Necesita herramientas de corte que soporten temperaturas muy altas y que permanezcan afiladas durante mucho tiempo. Cuchillas de cizalla para trabajo en caliente Fabricados con acero H13, son resistentes y confiables. Son ideales para trabajos pesados. El acero H13 es especial porque no se desgasta con el calor ni se desgasta rápidamente. Se puede moldear en diversas formas. A continuación, se comparan sus ventajas:

| Ventaja | Descripción |

|---|---|

| Resistencia a la fatiga térmica | Soporta múltiples usos de calefacción y refrigeración. No se agrieta ni se ablanda. |

| Buena resistencia al desgaste | Se mantiene afilado y fuerte durante mucho tiempo. |

| Capacidad de ser mecanizado | Se puede moldear con precisión para muchos usos. |

En Metal Industrial nos esforzamos por ofrecerle cuchillas de alta calidad. Estas cuchillas son muy duraderas.

Puntos clave

- Las hojas de acero H13 no se desgastan con el calor. Esto las hace ideales para cortar en lugares cálidos. Estas hojas se mantienen afiladas y resistentes durante mucho tiempo. No es necesario reemplazarlas con frecuencia. El acero H13 tiene una mezcla especial de metales. Esto hace que las hojas sean resistentes y difíciles de desgastar. Las hojas funcionan bien y duran mucho tiempo. Puede obtener cuchilla personalizada Diseños para trabajos de corte especiales. Esto le ayuda a trabajar mejor y obtener buenos resultados. Las cuchillas se fortalecen con el tratamiento térmico adecuado, lo que les permite durar más en trabajos pesados. Si revisa y cuida las cuchillas con frecuencia, puede prevenir grietas y daños. Esto prolonga su vida útil. Las cuchillas para cizallas de trabajo en caliente H13 se utilizan en muchas industrias. Se utilizan en automóviles, aviones y reciclaje. Elegir la cuchilla adecuada para su trabajo le ayuda a trabajar mejor y a no perder tiempo.

Descripción general de las cuchillas para cizallas para trabajos en caliente

Propiedades del acero H13

Composición de la aleación

Debe saber qué hace que el acero H13 sea especial para las hojas de cizallas para trabajos en caliente. El acero H13 contiene cromo, molibdeno y vanadio. Estos elementos ayudan al acero a resistir el calor y el desgaste. El cromo le da resistencia y ayuda a mantener su dureza a altas temperaturas. El molibdeno mejora la tenacidad y ayuda a la hoja a resistir el agrietamiento. El vanadio aumenta la resistencia al desgaste y mantiene el filo afilado. Esta combinación de elementos convierte al acero H13 en la mejor opción para herramientas de corte que se exponen a temperaturas extremas.

Microestructura

La microestructura del acero H13 influye enormemente en el rendimiento de las hojas de cizallas para trabajo en caliente. Al observar el acero al microscopio, se observa una mezcla de martensita y carburos. La martensita proporciona dureza y resistencia a la hoja. Los carburos ayudan a la hoja a resistir el desgaste y a conservar su filo durante más tiempo. El enfriamiento y el tratamiento del acero modifican el tamaño y la forma de estas piezas. Un buen tratamiento térmico crea una estructura fina y uniforme. Esto ayuda a que la hoja se mantenga fuerte y dure más, incluso en trabajos exigentes.

También puedes observar algunas propiedades mecánicas y térmicas clave que distinguen al H13:

- La resistencia a la tracción varía entre 1200 y 1590 MPa, dependiendo de cómo se trate térmicamente el acero.

- La resistencia a la tracción varía entre 1000 y 1380 MPa.

- El módulo de elasticidad es de aproximadamente 215 GPa.

- El coeficiente de Poisson varía entre 0,27 y 0,30.

Estos números muestran que el acero H13 puede soportar cargas pesadas y altas temperaturas sin perder su forma ni su filo.

