Debes tener herramientas de corte que hagan más que solo lo básico. Cuchillas de cizalla industriales personalizadas Son más resistentes y precisas que las convencionales. Las cuchillas estándar no pueden igualar su calidad. Las cuchillas personalizadas se fabrican con filos especiales, materiales de mejor calidad y mano de obra calificada. Las herramientas de corte Metal Industrial, fabricadas en EE. UU., utilizan pasos personalizados para mantener el filo por más tiempo. Las cuchillas personalizadas pueden durar hasta... 50% más largoTambién requieren reemplazos 30% con menos frecuencia. Al elegir soluciones personalizadas, obtiene herramientas confiables y gasta menos en reparaciones.

Puntos clave

- Las cuchillas de tijera industriales personalizadas duran hasta la mitad que las cuchillas convencionales. Esto significa que no es necesario reemplazarlas con tanta frecuencia.

- El uso de cuchillas personalizadas permite a las empresas ahorrar aproximadamente 281 TP4T al año, gracias a la reducción del tiempo de inactividad y las reparaciones.

- Las cuchillas personalizadas se fabrican para trabajos especiales. Ofrecen mayor precisión de corte y se adaptan mejor a sus necesidades.

- Las cuchillas personalizadas utilizan materiales avanzados y tratamiento térmico. Esto las hace más resistentes y resistentes para trabajos exigentes.

- Limpiar y engrasar las cuchillas personalizadas prolonga su vida útil. El cuidado regular también mejora su rendimiento y ahorra dinero.

- Las cuchillas personalizadas pueden cortar diversos materiales, como metal, plástico y textiles. Esto las hace útiles en diversas industrias.

- Elegir cuchillas personalizadas contribuye al medio ambiente. Reduce los residuos y utiliza materiales reciclables.

- Las cuchillas personalizadas llegan rápidamente, en un plazo de 15 a 20 días. No tendrá que esperar mucho para recibir sus herramientas.

Cuchillas de tijera industriales personalizadas vs. estándar

Diferencias de rendimiento

Necesita herramientas que se adapten bien a sus necesidades. Las cuchillas de tijera industriales personalizadas son mejores que las cuchillas estándar. Al elegir la fabricación a medida, obtiene cuchillas hechas a medida. Notará la diferencia cada vez que corte.

Comparación de vida útil y precisión de corte

Las cuchillas de tijera industriales personalizadas duran más y cortan con mayor suavidad. Las cuchillas estándar se desgastan rápidamente y deben reemplazarse con frecuencia. La fabricación a medida le permite elegir los mejores materiales y formas de filo para su trabajo. Sus cuchillas se mantienen afiladas y resistentes, incluso en trabajos difíciles.

Un estudio de 2022 descubrió que las empresas que usaban cuchillas optimizadas para el rendimiento ahorraron aproximadamente 28% sobre costes En un año, gastará menos dinero en cuchillas nuevas y reparaciones. Además, realizará más trabajo y obtendrá mejores resultados.

