UN poinçonneuse de presse plieuse is an essential industrial machine blade used in a press brake machine to shape and bend sheet metal with precision. Nanjing Metal specializes in manufacturing high-quality press brake punches that work seamlessly with press brake dies to create accurate bends in metal sheets. Many factories depend on Nanjing Metal’s custom blades to produce parts for cars, appliances, and buildings. The global press brake market reached $568.2 million in 2022 and continues to grow as companies seek better efficiency and safety. For those interested in enhancing their metal bending processes, please contact Nanjing Metal to learn more about their advanced press brake punch solutions.

Principaux points à retenir

- Press brake punches shape sheet metal by pressing it into a die, creating precise bends for many industries like automotive and construction.

- Choosing the right punch depends on the metal type, thickness, and bend angle to ensure strong, accurate bends and protect the machine.

- Regular maintenance, including cleaning, lubrication, and inspection, extends punch life and keeps bending results consistent and safe.

- Custom press brake punches help manufacturers handle complex shapes and unique materials, improving efficiency and reducing waste.

- Using proper tonnage and matching punches to machines prevents damage, boosts safety, and ensures high-quality metal forming.

Press Brake Punch Basics

Definition and Aliases

UN poinçonneuse de presse plieuse is a specialized industrial machine blade designed for use in a press brake machine. This tool shapes and bends metal sheets by pressing them into a matching die. People sometimes refer to these punches by different names, depending on their shape or function. The table below shows common types, their technical definitions, and documented aliases:

| Type de poinçon | Technical Definition | Documented Aliases |

|---|---|---|

| Poinçon standard | Most frequently used punch; bends thick materials due to narrower tip and larger body; outside inward side flat with small concave curve. | N / A |

| Coup de poing en jogging | Specialized tool for bends around corners; thinner profile; useful for S shapes; uncommon and specialized. | Z-tool |

| Poinçon supérieur à rayon | Rounded tip producing U-shaped bends instead of sharp V; used with U-shaped die for rounded corners. | N / A |

| Poinçon étroit | Low-thickness, uniform along length; used where clearance is limited; popular for closing square or box profiles. | Sword punch |

| Coup de poing au col de cygne | Used for marking and creating specialized U profiles; unique shape prevents bent legs from hitting tooling; less strong with smaller tonnage capacity. | Gooseneck punch (variant) |

| Poinçon à angle aigu | Short angle bends (up to 30° or 60°); thick body with pointy tip; sometimes called acute punches. | Acute punches |

| Perforatrice de ceinture | Small body with angled tip; allows bending around curves; commonly used for door jambs and sashes. | N / A |

These aliases help workers and engineers identify the right press brake tooling for each job.

Comment ça marche

A press brake punch installs on the upper worktable, also called the ram or slider, of a press brake machine. During operation, the punch moves downward and presses the sheet metal into a die fixed on the lower table. This action creates a precise bend along a straight line.

The bending process uses hydraulic or mechanical force to apply controlled pressure. Operators can change the punch and die to create different shapes and angles. Modern machines, such as a cnc press brake or a hydraulic press brake, use computer programs to set exact dimensions and angles. This technology improves accuracy and repeatability in press brake forming.

Key steps in the press brake operation include:

- Placing the sheet metal on the lower die.

- Aligning the punch above the desired bend line.

- Activating the press brake machine to lower the punch.

- Applying force to bend the metal to the required angle.

- Raising the punch and removing the finished part.

Safety features, such as sensors and guards, protect operators during high-pressure bending. The integration of CNC and CAD software allows for complex shapes and multiple bends, making the metal bending machine suitable for many industries.

Applications in Industry

Press brake punches play a vital role in many industrial sectors. Factories use them to produce parts for cars, airplanes, ships, and buildings. The largest press brake in the world, with a force of 5,500 tons, operates in industries like aerospace, automotive, construction, shipbuilding, and heavy machinery. Some machines can handle raw materials up to 320 mm thick, showing the power and flexibility of modern press brake tooling.