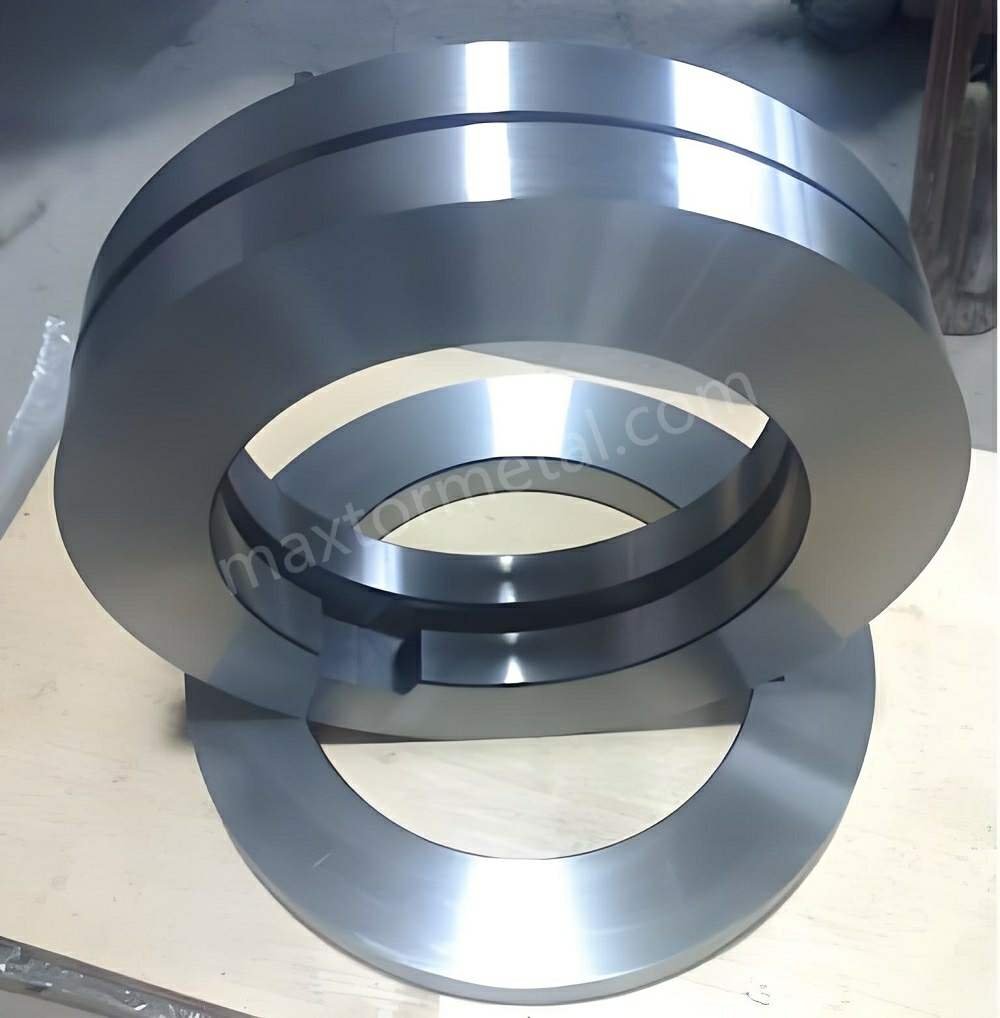

Diseño y fabricación de cuchillas

Geometría del borde

La geometría del filo de las hojas de cizallas para trabajo en caliente afecta la calidad del corte de metal. Metal Industrial utiliza máquinas avanzadas para dar forma a los filos de las hojas. El ángulo y la forma del filo concentran la fuerza de corte. Esto significa que obtendrá cortes limpios y rápidos con menos esfuerzo. Puede elegir entre diferentes diseños de filo, como recto, curvo o dentado. Cada diseño es ideal para ciertos materiales y trabajos de corte. Si necesita una forma o tamaño especial, puede solicitar hojas personalizadas.

Tratamiento térmico

El tratamiento térmico es un paso clave para que las hojas de cizallas para trabajo en caliente sean resistentes y fiables. Se calienta el acero a alta temperatura y luego se enfría de forma controlada. Este proceso modifica la microestructura y garantiza el equilibrio perfecto entre dureza y tenacidad. Metal Industrial utiliza métodos avanzados de tratamiento térmico y forjado. Estos pasos ayudan a que las hojas resistan el agrietamiento y el desgaste, incluso después de muchos usos. La empresa también ofrece diferentes niveles de dureza para satisfacer sus necesidades.

Puede ver la gama de opciones de personalización disponibles para las hojas de cizallas para trabajos en caliente en la siguiente tabla:

| Aspecto de personalización | Detalles |

|---|---|

| Rango de diámetro | Barras redondas de 20 mm a 500 mm |

| Opciones de espesor | Planos y placas de 10 a 500 mm |

| Geometrías personalizadas | Configuraciones de bordes especiales y patrones de dientes |

| Niveles de dureza | Dureza personalizada de 44-52 HRC |

| Tratamientos de superficies | Recubrimientos de TiN, TiCN y DLC disponibles |

Cuando elige hojas de tijeras para trabajos en caliente de Nanjing Metal IndustrialObtendrá productos fabricados con un estricto control de calidad. La empresa verifica el filo, la resistencia y la durabilidad de cada cuchilla antes del envío. También puede solicitar recubrimientos especiales para reducir la fricción y prolongar la vida útil de la cuchilla.

Consejo: Siempre adapte la dureza y el diseño del filo de la cuchilla a su trabajo de corte. Esto le ayudará a obtener los mejores resultados y a prolongar la vida útil de las cuchillas.

Las cuchillas para cizallas para trabajos en caliente desempeñan un papel fundamental en muchas industrias. Se encuentran en la industria automotriz, aeroespacial, de reciclaje y de construcción. Pueden usarse para cortar láminas metálicas, placas e incluso plásticos. Con el diseño y el tratamiento adecuados, estas cuchillas ofrecen cortes limpios y una larga vida útil.

