So Schärfen und Pflegen Sie Wolframcarbidmesser

Das Schärfen und Pflegen von Wolframkarbidmessern kann eine Herausforderung sein. Das Material nutzt sich zwar nicht leicht ab, kann aber bei unvorsichtiger Behandlung ausbrechen. Manche erhitzen die Klinge zu stark, was zu feinen Rissen führen kann. Die Verwendung weicherer Schleifmittel als Wolframkarbid kann die Klinge beschädigen. Um Wolframkarbidmesser effektiv zu pflegen, sollte man […]

Warum Wolframcarbidmesser Absplittern — Häufige Fehlerursachen und Wie Man Sie Vermeidet

Wolframkarbidmesser können bei unsachgemäßer Verwendung oder starken Stößen ausbrechen. Da sie sehr hart sind, bleiben sie lange scharf. Dennoch ist Vorsicht geboten. Die industrietauglichen Wolframkarbidmesser von Metal sind in Fabriken äußerst robust. Viele Anwender berichten von einer langen Lebensdauer dieser Messer.

Wolframkarbid vs. Stahl für Industrieklingen: Leistung, Verschleiß und Kosten

When you compare tungsten carbide vs steel blades, you notice significant differences. Tungsten carbide blades are much harder and do not wear out quickly. They maintain their sharpness even under high temperatures. On the other hand, steel blades are better at absorbing hits and shocks. Initially, steel is less expensive. The table below highlights these main differences: […]

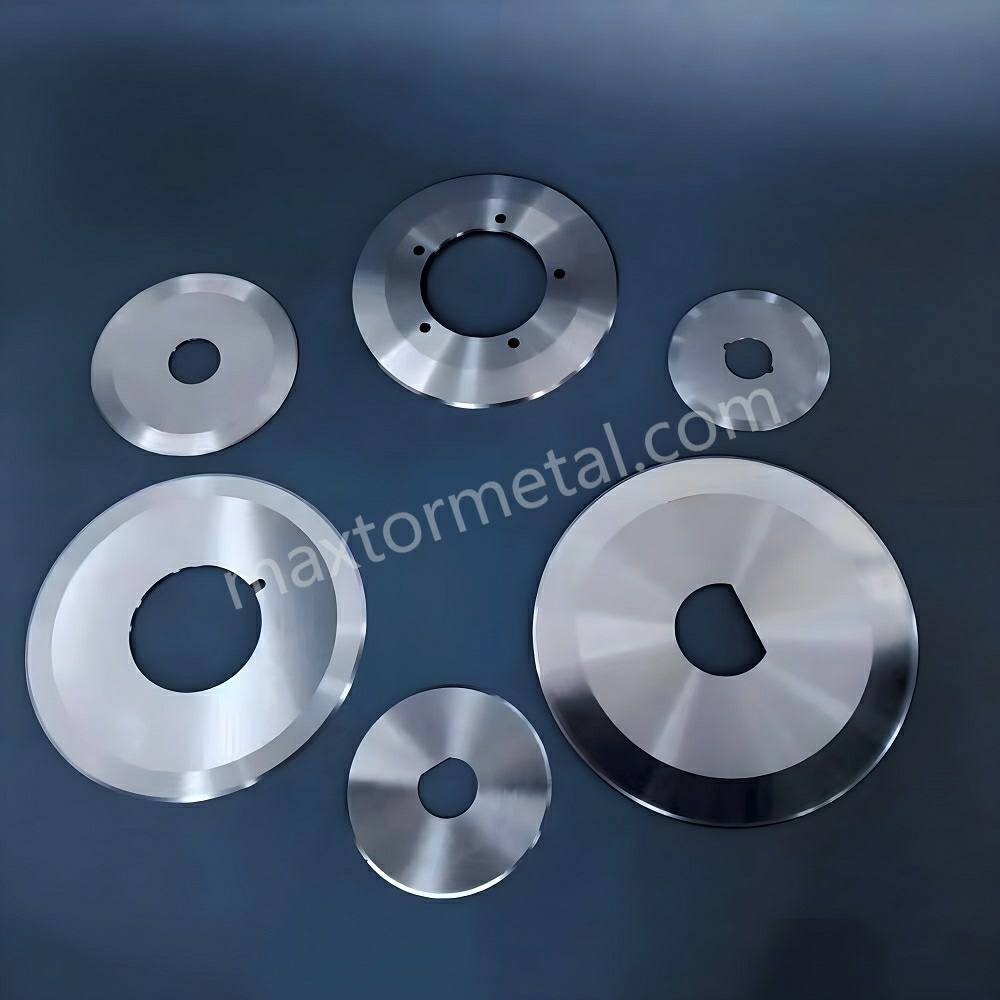

Rotationsschneidklingen Aftermarket vs. OEM: Eine Kosten-Nutzen-Analyse

You want blades that give you good value. Many people pick OEM rotary slitter blades. These blades have high quality. They last a long time. They work well and do not break easily. When you choose blades, you think about cost. You should also consider how long they will last. Check how often they need fixing. […]