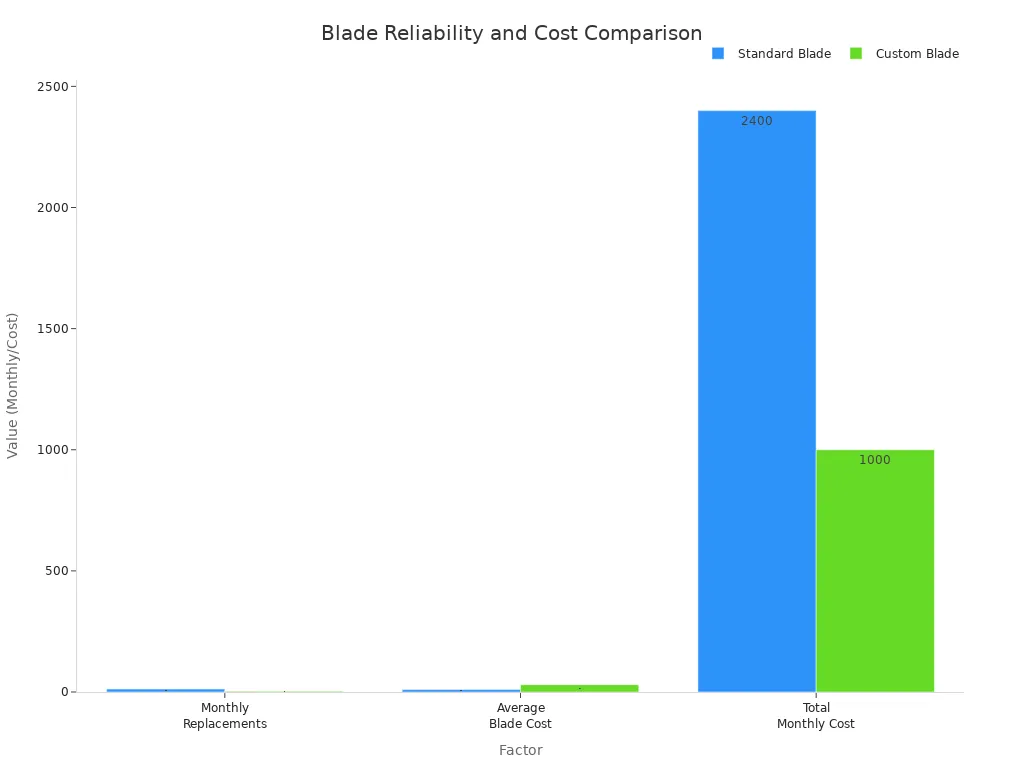

He aquí una comparación sencilla:

| Factor | Hoja estándar | Hoja personalizada |

|---|---|---|

| Reemplazos mensuales | 12 | 3 |

| Costo promedio de la cuchilla | $10 | $30 |

| Costo mensual total (incl. mano de obra) | ~$2,400 | ~$1,000 |

Ahorra dinero rápidamente. La fabricación a medida te ofrece hojas que se adaptan a tus máquinas y materiales. Consigue el ángulo de ataque, el bisel y la holgura adecuados para cada trabajo. Esto se traduce en menos desperdicio y mayor precisión.

Puede obtener más información sobre las opciones de cuchillas personalizadas en Página del producto de cuchillas personalizadas.

Desventajas de las cuchillas genéricas

Las cuchillas genéricas no solucionan sus problemas específicos. Utilizan diseños simples y materiales comunes. Obtiene herramientas que sirven para muchos trabajos, pero no son excelentes para ninguno. Esto provoca más tiempo de inactividad, mayores costos y menor rendimiento.

La fabricación a medida soluciona estos problemas. Obtendrá cuchillas hechas a medida. Así es como las cuchillas a medida ayudan con problemas comunes:

| Desafíos operativos | Soluciones proporcionadas por Custom Blades |

|---|---|

| Costos más altos | Alternativas rentables |

| Plazos de entrega lentos | Opciones de entrega más rápidas |

| Disponibilidad limitada | Soluciones a medida para necesidades específicas |

| Operaciones ineficientes | Eficiencia optimizada y tiempo de inactividad reducido |

| Desafíos de la mezcla no convencional | Capacidad para abordar requisitos únicos |

Quiere que su producción sea confiable. Las cuchillas de cizallas industriales personalizadas se lo garantizan. Por ejemplo:

- Una planta de cajas redujo el tiempo de inactividad de 14 horas a menos de 5 horas mediante el uso de cuchillas de microdientes personalizadas.

- Una planta de granulado de plástico permitió que las palas duraran entre 10 y 42 días, ahorrando 18.000 TPM al año.

- Una instalación de procesamiento de carne mejoró la velocidad con hojas de acero inoxidable 440C y revestimiento DLC, solucionando el óxido y el opacamiento.

La fabricación a medida le permite elegir materiales y formas de filo avanzados. Obtendrá cuchillas compatibles con la impresión 3D, la metalurgia y el procesamiento de alimentos. Podrá manejar nuevos materiales y nuevas formas de fabricar fácilmente.

Quiere herramientas que sigan el ritmo de su negocio. Cuchillas de tijera industriales personalizadas de Nanjing Metal Industrial Le ayudamos a mejorar. Obtendrá una mayor vida útil de la cuchilla, menos tiempo de inactividad y mejores resultados. También podrá afrontar nuevos desafíos, como la impresión 3D y la fabricación avanzada.

La fabricación a medida es mucho más que simplemente fabricar una cuchilla. Se trata de ofrecerle la solución perfecta para su trabajo. Obtendrá el mejor rendimiento, fiabilidad y valor. Puede confiar en que sus herramientas funcionarán siempre.

Diseño y geometría de bordes de precisión

Quiere que cada corte sea suave y preciso. La fabricación a medida le ayuda a conseguirlo. Obtendrá hojas con formas y ángulos de filo especiales para su trabajo. Esto significa que siempre cumplirá con altos estándares de precisión.

Ángulos de cuchilla optimizados

La fabricación a medida le permite elegir los ángulos de cuchilla según sus necesidades. No tiene que usar una cuchilla que se adapte a cada trabajo. Obtendrá una geometría de herramienta que se adapta a su material y proceso. Esto es importante para la impresión 3D, la metalurgia y el procesamiento de alimentos.