Resistencia térmica y rendimiento

Corte a alta temperatura

Retención de dureza

Necesita cuchillas que se mantengan duras al aumentar la temperatura. Las cuchillas para cizallas de trabajo en caliente H13 conservan su dureza incluso en entornos muy cálidos. Esto es importante, ya que las cuchillas blandas no pueden cortar el metal con precisión. El acero H13 funciona mejor en un rango de templado de entre 530 °C y 650 °C. En este rango, las cuchillas muestran su mejor rendimiento y mayor durabilidad.

| Rango de templado (°C) | Descripción |

|---|---|

| 530-650 | Rango de templado habitual para acero H13, que indica condiciones óptimas de rendimiento. |

Puede confiar en que las hojas de las cizallas para trabajos en caliente H13 mantendrán su filo durante los trabajos más exigentes. El acero no pierde su forma ni su filo, incluso después de muchos ciclos de calentamiento y enfriamiento. Esto significa que obtendrá más cortes antes de tener que reemplazar la hoja.

Resistencia al desgaste

Necesita cuchillas que no se desgasten rápidamente. Las cuchillas para cizallas de trabajo en caliente H13 ofrecen una excelente resistencia al desgaste. Esta propiedad permite que la cuchilla siga cortando sin desafilarse. La combinación especial de elementos del acero H13, como el cromo y el vanadio, le confiere una gran resistencia al desgaste. Puede usar estas cuchillas durante largos periodos, incluso al cortar materiales duros o abrasivos.

La resistencia al desgaste es fundamental al cortar palanquillas calientes o láminas metálicas gruesas. La hoja soporta la fricción y el calor, pero no se rompe fácilmente. Notará que el filo se mantiene afilado, lo que significa que dedicará menos tiempo a cambiar las hojas y más tiempo a trabajar. El acero H13 destaca por su resistencia al calor y al desgaste. Otros aceros para trabajo en caliente pueden perder el filo más rápido, pero el H13 sigue funcionando.

El acero H13 es conocido por su capacidad para soportar altas temperaturas sin deformarse. Esto lo convierte en una excelente opción para trabajos como fundición a presión y forja. Puede comparar el H13 con otros aceros para trabajo en caliente en la siguiente tabla:

| Tipo de acero | ΔT₀ (°C) |

|---|---|

| H13 | 476 |

| H21 | 436 |

Un valor ΔT₀ más alto implica una mejor resistencia térmica. Las hojas de corte para trabajos en caliente H13 ofrecen una mayor vida útil gracias a su alta resistencia al desgaste y a su capacidad de mantener su dureza bajo calor.

Nota: Revise siempre las cuchillas para detectar signos de desgaste. Reemplazarlas a tiempo mantiene los cortes limpios y el equipo seguro.

Variante ESR H13

Pureza y dureza

Quizás desee un rendimiento aún mejor de sus cuchillas para cizallas de trabajo en caliente. La variante H13 ESR (Electroescoria refundida) le ofrece mayor pureza y tenacidad. El proceso ESR elimina los elementos no deseados del acero. Esto hace que la cuchilla sea más resistente y menos propensa a agrietarse. Obtendrá una cuchilla que soporta cargas pesadas y trabajos difíciles sin romperse.

La alta pureza del acero H13 ESR también mejora la resistencia al desgaste. Estas hojas se pueden usar en entornos exigentes y conservarán su filo durante más tiempo. La robustez de la variante ESR permite que la hoja resista más impactos sin astillarse ni fallar.

Propiedades isotrópicas

Necesita hojas que rindan igual en todas las direcciones. El acero H13 ESR tiene propiedades isotrópicas. Esto significa que la hoja tiene la misma resistencia y resistencia al desgaste independientemente del uso. La estructura uniforme del acero ayuda a que la hoja resista el agrietamiento y la deformación.

Las propiedades isotrópicas son importantes al utilizar la hoja para diferentes tipos de corte. Puede confiar en que la hoja le brindará resultados consistentes, ya sea que corte líneas rectas o curvas. La combinación de pureza, tenacidad y propiedades isotrópicas convierte a las hojas para cizalla de trabajo en caliente H13 ESR en una opción inteligente para cortes a alta temperatura y corte de palanquillas.

Consejo: Elija las hojas H13 ESR cuando necesite el mayor nivel de resistencia al desgaste y confiabilidad para sus trabajos más difíciles.

Aplicaciones de corte de palanquillas

Descripción general del proceso

El corte de palanquillas es importante en la metalurgia. Las cuchillas de corte cortan palanquillas metálicas a longitudes exactas. Esto ayuda a preparar los materiales para su posterior conformado o laminado. Muchas industrias utilizan el corte, como la automotriz, el reciclaje y la manufactura. Las cuchillas de corte cortan placas, barras y alambrón. También se utilizan en el laminado en frío y el procesamiento de metales.

