Хватит Идти на Компромисс: Почему Ножи Для Сдвиговых Ножниц, Изготовленные на Заказ, Превосходят Готовые Альтернативы

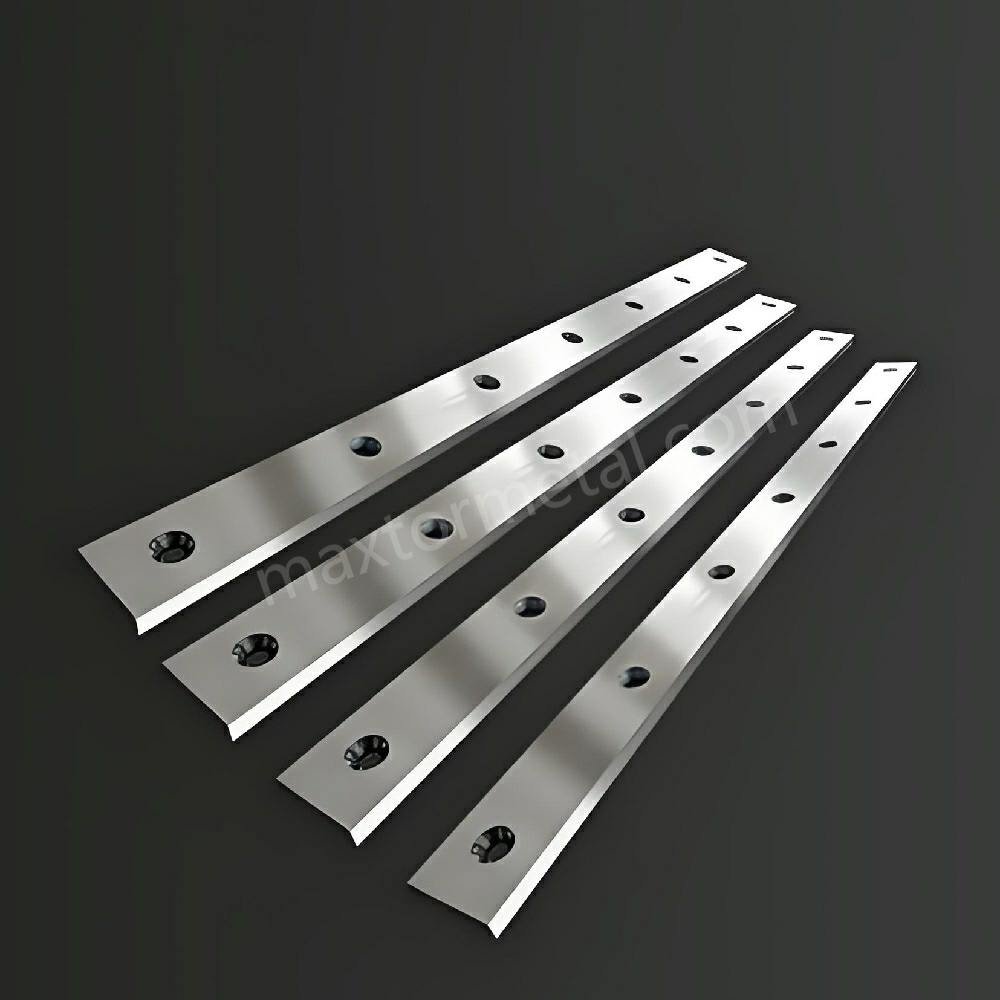

You should have cutting tools that do more than just the basics. Custom industrial shear blades are stronger and more exact than regular ones. Off-the-shelf blades cannot match their quality. Custom blades are made with special edge shapes, better materials, and skilled work. Metal Industrial’s made in usa cutting tools use custom steps to stay sharp longer. […]

Полное Руководство по Сдвиговым Ножам для Нержавеющей Стали: Материалы и Геометрия для Высококачественной Резки

When you pick shear blades for stainless steel, you face special problems. Stainless steel gets hard fast and wears out tools. Galling and strong metal make cutting hard. You may see too much burring, blade wear, and bent material. Good blade material and exact shape help stop bite and tear. Metal Industrial uses new ways to […]

Анализ Сколов Сдвиговых Ножей: Топ-5 Коренных Причин и Экспертные Стратегии по Предотвращению и Ремонту

Анализ сколов на режущих лезвиях помогает определить причины их повреждения. Он также показывает, почему система выходит из строя в процессе гидравлической резки. Когда лезвия изнашиваются или подвергаются нагрузке, они начинают скалываться. Это приводит к потере времени и ухудшению качества резки. Повреждения, вызванные ненадлежащим техническим обслуживанием или проблемами с гидравликой, могут остановить работу и привести к финансовым потерям. Вам необходимо проверить […]

За Пределами Термической Обработки: Достижение Превосходного Срока Службы с Криогенно Обработанными Сдвиговыми Ножами

Вам нужны лезвия, которые хорошо работают и дольше служат в сложных условиях. Лезвия ножниц, обработанные криогенным методом, лучше, чем обычные лезвия, подвергнутые термообработке. Ключевые моменты: Лезвия ножниц, обработанные криогенным методом: процесс и принципы. Что такое криогенная обработка? Криогенная обработка — это особый способ сделать лезвия ножниц прочнее и долговечнее. Сначала лезвие нагревается до высокой температуры. […]