Ajustes de inclinación y bisel

Puedes elegir los ángulos de ataque y bisel que mejor se adapten a tus necesidades. Para metales blandos como el aluminio, un ángulo de ataque de 10-15° y un ángulo de bisel de 20-25° facilitan el corte. Esto también evita que el metal se doble. Para materiales más duros como el acero inoxidable, un ángulo de ataque menor (5-8°) y un bisel más pronunciado (30-35°) hacen que la hoja sea más resistente y duradera.

Los ajustes personalizados le ayudan a obtener el filo perfecto para cada trabajo. Si corta plásticos, necesita un ángulo de corte más afilado para que el plástico no se derrita. Si trabaja con materiales rugosos, necesita biseles más firmes para proteger la hoja. Las hojas estándar utilizan ángulos básicos, pero la fabricación a medida le ofrece la geometría exacta que necesita. Esto se traduce en cortes más limpios, mayor vida útil de la hoja y menos tiempo reparando sus herramientas.

Espacio libre para tipos de materiales

También necesita la distancia correcta entre la cuchilla y el material. La fabricación a medida le permite ajustar esta distancia para cada trabajo. Si corta láminas delgadas, necesitará una distancia pequeña para un acabado uniforme. Si corta materiales gruesos o apilados, necesitará más espacio para evitar atascos. Esta configuración cuidadosa es importante para la impresión 3D, el reciclaje y el trabajo textil.

La fabricación a medida le permite controlar cada detalle del filo de su cuchilla. Obtendrá los mejores resultados en su trabajo.

Impacto en la calidad del corte

La geometría de filo personalizada cambia el resultado de sus cortes. Obtendrá mejores cortes y resultados más precisos. En la industria textil, se utilizan filos más anchos para tela y más afilados para papel. Esto proporciona cortes más rápidos y un producto más atractivo. En el reciclaje, las formas especiales prolongan la vida útil de las cuchillas y reducen las reparaciones.

Cambiar el ángulo de corte de la cuchilla reduce la fuerza necesaria. Consume menos energía y sus herramientas duran más. Además, las cuchillas se desgastan menos. Esto significa que ahorra dinero y realiza más trabajo.

| Material | Tipo de geometría | Resultado del desempeño |

|---|---|---|

| Papel artesanal | Hoja microdentada de 0,5 mm | 26% menor desgarro en los bordes, 15% cortes más limpios |

| Algodón | Bisel pulido, festoneado | 18% menos desperdicio de tela |

| etiquetas térmicas | Corte ondulado fino, capa DLC | 21% mayor tiempo de actividad de la máquina |

| Antes del ajuste | Después de la optimización de la geometría |

|---|---|

| Cambios de cuchillas: 3 veces al día | Cambio de cuchillas: una vez cada 2 días |

| Bolsas desalineadas: 7% | Bolsas desalineadas: <1% |

| Tiempo de inactividad de la línea: 2 horas/semana | Tiempo de inactividad de la línea: <30 minutos/semana |