Las cuchillas de corte funcionan en diferentes líneas. Se ven en laminado en caliente, líneas de desbastado y trabajos de remate de cultivos. En el laminado en caliente, Cuchillas para cizallas para trabajos en caliente H13 Cortan palanquillas, alambres de hierro y varillas corrugadas. En las líneas de desbaste, cuchillas paralelas cortan losas, tochos y barras. El corte de extremos de corte elimina la cabeza y la cola de las losas o palanquillas. Esto ocurre entre la llegada de la máquina de colada y el primer laminador.

| Tipo de aplicación | Descripción |

|---|---|

| Laminación en caliente | Las cuchillas para corte de palanquillas H13K cortan palanquillas, alambres de hierro y barras de refuerzo en líneas de corte a medida. |

| Líneas de losas | Las cuchillas paralelas se utilizan en los laminadores de desbastes, desbastes y barras y palanquillas para cortar. |

| Extremos de los cultivos | Las cuchillas para palanquillas y tochos cortan los extremos de la cabeza y la cola de los desbastes, tochos o palanquillas, generalmente entre la entrega de la máquina de colada y el primer laminador. |

El cizallamiento también se utiliza en la industria automotriz para paneles y piezas de chasis. Las plantas de reciclaje utilizan cuchillas de cizallamiento para cortar chatarra. En la industria manufacturera, el cizallamiento se utiliza para láminas de aluminio, cobre y acero inoxidable.

Esquila en caliente vs. esquila en frío

Es importante conocer el corte en caliente y en frío. El corte en caliente corta tochos cuando están muy calientes. Las cuchillas de corte en caliente H13 son ideales para esto porque resisten el calor y se mantienen afiladas. El corte en caliente corta metal blando por el calor. Esto proporciona cortes más suaves y un menor desgaste de la cuchilla.

El corte en frío se realiza a temperatura ambiente. Las cuchillas cortan metal duro sin calentar. El corte en frío requiere mayor fuerza, por lo que las cuchillas se desgastan más rápido. Se utiliza para chapas y barras de acero que no requieren calentamiento.

El corte en caliente es mejor para cortes rápidos y menor desgaste de la cuchilla. El corte en frío es mejor para cortes precisos en materiales terminados. Ambos utilizan cuchillas de corte, pero debe elegir la adecuada para su trabajo.

Ventajas de las cuchillas H13

Corte de precisión

Quiere cortes limpios y precisos. Las cuchillas para cizallas de trabajo en caliente H13 le ayudan a conseguirlo. La aleación especial y el tratamiento térmico mantienen las cuchillas afiladas. Obtendrá cortes rectos con mínimas rebabas y dobleces. Estas cuchillas cortan tochos, barras y placas en diversas industrias.

Puede solicitar hojas con formas y tamaños personalizados. Si necesita un filo o patrón de dientes especial, consulte página de cuchillas personalizadas Para elegir. Las cuchillas personalizadas le ayudan a obtener los mejores resultados en su trabajo.

| Propiedad | Cuchillas para cizalla de trabajo en caliente H13 | Otros materiales de cuchillas |

|---|---|---|

| Resistencia a la fatiga térmica | Alto | Variable |

| Dureza en caliente | Excelente | Moderado a bajo |

| Tenacidad | Bien | Variable |

| Resistencia a la incrustación y a la oxidación | Alto | Variable |

Las hojas de corte para trabajos en caliente H13 ofrecen alta resistencia a la fatiga térmica y gran dureza en caliente. Son robustas y resistentes a la descamación y la oxidación. Estas características le permiten obtener cortes precisos y una larga vida útil.

Eficiencia y seguridad

Necesita que el corte sea rápido y seguro. Las cuchillas para cizalla de trabajo en caliente H13 le ayudan a trabajar con rapidez y seguridad. Las cuchillas se mantienen afiladas, por lo que no es necesario cambiarlas con frecuencia. Esto se traduce en menos tiempo de inactividad y una producción fluida.

Las cuchillas H13 también aumentan la seguridad en el trabajo. Su robustez reduce la probabilidad de fallo. Las cuchillas resisten la fatiga térmica, por lo que no se agrietan ni se rompen con el calor. Reduce el gasto en mantenimiento y mantiene la producción en buen estado.

| Característica | Contribución a la seguridad y la eficiencia |

|---|---|

| Alta dureza | Reduce el riesgo de falla de la cuchilla durante el uso. |

| Resistencia a la fatiga térmica | Mantiene las cuchillas funcionando bien a altas temperaturas. |

| Mantiene la nitidez | Significa menos cambios de cuchillas y menos tiempos de inactividad. |

| Integridad durante el uso | Reduce los costos de mantenimiento y aumenta la eficiencia de la producción. |

Estos beneficios son útiles en las áreas de automoción, reciclaje y procesamiento de metales. Las cuchillas de cizalla para trabajo en caliente H13 dan forma a paneles de marcos, cortan chatarra y procesan láminas de aluminio, cobre y acero inoxidable.

