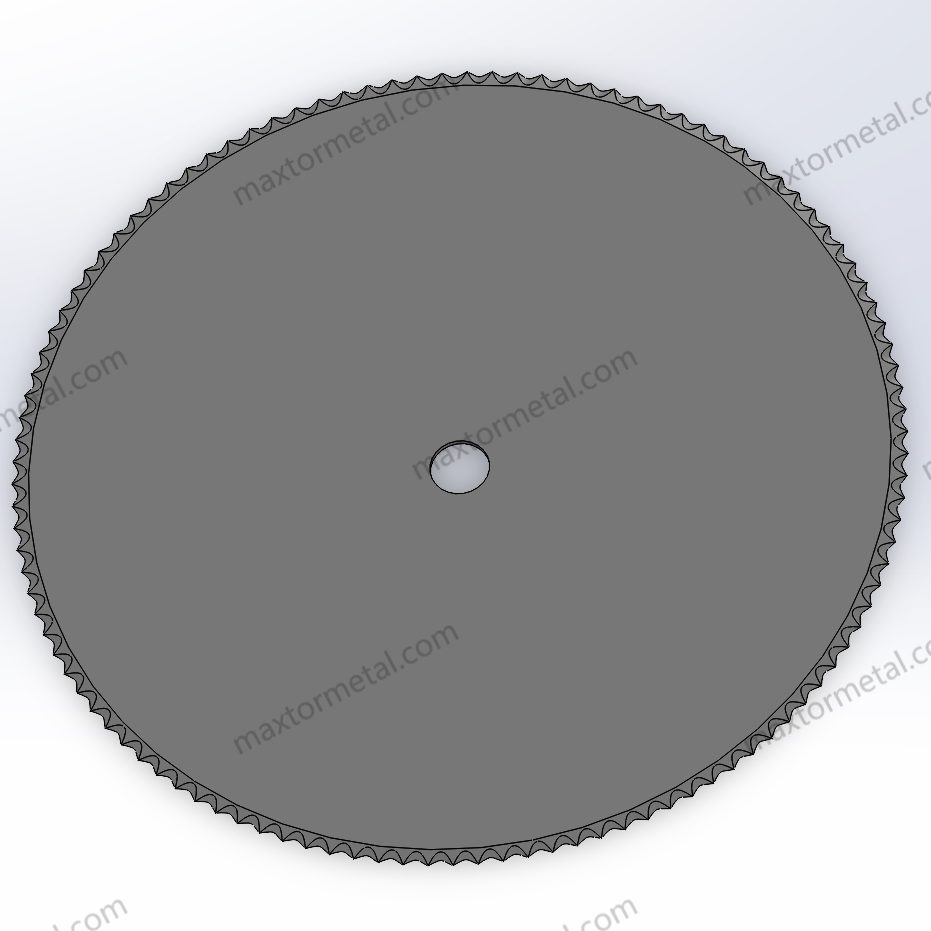

Perforating Blade Knives Types

Perforating blade knives come in a few main types. Each type is made for a certain job and machine. You must pick the right blade for your material and needs. The most common types are straight, rotary, toothed, and circular blades. There are also custom blades for special jobs.

Straight and Rotary

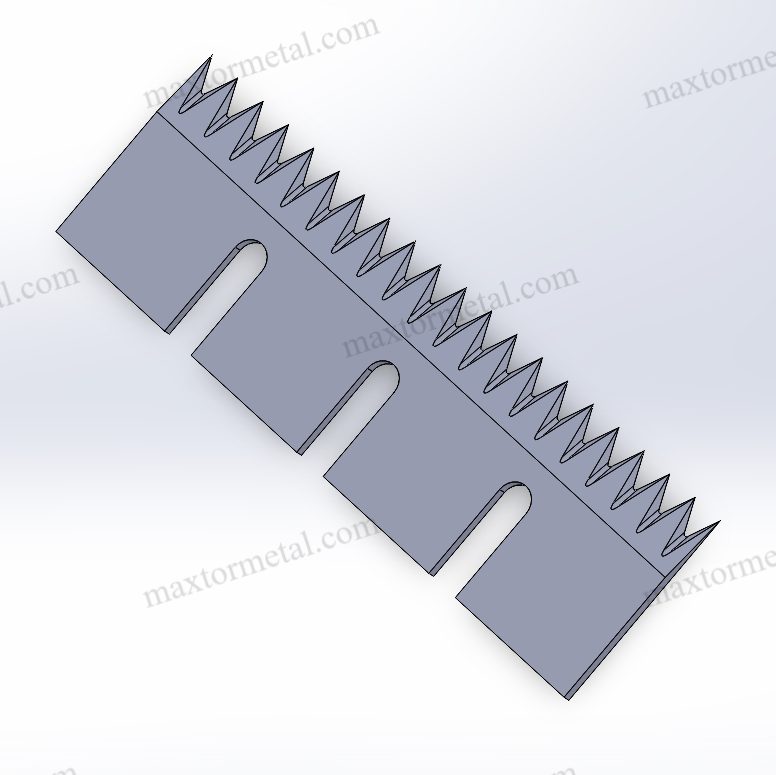

Straight Perforating Blades

Straight perforating blades have a flat edge. You use them to cut in a straight line. These blades work best for packaging, paper, and film. They make clean, straight lines. Straight blades can cut thick things like metal sheets and rebar. You use them when you need careful, exact cuts.