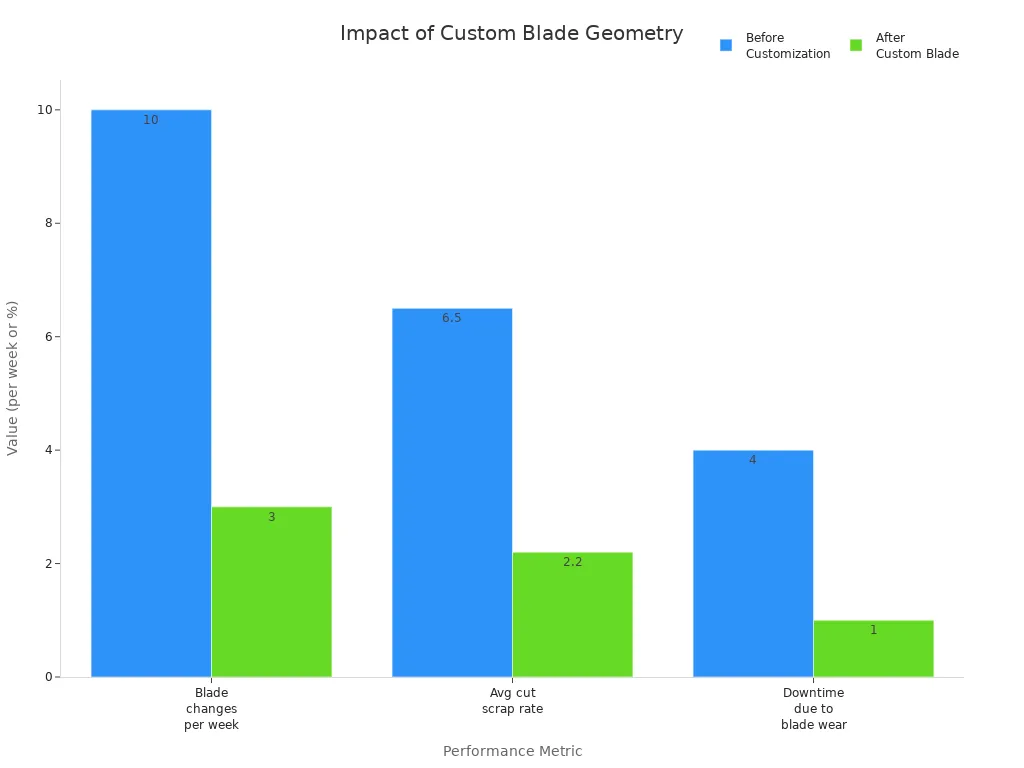

| Métrica | Antes de la personalización | Después de Nanjing Metal Custom Blade | Mejora |

|---|---|---|---|

| Cambios de cuchillas por semana | 10 | 3 | –70% |

| Tasa promedio de corte de desechos | 6.5% | 2.2% | –66% |

| Tiempo de inactividad debido al desgaste de la cuchilla | 4 horas/semana | 1 hora/semana | –75% |

Nota la diferencia en su trabajo. La fabricación a medida reduce el desperdicio y aumenta su tiempo de actividad. Obtiene más de cada cuchilla.

Tratamiento térmico avanzado y forjado

Quiere cuchillas que duren mucho tiempo. Metal Industrial utiliza un tratamiento térmico especial y etapas de forjado. Estas etapas hacen que sus cuchillas sean más resistentes y confiables. Obtendrá cuchillas con la dureza y resistencia adecuadas para su trabajo.

| Proceso | Beneficio |

|---|---|

| Austenitización al vacío | Hace que la hoja sea fuerte por dentro. |

| Enfriamiento con gas a presión | Mantiene la hoja con la forma correcta. |

| Múltiples ciclos de templado | Ayuda a que la hoja se mantenga fuerte en el calor. |

- Forja: Calienta el material para hacerlo más fuerte y denso.

- Tratamiento térmico: utiliza temple y revenido para hacer que la hoja sea más dura y dure más.

Con estos métodos especiales, obtendrá cuchillas que cumplen con estrictos estándares. Además, obtendrá una mejor preparación del filo. Esto significa que sus cuchillas se mantendrán afiladas y resistentes, incluso en trabajos exigentes de impresión 3D o metalurgia.

La fabricación a medida le brinda control total sobre el diseño y el filo de la cuchilla. Obtendrá el mejor rendimiento, menos tiempo de inactividad y mayor valor para sus herramientas. Podrá afrontar cualquier desafío, desde la impresión 3D hasta el reciclaje, con confianza.

Fabricación personalizada y selección de materiales

Necesita cuchillas que soporten trabajos pesados. La fabricación a medida le permite elegir los materiales y pasos adecuados para su trabajo. Dispone de cuchillas industriales diseñadas para usos importantes, como la impresión 3D, el reciclaje o la metalurgia.

Materiales avanzados para cuchillas de corte

La fabricación a medida le permite elegir mejores materiales para sus cuchillas. No tiene que usar solo acero. Puede optar por metales en polvo, aleaciones o insertos de carburo. Estos materiales prolongan la vida útil de las cuchillas y optimizan su funcionamiento, incluso en entornos difíciles.

Metal en polvo y aleaciones

Los metales en polvo y las aleaciones especiales son muy fuertes y resistentes. Sus cuchillas se mantienen afiladas por más tiempo y cortan con mayor precisión. El proceso comienza con la selección de los polvos metálicos adecuados. Los ingenieros mezclan y prensan estos polvos. Esto crea una cuchilla sólida y uniforme en todas sus partes. De esta manera, todas las cuchillas tienen la misma forma y funcionan de la misma manera.