Si busca cuchillas confiables, pruebe Nanjing Metal Industrial. Utilizan métodos avanzados y rigurosos controles para fabricar cuchillas de alta calidad. Obtendrá cuchillas que le permitirán trabajar con rapidez y seguridad en el corte de palanquillas.

Consejo: Utilice siempre la cuchilla de corte adecuada para su trabajo. Esto le proporcionará mejores resultados y una mayor vida útil.

Modos de fallo y prevención

Problemas comunes

Al usar cuchillas para cizallas de trabajo en caliente H13, es posible que experimente algunos problemas comunes. Estos problemas pueden afectar el rendimiento de las cuchillas durante el corte. Debe saber qué buscar para evitar daños y mantener sus cuchillas en buen estado.

| Modo de falla | Descripción |

|---|---|

| Agrietamiento | Grietas largas desde la superficie hasta el centro de la pieza. |

| Delaminación | Separación de capas dentro del material. |

| Distorsión | Deformación o flexión de la herramienta durante su uso. |

Comprobación de calor: causas

El agrietamiento por calor se produce cuando la hoja se somete a calentamientos y enfriamientos repetidos. Este problema se observa con mayor frecuencia durante el corte en caliente. La superficie de la hoja se expande y contrae repetidamente. Esta tensión provoca la formación de pequeñas grietas. Si se utiliza la hoja a temperaturas muy altas o se enfría demasiado rápido, aumenta el riesgo de agrietamiento por calor.

Comprobación de calor – Manifestación

Puedes detectar grietas por calor buscando grietas finas en la superficie de la hoja. Estas grietas suelen tener forma de red. Empiezan siendo pequeñas, pero pueden hacerse más profundas con el uso continuo de la hoja. Si ignoras estas grietas, pueden provocar problemas más graves, como la rotura de la hoja.

Comprobación de celo: métodos de detección

Debes revisar las cuchillas con frecuencia. Usa una lupa o un microscopio para buscar pequeñas grietas. Una buena iluminación te ayudará a ver mejor la superficie. También puedes pasar el dedo suavemente sobre la cuchilla para detectar asperezas. La detección temprana te ayuda a solucionar los problemas antes de que empeoren.

Control de calor: medidas preventivas

Puede evitar el agrietamiento por calor controlando la temperatura durante el uso. No permita que la cuchilla se caliente demasiado ni se enfríe demasiado rápido. Utilice métodos adecuados de tratamiento térmico y precalentamiento. Siga siempre los pasos de enfriamiento correctos después de terminar de esquilar. Las revisiones regulares y las reparaciones oportunas ayudan a mantener sus cuchillas seguras.

Deformación

La deformación significa que la cuchilla se dobla o deforma durante el uso. Esto puede ocurrir si la cuchilla se somete a demasiada fuerza o calor. Es posible que note que la cuchilla ya no corta recto. Para evitar la deformación, utilice la cuchilla adecuada para su trabajo y no la sobrecargue. Asegúrese de que su equipo esté configurado correctamente.

Estrategias de mantenimiento

Puede prolongar la vida útil de las cuchillas de su cizallas para trabajos en caliente H13 con un buen mantenimiento. Expertos y foros del sector comparten rutinas útiles y buenas prácticas.

Rutinas preventivas

- Utilice un tratamiento térmico adecuado para sus cuchillas. Precaliente el acero y temple con cuidado.

- Inspeccione sus cuchillas con frecuencia. Busque señales de fatiga térmica y desgaste.

- Repare o recaliente sus cuchillas tan pronto como encuentre un problema.

Estos pasos le ayudarán a detectar problemas a tiempo y a mantener sus cuchillas listas para cortar.

Mejores prácticas del foro

Muchos profesionales comparten sus consejos para mantener las cuchillas en óptimas condiciones. Aquí tienes algunas buenas prácticas de foros del sector:

| Mejores prácticas | Detalles |

|---|---|

| Precalentamiento | Precalentar a 800/1000°F Mínimo (430/540 °C). Mantener por encima de 370 °C durante la soldadura. |

| Enfriamiento | Enfriar a 150°F (65°C) después de soldar. |

| Templado | Revenido 25°F (15°C) por debajo de la temperatura de revenido original (1000°F (540°C) mínimo). |

| Material de relleno | Utilice relleno H-11 para soldar. |

| Técnica de soldadura | Evite que se formen charcos excesivos durante la soldadura para evitar el agrietamiento. |

Consejo: Siga siempre estos pasos para reducir el riesgo de grietas y mantener las cuchillas fuertes.

Puede prevenir la mayoría de las fallas con las rutinas de mantenimiento adecuadas. El mantenimiento regular ayuda a que sus cuchillas soporten la tensión del corte y garantiza un trabajo seguro y eficiente.

Comparación de aceros para trabajo en caliente

Al elegir una cuchilla de corte para cortar metal a alta temperatura, suele haber dos opciones principales: aceros para trabajo en caliente H13 y H11. Ambos tienen ventajas, pero se adaptan a diferentes tareas. Es importante compararlos para elegir la cuchilla adecuada para su trabajo.

