You often have hard problems when cutting composite films. Rotary blades have trouble with frayed edges, heat, and sticky mess. Ultrasonic knives fix these issues. You get smooth edges, less heat, and great results with thin or layered films. For neat, high-quality cuts, ultrasonic knives work better.

Key Takeaways

- Ultrasonic knives cut composite films with fast vibrations. This makes the cuts clean and stops frayed edges. They also cause less heat damage than rotary blades.

- Rotary blades are good for simple, single-layer films. These films can be plastic, paper, or nonwovens. Rotary blades are cheap and easy to use.

- Ultrasonic knives are best for cutting tough films. These films can be sticky, have many layers, or have fibers inside. Ultrasonic knives give smooth, sealed edges and make less waste.

- Ultrasonic knives do not need cleaning or blade changes often. This helps production lines move faster with fewer stops.

- Rotary blades must be sharpened and lined up often. If not, they can make rough edges and waste material, especially with hard films.

- Ultrasonic knives work well in automated and robotic systems. They help make cuts more exact and faster for hard jobs.

- You should pick your cutting tool based on your film type. Also think about edge quality, speed, and how much you want to spend.

- Working with trusted blade makers like Nanjing Metal can help. They can give you custom solutions to make cutting better and faster.

Rotary Blades Overview

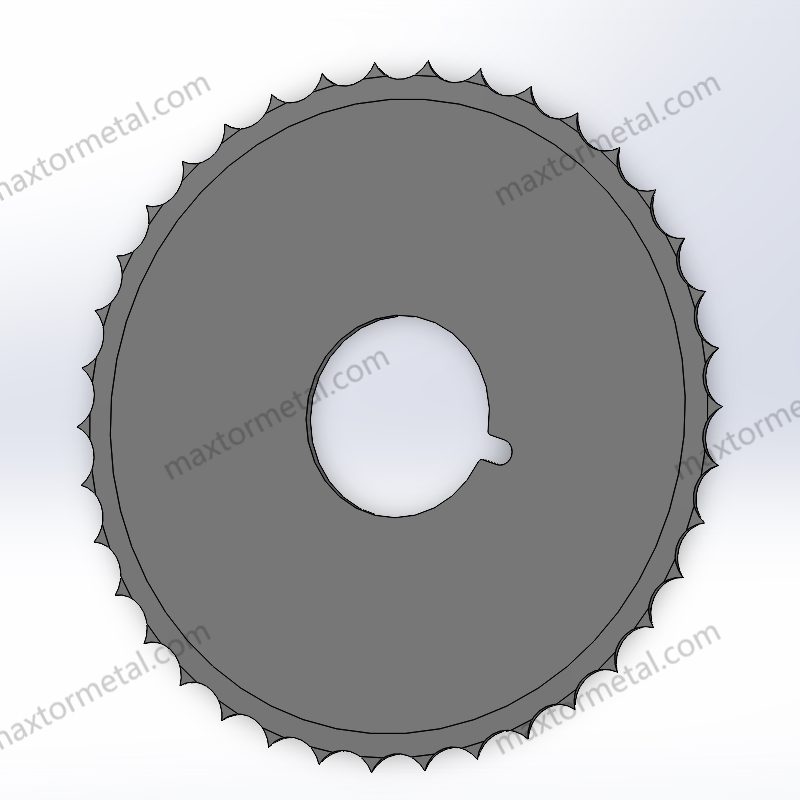

How Rotary Blades Work

Rotary blades cut like scissors do. Two round knives spin in different ways. This makes a force that cuts the material. Sometimes, the material wraps around the lower blade. This helps keep the pressure steady and gives you more control. You can make clean cuts and pick the slit width you want. This way, the film does not wrinkle or sag. You must line up the knives right and take care of them. The person using the machine needs to be careful. If you do not do these things, you might see tears or dirty edges.

- Shear slitting uses two rotary knives for a scissor-like action.

- The wrap shear setup gives better edge control for thick or stiff films.

- You get neat cuts and the slit width you need.

- Good alignment and care are needed for the best cuts.

- Shear slitting is very precise and works well for big jobs.