Puede confiar en cuchillas de cizallas industriales personalizadas que cumplen con altos estándares. Los informes de análisis de materiales demuestran que los productos químicos son los adecuados para el grado. Los informes de tratamiento térmico indican la dureza y resistencia de la cuchilla. Los informes de pruebas de dureza y metalografía muestran el interior de la cuchilla y demuestran su resistencia al desgaste.

| Tipo de evidencia | Descripción |

|---|---|

| Informe de análisis de materiales | Muestra que los productos químicos son los adecuados para el grado de la hoja. |

| Informe del proceso de tratamiento térmico | Explica cómo se calienta y se enfría la hoja para equilibrar la dureza y la tenacidad. |

| Informe de prueba de dureza y Metallográfica | Demuestra que la hoja es lo suficientemente dura y tiene la estructura adecuada para durar más. |

Insertos de carburo para abrasión

Los insertos de carburo hacen que las hojas sean aún más resistentes. Las puntas de carburo de tungsteno se unen a una base de acero resistente. Esta combinación proporciona a la hoja una larga vida útil y un gran poder de corte. Los insertos de carburo evitan que la hoja se desgaste rápidamente. Mantienen el filo afilado, incluso al cortar materiales muy duros. Cambia menos hojas y sus máquinas se detienen menos.

| Material | Aplicación |

|---|---|

| Carburo | Se utiliza para cortar metales duros. |

| Titanio | Bueno para muchos trabajos difíciles |

| Cuchillas Personalizadas | Hecho para necesidades de corte especiales |

Las cuchillas personalizadas de carburo y titanio no se desgastan rápidamente. Obtendrá cuchillas más duraderas y con menos cambios. Esto es importante para aplicaciones como la impresión 3D, donde se requieren cuchillas precisas y resistentes.

Cuchillas compatibles con las necesidades de la aplicación

La fabricación a medida significa que sus cuchillas están hechas para su trabajo. No tiene que usar cuchillas que se adapten a cada tarea. Puede adaptar el material y la forma del filo a sus necesidades, como procesamiento de alimentos, reciclaje o impresión 3D.

- Las hojas personalizadas utilizan materiales resistentes como carburo y titanio.

- Estos materiales ayudan a que las cuchillas duren más y funcionen mejor en superficies duras.

- Los diseños especiales hacen que las cuchillas duren más y necesiten menos cambios.

Cada trabajo requiere cuchillas diferentes. El procesamiento de alimentos requiere cortes limpios y precisos. El reciclaje requiere cuchillas resistentes para materiales duros. La impresión 3D requiere cuchillas con la forma y el recubrimiento adecuados. La fabricación a medida garantiza que sus cuchillas cumplan su función correctamente y generen menos desperdicio.

Obtendrá cuchillas que se adaptan a sus máquinas y al material que corta. Obtendrá mejores resultados, menos paradas de la máquina y más valor en cada corte.

Metal Industrial utiliza ingeniería inteligente y controles minuciosos para garantizar que las cuchillas estén siempre en buen estado. Obtendrá cuchillas fabricadas con ajustes de máquina comprobados, piezas inspeccionadas y controles rigurosos. Cada cuchilla cumple con altos estándares de resistencia y buen funcionamiento.

| Medida de control de calidad | Descripción |

|---|---|

| Calibración de parámetros de la máquina | Asegura que los cortes tengan la longitud adecuada y que la cuchilla se mueva a la velocidad y presión adecuadas. |

| Inspección rigurosa de las piezas | Los trabajadores comprueban el tamaño y buscan problemas para asegurarse de que todo esté bien. |

| Control de tolerancia | Mantiene el tamaño de la hoja muy cerca de la perfección, por lo que se adapta y funciona bien. |

Quiere cuchillas que siempre funcionen de la misma manera. La experiencia de Metal Industrial en la selección de materiales y la fabricación de cuchillas le garantiza lo que necesita. Puede obtener más información sobre cuchillas y materiales personalizados.

La fabricación a medida le permite elegir cada componente de su cuchilla. Usted elige el material, la forma del filo y el recubrimiento. Obtendrá cuchillas ideales para sus trabajos más importantes, como la impresión 3D o la metalurgia. Notará que sus cuchillas son más fiables, duran más y funcionan mejor.

Aplicaciones de cuchillas fabricadas a medida

Quiere que sus herramientas funcionen a la perfección en todo momento. La fabricación a medida le ayuda a conseguirlo. Puede usar hojas de tijera industriales personalizadas en muchos lugares. Estas hojas solucionan problemas difíciles y le ayudan a obtener excelentes resultados. Veamos cómo estas hojas ayudan en diferentes trabajos.

Metaltrabajo y Construcción

El trabajo y la construcción Metal utilizan materiales duros y grandes trabajos. La fabricación a medida le permite elegir las cuchillas que mejor se adapten a sus necesidades. Dispone de cuchillas que cortan acero grueso y barras resistentes. No se preocupe por roturas o desgastes rápidos.

- En la industria automotriz, las cuchillas personalizadas cortan y dan forma a piezas de metal como paneles y marcos de automóviles.

- En la industria aeroespacial, se necesitan palas que Cortar materiales ligeros pero resistentes para aviones..

- En la construcción, se utilizan hojas personalizadas para cortar acero y otras piezas de construcción.