H13 frente a H11

Composición química

La combinación de elementos del acero modifica su funcionamiento. El H13 y el H11 parecen similares, pero pequeñas diferencias tienen un gran impacto en el rendimiento de la hoja.

| Elemento | H13 (típico wt%) | H11 (típico wt%) |

|---|---|---|

| C (Carbono) | 0,32 – 0,45 | 0,32 – 0,45 |

| Mn (manganeso) | 0,20 – 0,50 | 0,20 – 0,50 |

| Si (silicio) | 0,80 – 1,20 | 0,80 – 1,20 |

| Cr (cromo) | 4,75 – 5,50 | 4,75 – 5,50 |

| Mo (molibdeno) | 1,10 – 1,75 | 0,80 – 1,20 |

| V (vanadio) | 0,80 – 1,20 | 0,60 – 1,20 |

El acero H13 contiene más molibdeno y vanadio que el H11. Esto le confiere una mayor resistencia al calor y al desgaste. Puede utilizar hojas de tijera para trabajos en caliente H13 en trabajos donde la hoja se calienta mucho y se somete a mucha fricción. El H11 contiene menos molibdeno, por lo que es más resistente y soporta bien los impactos, pero no resiste el calor tanto como el H13.

Rendimiento del tratamiento térmico

El tratamiento del acero modifica su resistencia y tenacidad. El H13 y el H11 reaccionan de forma diferente al tratamiento térmico.

| Propiedad | Acero H11 | Acero H13 |

|---|---|---|

| Resistencia a la fatiga térmica | Mejor por tener menos vanadio, se puede doblar sin romperse. | Menos eficaz, más propenso a agrietarse bajo estrés térmico. |

| Resistencia a la abrasión y al desgaste | Moderado, adecuado para aplicaciones menos abrasivas. | Superior, maneja mejor la fricción y los materiales abrasivos. |

| Tenacidad | Dureza superior, soporta ciclos repetidos de calentamiento y enfriamiento. | Menos resistente, más rígido debido al mayor contenido de vanadio |

Con H13, obtendrá mayor resistencia al desgaste y dureza en caliente. Esto significa que las hojas de sus tijeras para trabajos en caliente H13 se mantendrán afiladas durante más tiempo, incluso después de muchos ciclos de calentamiento y enfriamiento. H11 le ofrece mayor tenacidad, por lo que se dobla en lugar de romperse al recibir un golpe fuerte.

Aplicaciones Típicas

Ves H13 y H11 en diferentes lugares debido a sus fortalezas especiales.

| Aplicaciones H11 | Aplicaciones H13 |

|---|---|

| Matrices de forja en caliente donde los impactos mecánicos fuertes y la tenacidad a la fractura son preocupaciones principales (matrices de forja de gran tamaño, matrices de recalcado) | Matrices de fundición a presión, herramientas de extrusión, matrices de estampación en caliente donde la dureza en caliente sostenida y la resistencia a la fatiga térmica son fundamentales |

| Ciertas aplicaciones de punzonado y cizallamiento que requieren buena tenacidad | Punzones y núcleos para trabajo en caliente, insertos múltiples, núcleos de fundición a presión sujetos a carga térmica cíclica |

| Insertos donde la ductilidad y la resistencia a los impactos reducen el riesgo de fractura catastrófica | Herramientas y moldes que operan a altas temperaturas continuas y ciclos térmicos repetitivos |

Las cuchillas de corte para trabajo en caliente H13 se utilizan para cortar palanquillas calientes, fundición a presión y forja. La H11 es ideal para herramientas que requieren resistencia a impactos y flexiones, como matrices y punzones de forja de gran tamaño.

Resistencia al choque térmico

El choque térmico ocurre cuando una hoja se calienta y se enfría rápidamente. Necesita una hoja que pueda soportar estos cambios sin agrietarse.

| Tipo de acero | Tenacidad | Fortaleza | Resistencia al choque térmico |

|---|---|---|---|

| H11 | Más alto | Más bajo | Bien |

| H13 | Más bajo | Más alto | Excelente |

- El acero H11 tiene mayor tenacidad, por lo que resiste el agrietamiento por cambios bruscos de temperatura.

- El acero H13 tiene mayor resistencia y dureza, lo que le confiere una excelente resistencia al choque térmico.

Puede confiar en que las hojas de tijeras para trabajos en caliente H13 seguirán funcionando incluso cuando corte metal al rojo vivo y luego enfríen la hoja rápidamente.

Dureza y costo

Al elegir una hoja, debes encontrar un equilibrio entre dureza y costo.

- Las cuchillas para cizalla de trabajo en caliente H13 ofrecen mayor resistencia al desgaste y al calor. Su coste es mayor debido a los elementos de aleación y al procesamiento adicionales.

- Las hojas H11 son más resistentes y económicas. Se utilizan cuando se necesita manejar impactos fuertes y no se requiere tanta resistencia al calor.