Rotary Blades: Applications

Many industries use rotary blades to cut films, foils, and soft materials. These blades can slit, sheet, perforate, and score. Packaging, textiles, rubber, plastics, medical, hygiene, and label making all use this tool. The spinning blades cut fast and work well for busy lines. For example, rotary blades can cut many fabric layers, technical textiles, vinyl, fiberglass, and composite materials. Big machines from top brands use these blades for cutting textiles and composite films.

Tip: Custom rotary blades from a good maker help you get better cuts and last longer, especially with tough materials.

Rotary Blades: Limitations

Rotary blades have some problems when cutting composite films:

- The edge can fray if the blade gets dull or the angle is wrong.

- Heat can build up because composite films do not cool well. This heat can hurt the film and make the cut worse.

- Sticky or heat-sealed films can leave glue on the blade. Even with special coatings, you may need to clean the blade a lot.

- Some composites are rough and wear out the blade fast. You will need to change or sharpen the blade more often.

- If the tool holder is not steady, the edge can look bad and fray more.

- Cooling with air or spray can help with heat but makes things harder.

You must check the blade and how you cut often. If you do not, you may have more stops, waste, and uneven cuts.

Note: Taking care of your blades and picking the right one helps stop these problems.

Ultrasonic Knives Overview

How Ultrasonic Knives Work

Ultrasonic knives cut with very fast vibrations. The blade moves back and forth 20,000 to 40,000 times each second. A transducer makes the blade vibrate by turning electricity into movement. The horn connects to the transducer and makes the vibrations stronger. These strong vibrations go right to the blade’s edge.

- The blade sends ultrasonic energy to the cutting spot.

- The material melts and softens right at the edge, so you use less force.

- There is less rubbing, and sticky films do not stick to the blade.

- The system has a generator, transducer, horn, and blade that work together.

- You do not need a very sharp blade or lots of pressure, so the film does not chip or break.

This way of cutting works great for sticky, stretchy, or tough composite films. You get a neat and exact cut every time.

Ultrasonic Knives: Applications

Ultrasonic knives can cut many kinds of composite films and special materials. These tools are good for jobs that need clean and careful cuts on hard films. Here is a table that shows some composite films you can cut with ultrasonic knives:

| Composite Film Type | Examples / Description |

|---|---|

| Aerospace Composites | Carbon fiber, Nomex, honeycomb structures |

| Resin Composites | Resin-based composite materials |

| Rubber Composites | Rubber and rubber-based composite materials |

| Non-woven Fabric Composites | Non-woven fabrics and their composite materials |

| Thermoplastic Films and Fabrics | Synthetic leather, thermoplastic composites |

You will see ultrasonic knives used in aerospace, cars, electronics, and packaging. These places need very neat and smooth edges for their products. You can also use ultrasonic knives for resin things, rubber items, and non-woven fabrics.

Ultrasonic Knives: Advantages

Ultrasonic knives have many good points over rotary blades:

- You get sealed edges that do not fray or come apart, so the edge looks better.

- The cut is always smooth and neat, even on sticky or layered films.

- There is almost no heat, so the film does not bend or melt.

- This way is up to four times faster than sewing and ten times faster than glue.

- You do not get holes from stitches or gaps from glue, so seams stay strong.

- Cutting and sealing happen at the same time, which saves time and keeps the film strong.

Ultrasonic knives are easy to use in fast and automatic lines. You can run many knives with one generator, set up different cuts, and use smart controls for good timing. These things help your line work fast and smooth, with less stopping and more even results.

Tip: If you want to make your line faster and get better edges, ultrasonic knives are a smart choice for today’s factories.

Rotary Blades vs. Ultrasonic Knives

Cutting Quality

When you cut composite films, the edge quality is important. You want the edges to look smooth and clean. There should not be fraying or tearing. Rotary blades often leave rough edges. This happens more with sticky or layered films. Sometimes, the edge curls or has small burrs. These problems get worse if you push harder or if the blade is dull.

Ultrasonic knives make a much cleaner cut. The fast vibration melts and splits the film at the edge. This gives you less roughness and almost no curling. You will not see big tears. Even when cutting fast, ultrasonic knives keep the edge smooth. The layers stay together. You do not have to worry about the film breaking.

