In industrial settings, Bread Cutting Blades are essential for producing neat, uniform slices of bread. These high-quality Bread Cutting Blades ensure that each loaf maintains its appearance and freshness, contributing to both the look and taste of the final product. Choosing the right lame personnalisée guarantees consistent results and helps workers operate more efficiently. The selection of Bread Cutting Blades directly impacts production costs and overall efficiency. When selecting a blade, it’s important to consider its durability, maintenance requirements, and compatibility with various types of bread and production volumes.

Principaux points à retenir

- Serrated and scalloped-edge blades are great for factories. They cut bread fast and even. They also last longer and need less care.

- The best blade depends on the bread and how much you make. Soft breads need serrated blades. Crusty artisan breads use scalloped blades better.

- Custom blades from Nanjing Metal help factories change blades less often. This saves money and makes cutting faster and better.

- Cleaning and taking care of blades helps them last longer. It also keeps bread slices neat and the same size.

- Using the right blade helps factories work better. It cuts down on stops and makes bread look nicer with less waste.

Aperçu des types de lames

Lames dentelées

Serrated bread knives are used a lot in factories. They can cut both soft and hard bread easily. The teeth hold the bread, so it does not tear. This makes every slice look the same. Serrated bread knives stay sharp longer than straight-edged bread knives. The teeth do most of the work when cutting. Factories pick serrated bread knives because they work well and save time. Studies show these blades work right 99.83% of the time. This is better than regular blades. If you clean them with soft brushes and dry them, they last longer. Serrated bread slicing blades also make cutting easier. This helps workers cut more bread in busy factories.

| Paramètre | Details & Impact |

|---|---|

| Tooth Geometry & Pitch | Serrated blades with 2–4 mm pitch cut well and stop tearing. |

| Matériau de la lame | Food-grade stainless steel like SS420 keeps blades clean and sharp. |

| Durée de vie de la lame | Serrated bread slicing blades last 5–7 days in factories. |

Scalloped-Edge Blades

Scalloped-edge bread slicing blades have a wavy edge. This edge lets them cut smoothly and make less crumbs. They work well on bread with hard crusts. Factories use these blades to get even slices and waste less bread. Scalloped-edge bread slicing blades do not rub as much, so they last longer. These blades are made for both soft and hard bread. This makes them good for many types of bread. The special edge helps keep bread looking nice and means workers do not have to change blades as often.

Tip: Scalloped-edge bread slicing blades are great for bakeries that want neat cuts and strong blades.

V-Tooth Blades

V-tooth bread slicing blades have sharp teeth in a V shape. These blades are good for bread with thick crusts or heavy insides. The V shape helps them cut tough bread fast. But, they may not make slices as smooth as other blades. Factories use V-tooth blades for special bread or fancy loaves. The shape helps workers use less force when cutting. But, these blades might need more cleaning and care than other bread slicing blades.

Lames droites

Straight-edged bread knives cut bread in a smooth line. But, factories do not use them as much. They work best on soft bread or bread with little crust. Straight-edged bread knives can make neat slices. But, they get dull faster and can tear hard bread. Some factories use straight-edged bread knives for things like buns or rolls. Still, most busy factories like serrated or scalloped-edge bread slicing blades better. These blades last longer and work better.

Note: Picking the right bread slicing blade depends on the kind of bread and how you want the slices to look.

Bread Knives in Factory Settings

Application in Industrial Slicers

Workflow in Automated Production Lines

Factories use bread knives to slice bread quickly and evenly. Workers put the bread slicing blades on the slicer arms. Each blade must line up just right for even slices. The bread slicing machine moves the blades with the conveyor belt. The conveyor brings loaves at a steady speed. As bread moves, the bread knives cut it into even pieces. This helps make less waste. Technicians watch the process to keep blades sharp and lined up. This makes sure every slice is the same during the shift.