Consejo: Elija H13 para trabajos de alta temperatura y alto desgaste. Elija H11 si necesita mayor resistencia y menor costo.

Aceros para trabajo en caliente vs. aceros para trabajo en frío

Límites de la aplicación

Los aceros para trabajo en caliente y los aceros para trabajo en frío cumplen funciones diferentes. Es necesario saber dónde se adapta mejor cada uno.

- Los aceros para trabajo en caliente, como el H13 y el H11, funcionan bien a altas temperaturas. Se utilizan para corte en caliente, forjado y fundición a presión. Resisten el ablandamiento y el agrietamiento por calor.

- Los aceros para trabajo en frío, como el D2, son ideales para trabajos a temperatura ambiente o ligeramente calientes. Ofrecen una gran resistencia al desgaste y mantienen su forma durante largos periodos de producción.

Análisis de valor

Quiere obtener el mejor valor por su trabajo. Tanto los aceros para trabajo en caliente como los aceros para trabajo en frío ofrecen ventajas especiales.

| Tipo de acero | Mejor para | Puntos de valor clave |

|---|---|---|

| Aceros para trabajo en caliente | Trabajos de alta temperatura (cizallado en caliente, forjado, fundición a presión) | Larga vida útil, menos tiempos de inactividad y menos reemplazos |

| Aceros para trabajo en frío | Trabajos de gran volumen y baja temperatura (corte, recorte) | Rentable, excelente retención de filo, alta resistencia al desgaste. |

Por ejemplo, en una acería, se utilizan cuchillas de corte en caliente H13 para cortar palanquillas al rojo vivo. Estas cuchillas mantienen el filo y resisten la fatiga térmica. En la misma acería, se utilizan cuchillas de corte en frío D2 para troquelar chapas de acero frías. En este caso, se busca más el afilado y la resistencia al desgaste que la resistencia al calor.

Nota: Siempre elija el tipo de acero adecuado para su trabajo. Esto le ayudará a obtener el mejor rendimiento y valor de sus cuchillas.

Tratamiento térmico y selección

Técnicas de templado

Doble/triple templado

Quiere que sus hojas de cizallas para trabajos en caliente H13 duren más y funcionen mejor. El revenido doble y triple le ayuda a lograr este objetivo. Al usar el revenido doble, la hoja es más resistente y mejora su rendimiento en los procesos de cizallamiento. Un tercer revenido proporciona un alivio adicional de la tensión, especialmente después de terminar el mecanizado de la hoja. Este paso ayuda a que la hoja se mantenga fuerte y resista el agrietamiento durante trabajos difíciles.

A continuación se muestra una tabla que muestra la beneficios de cada proceso de templado:

| Proceso de templado | Beneficios |

|---|---|

| Doble temple | Maximiza la tenacidad y el rendimiento de la herramienta. |

| Triple templado | Proporciona un alivio de tensión adicional después del mecanizado. |

Cada paso del templado mejora la dureza de la hoja de forma diferente. El doble templado la hace más resistente. El triple templado la fortalece aún más una vez moldeada. Estos pasos prolongan la vida útil y mejoran el rendimiento de la hoja.

- El doble templado hace que las hojas sean más resistentes.

- El triple templado ayuda a que las hojas soporten la tensión después del moldeado.

Elija siempre el temple adecuado para sus hojas. Esto contribuye a un mejor funcionamiento y una mayor durabilidad.

Estabilización de la microestructura

Necesita una microestructura estable para que sus hojas funcionen correctamente. El templado de las hojas de cizallas para trabajos en caliente H13 modifica la estructura del acero. Esto reduce la probabilidad de que la hoja se agriete o se doble durante el uso. Un buen tratamiento térmico crea una estructura fina y uniforme. Esto ayuda a que la hoja se mantenga afilada y resista el desgaste.

Si no se templa, la hoja puede volverse quebradiza. Las hojas quebradizas se rompen fácilmente y no duran mucho. Es importante que la hoja se mantenga fuerte, incluso después de muchos usos. La estabilización de la microestructura ayuda a que las hojas funcionen bien en todos los trabajos de corte.

Consejo: Siga siempre los pasos correctos de tratamiento térmico. Esto mantiene sus cuchillas resistentes y confiables.

Guía de selección de cuchillas

Tamaño y geometría

Debe elegir el tamaño y la forma adecuados para las cuchillas de su tijera para trabajos en caliente H13. El tamaño y la forma afectan la calidad del corte y la duración de la cuchilla. Si usa una cuchilla demasiado pequeña o con una forma incorrecta, podría no funcionar bien o desgastarse rápidamente.

Piensa en lo que necesitas cortar. Los tochos gruesos necesitan una hoja gruesa y ancha. Las chapas delgadas necesitan una hoja más delgada. La forma del filo también importa. Los filos rectos cortan limpio. Los filos dentados ayudan con materiales duros o irregulares.