Here is a table that shows how the cutting quality is different:

| Cutting Method | Edge Roughness | Edge Curling | Burr Formation | Material Separation |

|---|---|---|---|---|

| Rotary Blades | High | Present | Occasional | More tearing |

| Ultrasonic Knives | Low (31% less) | Minimal | None | Layers stay intact |

Tip: If you want perfect edges and less rework, ultrasonic knives are better for composite films.

Material Compatibility

You need to pick the right tool for your material. Rotary blades work well for simple, single-layer films. They also work for paper and nonwoven materials. But rotary blades can have trouble with sticky, layered, or fiber-reinforced films. The blade can get sticky, and you may waste more material.

Ultrasonic knives can cut many types of materials. You can use them for composite films, prepregs, and pressure-sensitive adhesives. They also work for fiber-reinforced materials like carbon fiber or aramid. The vibration keeps the blade clean. Glue does not build up. You get a neat cut, even with tough or sticky films.

Note: Always use the right blade for your material. Using the wrong tool can cause more stops and higher costs.

Production Efficiency

You want your line to run fast and without problems. Rotary blades can cut quickly. But you may need to stop often to clean or change the blade. Sticky films and tough composites wear out the blade faster. This means more stops and more work.

Ultrasonic knives are good for fast, automatic lines. The blade stays clean longer. You do not need to sharpen or change it as much. You can cut more material with fewer stops. Many people say they have less downtime and get more done with ultrasonic knives. This is true for complex or sticky films.

🚀 Boost your output: Ultrasonic knives help you cut more, waste less, and keep your line running.

Maintenance and Cost

When you pick a way to cut, think about care and price. Each choice has its own needs and costs. You want your line to work well and not spend too much.

Rotary blades need a lot of care. You have to sharpen or change them often. This is true when you cut sticky or tough films. Sticky stuff can leave glue on the blade. You will need to stop and clean the blade more. If the blade is not sharp, cuts look bad and waste goes up. Buying new blades and doing care work can cost a lot. For easy jobs, rotary blades do not cost much at first. You do not need special skills to use them. Many factories use rotary blades for simple films. They are easy to set up and swap out.

Ultrasonic knives cost more at the start. You need special tools and training to use them. But you will spend less time on care. The blade stays cleaner because vibration keeps glue off. You do not need to sharpen or change the blade as much. This means you stop less and cut more. Over time, you may save money with less waste and downtime. Ultrasonic knives are good for hard jobs that need clean edges and fast speed.

Here is a table to help you compare:

| Feature | Rotary Blades | Ultrasonic Knives |

|---|---|---|

| Initial Cost | Low | High |

| Maintenance Frequency | High | Low |

| Blade Replacement | Frequent | Rare |

| Cleaning Needs | Often | Minimal |

| Downtime | More | Less |

| Training Needed | Basic | Specialized |

Note: If you need special rotary blades for your films, you can work with a trusted maker. Nanjing Metal has over 20 years of skill. Their team makes custom blades for many jobs. You can check their custom blade solutions for your needs.

Many people say ultrasonic knives help them cut more with less trouble. In places like aerospace and cars, companies pick ultrasonic knives for their good cuts and low care. If you run fast lines or cut sticky, layered films, ultrasonic knives can save you time and money.

💡 Tip: Always look at your needs and budget before you pick. The right tool can help you spend less and make more.

When to Choose Ultrasonic Knives

Multi-Layer Films

Composite Films with Multiple Layers

Cutting films with many layers is hard. Rotary blades can make the layers come apart or leave rough edges. This causes more waste and lowers the quality. Ultrasonic knives fix these problems. The fast vibration lets you cut each layer cleanly. You get smooth, sealed edges and the layers stay together.

Many industries use ultrasonic knives for carbon fiber prepreg, glass fiber composites, and packaging films with many layers. You lose less material and get more good products. German car makers say they have fewer mistakes and better cuts after switching to ultrasonic knives for composite films.

Tip: If you want to keep all layers together, ultrasonic knives are a great choice.

Fiber-Reinforced Materials

Fiber-reinforced materials like carbon fiber or aramid are tough to cut. Rotary blades often leave messy edges or hurt the fibers. Ultrasonic knives cut these materials easily. The vibration cuts through fibers without pulling or tearing. You get a neat edge every time.