La fabricación a medida le ayuda a terminar cada trabajo con menos estrés. Sus cuchillas duran más y realizan cortes más limpios. Pasa menos tiempo cambiando cuchillas y más tiempo trabajando.

Automotriz y aeroespacial

Los trabajos en la industria automotriz y aeroespacial requieren herramientas resistentes y precisas. La fabricación a medida le permite elegir la forma y el material de la cuchilla adecuados. Puede cortar titanio, aluminio y compuestos especiales sin problemas.

- Las cuchillas personalizadas con formas especiales le ayudan a cortar materiales aeroespaciales resistentes. Evita problemas como la separación de capas o el desprendimiento de fibras.

- Al cortar titanio, las hojas de carburo personalizadas se encargan del trabajo duro. Obtienes más piezas por hoja y ahorras dinero.

- Para el aluminio, las hojas personalizadas permiten cortar con rapidez y sin vibraciones. Termina los trabajos más rápido y obtiene bordes más lisos.

La fabricación a medida le ofrece la herramienta ideal para trabajos importantes. Puede confiar en que sus cuchillas funcionarán siempre, incluso con materiales duros.

Industrias del reciclaje, la alimentación y los textiles

Necesita cuchillas que funcionen en diversos entornos. La fabricación a medida le permite diseñar cuchillas para reciclaje, alimentos y textiles. Puede manipular materiales especiales y mantener sus máquinas en funcionamiento.

- En el reciclaje, las cuchillas personalizadas trituran y cortan fibras resistentes. Estas cuchillas evitan que las fibras se enreden en las máquinas.

- En la industria textil, se necesitan cuchillas para fabricar muebles, ropa y más. Las cuchillas de corte y las cizallas personalizadas le ayudan a cortar todo tipo de telas.

- En el procesamiento de alimentos, se utilizan cuchillas personalizadas para obtener cortes limpios y precisos. Así, se mantiene la buena apariencia de los alimentos y la velocidad de las líneas de producción.

Las cuchillas personalizadas son cada vez más necesarias a medida que las industrias crecen. El mercado del reciclaje textil podría alcanzar los 1.500 millones de toneladas métricas en 2030.Necesita cuchillas que resistan el paso del tiempo. La fabricación a medida le ayuda a satisfacer nuevas necesidades.

La fabricación a medida le permite elegir la cuchilla ideal para cada trabajo. Obtendrá herramientas que se adaptan a sus máquinas y materiales. Obtendrá mejores resultados y menos problemas.

| Industria | Aplicaciones | Beneficios |

|---|---|---|

| Procesamiento de alimentos | Operaciones de corte y rebanado | Precisión y cortes limpios |

| Textil | Varias aplicaciones de corte | Versatilidad y eficiencia en el corte |

| Industria del Caucho | Herramientas de corte especializadas | Soluciones a medida para materiales únicos |

| Fabricación Metal | Corte de materiales pesados | Durabilidad y longevidad bajo estrés |

La fabricación a medida le da control sobre sus cuchillas. Usted elige la forma, el material y el filo de la cuchilla. Obtendrá cuchillas más duraderas y de mejor rendimiento. Podrá realizar cualquier trabajo, desde el reciclaje hasta la industria aeroespacial, con confianza.

Las hojas fabricadas a medida demuestran la utilidad y resistencia de estas herramientas. Obtendrá la hoja ideal para cada trabajo. Ahorrará tiempo, desperdiciará menos y logrará más.

Beneficios de rendimiento y productividad

Vida útil prolongada de la cuchilla

Quiere herramientas que duren y funcionen bien. La fabricación a medida garantiza la resistencia de las hojas para trabajos pesados. Obtendrá hojas con el filo y el recubrimiento adecuados. Esto significa que cambiará las hojas con menos frecuencia y terminará más trabajo.

Las cuchillas personalizadas utilizan mejores materiales y un diseño inteligente. Se mantienen afiladas y resistentes, incluso en trabajos difíciles. El tratamiento térmico especial y el forjado prolongan su vida útil. Estos pasos ayudan a que las cuchillas se rompan menos y se desgasten más lentamente. Ahorra dinero al no tener que reemplazar las cuchillas con frecuencia.

Las cuchillas personalizadas le ayudan a optimizar su trabajo. Cortará más rápido y con menos esfuerzo. Estas cuchillas resistentes son ideales para fábricas con mucha actividad. Reducirá el tiempo de inactividad y ahorrará en reparaciones.

Reducción del tiempo de inactividad y del mantenimiento

El tiempo de inactividad es perjudicial para su negocio. La fabricación a medida le ayuda a evitarlo. Obtendrá cuchillas que se adaptan a sus máquinas y funcionan a la perfección. Esto significa menos paradas y menos reparaciones.