Automation has improved the efficiency of press brake operation. Robotic systems with automatic tool changers allow for continuous 24/7 production. Case studies show that custom fixtures manufacturers using panel benders have increased productivity by 30%. Prototype development workshops rely on press brakes to maintain diverse production capabilities. These examples highlight the wide range of applications of press brakes in today’s manufacturing world.

| Secteur industriel | Machine Used | Résultat |

|---|---|---|

| Custom Fixtures Manufacturer | Panel Bender | 30% Productivity Increase |

| Prototype Development Workshop | Press Brake | Maintained Diverse Production Capabilities |

Matériaux courants

Manufacturers make press brake punches from strong and durable materials. Tool steel is the most common choice because it resists wear and keeps a sharp edge. Some punches use hardened steel or high-speed steel for extra strength. Special punches may use alloy steels or receive surface treatments to handle tough jobs. The choice of material depends on the type of press brake tooling and the demands of the bending process.

Tip: Using the right material for a press brake punch extends its life and ensures consistent results during sheet metal bending.

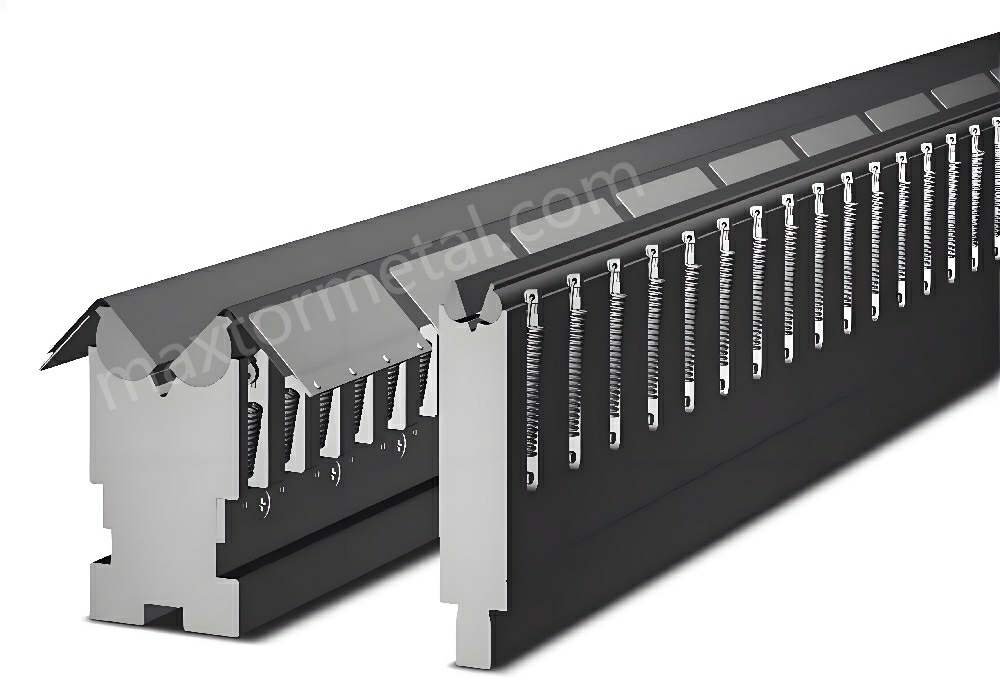

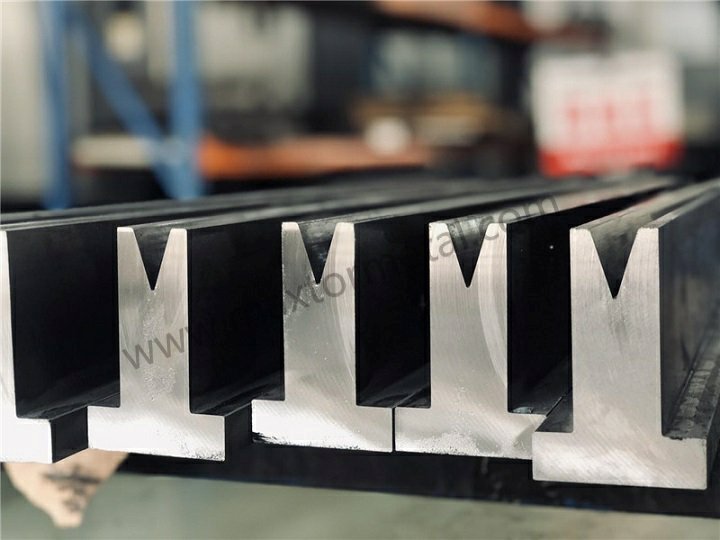

Types of Press Brake Tooling

Outillage de Presse Plieuse includes many shapes and designs. Each type of punch serves a special purpose in the bending process. The different types of press brakes use these punches to create a wide range of metal parts.

Standard Punches

Standard punches are the most common tools in press brake tooling. They help create basic bends and shapes in sheet metal.

Straight Punches

Straight punches make 90-degree bends in materials like mild steel, stainless steel, and aluminum. Factories use them for general bending tasks. Performance tests, such as ball punch and shear punch tests, show that straight punches provide reliable results. These tests measure properties like tensile strength and ductility, which are important for quality control in manufacturing.

Gooseneck Punches

Gooseneck punches have a curved shape. They allow for deep bends without hitting the workpiece. Workers use them to form channels or boxes. These punches are common in HVAC, electrical enclosures, and appliance manufacturing.

Acute Angle Punches

Acute angle punches create sharp bends, often less than 90 degrees. They are useful for making decorative metalwork and precision parts. The thick body and pointed tip help form tight angles.

Hemming Punches