Key Advantages in Factory Environments

Bread knives have many good points in factories. They make every slice the same thickness. This is important for how the bread looks and is packed. Serrated and scalloped bread slicing blades need less force to cut. This means soft or crusty bread does not get squished. The bread keeps its shape and texture. Bread knives help bakeries cut many loaves fast. Their design means workers do not have to change blades often. This saves time and keeps things running. Good bread slicing blades also need less fixing. This helps the factory work without stopping.

Case Study: High-Volume Bakery Implementation

A big bakery changed its bread slicing machine. They switched from regular blades to scalloped-edge bread knives. After this, they needed to replace blades 15% less often. The new bread slicing blades made more even slices. They worked well on both soft and crusty bread. Workers saw less crumbling and better-looking loaves. The bakery had fewer stops for fixing the machine. This made production smoother and faster. This shows how the right bread knife can help factories make better bread and work better.

Comparison with Other Blade Types

Performance and Maintenance Comparison Table

Bread knives work better than other blades for most bread cutting jobs. The table below shows how different bread slicing blades compare in cutting, how long they last, how often they need fixing, and cost:

| Type de lame | Efficacité de coupe | Durée de vie de la lame | Fréquence de maintenance | Cost Level |

|---|---|---|---|---|

| Serrated Bread Knives | Haut | 5 à 7 jours | Faible | Modéré |

| Scalloped-Edge Bread Knives | Haut | 6–8 days | Faible | Moderate-High |

| V-Tooth Blades | Moyen | 4–5 days | Moyen | Modéré |

| Lames droites | Low-Medium | 2 à 3 jours | Haut | Faible |

Tests show serrated bread knives need less force to cut. They use about 72.6 N, while blunt blades need 107.3 N. This means bread knives cut easier and faster. The serrated blade works well at high speeds. This helps factories make more bread with less effort. It also means the bread slicing blades last longer and need fewer changes.

Why Factories Prefer Bread Knives

Factories like bread knives for many reasons:

- Consistent Slice Quality: Bread knives keep slices the same size and neat.

- Temps d'arrêt réduits: Serrated and scalloped bread slicing blades last longer and need less fixing.

- Polyvalence: Bread knives work on many types of bread, soft or crusty.

- Rentabilité: Long-lasting blades and less fixing save money in big factories.

- Proven Efficiency: Bread knives help bakeries cut bread fast and keep up with busy orders.

Note: Picking the right bread knife helps factories meet quality rules and work fast, even if they make new kinds of bread.

Performance Comparison

Efficacité de coupe

Speed Comparison by Blade Type

Factories check how fast they slice bread each shift. Good bread slicing blades help machines cut hundreds of loaves every hour. Serrated and scalloped blades cut bread quickly. Straight blades are slower. Carbide-tipped and bi-metal blades, made from stainless steel, stay sharp longer and cut faster. The table below shows how each blade type works:

| Type de lame | Cutting Speed (Loaves/Hour) | Slice Uniformity | Meilleur cas d'utilisation |

|---|---|---|---|

| Cranté | 800–1200 | Haut | Sandwich, soft loaves |

| Festonné | 700–1100 | Haut | Crusty, artisan bread |

| V-Tooth | 600–900 | Moyen | Dense, specialty bread |

| Droit | 400–700 | Moyen | Buns, rolls |

Factory Case Study: High-Speed Slicing Line

A big bakery got new machines with serrated bread knives. They sliced bread 20% faster. The blades needed fewer changes, so there was less downtime. The bakery made more bread and wasted less. Smart computers tracked every shift. They showed the bakery worked better and made nicer slices.

Impact of Blade Material and Design on Efficiency

Blade material and design change speed and quality. Stainless steel blades do not rust and stay sharp. Serrated and scalloped blades make cutting smoother. Automation and data tracking help factories know when to change blades. This keeps machines working longer.