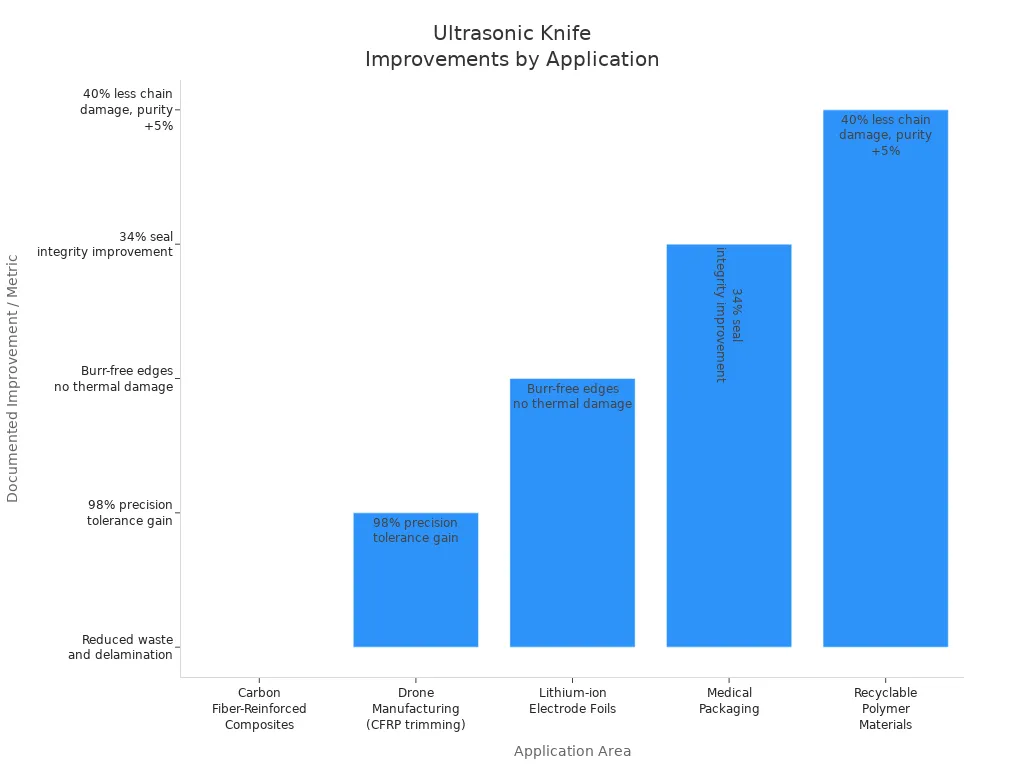

A study shows over 60% of European composite makers now use advanced cutting tools, including ultrasonic knives. Drone makers saw a 98% better precision for carbon fiber-reinforced plastics. This means cleaner edges and less waste.

| Application Area | Documented Improvement / Benefit | Supporting Detail / Metric |

|---|---|---|

| Carbon Fiber-Reinforced Composites | Stops layers from coming apart and lowers waste | Over 60% of European composite makers use advanced cutting; German car makers report better cuts and less waste |

| Drone Manufacturing (CFRP trimming) | 98% better precision than old ways | Cleaner edges and more good products |

Adhesive and Sticky Materials

Pressure-Sensitive Adhesive Films

Sticky films, like pressure-sensitive adhesives, are hard for rotary blades. Glue sticks to the blade, so you must stop and clean more. This slows your work and costs more money. Ultrasonic knives use vibration to keep the blade clean. You spend less time fixing things and get better cuts.