| Recurso | Lâminas rectas | Lâminas rotativas |

|---|---|---|

| Design da lâmina | Flat edge; good for thick materials | Round, spins; best for thin materials |

| Mecanismo de corte | One straight cut | Spins for fast, repeated cutting |

| Cutting Speed & Efficiency | Slower; better for thick or small jobs | Faster; good for lots of cutting |

| Aplicação | Metal sheets, rebar, thick plates | Thin metals, foil, strips, films, paper |

| Desgaste e manutenção | Wears unevenly; needs more sharpening | Wears evenly; less sharpening needed |

| Durability & Longevity | Changes with what you cut | Lasts longer with heat treatments |

| Qualidade do corte | Clean, exact cuts on thick things | Cleaner cuts, less waste on thin things |

Straight blades give you good cuts. You need to sharpen them often because they wear out unevenly. They work best for small jobs or thick things.

Lâminas de perfuração rotativas

Rotary perforating blades spin on a shaft. You use them for fast, nonstop cutting. These blades fit in machines that work by themselves. Rotary blades are best for thin things like foil, films, and paper. They cut faster and save time. Rotary blades last longer because they are heat-treated. You do not need to fix them as much and they make cleaner cuts with less waste.

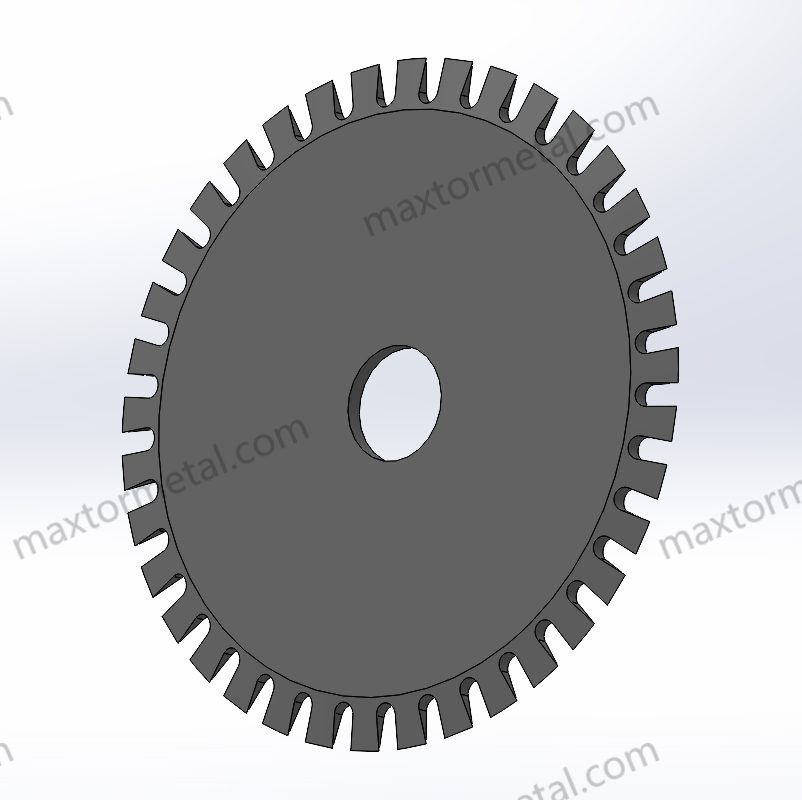

Toothed and Circular

Lâminas Serrilhadas

Toothed perforating blades have jagged edges. You use them to make small cuts or holes. These blades help you make easy-tear lines. You see them in tickets, labels, and packages. Toothed blades are good when you want things to tear easily. You can pick fine or big teeth for your job. Fine teeth stop the surface from tearing. Big teeth cut rubber faster and last longer.

- Toothed blades make neat perforation patterns.

- You pick the tooth shape for your material and finish.

- The right tooth design gives you faster cutting and less downtime.