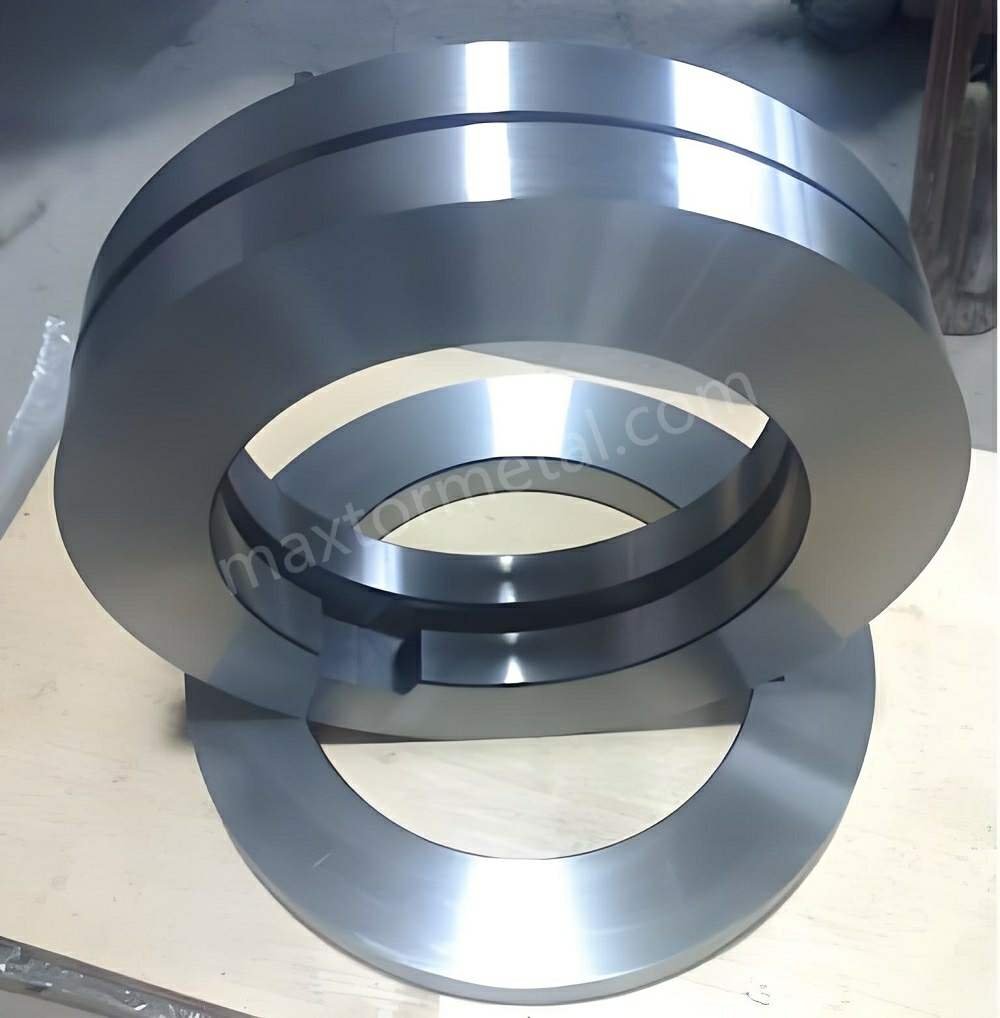

Специализированные Ножи для Резки Сортового Проката: Достижение Точности и Минимизация Деформации при Резке Заготовок

You need good tools to cut billets well. Bar shear blades with the right shape and material help you make clean cuts. They also help you waste less material. If you pick the right blade size and edge shape for your material, you get better results. Your blades will last longer too. Many workers have problems like bent steel, […]

Ножи Сдвиговых Ножниц OEM против Альтернатив Послепродажного Обслуживания: Что Обеспечивает Лучший ССВ?

You want the best deal for your work. Picking OEM shear blades or aftermarket ones depends on your needs. It also depends on how much risk you can handle. It matters how important your job is. Total cost of ownership (TCO) means more than the price you pay. It also includes how long the blades last, the […]

Мастерство Резки: Критическая Роль Переднего Угла (Угла Заточки Сдвигового Ножа) в Промышленном Сдвиге

You will see that the rake angle is very important in industrial shearing. This angle changes how well you cut, how fast you work, and how long your blade lasts. The table below shows how different rake angles change shearing force and cut quality: Rake Angle Type Effect on Shearing Force Effect on Cut Quality […]

Максимизация Времени Безотказной Работы: Выбор Лучших Ножей Для Сверхмощных Сдвиговых Ножниц для Металлолома и Обработки Толстых Листов

Вы хотите, чтобы станки долго работали при резке металлолома и толстых листов. Выбирайте прочные режущие лезвия, которые прослужат долго и изготовлены из подходящей для вашей работы стали. Подбирайте материал лезвия в соответствии с обрабатываемым металлом. Найдите режущие лезвия, изготовленные по новым технологиям и с возможностью индивидуального заказа. Компания Metal Industrial предлагает вам эти возможности. […]

Ножи Для Горячей vs. Холодной Резки: Полное Руководство по Выбору Материала и Температурным Пределам

Imagine you choose the wrong blades for a job. The blades fail quickly because you did not match the material to the heat of the metal. You need to know the right blades for hot or cold metal. Metal changes when you cut it at high or low temperatures. The right blades make a big […]

Исчерпывающее Руководство Покупателя по Промышленным Сдвиговым Ножам: 7 Проверок Качества Перед Покупкой

You should look at seven important things before buying industrial shear blades. These things are blade material, application match, manufacturing tolerances, edge design, equipment compatibility, supplier reputation, and total cost. If you do not check these, your machine may stop working. You could face safety problems and spend more money. Use the Buying guide for Industrial […]