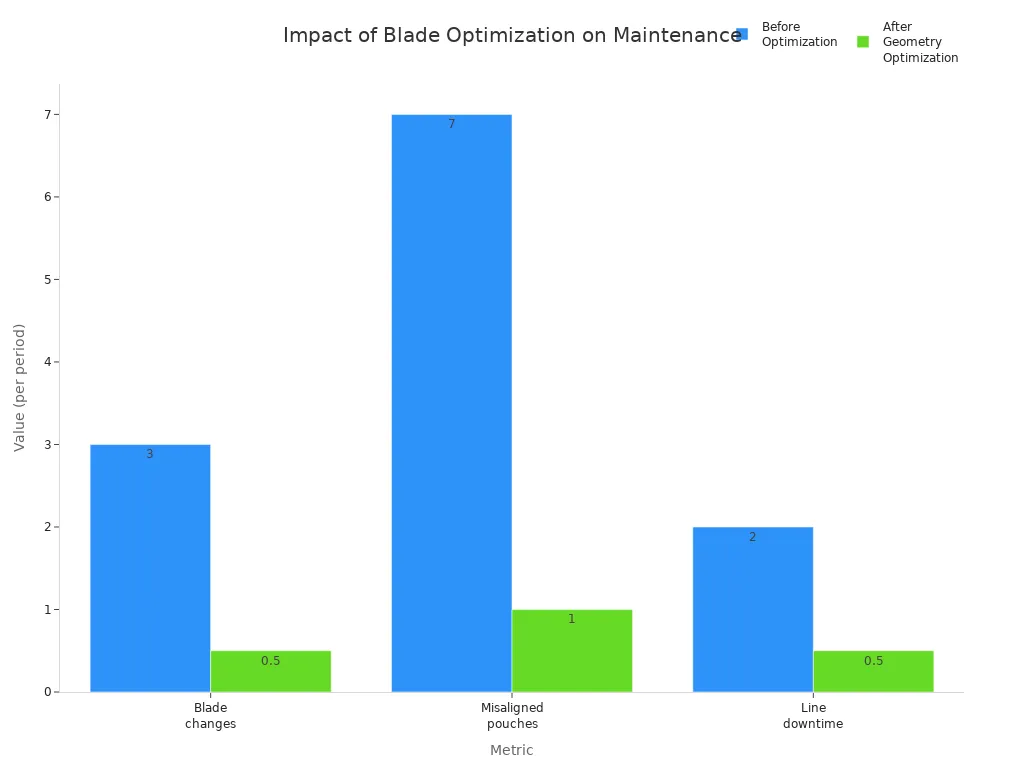

A case study shows the change:

| Metric | Before Optimization | After Geometry Optimization |

|---|---|---|

| Blade changes | 3 times per day | Once every 2 days |

| Misaligned pouches | 7% | Less than 1% |

| Line downtime | 2 hours per week | Less than 30 minutes per week |

You can use special coatings like Titanium Nitride or Teflon to stop sticking. Some people say Diamond-Like Carbon coated blades had no glue build-up in four weeks. These coatings help you change blades less and keep your line running well.

Tacky or Sticky Laminates

Sticky laminates, like protective films or double-sided tapes, often mess up rotary blades. This causes rough edges and more stops. Ultrasonic knives use fast vibration to stop this. The blade stays cleaner and you get a neat, sealed edge.

You will have less time cleaning and fewer blade changes. Cleaning with solvents or ultrasonic systems after each shift keeps blades working well. This lets you focus on making products, not fixing blades.

Note: If you cut sticky films, ultrasonic knives help you work faster and clean less.

High Precision Needs

Tight Tolerances and Complex Shapes

Some jobs need very exact cuts and tricky shapes. Rotary blades may not be accurate enough. Ultrasonic knives are great for these jobs. The vibration lets you make careful, exact cuts, even on hard patterns.

In electronics and medical devices, you need perfect edges and shapes. Ultrasonic knives help you meet these rules. For example, battery makers use ultrasonic knives to get smooth edges, which is important for safety.

Micro-Patterned or Delicate Films

Thin or special films need gentle cutting. Rotary blades can tear or bend them. Ultrasonic knives use less force and almost no heat. This keeps the film safe and the pattern perfect.

Medical packaging companies saw a 34% better seal with ultrasonic knives. Recyclers saw up to 40% less damage and cleaner flakes. You get better cuts and higher quality.

💡 Pro Tip: For very careful work, ultrasonic knives help you meet strict rules and waste less.

Automation Requirements

High-Speed Production Lines

You want your line to go fast without stopping. Rotary blades need lots of stops for cleaning or blade changes, especially with tough or sticky stuff. Ultrasonic knives work well on fast, automatic lines. The vibration keeps the blade clean and lowers the need for fixing.