Durability and Wear

Average Lifespan and Replacement Frequency Table

| Type de lame | Average Lifespan (Days) | Replacement Frequency (per month) |

|---|---|---|

| Cranté | 6 | 5 |

| Festonné | 7 | 4 |

| V-Tooth | 5 | 6 |

| Droit | 3 | 10 |

Factors Affecting Wear (Material, Bread Type, Production Volume)

How long a blade lasts depends on a few things:

- Stainless steel blades last longer when used a lot.

- Hard crusts and thick bread wear blades out faster.

- More bread means you need stronger blades.

Case Example: Durability in Continuous Operation

One bakery used serrated bread slicing blades all week. The blades stayed sharp, even with lots of use. This saved money on repairs and made the blades last longer.

Besoins d'entretien

Maintenance Frequency by Blade Type

Serrated and scalloped bread knives need less fixing than straight or V-tooth blades. Factories watch for blade wear early. This helps them plan repairs and avoid sudden problems.

Common Maintenance Challenges

Technicians sometimes see blade build-up and damage. These problems make cutting worse and slow down work. Using good stainless steel blades helps stop these issues.

Case Study: Maintenance Optimization in a Commercial Bakery

A bakery used special tools to check blade wear. They changed blades at the right time. This cut downtime by 15%. The bakery planned repairs better and kept machines running.

Bread Type Compatibility

Blade Suitability for Artisan Breads

Scalloped and serrated bread knives are best for artisan bread. They cut thick crusts without squashing the loaf.

Blade Suitability for Buns and Rolls

Straight blades are good for buns and rolls. These breads need soft, clean cuts. The blade must stay sharp for even slices.

Blade Suitability for Soft Loaves

Serrated bread knives work great on soft loaves. The teeth hold the bread and stop it from tearing.

Example: Matching Blade to Bread Type in Mixed-Product Factories

In factories that make many breads, managers pick blades for each bread. Serrated blades cut soft loaves. Scalloped blades slice artisan bread. Straight blades work on buns. This helps keep quality and speed high.

Solutions de lames personnalisées

Avantages de la personnalisation

Factories have different problems when making bread. Custom bread slicing blades help fix these problems. They fit each factory’s needs. Custom blades cut better and waste less bread. Workers see more even slices and fewer mistakes. Studies show factories can work up to four times faster with the right tools. Custom blades are made to fit exactly. This helps factories work better. Many companies say they stop less and work smoother with custom blades. These blades last longer and do not need to be replaced as much.

When Custom Blades Are Needed

Custom blades are needed when regular blades do not work. Factories that make many kinds of bread or work very fast need special blades. Some bakeries need blades for both soft and artisan bread. They do not want to change machines. Custom blades help save time on repairs and make slices more even. Reports say custom blades and new materials like stainless steel help factories work better and stop less. Workers pick custom blades to fix problems like changing blades too often, wasting bread, or uneven cuts.

Nanjing Metal Lames Sur Mesure

Nanjing Metal is a top company for bread cutting blades. They have made blades for 18 years. Their teams design and make custom blades for factories. Customers who use Nanjing Metal custom blades see big changes:

- They change blades only three times a month instead of twelve.

- Blade costs go down from $2,400 to $1,000 each month.

- Workers save two days of machine time every month.

- The blades pass safety tests and work better.

| Indicateur de performance | Before Using Nanjing Metal Custom Blades | After Using Nanjing Metal Custom Blades | Amélioration |

|---|---|---|---|

| Changements de lames par semaine | 10 | 3 | 70% reduction |

| Taux moyen de rebut de coupe | 6.5% | 2.2% | 66% reduction |

| Temps d'arrêt dus à l'usure de la lame | 4 heures/semaine | 1 heure/semaine | 75% reduction |

Customers also say cutting is 22% faster. The blades last longer and cut more exactly.

Guide de sélection des lames

Assessing Bread Types

Identify Bread Varieties Produced

Factories start by listing all the bread they make. Some only bake soft loaves. Others make crusty artisan bread, buns, or rolls. Each kind of bread needs a special way to slice it.