Hemming punches fold sheet metal over itself. This process strengthens the edge of the metal. Automotive panels and sheet metal doors often require hemming operations.

Radius Punches

Radius punches bend metal with smooth, rounded edges. Furniture makers and architects use them to create curved parts. The rounded tip helps prevent cracks in the metal.

Special Punches

Special punches handle unique bending tasks. They work with different types of press brakes to meet specific needs.

Offset Punches

Offset punches make Z-shaped bends. Bracket and support fabrication often use these punches.

U-Shaped Punches

U-shaped punches form U-channels. Construction and framing applications rely on these tools.

Custom Profile Punches

Custom profile punches have unique shapes. Aerospace and custom machinery industries often need these special designs.

Multi-V Punches

Multi-V punches can make several bend radii. Flexible manufacturing environments benefit from these punches because they reduce tool changes.

Application Areas and Materials

Standard Punches

Standard punches work well in many industries. They help with automotive, appliance, and construction projects. Technical documentation shows that standard punches provide accurate and repeatable results. Shear punch testing and other methods confirm their value in material testing and manufacturing.

Special Punches

Special punches fit jobs that need unique shapes or multiple bends. Industries like aerospace, construction, and custom machinery use these tools for complex parts.

Matériaux courants

Manufacturers make most standard punches from tool steel, hardened steel, or high-speed steel. These materials resist wear and keep a sharp edge. Special punches may use alloy steels or get surface treatments for extra strength. Studies show that punch shape and material choice affect the strength and quality of the finished part. For example, punch curvature and compaction pressure can change how well layers bond in tablet manufacturing. Material compatibility depends on properties like plasticity and brittleness, which influence the final product’s strength.

Note: Choosing the right punch and material helps ensure strong, accurate bends and long-lasting press brake tooling.

Selecting a Press Brake Punch

Matériau et épaisseur

Types de matériaux

Choosing the right punch starts with knowing the type of metal. Manufacturers often use Cr-Mo alloy punches for carbon steel. Cobalt-alloy or carbide punches work best for stainless steel. Aluminum needs polished punches to avoid marks. Matching the punch material to the sheet metal helps prevent damage and keeps the punch strong.