Reports show ultrasonic knives need less pressure to cut. This means fewer mistakes like tears or rough edges. The blade lasts longer and makes less dust. You get a cleaner and faster process.

Integration with Robotic Systems

Modern factories use robots and CNC machines for hard cutting jobs. Ultrasonic knives fit well in these systems. They can move in many ways and cut with high speed and accuracy. You can cut tough materials, like composites and honeycomb, with great results.

Ultrasonic knives also use less energy and cause little heat damage. This makes your work better for the planet and saves money.

Note: If you want to make your line better, ultrasonic knives give you better quality, speed, and help the environment.

Automation Requirements

High-Speed Production Lines

You want your line to go fast and work well. Ultrasonic knives help you cut faster without losing quality. The blade vibrates, so there is less rubbing. You do not have to stop a lot to clean or change the blade. This means you get more products done in less time.

Many factories need to fill big orders for composite films. Rotary blades can slow you down with more stops. Sticky films and tough layers make this worse. Ultrasonic knives help you skip these problems. The blade stays clean, and glue or fibers do not build up.

Tip: If you want to make more products and keep your line moving, ultrasonic knives are best for fast jobs.

Here is a quick comparison:

| Feature | Rotary Blades | Ultrasonic Knives |

|---|---|---|

| Maximum Line Speed | Moderate | High |

| Downtime for Maintenance | Frequent | Rare |

| Edge Quality at High Speed | Inconsistent | Consistent |

| Cleaning Intervals | Short | Long |

Ultrasonic knives help your line keep moving. You spend less time fixing things and more time making products.

Integration with Robotic Systems

Modern factories use robots to cut hard shapes and patterns. Ultrasonic knives work great with these machines. Robots can be set to cut composite films with tricky designs. The vibrating blade makes it easy for robots to move fast and stay in control.

If you want to upgrade your line, you need tools that fit with robots. Ultrasonic knives are simple to add to robot arms or CNC machines. You get better cuts and waste less material. The blade does not get stuck on sticky stuff. Robots can work longer without stopping.

💡 Note: For smart factories, ultrasonic knives help you go faster and cut better.

When Rotary Blades Are Suitable

Rotary blades are a good choice for many film cutting jobs. You can use them for normal materials, low-cost work, and simple tasks. In these cases, you get steady results without needing fancy tools or spending a lot at the start.

Standard Films

Thin Plastic Films

Rotary blades cut thin plastic films very well. Materials like PE, PP, and PVC work great with this method. High-speed steel rotary blades made with CNC tools are very accurate. This helps stop shaking and gives even cuts. You will see little waste and steady quality, even if you run the machine for a long time.

- Rotary blades are best for cutting single-layer plastic films.

- You get smooth edges and do not have to worry about fraying.

- Special rotary knives have made 30% fewer cutting mistakes and 22% more machine time in real use.

Paper and Cardboard

If you cut paper or cardboard, rotary blades are easy and work well. The way they cut fits these materials and gives sharp edges. You do not need a hard setup or special training to get good cuts.

Nonwoven Materials

Nonwoven fabrics, like those in hygiene or filters, also cut well with rotary blades. The process is fast and keeps the material strong. You can cut a lot at once and do not need to change much.

Tip: For simple, single-layer films and basic stuff, rotary blades give you speed, good cuts, and are easy to use.

Cost-Sensitive Applications

High-Volume, Low-Margin Production

If you need to make a lot and do not make much money per item, rotary blades help you save. They last a long time, so you do not have to change them often. This means your line stops less and you make more.

- Good rotary blades last longer, so you do not change them much.

- Fewer changes mean less stopping and more work done.

- Strong materials like hardened steel or carbide keep the blade sharp and make better products.

- Long blade life also means your machines wear out slower and cost less to fix.

- You make less waste and use fewer things, which is better for the planet.

Limited Equipment Budgets

If you do not have much money for machines, rotary blades cost less at the start than other cutting tools. You do not need to buy special machines or pay for lots of training. This makes rotary blades a smart pick when you need to save money.