Determine Crust Hardness and Texture

Next, managers look at the bread’s crust. Hard crusts, like on sourdough or baguettes, need a different blade than soft sandwich bread. The texture changes how well the bread slicing blades work and how neat the slices look.

Match Blade Edge Type to Bread Characteristics

Picking a bread knife means matching the blade edge to the bread. The table below helps factories choose the right bread slicing blades for their bread:

| Type de lame | Suitable Bread Types | Principaux avantages | Factory Selection Factors |

|---|---|---|---|

| Lame dentelée | Crusty artisan breads, hard rolls | Grips hard crust, keeps soft inside safe | Good for big, dense loaves, less sharpening |

| Straight-Edged Blade | Soft breads, pastries, sandwich loaves | Makes clean slices, easy to sharpen | Best for soft breads, helps with even pieces |

Example: Selecting Blades for Mixed-Product Lines

A factory that makes both artisan and soft bread uses serrated bread slicing blades for crusty loaves. They use straight blades for sandwich bread. This way, all slices look good.

Matching Production Volume

Calculate Average and Peak Output

Production teams count how many loaves they slice each hour and at busy times. High output means they need blades that last longer and can keep up.

Choose Blade Types for High-Speed or Batch Production

Factories with fast lines often use serrated or scalloped bread slicing blades. These blades can slice quickly and still make nice cuts.

Consider Blade Changeover Frequency

Managers check how often they must change blades. Fewer changes mean less stopping and better work flow.

Example: High-Volume vs. Small-Batch Operations

In big factories, workers pick strong bread slicing blades that last through many shifts. Small bakeries may choose blades that are easy to change for more flexibility.

Maintenance Considerations

Evaluate Maintenance Resources and Schedules

Factories look at their maintenance team and how often they do repairs. If there are not many workers, they need bread slicing blades that do not need much care.

Select Blades with Lower Maintenance Needs for Limited Staff

Serrated and scalloped blades often need less sharpening and cleaning. These are good choices for factories with fewer workers.

Factor in Cleaning and Sharpening Requirements

Some bread slicing blades are easy to clean and stay sharp longer. This means workers spend less time on repairs.

Example: Maintenance Optimization in Large Bakeries

A big bakery switched to blades that did not need sharpening as often. This helped them work faster and stop less.

Cost Analysis

Compare Initial Blade Costs and Replacement Rates

Managers look at how much each bread slicing blade costs and how often they need new ones.

Assess Total Cost of Ownership (TCO)

They also check the total cost, including buying, fixing, and lost time.

Balance Cost with Performance and Durability

Factories try to balance cost with how well and how long the blade works. A more expensive blade may save money if it lasts longer and keeps bread looking good.

Example: Cost-Benefit Analysis for Custom Blades

Many factories use guides and forms to compare choices. They find that custom bread slicing blades can save money over time by needing fewer replacements and making better slices.

For custom solutions, many top bakeries trust Nanjing Metal, a bread slicing blades maker with 18 years of experience. Their team makes strong, tested blades for every factory.

Readers who want more help can talk to a sales engineer on the Contact page.

Factory Recommendations

Production à grande échelle

Factories that make lots of bread need strong blades. These blades must work all day without stopping. Serrated and scalloped-edge blades are best for cutting many loaves fast. They help workers slice bread quickly and evenly. These blades last longer, so workers do not have to change them often. This means less time is lost during the day. If factories use carbide or heat-treated blades, they can make up to 30% more bread. They also save a lot of money because machines stop less. The table below shows how different blades help in busy factories:

| Type de lame | Domaine d'application | Performance Benefit |

|---|---|---|

| Carbide Shear Blades | Metal Fabrication Plant | 30% output increase, less downtime |

| Heat-Treated Blades | General Industrial Use | 25% more load endurance |

| Custom Slitter Blades | Packaging Line | 18% efficiency improvement |

Tip: Factories should check blades often. They should pick carbide or high-speed steel blades for fast bread slicing.