Sheet Thickness Considerations

Sheet thickness affects how much force the punch needs. Thin sheets, from 0.5 to 2 mm, need sharp, precision-ground punches. Medium sheets, between 2 and 6 mm, use hardened tool steel punches. Thick sheets, over 6 mm, require reinforced cast punches. The table below shows how punch force and energy change with thickness:

| Fonctionnalité | Relation to Sheet Thickness | Description |

|---|---|---|

| Maximal Punch Force | Increases with thickness | Thicker sheets need more force during operation |

| Work Done | Dependent on thickness | More energy is needed for thicker sheets |

| Punch-Phase Length | Proportional to thickness | Punch phase gets longer as thickness increases |

| Elastic Gradient | Function of thickness | Punch response changes with different thicknesses |

Impact on Punch Selection

Punch selection depends on both material and thickness. A punch that works for thin aluminum may not suit thick stainless steel. Manufacturer specifications and industry benchmarks guide these choices. Using the right punch improves bending quality and reduces defects.

Bend Angle and Compatibility

Required Bend Angles

Every bending job needs a certain angle. Some punches make sharp bends, while others create smooth curves. Operators must pick a punch that matches the needed angle for the part.

Minimum Bend Radius

The minimum bend radius depends on the metal type and thickness. A small radius can crack hard metals. Operators check charts or use software to find the safe minimum radius for each operation.

Tooling and Machine Compatibility

Punches must fit the press brake machine. Hydraulic press brake and cnc press brake models have different requirements. The punch must match the machine’s tonnage and size. Proper fit keeps the operation safe and accurate.

Matching Tooling to Application

Scénarios d'application

Different industries use press brake punches for many tasks. For example, factories use them to make car parts, appliances, and building frames. Some operations need special punches for complex shapes.

Industry-Specific Requirements

Studies show that matching the right tooling to each industry reduces injury risks and boosts productivity. For example:

- CNC press brake operations in tool manufacturing lower strain and cut risks.

- Automation in metal shops reduces repetitive motion injuries.

- Safety checks and employee feedback help choose the best tooling for each sector.

Practical Selection Tips

Les opérateurs doivent :

- Check manufacturer guidelines for punch and machine compatibility.

- Use tables and charts to match punch type to material and thickness.

- Consider production volume and maintenance needs.Tip: The right punch makes bending safer, faster, and more reliable.

Press Brake Punch Performance

Tonnage and Load

Calculating Required Tonnage

Operators must calculate the correct tonnage before starting a press brake operation. Tonnage means the amount of force needed to bend metal. The right tonnage depends on the material type, thickness, die opening width, and punch radius. For example, stainless steel needs about 1.5 times more force than mild steel. Aluminum needs less, while titanium may need double the force. The table below shows how these factors affect tonnage:

| Facteur | Description | Impact on Tonnage |

|---|---|---|

| Largeur d'ouverture de la matrice | 6-8x material thickness for mild steel | Reduces tonnage by up to 30% |

| Punch Radius | Sharp radii need more force | Rounded profiles lower force needed |

| Épaisseur du matériau | Thicker sheets need more force | Directly increases required tonnage |

| Type de matériau | Different metals need different multipliers | Stainless steel 1.5x, aluminum 0.55x, titanium 2x |

Load Distribution and Safety Margins

Proper load distribution keeps the press brake safe and extends tool life. Operators use test bends, force sensors, or software to check the force during operation. Safety margins help prevent overload. For example, using 20% more force than needed can reduce hydraulic seal life from five years to only eighteen months. Ram guides and frame bolts also wear out faster if the load is too high.

Factors Affecting Tonnage Selection

Several factors affect tonnage selection. These include the shape of the punch, the width of the die, and the type of metal. If operators use too little force, the bend may not form correctly. Too much force can damage the machine or cause safety risks. Accurate tonnage calculation keeps the operation safe and efficient.

Entretien

Routine Cleaning Procedures

Operators should clean press brake punches after each use. Removing dust and metal shavings prevents buildup. Clean tools work better and last longer.