Minimal Maintenance Requirements

Rotary blades are easy to take care of. Their simple design means you do not spend much time fixing them. When you need a new blade, it is quick and does not need special tools or skills.

Note: Rotary blades are a cheap way to cut a lot when you do not make much money per item.

Simpler Production Lines

Manual or Semi-Automated Systems

Rotary blades fit well in lines that are run by hand or are only a little bit automatic. You do not need fancy tech or hard software to use these systems. For example, servo motor rotary tools from iECHO and Eastman cut fast for woven and composite materials. These tools can use barcodes, check problems from far away, and pick blades by themselves. This makes them easy for workers with different skills.

- Rotary blades work well with powered feeders and belts.

- You can cut one or a few layers of any length and keep the tension even.

- You can add marking and rewinding systems to help keep track of pieces.

Low-Complexity Operations

If your work is simple, rotary blades keep things easy. You can do basic cuts without needing fancy machines or software. This means less training and you can focus on your main work.

Environments with Limited Technical Support

If you do not have much tech help, rotary blades are great. They are easy to use and fix, so your line keeps running with little help. You do not need outside experts or hard problem-solving.

💡 Pro Tip: For lines run by hand or with some automation, rotary blades give fast, steady cuts and can handle many materials.

Limitations and Considerations

Ultrasonic Knives: Challenges

When you think about using ultrasonic knives, you should look at a few big things. The first problem is the high starting cost. Many small and medium businesses say the price is too much. This makes it hard for them to stop using old cutting tools. Almost 68% of these businesses say the cost of ultrasonic systems is a big problem.

Even though maintenance costs are lower than with old blades, you still spend money each year. You might use up to 15% of your yearly budget just on maintenance. Training your workers is also important. Your team must learn how to use and care for the equipment safely. This training takes time and money.

Adding ultrasonic knives to your current line can be tricky. Sometimes, the new tools do not fit well with your old machines. You may need help from tech experts. More than half of factories say they have big problems when adding ultrasonic systems. Almost half also say they need tech support all the time.

Note: Before you buy ultrasonic knives, check your budget, training, and tech support. This helps you avoid surprise costs and stops in your work.

Rotary Blades: Drawbacks

Rotary blades work well for many simple films, but they have problems with tough or delicate composite films.

- Rotary blades wear out fast because they touch hard materials all the time. This means you must fix or change them a lot.

- You have to match the cutting speed just right. If you do not, the film can slip or get out of place. This can ruin delicate films.

- The space between the die and anvil must be set carefully. If it is wrong, the film can bend or get damaged, especially with soft composites.

- Flexible rotary dies are good for light films but wear out faster than solid ones. You get more flexibility but less strength.

- Cutting thick or very strong materials is hard. Rotary blades may not work well for multi-layer or stiff composites.

You will spend more time fixing and checking the blades. This can slow down your work and lower how much you make. When you cut special or expensive films, these problems can waste more material and cost more money.

Material Restrictions

Not every tool works for every film. You must pick the right tool for your film to get the best results.

- Ultrasonic knives are best for composite films, prepregs, sticky adhesives, and fiber-reinforced materials. But they may not work for very hard or super thick things, like metal foils or thick rubber sheets.

- Rotary blades are good for single-layer plastic films, paper, cardboard, and nonwovens. They have trouble with sticky, layered, or fiber-reinforced films, where the edge and layers matter a lot.

Safety and training are important too. You must teach your workers to use ultrasonic tools safely because they vibrate very fast. For rotary blades, you need to handle them right and keep them clean to stop accidents and keep cuts nice.

Note: Always check your film type, what your line needs, and what tech help you have before you pick a tool. The right choice helps you waste less, work better, and keep your team safe.

User Feedback and Industry Insights

Professional Experiences

You can learn a lot from people who use these cutting tools every day. Many workers and engineers talk about how ultrasonic knives help with composite film cutting:

- Ultrasonic carbide blades move back and forth up to 30,000 times each second. This makes cuts that are clean and exact without much work.

- You do not have to clean these blades as much. The vibration stops glue and dirt from sticking, so you do not stop your line as often.

- Some machines let you swap cutting heads. You can use either ultrasonic or rotary polygon blades, so you can do more types of jobs.