Specialty and Artisan Breads

Specialty and artisan breads can have hard crusts or special shapes. Scalloped-edge and serrated blades cut these breads without smashing them. These blades help keep the bread looking nice. This is important for fancy or expensive bread. Factories that make artisan bread use blades that stay sharp and do not wear out fast. New trends show bakeries use smart blades and eco-friendly materials. This helps them make good bread and work better.

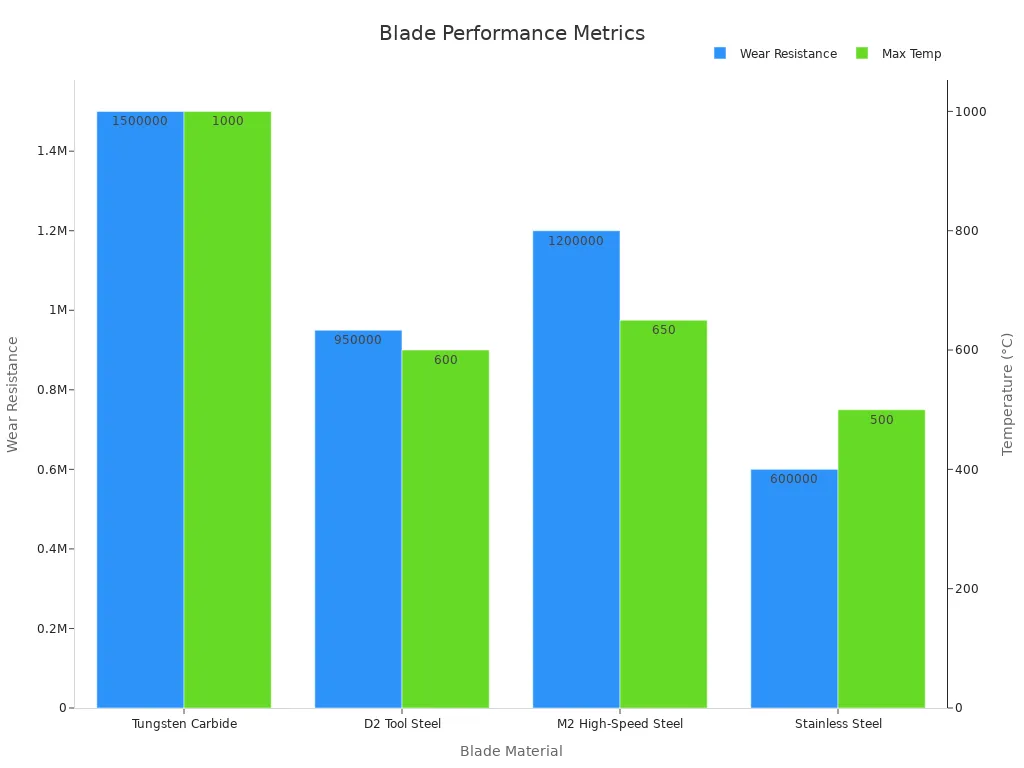

Mixed-Product Lines

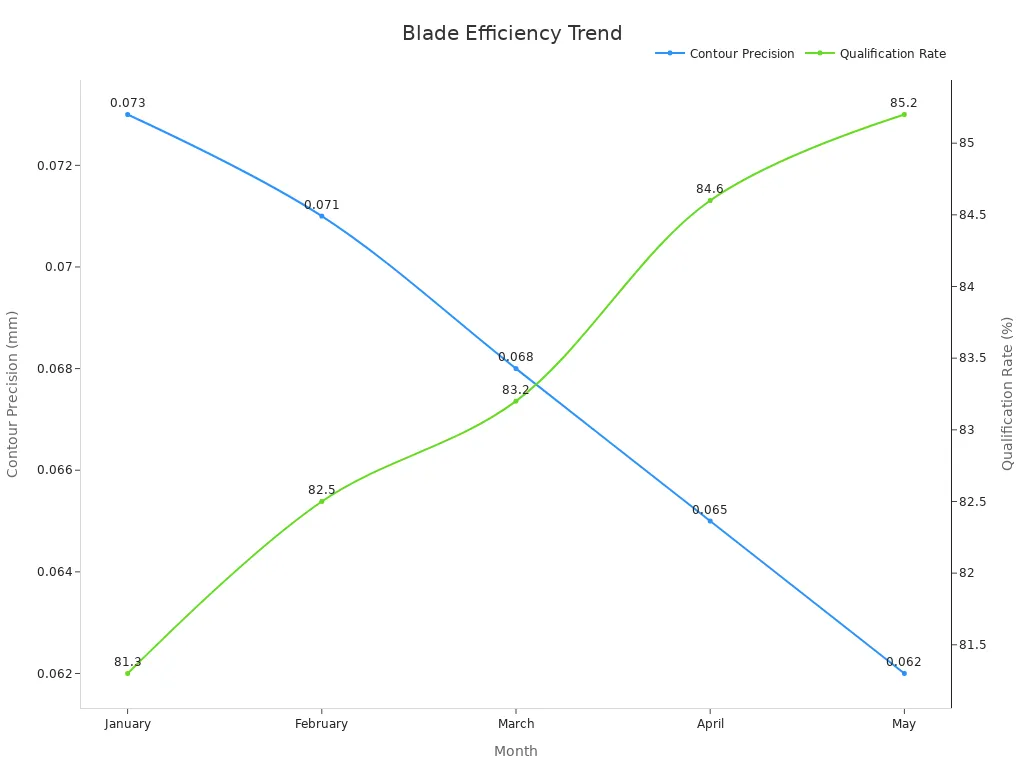

Some factories make many kinds of bread. They need different blades for each type. Managers pick serrated, straight, or custom blades to match each bread. Using the right blade for each loaf keeps slices even and stops waste. The chart below shows which blade materials last longer and work at higher temperatures. This helps factories pick the best blade for their needs.

Small-Scale Operations

Small bakeries or factories with less bread use easy-to-care-for blades. Straight blades or regular serrated blades are good choices. These blades are not expensive and work well every day. They do not need much fixing or cleaning. Picking the right blade helps small teams make good bread and spend less money.

Note: For special blade needs, many factories trust a top Bread Cutting Blades manufacturer with 18 years of experience. They are known for quality and new ideas. People can talk to a sales engineer on the contact page.