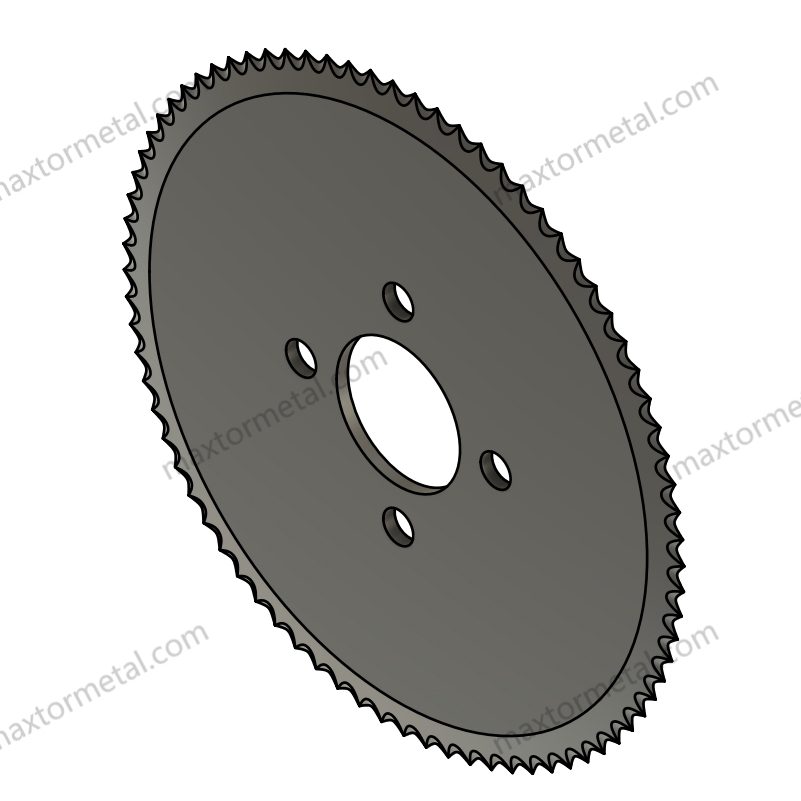

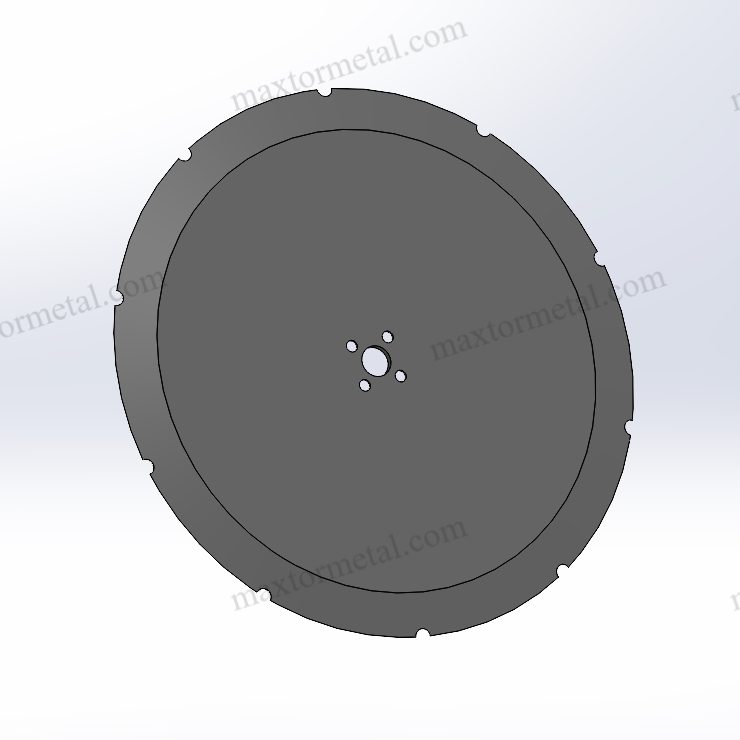

Lâminas Circulares

Circular perforating blades are round. You use them for spinning cuts and perforating. Circular blades can be smooth or toothed. You see them in places that need fast, nonstop cuts. Circular blades are good for textiles, packaging, and labels. They give you even perforation and high output.

- Circular blades fit machines that spin.

- Pick smooth edges for clean cuts or toothed for easy tearing.

- Circular blades help you keep up a steady work pace.

Custom Options

OEM/ODM Customization

You can get custom perforating blades for your needs. Nanjing Metal makes custom blades. You choose blade shape, tooth type, and hole pattern. Custom blades work best for your material, machine, and speed. Special machines like CNC and grinding make sure blades are sharp and exact.