Las cuchillas personalizadas reducen los costos de reparación. Dedica menos tiempo a cambiar cuchillas y reparar piezas. Los estudios demuestran que las cuchillas personalizadas pueden reducir los costos a más de la mitad y permiten un trabajo más preciso. Ahorra dinero y su trabajo mejora.

Así es como las cuchillas personalizadas le ayudan a:

| Descripción de la evidencia | Beneficio |

|---|---|

| Las cuchillas personalizadas le ayudan a realizar su mejor trabajo, incluso si su línea cambia mucho o utiliza materiales duros. | Corte más rápido y mejor trabajo. |

| Las cuchillas personalizadas reducen los costos de reparación y el tiempo empleado en cambiarlas. | Menos dinero gastado y menos tiempo de inactividad |

| Los estudios demuestran que las hojas personalizadas pueden reducir los costos a más de la mitad y hacer que el trabajo sea más preciso. | Grandes ahorros y mejores resultados |

- Las hojas resistentes y personalizadas son buenas para lugares concurridos.

- Un mejor corte y menos desperdicio le ayudarán a trabajar más rápido.

- Las cuchillas de corte giratorias cortan mejor, desperdician menos y producen más.

La fabricación a medida le ofrece opciones. Metal Industrial puede entregar en 15-20 días y le permite pedir como desee. Recibirá las cuchillas cuando las necesite. Esto le permite seguir trabajando.

Mayor seguridad y eficiencia

La seguridad es importante en el trabajo. La fabricación a medida le ayuda a mantenerse seguro y a trabajar con rapidez. Obtendrá cuchillas fabricadas con aleaciones resistentes y materiales compuestos. Estas cuchillas funcionan mejor y duran más.

Las cuchillas personalizadas te ayudan a trabajar mejor. Consigues cortes más suaves y desperdicias menos material. Tecnología inteligente y automatización Simplifique su trabajo. El uso de IoT e IA en sistemas de corte le ayuda a supervisar el desgaste de las cuchillas y la calidad del corte. Esto garantiza la seguridad en su lugar de trabajo.

- El diseño inteligente y la automatización hacen que el trabajo sea más rápido.

- IoT e IA le ayudan a comprobar el desgaste y el corte de la cuchilla.

- Los materiales resistentes permiten que las cuchillas funcionen durante más tiempo y de forma más segura.

Las cuchillas personalizadas le ofrecen el mismo corte de calidad en todo momento. Obtendrá cortes precisos para trabajos importantes. Obtendrá un mejor trabajo y menos accidentes. La fabricación a medida le permite elegir todo, desde los materiales hasta la forma de la cuchilla.

La fabricación a medida le ayuda a sacar el máximo provecho de sus herramientas. Ahorra tiempo, gasta menos y trabaja con mayor seguridad. Estos beneficios se ven en cada trabajo.

Abordar las inquietudes de los compradores

Si desea cambiar a cuchillas de tijera industriales personalizadas, quizás le preocupe la demora en los pedidos, su cuidado y su impacto en el medio ambiente. Hablemos de estos aspectos para que pueda elegir la mejor opción para su negocio.

Plazo de entrega para pedidos personalizados

Quiere sus herramientas rápido. Algunos piensan que los pedidos personalizados son lentos. Pero puede conseguir hojas personalizadas rápidamente. Metal Industrial le ofrece opciones que se adaptan a su horario. La mayoría de los pedidos personalizados tardan solo unas semanas. Esto es casi tan rápido como los productos estándar. Obtendrá hojas hechas a medida sin esperar demasiado.

| Tipo de orden | Plazo de entrega típico |

|---|---|

| Pedidos personalizados | 7 a 25 días |

| Artículos listos para usar | Generalmente más rápido |

| Cuchillos de diseño personalizado | 4 a 9 semanas |

Puede planificar su trabajo con confianza. Las cuchillas personalizadas no implican esperar meses. Metal Industrial revisa cada pedido para que reciba las cuchillas correctas a tiempo.

Cuidado y mantenimiento

Quieres que tus cuchillas personalizadas duren mucho tiempo. Un cuidado sencillo te ayudará a sacarles el máximo provecho. Prueba estos sencillos pasos:

- Limpie sus cuchillas personalizadas después de cada uso. Limpie el polvo, las piezas metálicas y el aceite. Esto previene la oxidación y el desgaste.

- Lubrique las cuchillas y las piezas móviles con frecuencia. La lubricación reduce la fricción y el calor. Su equipo dura más.

- Guarde sus cuchillas personalizadas en un lugar seco y fresco. Esto las mantiene resistentes y listas para usar.