- Blade-wear checks make sure every cut is sharp and right. You get the same good results, even when you cut for a long time.

- Quick connects and pins help you set up and fix things faster. You spend less time getting ready and more time making parts.

- Rotary ultrasonic systems give steady power. This means you can seal things faster and better, and you do not have to fix the machine as much.

- Special designs let you add these tools to your machines easily. This helps you make more products and save money.

- Some systems, like Soniseal™, can be washed down. You can clean them without taking them off the line, which saves time and keeps things running.

Note: Many workers say that using ultrasonic knives means less fixing, better edges, and more products made.

Community Discussions

You can find good tips in online groups and factory forums. People share what works for them when cutting composite films:

- Ultrasonic cutting and bonding give fast, neat results. You do not need glue or extra stuff, so your work is easier.

- Ultrasonic bonding joins things at the molecular level. This stops holes or weak spots that sewing can make. Your finished items stay strong.

- Using ultrasonic bonding means you do not need glue tools or spray nozzles. You spend less time fixing things and more time working.

- Rotary ultrasonic systems give steady, strong power. This helps you seal things faster, even with tricky or thick films.

- Many people see less waste. Ultrasonic systems do not use heat bars that waste energy or materials.

- Ultrasonic cut and seal works for many kinds of composite films and nonwovens. You can do more jobs with just one tool.

- Some special ultrasonic tools let you put elastic right onto other materials. You do not need glue, so your work is simpler and costs less.

💡 Tip: People in these groups say ultrasonic knives are best for hard-to-cut films and fast lines. You get cleaner cuts, less waste, and fixing is easier.

Picking the best cutting tool depends on what you are cutting, how nice you want the edges, and what your work goals are. Look at this table to help you choose:

| Decision Point | Ultrasonic Knives | Rotary Blades |

|---|---|---|

| Material Type | Delicate, heat-sensitive, or multi-layer films | Standard fabrics, textiles, nonwovens |

| Edge Quality | Clean, precise, minimal fraying | Smooth, continuous, less critical edges |

| Production Needs | High-precision, specialized, automated lines | High-volume, cost-sensitive, simple setups |

FAQ

What advantages do ultrasonic knives offer over rotary blades for composite film cutting?

Ultrasonic knives give you smoother edges and less sticky mess. They do not get as hot as rotary blades. These knives are great for films with many layers or sticky parts. You will see fewer mistakes and waste in your work.

Can you use rotary blades for composite films?

Rotary blades work for simple or single-layer films. If the film is sticky or has many layers, rotary blades may fray the edges. You might need to clean them more often. For hard jobs, ultrasonic knives work better.

Is ultrasonic cutting better for carbon fiber prepreg?

Yes, ultrasonic knives are better for carbon fiber prepreg. The vibration keeps the layers together and stops fibers from pulling out. You get neat, sealed edges for strong parts in cars and planes.

How do you choose between ultrasonic knives and rotary blades?

Think about your film type, how neat you want the edge, and how fast you need to work. Use ultrasonic knives for tricky, sticky, or careful jobs. Rotary blades are good for normal films and saving money. Ask a trusted maker for help if you need a special answer.

What materials work best with ultrasonic knives?

Ultrasonic knives work best with composite films, prepregs, sticky adhesives, and fiber-reinforced stuff. They also cut nonwovens and thin laminates well. For very hard or thick things, test first to make sure they work.

Do ultrasonic knives require special maintenance?

You should clean the blade and check the vibration system often. Taking care of the knife helps it last longer and work well. Training your team helps stop problems and keeps your line running.

See Also

The Essential Guide to Rotary Slotter Blades in Packaging

Top 10 Tips to Make Your Circular Razor Blades Last Longer

What Are Rolling Shear Blades and How Do They Work

What Are Round Blades and How Are They Used in Industries

Maintaining Paper Roll Splitter Blades for Maximum Efficiency

What Are Corrugated Packaging Blades and Their Industrial Applications

One Response

It is appropriate time to make some plans for the future and it’s

time to be happy. I have read this post and if I could

I want to suggest you some interesting things or advice.

Perhaps you could write next articles referring to this article.

I wish to read even more things about it!