Custom blades cut better and last longer. You get blades that fit your machines just right. Special coatings like Titanium Nitride or Diamond-like Carbon make blades harder and smoother. You spend less time fixing blades and get steady results.

| Aspecto | Detalhes |

|---|---|

| Materiais | High-Speed Steel, Carbide, Stainless Steel, Ceramic |

| Revestimentos | Titanium Nitride, Diamond-like Carbon, Chrome |

| Características | Made with care, stays sharp, smooth finish |

| Durabilidade | Better against wear and heat |

| Compatibilidade | Can be made for many machines and materials |

| Application Benefits | More work done, less stopping, saves money |

| Impacto Ambiental | Blades last longer, so less waste |

Opções de materiais

You can pick from many materials for your blades. The most used are Stainless Steel and Tungsten Carbide. These are popular because they are strong and cut well. For tough jobs, you can pick D2 Steel, M2 Steel, CPM-10V Steel, Solid Carbide, High Carbon Steel, Stainless Steel, Alloy Steel, or Ceramic.

| Material | Key Properties and Suitability for High-Wear Environments |

|---|---|

| Aço D2 | Very hard, lasts long, tough, resists wear and rust |

| Aço M2 | Great against wear, stays strong when hot |

| CPM-10V Steel | Best for wear and hard hits |

| Solid Carbide | Super tough, lasts long, less stopping |

| Aço de alto carbono | Hard, stays sharp, not as tough for hard jobs |

| Aço inoxidável | Stops rust, good for food and medical work |

| Liga de aço | Hard and tough, great against wear |

| Cerâmica | Very tough, stays sharp, but can break if hit hard |

You match the blade material to your job. Stainless Steel is good for food and medical uses. Tungsten Carbide and Solid Carbide are best for tough, busy jobs. D2 and M2 Steel give you both strength and long life. Lâmina personalizada shapes and coatings make blades work even better.

Tip: You get the best results when you pick perforating blades with the right shape, material, and custom features for your job.

Improve Cutting Efficiency

You can make cutting better by looking at blade shape and what it’s made of. If you change groove width, perforation radius, and edge angle, each cut gets quicker and more exact. This also helps blades last longer and keeps your work neat in real jobs.

Geometry Optimization

Groove Width Adjustment

Groove width is important for how well blades cut. Making the main groove smaller and changing the second groove helps resin spread and load move better. This makes the shear modulus higher and helps things work faster. You get cleaner cuts and quicker work. The Kruskal–Wallis test shows that changing groove width lowers cutting force and makes things more efficient.

| Parâmetro | Effect on Cutting Efficiency |

|---|---|

| Groove Width | Smaller grooves help load move, shear modulus go up, and cutting get better. |

Perforation Radius Selection

Perforation radius changes how the blade handles stress and load. Making the radius bigger helps the blade move load better and work stronger. This spreads stress out and stops it from building up in one spot. You get smoother cuts and more exact work. Picking the right perforation radius helps you get the same good results every time.

| Parâmetro | Efeito no desempenho de corte |

|---|---|

| Perforation Radius | Bigger radius helps load move, lowers stress, and makes cutting better. |

Edge Angle Tuning

Edge angle tells you how sharp and tough your blade is. A sharper angle means less friction and easier cutting, so you work faster. But it can make the blade wear out sooner. You need to pick between sharpness and toughness for your material. Setting the edge angle at 65° makes the shear modulus highest and helps cutting work best. You get more exact cuts and blades last longer.

| Parâmetro | Efeito no desempenho de corte |

|---|---|

| Ângulo da aresta | Sharper angles make cutting easier; best angle helps blades last. |

Tip: Changing blade shape the right way makes cutting faster and more exact. You will see less force needed and better results in your finished work.