Picking the right blade helps factories make bread easily and well. Factories need to choose a blade that fits their bread and how much they make. They also need to think about how much fixing the blade needs. Custom blades can help factories work better and stop less. Nanjing Metal is a trusted Industrial Blades manufacturer with 18 years of experience. They know how to make blades that fit each factory’s needs. 🛠️ If you want help, you can talk to a sales engineer on the contact page.

FAQ

What is the best blade type for slicing soft sandwich bread in factories?

Serrated-edge blades are best for soft sandwich bread. The teeth hold the loaf and make neat slices. Factories pick these blades because they cut fast and always work well.

How often should factories replace bread slicing blades?

How often you change blades depends on how much bread you make and what kind. Most factories put in new blades every 5 to 7 days. Checking blades often helps keep slices nice and stops delays.

Can one blade type handle all bread varieties in a mixed-product bakery?

No single blade works for every bread. Factories use serrated blades for soft bread. They use scalloped-edge blades for artisan bread. Picking the right blade for each bread gives the best slices.

What materials are most common for industrial bread slicing blades?

Most bread slicing blades are made from food-grade stainless steel. This metal does not rust and stays sharp. Some factories use carbide-tipped blades because they last longer.

How do factories keep bread slicing blades clean and safe?

Workers clean blades with soft brushes and safe cleaners. Cleaning often stops stuff from building up and keeps slices tidy. Taking care of blades helps them last and keeps food safe.

Voir aussi

Conseils essentiels pour l'entretien des lames de coupe du pain