Präzision und Langlebigkeit: Rotationsschneidklingen zum Schneiden von Gummi und Kunststoff

You use rotary slitter blades for rubber and plastic to make accurate and strong cuts. Good blades help you get cleaner cuts and last longer. This is true when you pick blades that fit your needs. Companies like Nanjing Metal Industrial have many choices. They focus on making blades that work well for you. The table below shows how […]

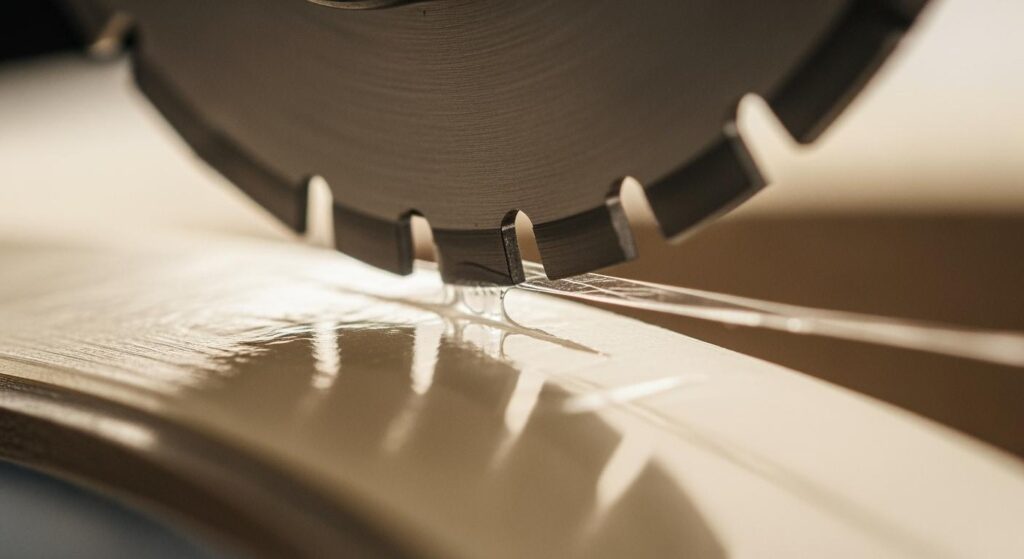

5 Bewährte Methoden zur Verlängerung der Lebensdauer von Rotationsschneidklingen

You want your rotary slitter blades to last a long time and extend rotary slitter blade life. By keeping your blades sharp, you save money while also experiencing less downtime and improved product quality. For instance, using high-speed steel or carbide-tipped blades significantly contributes to this goal. These blades can enhance your productivity by making you […]

10 Entscheidende Faktoren bei der Auswahl eines Rotationsschneidmesser-Lieferanten

Choosing the right rotary slitter knife supplier can change your cutting results. You need slitting tools that work well and give steady quality. A good supplier with smart manufacturing and helpful service can lower downtime and make your results better. Key Takeaways Blade Quality Standards Precision and Consistency You want slitting knives that work the same every […]

Rotationsschneidklingen für Klebeband: Durchschneiden der Klebehaftung

You use rotary slitter blades for tape to cut sticky materials. These blades help you handle tough sticky problems. Sticky problems can slow down how fast you work. If you pick good blades, you get cleaner cuts. Cleaner cuts mean you waste less tape. Blades made from tungsten carbide and high-speed steel last longer. These materials also […]

Warum Hochpräzise Rotationsschneidklingen Entscheidend für Ihren Betrieb Sind

You need high precision rotary slitter blades for your work. These blades help your machines run well and not break down. Sharp and balanced rotary slitter blades make clean cuts. They also help you use less material and waste less. This tool cuts wide rolls into smaller pieces with exact sizes. It helps you keep your products […]

Austausch von Rotationsschneidklingen: Eine Schritt-für-Schritt-Anleitung

If you do not perform a rotary slitter blade replacement the right way, you can lose time making products. About 25% of machine downtime occurs because tools break, such as blades. Good blades help you cut better and waste less. These blades also enhance workplace safety by reducing accident risks. There are many blade types and custom […]