Seleção de Materiais

Blade Material Types

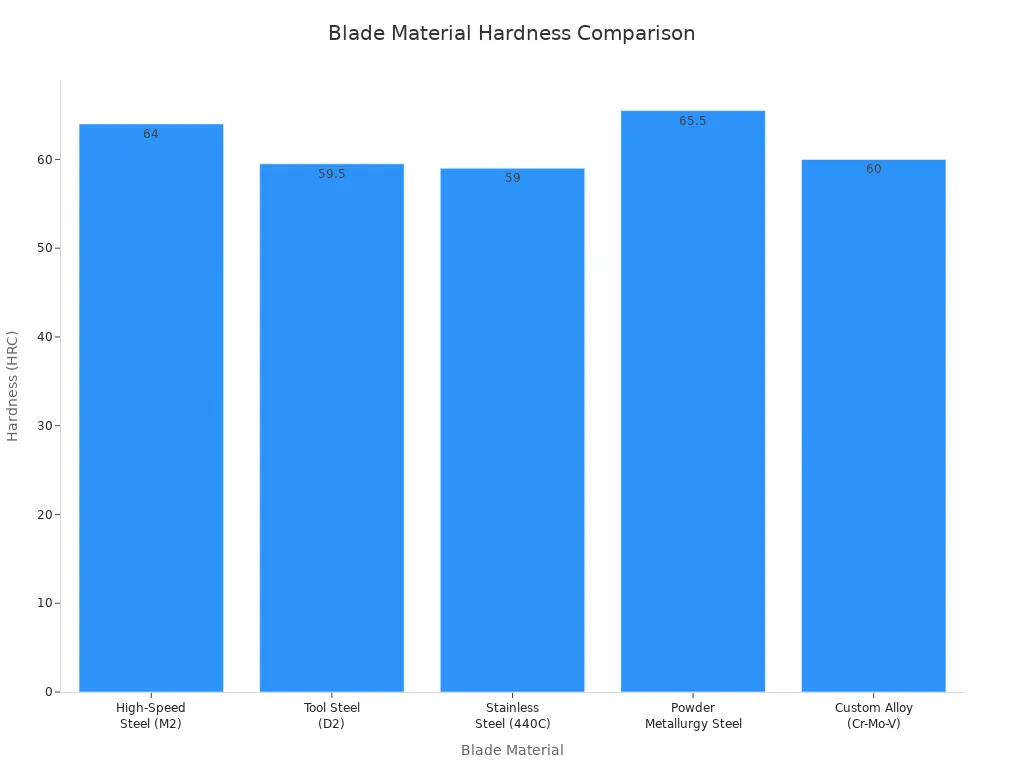

Picking the right blade material is key for good cutting and blade life. You can choose tool steel, high-speed steel (HSS), stainless steel, carbide, or powder metallurgy steel. Each one has different hardness, strength, and how well it fights wear. Tungsten carbide blades last up to ten times longer than some steels. Powder metallurgy steels have even structure and are easier to work with.

| Material da lâmina | Dureza (HRC) | Força | Resistência à corrosão | Aplicações típicas |

|---|---|---|---|---|

| High-Speed Steel (M2) | 62–66 | Bom | Baixo | Papel, têxteis |

| Aço ferramenta (D2) | 58–61 | Excelente | Moderado | Plástico, borracha |

| Aço inoxidável (440C) | 58–60 | Bom | Alto | Food, pharmaceutical |

| Pó Metallurgy Aço | 64–67 | Extremo | Low–Moderate | Abrasivos, metais |

| Custom Alloy (Cr-Mo-V) | 60+ | Ajustável | Moderado a Alto | Materiais recicláveis, materiais mistos |

Wear Resistance Considerations

Wear resistance matters a lot for big cutting jobs. Tool steel like D2 and A2 are tough and fight wear well. High-speed steel stays sharp even when hot. Carbide blades fight wear best but are not as tough. Stainless steel is okay for wear and great against rust.

| Material | Hardness (Rockwell) | Resistência ao desgaste | Notas adicionais |

|---|---|---|---|

| Aço inoxidável | Moderado a alto | Okay, best for rust | Used in food and medical places |

| Tool Steel (D2/A2) | 54-62 | Very good, D2 is best | Good for long runs |

| Aço de alta velocidade | 62-65 | Great, works well when hot | Good for fast cutting |

| Carboneto | Above HSS | Best, stays hard over 1000°C | Best for rough materials |

Application-Specific Choices

You need to match blade material to what you are cutting. Alloy tool steels are good for metal and plastic. Tungsten carbide is best for hard and rough stuff. Martensitic stainless steel works well for food and chemicals. Powder metallurgy steel is good for tough jobs. In real life, custom blades and materials fix problems like blades breaking and too much downtime. For example, a tire shredding place used custom A8 steel blades and got blades that lasted four times longer, downtime dropped by 70%, and yearly costs went down by 60%.

Throughput and Clean Cuts

Maximizing Production Speed

Changing blade shape and picking good materials helps you work faster. Sharper angles and smooth edges lower friction and make cutting easier. Polished or coated blades stay sharp longer and need less fixing. Using strong materials like stainless steel, cobalt alloys, and high-speed steel helps blades last and fight heat. You keep working fast and cutting better.

| Fator | Descrição | Impact on Production Speed and Efficiency |

|---|---|---|

| Ângulo da lâmina | Sharper angles make cutting easier and faster. | Faster work and more products made. |

| Design de Borda | Smooth or jagged edges fit different materials. | Better accuracy and faster work. |

| Acabamento de superfície | Polished or coated blades lower friction and wear. | Blades last longer and work faster. |

| Seleção de Materiais | Strong materials help blades stay sharp and tough. | Blades keep working well and stay strong. |

Note: Making blade shape and material better can make work faster by 1.2% to 10%. You cut quicker and stop less.

Achieving Consistent Cut Quality

You get the same good cuts by controlling entry angles, feed rates, and using smart toolpaths. Entry angles of at least 45° lower sudden loads by 30%. Trochoidal milling keeps cutting forces and tool bending low. Keeping one tooth working stops shaking and uneven cuts. Good chip removal and smart toolpaths keep surfaces smooth. Hold your work close to the blade to stop shaking.

- Entry angles help blades last and keep cuts smooth.

- Trochoidal milling keeps forces and bending low.

- Steady spindle load stops shaking.

- Good feed rates balance chip size and tool load.

- Smart CAM software changes toolpaths for blade shape and material.

Reducing Cutting Force and Wear

You lower cutting force and blade wear by splitting cuts into rough and finish passes. Use vibration sensors to spot shaking and change feed rates. Watch blade condition and change blades when they reach 80% of their life. This lowers waste and keeps cutting good. Use strong coolant or air blasts to keep blades cool and clean.