Consejo: El mantenimiento regular implica menos reemplazos y un mejor rendimiento. Ahorra dinero y evita tiempos de inactividad.

Las cuchillas personalizadas son resistentes, pero un buen cuidado las prolonga. Cada cuchilla que compras te aporta más valor.

Impacto ambiental

Te preocupas por el planeta. Las cuchillas personalizadas te ayudan a ser más ecológico. Metal Industrial utiliza materiales resistentes como carburo de tungsteno y acero inoxidable. Estos duran más y son reciclables. La fabricación inteligente de la empresa reduce los residuos y el consumo de energía.

| Práctica de sostenibilidad | Descripción |

|---|---|

| Uso de materiales duraderos | Los aceros y aleaciones de alta calidad duran más y son reciclables. |

| Procesos de fabricación eficientes | Menos residuos y un menor consumo de energía ayudan a proteger el medio ambiente. |

| Reducción de residuos | Las cuchillas personalizadas de mayor duración significan menos reemplazos y menos desperdicio. |

| Recubrimientos para un mejor rendimiento | Los recubrimientos especiales reducen la acumulación, por lo que es necesario limpiar y reemplazar las cuchillas con menos frecuencia. |

Contribuye al medio ambiente eligiendo cuchillas personalizadas. Menos reemplazos significan menos residuos. La fabricación ecológica y el diseño inteligente contribuyen a los objetivos ecológicos de su empresa.

Elegir cuchillas personalizadas es bueno para su negocio y para el planeta.

Necesita herramientas que funcionen bien siempre. Las hojas de tijera industriales personalizadas le ofrecen mejores cortes y mayor duración. Además, le ayudan a ahorrar dinero. Vea cómo... Las cuchillas personalizadas superan a las normales:

| Factor | Cuchillas Personalizadas | Cuchillas estándar | Eficiencia de costo |

|---|---|---|---|

| Durabilidad | Alto (dura 2 veces más) | Moderado | +30% Ahorro |

| Frecuencia de reemplazo | 1-2 veces al año | 4-5 veces al año | +40% Ahorros |

| Costos de mantenimiento | Mínimo | Alto | +20% Ahorro |

Elija cuchillas personalizadas para trabajos difíciles. Obtendrá diseños especiales y materiales resistentes. Las cuchillas personalizadas le ayudan a terminar el trabajo más rápido y a desperdiciar menos. Estas herramientas mantienen sus máquinas en perfecto funcionamiento. ¿Necesita ayuda? Hable con los ingenieros de ventas de Metal Industrial. aquí.

Preguntas frecuentes

¿Qué hace que las hojas de tijeras industriales personalizadas sean mejores que las hojas estándar?

Cuchillas de tijera industriales personalizadas, diseñadas para su trabajo. Se adaptan a sus máquinas y materiales. Obtendrá cortes más suaves, cuchillas más duraderas y menos tiempo de inactividad de la máquina.

¿Cuánto tiempo se tarda en recibir hojas de tijera industriales personalizadas?

Normalmente, recibirá sus cuchillas de tijera industriales personalizadas en un plazo de 15 a 20 días. Esta entrega rápida le ayuda a mantener su trabajo al día.

¿Puedo utilizar hojas de tijera industriales personalizadas para diferentes materiales?

¡Sí! Puedes usar cuchillas de tijera industriales personalizadas para metal, plástico, caucho, textiles y más. Consigue la forma de cuchilla perfecta para cada material.

¿Son más caras las hojas de tijeras industriales personalizadas?

Al principio podrías pagar más, pero luego ahorrarás dinero. Las cuchillas de tijera industriales personalizadas duran más y requieren menos cambios. Esto significa que gastarás menos con el tiempo.

¿Cómo cuido mis hojas de tijera industriales personalizadas?

- Limpie las cuchillas después de usarlas.

- Lubrique con frecuencia las piezas móviles.

- Mantenga las cuchillas en un lugar seco.

El cuidado de las hojas de sus tijeras industriales personalizadas ayuda a que duren más y funcionen mejor.

¿Las cuchillas de tijera industriales personalizadas ayudan al medio ambiente?

Sí. Las cuchillas de tijera industriales personalizadas duran más, por lo que se desechan menos. Muchas están fabricadas con materiales reciclables. Esto ayuda a reducir los residuos y es mejor para el planeta.

¿Puedo obtener ayuda para elegir las hojas de tijera industriales personalizadas adecuadas?

Siempre puedes pedir ayuda a un experto. Muchos proveedores cuentan con ingenieros que pueden ayudarte. Recibirás asesoramiento para elegir la cuchilla más adecuada para tu trabajo.