Ngừng Thỏa Hiệp: Tại Sao Lưỡi Dao Cắt Xén Công Nghiệp Tùy Chỉnh Vượt Trội Hơn Các Lựa Chọn Sẵn Có

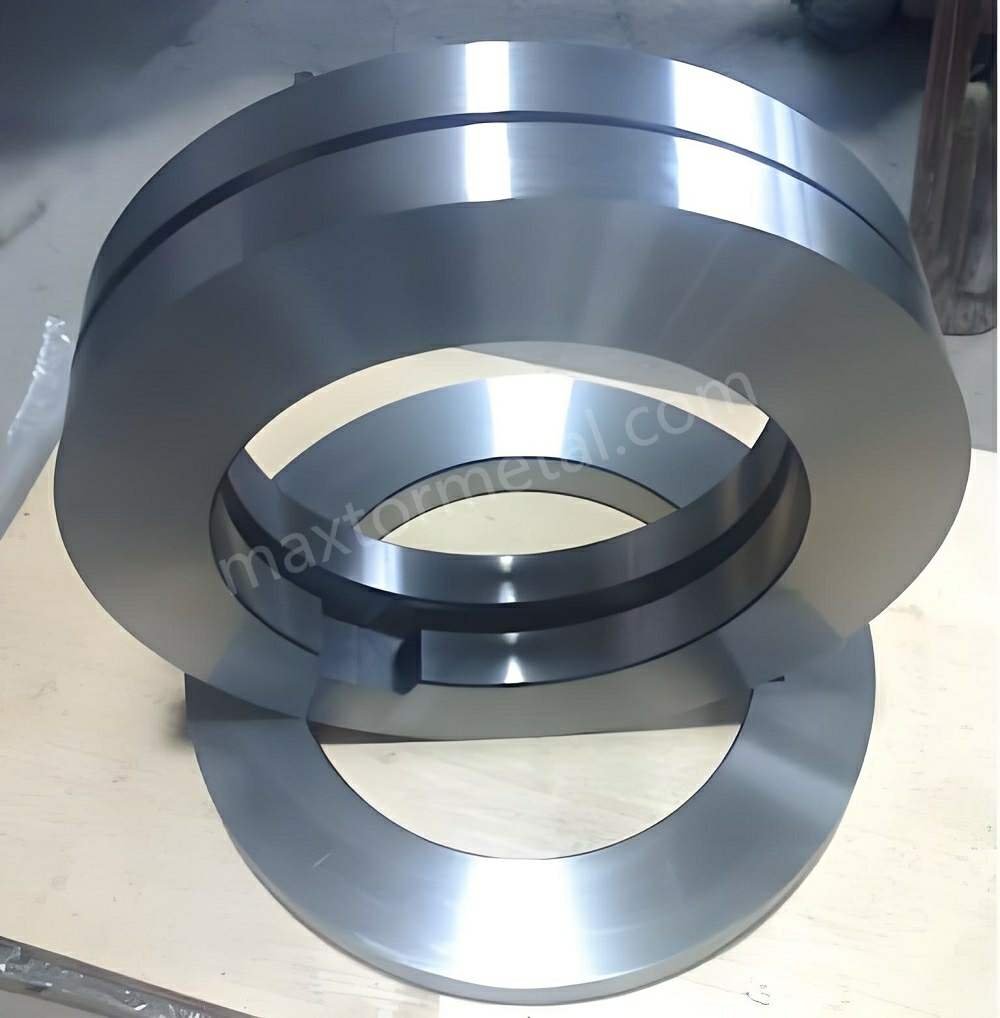

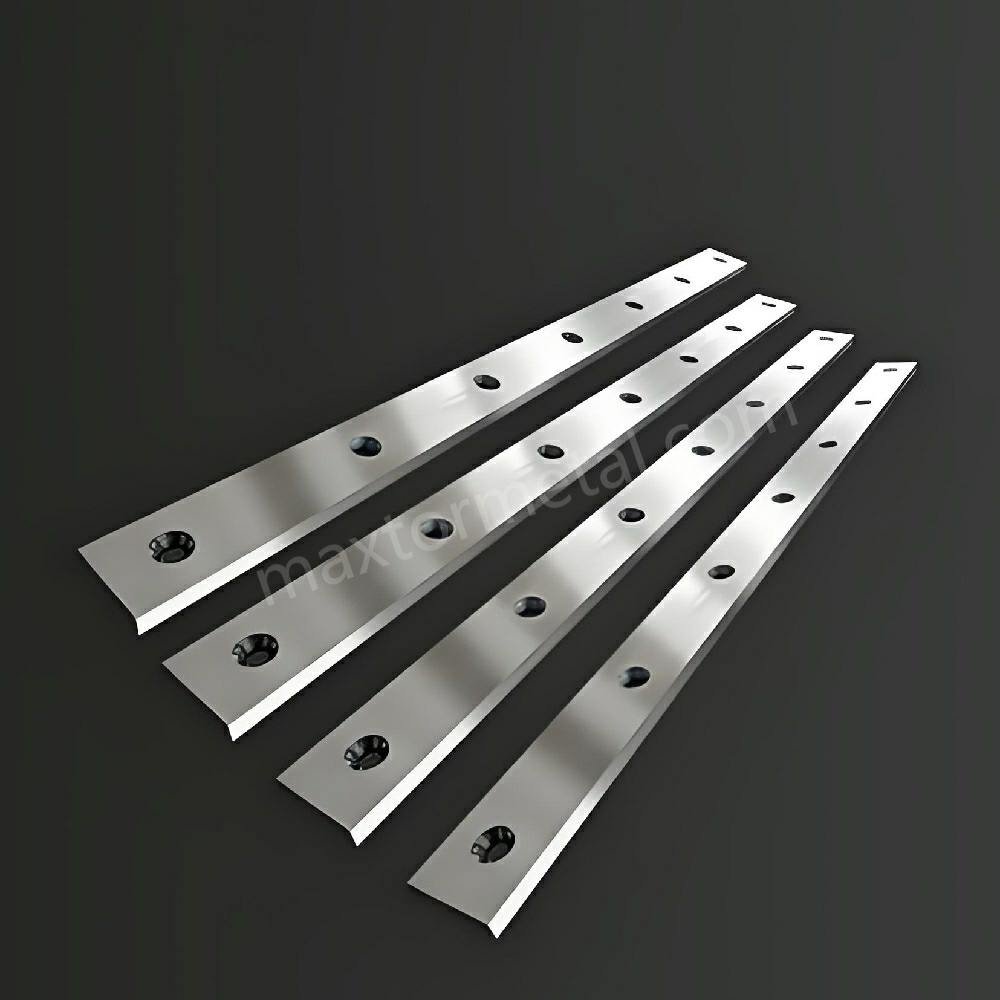

You should have cutting tools that do more than just the basics. Custom industrial shear blades are stronger and more exact than regular ones. Off-the-shelf blades cannot match their quality. Custom blades are made with special edge shapes, better materials, and skilled work. Metal Industrial’s made in usa cutting tools use custom steps to stay sharp longer. […]

Hướng Dẫn Chi Tiết Về Lưỡi Dao Cắt Xén cho Thép Không Gỉ: Vật Liệu và Hình Học cho Vết Cắt Chất Lượng Cao

When you pick shear blades for stainless steel, you face special problems. Stainless steel gets hard fast and wears out tools. Galling and strong metal make cutting hard. You may see too much burring, blade wear, and bent material. Good blade material and exact shape help stop bite and tear. Metal Industrial uses new ways to […]

Phân Tích Mẻ Lưỡi Dao Cắt Xén: 5 Nguyên Nhân Gốc Hàng Đầu và Các Chiến Lược Chuyên Môn để Phòng Ngừa và Sửa Chữa

Shear blade chipping analysis helps you find why blades get damaged. It also shows why the system fails in your hydraulic cutting process. When blades get tired or stressed, they chip. This makes you lose time and good cuts. Damage from bad maintenance or hydraulic problems can stop work and cost money. You need to check […]

Vượt Ra Ngoài Xử Lý Nhiệt: Mở Khóa Tuổi Thọ Vượt Trội với Lưỡi Dao Cắt Xén Xử Lý Lạnh Sâu

You want blades that work well and last longer in hard places. Cryogenic treated shear blades are better than regular heat-treated blades. Key Takeaways Cryogenic Treated Shear Blades: Process and Principles What Is Cryogenic Treatment Cryogenic treatment is a special way to make shear blades stronger and last longer. First, the blade gets heated to a high temperature. […]

Lưỡi Dao Cắt Xén Thanh Chuyên Dụng: Đạt Được Độ Chính Xác và Giảm Thiểu Biến Dạng trong Việc Cắt Phôi Thỏi

You need good tools to cut billets well. Bar shear blades with the right shape and material help you make clean cuts. They also help you waste less material. If you pick the right blade size and edge shape for your material, you get better results. Your blades will last longer too. Many workers have problems like bent steel, […]