Aquí hay algunas cosas para recordar:

- Adapte el grosor de la hoja al objeto que vaya a cortar.

- Elija la forma de borde adecuada para su trabajo.

- Solicite tamaños personalizados si su máquina los necesita.

Elegir el tamaño y la forma adecuados ayudará a que las cuchillas funcionen mejor y duren más.

Compatibilidad de equipos

Asegúrese de que sus cuchillas se ajusten a sus máquinas. La compatibilidad de los equipos es fundamental para un trabajo seguro y sencillo. Las cuchillas para cizallas de trabajo en caliente H13 se pueden fabricar en formas y tamaños personalizados. Esto significa que puede obtener cuchillas que se ajusten perfectamente a sus máquinas.

Aquí hay una tabla que explica por qué es importante la compatibilidad:

| Evidencia | Explicación |

|---|---|

| Configuraciones personalizadas | Las cuchillas de corte, incluidas las de H13, se pueden adaptar a requisitos industriales específicos. La compatibilidad con los equipos existentes es un factor clave en su selección. |

Si la cuchilla encaja bien, obtendrá mejores resultados y menos tiempo de inactividad. Las cuchillas que no encajan pueden causar daños o ralentizar el trabajo. Siempre verifique las necesidades de su máquina antes de pedir cuchillas nuevas.

Nota: Las cuchillas personalizadas le ayudan a obtener los mejores resultados. Garantizan que sus trabajos de corte se realicen de forma segura y sin problemas.

El tratamiento térmico, el tamaño, la forma y el ajuste adecuados se complementan a la perfección. Estos pasos le ayudarán a sacar el máximo provecho de sus cuchillas para cizalla H13. Obtendrá un mejor rendimiento, menos desgaste y un corte más suave.

Ahora sabe que las hojas de corte para trabajos en caliente H13 son ideales para cortar metal en ambientes calientes y para el corte de palanquillas. Estas hojas tienen muchas ventajas.

- Duran mucho tiempo porque son muy fuertes.

- Cortan el metal limpiamente y dejan bordes prolijos.

- Ayudan a ahorrar dinero para su negocio.

Si eliges la cuchilla adecuada y la cuidas, obtendrás los mejores resultados. Si necesitas ayuda, puedes... Hable con nuestro ingeniero de ventas para pedir consejo.

Preguntas frecuentes

¿Para qué se utilizan las hojas de tijeras para cortar metal?

Las cuchillas de cizalla Metal cortan láminas, barras y placas de metal. Se encuentran en sectores como el reciclaje, la construcción y la fabricación. También cortan acero inoxidable y otros materiales resistentes con una cizalla.

¿Cómo elijo la cuchilla de corte adecuada para mi máquina de corte?

Elija un tamaño y forma de cuchilla adecuados para su máquina. Piense en el material que desea cortar. También considere el tipo de corte que necesita. Las cuchillas de acero aleado son ideales para trabajos rápidos y a altas temperaturas.

¿Por qué es popular el acero H13 para las hojas de tijeras de metal?

El acero H13 soporta altas temperaturas y resiste el desgaste. Ofrece un corte potente en trabajos rápidos y con altas temperaturas. Las hojas H13 duran más y no se doblan fácilmente. Son ideales para metales duros y trabajos exigentes.

¿Puedo utilizar hojas de corte de carburo para cortar metales duros?

Sí, las hojas de carburo para cizallas cortan bien metales duros. El carburo resiste el desgaste y corta con rapidez. Estas hojas son ideales para cizallas en trabajos difíciles. Cortan acero inoxidable y otras aleaciones resistentes.

¿Cómo debo mantener las hojas de tijeras de metal para obtener el mejor rendimiento de corte?

Revise sus cuchillas con frecuencia para detectar daños o desgaste. Límpielas después de cada uso. Afile o reemplace las cuchillas desafiladas. Un buen cuidado ayuda a que las cuchillas corten mejor y duren más.

¿Qué provoca el desgaste de las cuchillas de corte durante el corte?

Las cuchillas se desgastan con los cortes repetidos. El corte rápido, los materiales duros y la mala alineación agravan el desgaste. Busque filos desafilados o astillas para mantener su máquina en buen funcionamiento.

¿Son las hojas de carburo mejores que las de acero para todas las aplicaciones?

Carbide blades resist wear and cut fast, but they can break easily. Steel blades, like H13, are tough and handle heat. Pick your blade based on your machine, cutting job, and metal type.

Can I use metal shear blades for both hot and cold shearing?

Yes, you can use metal shear blades for hot and cold shearing. H13 blades work well in high heat. For cold shearing, use steel or carbide blades that fit your needs.

Ver también

Logrando Cortes Sin Rebabas con Cuchillas de Cizalla de Guillotina de Precisión

Cuchillas de Cizalla D2: Por Qué el Acero D2 es el Rey para el Corte de Metales en Frío

Cómo Solucionar Problemas Comunes con las Cuchillas de Cizalla Hidráulica para Chatarra en 2025

Un comentario