- Split cuts into rough (70%) and finish (30%) passes.

- Use vibration sensors for steady work.

- Change blades before they wear out.

- Use strong coolant for chip removal.

Tip: When you focus on blade shape and material, you cut better, keep things exact, and get good results every time. These steps help you work faster and stop less in real jobs.

Performance in Applications

Embalagem

Perforating blade geometry is important in packaging. When you open a bag of chips, you see its effect. Tearing a strip from a label roll is easier because of good perforating. The right blade shape helps packages open clean and safe. This stops rough edges and saves material. In packaging, you often use straight or rotary perforating blades. These blades make easy-tear lines on films, foils, and paper. You can pick tooth shapes and edge angles for your packaging. This helps you get the same good cuts and work faster.

Nanjing Metal makes custom perforating blades for packaging. You can pick blade thickness and material for your job. Stainless steel blades do not rust in wet places. High-speed steel blades last longer in busy packaging lines. You get blades that fit your machines and keep your work going well.

Tip: Custom perforating blades help you stop delays and make packaging better. Your products look neat and open without trouble.

Indústria alimentícia

The food industry has strict rules for clean and careful work. Perforating blades are important for slicing, trimming, and dicing food. You need blades that cut clean without crushing or tearing. The right blade shape lets you cut bread, meat, cheese, and snacks well. You can use straight, circular, or toothed perforating blades. Each blade shape works best for a different food job.

Custom blades help you do better in food processing. You can choose blade shape, thickness, and edge style for your food. Scalloped or serrated blades cut bread without squashing it. Circular blades cut dough or pastry with little waste. Nanjing Metal uses CAD software and good materials to make blades. You get blades that are safe for food and work well every time.

- Custom perforating blades help you:

- Make even slices and pieces

- Waste less food

- Keep things clean and safe

- Work faster and better

Têxteis

Textile jobs need blades for many kinds of materials. You use perforating blades to cut, slit, or punch holes in cloth and fibers. The right blade shape gives smooth edges and stops fraying. You can pick toothed, straight, or curved blades for different textile jobs.

Custom blades let you match the blade to your fabric and machine. You can pick edge angles and tooth shapes to protect the fabric. You get blades that stay sharp, last long, and give steady results.

- With the right perforating blades, you:

- Cut faster and more exact

- Change blades less often

- Get clean, repeatable holes or cuts

- Work with many kinds of textiles and finishes

Fabricação

In manufacturing, you need cutting tools that work well and are accurate. Perforating blade geometry is very important for how your production line works. Picking the right blade helps you work faster, waste less, and keep your products the same every time. Blade design matters in jobs like making car parts, electronics, and packaging.

You need blades that can cut many materials, such as plastics, metals, rubber, and composites. Each material acts differently when you cut it. For example, thin plastic film needs a sharp edge angle and small teeth. Thick rubber sheets need a strong blade with bigger spaces between the teeth. If you pick the wrong blade geometry, you might get rough cuts, material stuck on the blade, or need to change blades often. These problems slow down your work and cost more money.

You can pick straight, rotary, toothed, or circular blades. Each blade type works best with certain machines and jobs. You can also change blade thickness, edge angle, and tooth shape to fit your needs. This lets you match the blade to your job. You get better results and blades that last longer.

Think about a factory that makes insulation panels. Workers use rotary perforating blades with special teeth. This setup makes neat holes in fiberglass sheets every time. The work goes faster and there are fewer stops. In another case, a company that makes car gaskets uses high-speed steel blades with a special edge angle. These blades cut tough composite materials without rough edges. The products look better and there are fewer mistakes.

You can also use new materials like carbide or powder metallurgy steel. These materials do not wear out fast and stay sharp longer. When you use these blades, you spend less time fixing them and more time working.

Tip: Always check what you are cutting and how before picking a blade. The right blade shape and material help you work better and reach your goals.

With the right perforating blade knives, you can do many manufacturing jobs. You get smoother cuts, faster work, and more steady results.

Application Selection

Picking the right perforating blade geometry and knife type helps you get the best results. You should think about what material you are cutting, the pattern of holes you want, and any specific needs your job has.

Compatibilidade de materiais

You need to match your perforating blade to the material you cut. Every material, like textiles, foil, steel, or stone, needs a certain blade geometry and tooth style. Harder materials need blades that are tougher and harder. Softer materials work better with sharper edges and smaller teeth. The table below lists important things to think about when picking blade geometry:

| Criteria for Selecting Perforating Blade Geometry | Explicação |

|---|---|

| Material Hardness and Toughness | Pick blade materials that are both hard and tough for sharpness and long life. |

| Type of Material Being Processed | Choose blade shapes and tooth styles for your material, like textiles or steel. |

| Desired Cut Quality | Match the blade edge and tooth shape to your material for clean holes. |

| Blade Geometry and Tooth Configuration | Choices include square edge, single or double bevels, serrated, scalloped, and different tooth styles. |

| Customization and Engineering Support | Reverse-engineering helps find the best tooth shape and blade hardness for your job. |

You can work with engineers to look at your current blades. They can test and measure blade size and metal type. This helps you pick or improve blades for your materials.