Rust Prevention and Lubrication

Applying a light oil coating helps prevent rust. Lubrication reduces friction during operation. This keeps the punch moving smoothly and protects the surface.

Wear Inspection and Replacement Guidelines

Regular inspections help spot wear or cracks early. Operators should check for uneven edges or surface damage. Replace worn punches to keep bending results accurate and safe.

Durée de vie de l'outil

Factors Influencing Tool Life

Tool life depends on correct tonnage, proper maintenance, and material choice. Overloading or using the wrong punch shortens tool life.

Best Practices for Extending Tool Life

Operators should use the right punch for each job, follow cleaning routines, and avoid overloading. Storing punches in a dry place also helps.

Modes de défaillance courants

Common failures include cracks, chipped edges, and surface wear. Regular checks and proper use help prevent these problems.

Custom Press Brake Punch Solutions

Avantages de la personnalisation

Custom press brake punches offer unique advantages for manufacturers with specialized needs. Companies that use customized tooling often see faster production cycles and less material waste. Liberty Systems reports that tailored press brake tooling maximizes efficiency and improves accuracy. These benefits of press brakes help factories meet strict quality standards and reduce costs over time. In one case, a fabrication shop used 3D-printed custom punches made from fiber-reinforced polymer. The shop produced tooling for 14-gauge steel in less than 48 hours at a fraction of the usual cost. This approach not only met performance requirements but also accelerated delivery and saved money. Customization allows manufacturers to match equipment to specific tasks, which supports higher productivity and better results.

Nanjing Metal Custom Punches

Nanjing Metal stands out as a trusted industrial blades manufacturer in the industry. With 18 years of experience, the company has built a strong reputation for quality and reliability. Nanjing Metal employs a skilled design and manufacturing team that focuses on custom industrial blades for press brake machines. Many clients choose Nanjing Metal for their ability to deliver precise, durable, and innovative solutions. The company’s expertise ensures that each custom punch meets the exact requirements of the application. Industry recognition and positive feedback highlight the company’s commitment to excellence. Nanjing Metal continues to lead the way in custom press brake punch manufacturing.

When to Choose Custom

Manufacturers should consider custom press brake punches when standard tooling cannot achieve the desired results. Complex part shapes, tight tolerances, or unique materials often require a tailored solution. Custom punches provide the benefits of press brakes by enabling new designs and improving process efficiency. Companies that face frequent design changes or work with advanced materials gain the most from customization. Choosing a custom punch helps solve production challenges and supports long-term growth.

Les lecteurs intéressés peuvent Contact a sales engineer to discuss custom press brake punch solutions.

Press brake punches shape metal sheets with accuracy and strength. The right punch and careful maintenance ensure each bend meets strict quality standards. Industry feedback shows that matching punches and dies to each job keeps bends precise and reliable. Custom solutions help factories handle unique projects and improve results.

For specialized needs, manufacturers can trust a professional press brake punch manufacturer with proven experience. Interested readers may contact a sales engineer for expert support.

FAQ

What is the main function of a press brake punch?

A press brake punch shapes and bends sheet metal by pressing it into a die. This tool helps create precise angles and forms in metal parts for many industries.

How often should operators inspect press brake punches?

Operators should check punches before each use. Regular inspections help find wear or damage early. This practice keeps the bending process safe and accurate.

Which materials work best with press brake punches?

Tool steel, hardened steel, and high-speed steel are common choices. These materials resist wear and keep a sharp edge. Some special punches use alloy steel for extra strength.

Can custom punches improve production efficiency?

Custom punches match unique project needs. They help reduce setup time and material waste. Many factories see faster production and better results with custom tooling.

Where can manufacturers find a reliable press brake punch supplier?

Many companies look for experienced press brake dies manufacturer with a strong reputation. For more information or to discuss custom solutions, interested readers can contact a sales engineer.

Voir aussi

Conseils d'entretien des outils de presse plieuse pour des outils durables

Comment l'outillage de presse plieuse personnalisé améliore votre efficacité de fabrication