Lưỡi Dao Cắt Xén OEM so với Tùy Chọn Thị Trường Sau: Loại Nào Mang Lại TCO Tốt Nhất?

You want the best deal for your work. Picking OEM shear blades or aftermarket ones depends on your needs. It also depends on how much risk you can handle. It matters how important your job is. Total cost of ownership (TCO) means more than the price you pay. It also includes how long the blades last, the […]

Nắm Vững Vết Cắt: Vai Trò Quan Trọng Của Góc Nghiêng (Góc Vát Lưỡi Dao Cắt Xén) Trong Cắt Xén Công Nghiệp

You will see that the rake angle is very important in industrial shearing. This angle changes how well you cut, how fast you work, and how long your blade lasts. The table below shows how different rake angles change shearing force and cut quality: Rake Angle Type Effect on Shearing Force Effect on Cut Quality […]

Tối Đa Hóa Thời Gian Hoạt Động: Chọn Lưỡi Dao Cắt Xén Chịu Lực Tốt Nhất cho Kim Loại Phế Liệu và Xử Lý Tấm Dày

You want to keep machines working for a long time when cutting scrap metal and thick plates. Pick heavy duty shear blades that last long and have the right steel for your job. Match the blade material to the metal you cut. Find shear blades with new manufacturing and custom choices. Metal Industrial gives you these features. […]

Lưỡi Dao Cắt Xén Nóng so với Lạnh: Hướng Dẫn Chi Tiết Về Lựa Chọn Vật Liệu và Giới Hạn Nhiệt Độ

Imagine you choose the wrong blades for a job. The blades fail quickly because you did not match the material to the heat of the metal. You need to know the right blades for hot or cold metal. Metal changes when you cut it at high or low temperatures. The right blades make a big […]

Hướng Dẫn Mua Hàng Toàn Diện cho Lưỡi Dao Cắt Xén Công Nghiệp: 7 Điểm Kiểm Tra Chất Lượng Trước Khi Mua

You should look at seven important things before buying industrial shear blades. These things are blade material, application match, manufacturing tolerances, edge design, equipment compatibility, supplier reputation, and total cost. If you do not check these, your machine may stop working. You could face safety problems and spend more money. Use the Buying guide for Industrial […]