Perforation Patterns

The perforation pattern you pick changes how your product looks and works. You can choose round, square, slot, hexagonal, or fancy holes. Each shape has its own good points:

- Round holes are useful and cheap, good for HVAC and building jobs.

- Square holes are strong and easy to see through, great for security.

- Slot holes let things flow in one direction, perfect for sorting materials.

- Hexagonal patterns spread out stress, so they are strong but light.

- Fancy and custom patterns look nice and still work well.

How you lay out the pattern matters too. Straight lines make things even, while staggered patterns are stronger and let in more air. You should balance hole size, space between holes, and open area to get the right airflow, strength, and look. For example, more open area lets in more air but can make things weaker. The thickness of your material should fit the pattern to keep quality and strength.

Customization Needs

Many jobs need custom perforating blades to reach special goals. You can pick blade materials, shapes, and tooth styles for your needs. The table below shows common ways to customize:

| Aspecto de personalização | Detalhes / Exemplos |

|---|---|

| Materiais da lâmina | Choices include 52100 steel, solid carbide, and other special steels. |

| Blade Designs | Pick from round blades, cutoff blades, and more. |

| Tooth Configurations | Choose high-low v-style, standard v-style, scalloped, peg style, or slant tooth. |

| Cut and Tie Measurements | Change the cut length and space between cuts for easy tearing and handling. |

| Formulários | Used in packaging, paper, food, and medical packaging. |

| Functional Purposes | For easy opening, air flow, safety seals, and easy tearing. |

| Customization Drivers | Based on material, hole pattern, and job type. |

| Blade Material Benefits | Solid carbide is good for long jobs; 52100 steel is strong and hard. |

| Métodos de corte | Guillotine, swing-style, and other ways to cut. |

| Tooth Design Benefits | Deep and high-low teeth make cutting easier and lower strain on the material. |

You can ask for reverse-engineering of old blades to make them better. This helps your blades cut clean, tear easily, and last longer. Custom blades help you meet tough rules and make your work faster.

Tip: Always check your material, the hole pattern you want, and any special needs before picking a perforating blade. The right blade gives you better results and fewer problems.

Manutenção

Wear and Replacement

When you use perforating blade knives in factories, you can have wear and replacement problems. If the blade edge gets dull or worn, it will not cut well. This makes the holes look uneven. If blades are chipped or bent, you might hear loud noises or feel shaking. This can hurt your machines. If you see nicks, chips, or cracks, the blade is not safe to use. Machines must work harder and use more power when blades are not sharp. Blades that jam or get too hot can stop your work often. If you see rough edges or cuts that take longer, your blades need fixing or changing. Damaged blades can even break and cause safety problems.

Common Wear and Replacement Issues Table

| Emitir | Impacto no desempenho |

|---|---|

| Dull edges | Poor cuts, uneven perforation |

| Chipped or bent blades | Vibration, noise, machine strain |

| Visible cracks or nicks | Blade integrity compromised |

| Increased energy use | Higher operational costs |

| Frequent downtime | Lower productivity |

| Inconsistent cut quality | Rough edges, uneven finishes |

| Overheating equipment | Safety risks, blade damage |

You should check your perforating blade knives often. Change them if you see any of these problems. This helps your work stay safe and run well.

Solução de problemas

Troubleshooting helps you fix problems with perforating blade knives fast. First, check the blade pressure so you do not hurt your material. Look at all moving parts to make sure nothing wobbles. Wobbling can make holes look bad. Sharpen or change counter knives to keep blades sharp. Clean your machine parts often so everything works smoothly. Use good parts when you need to replace something. Test the holes you make to see if they are right. Write down how you set up your machine so you can do it again next time.

Follow these steps to fix problems:

- Check blade pressure and change it if needed.

- Look for wobbling or parts that do not line up.

- Sharpen or change counter knives when they get dull.

- Clean rollers, belts, and machine parts often.

- Use good, certified parts for replacements.

- Test the holes to make sure they are even and right.

- Write down what works for future use.

- Make sure rollers and material feed move together.

- Keep the material feed speed steady.

- Change roller pressure and tension to stop slipping or stretching.

You can stop uneven holes by keeping your machine clean and lined up right. Troubleshooting keeps your blades working well and stops long breaks.

Preventive Care

Preventive care helps your perforating blade knives last longer and cut better. Plan regular checks and maintenance for your blades. Clean blades and machine parts to stop stuff from building up. Oil moving parts to lower rubbing and wear. Change blades before they get dull or broken. Watch blade condition with sensors or by looking at them. Teach your team to spot uneven holes or blade wear.

Nanjing Metal helps you keep your blades working well with strong quality checks. They check the first blades, new materials, and blades during and after making them. Special heat treatments and cold processes make blades stronger and last longer. ISO certification means you get the same good quality every time.

Tip: If you do regular care and fix problems fast, your perforating blade knives will work their best. You keep your products good, stop long breaks, and make your work safer.

Best Practices

Critérios de seleção

When picking perforating blade knives, you need to think about a few key things. The blades should fit your material and what you are making. This helps you get neat cuts, makes blades last longer, and keeps your work steady. Look at the blade type, what it is made of, the edge shape, any coatings, how much the maker knows, and if they check quality.

| Aspecto | Considerações-chave |

|---|---|

| Tipo de lâmina | Perforating knives are special blades that poke holes in materials and can cut over and over. |

| Materiais da lâmina | You want blades that are hard but not too easy to break. Some good choices are carbide, high-carbon steel, stainless steel, tool steels, and ceramics. |

| Design de Borda | Choose the edge shape you need: straight, serrated, scalloped, beveled, or toothed. The right edge shape helps you work faster. |

| Revestimentos | Use coatings like Titanium Nitride, Teflon, Hard Chrome, DLC, or PTFE to keep blades safe from sticky stuff, rust, and wearing out. |

| Manufacturer Expertise | Pick makers who know about packaging, textiles, and food jobs. They help you pick the best blade. |

| Garantia de qualidade | Good makers check their blades well so they last and work right. |

Tip: Always use perforating blade knives that fit your material and job. This stops problems and keeps your work going well.

Referência rápida

You can use these steps to pick and care for your perforating blade knives. This guide helps you keep blades working well and gives you the same good results every time.

- Check blades often for rust, cracks, chips, or dull spots. Use a magnifying glass and bright light to see better.

- Make a plan to check blades. Do it every day, week, or month, depending on how much you use them. Clean blades after each use to stop rust and dirt.

- If cuts look uneven, check the cutter strips, blade depth, cutting force, speed, and blade shape. Make sure the blade fits your material.

- Test cuts and use tools to see if the cuts are even. Do the tests again to make sure.

- Teach workers how to clean, check for safety, oil, and set up blades. Good training stops problems and helps blades last.

- Get new or custom blades if you need better cuts or want blades to last longer. Custom blades help you with new jobs.

- Write down what you do and use checklists for care and fixing problems. This helps you remember every step and not miss anything.

Note: If you follow these best practices for perforating blade knives, you cut better, make blades last longer, and stop work less. You get good results and keep your work running well.

To get the best results with perforating blade geometry, you should:

- Pick a blade thickness and stiffness that fits your material. This helps you cut at the right speed and waste less.

- Use blade materials like carbide, stainless steel, or tool steel for your job.

- Pick the right tooth size and shape for neat holes and easy tearing.

- Try coated blades to help them stay sharp and stop long breaks.

- Test and change knife settings before you start making lots of cuts.

- Make blade designs that fit your machines and materials.

- Watch how the blades work and make changes if needed.

If you take care of your blades and make smart changes, your cuts will stay neat and your work will go smoothly. If you need help or special blades, talk to Nanjing Metal’s sales engineers.

Perguntas frequentes

What is perforating blade geometry?

Perforating blade geometry means the blade’s shape, angle, thickness, and tooth profile. This geometry helps you control how the blade cuts. It also affects how neat the holes look and how long the blade lasts.

How do I choose the right perforating blade geometry for my material?

Match the blade’s edge angle, tooth profile, and thickness to your material. Use sharper angles and fine teeth for soft materials. Pick thicker blades and stronger tooth profiles for tough materials.

Why does blade material matter for perforating blade knives?

Blade material changes how strong and tough the blade is. It also affects how long the blade lasts and what it can cut. Stainless steel stops rust. Carbide works longer in hard jobs.

How often should I replace or sharpen my perforating blade knives?

Check your blades often. Replace or sharpen them if they get dull, make rough cuts, or need more force. Checking blades often keeps your cuts neat and stops long breaks.

Can I get custom perforating blade geometry for special applications?

Yes, you can ask Nanjing Metal for custom blade geometry. You pick the shape, tooth pattern, and material. Custom blades help you fix special cutting problems and work faster.

What maintenance steps keep perforating blade knives performing well?

Clean blades after you use them. Look for chips or dull spots. Oil moving parts. Change worn blades quickly. Regular care keeps your cuts neat and helps blades last longer.

How does perforating blade geometry affect production speed?

Better blade geometry lowers cutting force and heat. You work faster, get cleaner cuts, and stop less. The right geometry helps you keep up steady work and good quality.

Veja também

Por que as Facas de Perfurar para Embalagens São Amplamente Utilizadas na Indústria de Embalagem