Lames rondes Les lames de scie sauteuse sont des outils de coupe essentiels utilisés en usine et jouent un rôle crucial dans divers secteurs tels que le travail du bois, la métallurgie et l'agroalimentaire. Elles sont appréciées pour leur capacité à couper proprement et avec précision, améliorant ainsi l'efficacité et la qualité de la production.

La demande pour ces lames rondes continue d'augmenter, les projections indiquant que le marché mondial des lames de scie circulaire va s'étendre de $6 409,9 millions en 2024 à $10 936,1 millions en 2034Cette croissance souligne l'importance des lames rondes dans les applications industrielles. Des entreprises comme Nanjing Metal se spécialisent dans la fabrication de lames sur mesure adaptées à des exigences spécifiques. Si vous avez besoin d'aide pour des solutions de lames sur mesure, n'hésitez pas à contacter Nanjing Metal.

Principaux points à retenir

- Les lames rondes sont des outils importants utilisés dans de nombreuses industries.

- Ils aident au travail du bois, du métal et à la transformation des aliments pour des coupes nettes.

- Choisir la bonne taille et la bonne conception de lame facilite le travail.

- Cela réduit également les déchets et améliore la vitesse de production.

- Les lames personnalisées conçues pour des travaux spécifiques fonctionnent mieux et permettent d'économiser de l'argent.

- Les matériaux comme l’acier inoxydable et le carbure présentent des avantages particuliers.

- Ces matériaux conviennent à différentes tâches de coupe.

- Le marché des lames rondes connaît une croissance rapide avec de nouveaux modèles.

- De meilleurs matériaux et de meilleures idées les rendent plus utiles dans les usines.

Comprendre les lames rondes

Que sont les lames rondes ?

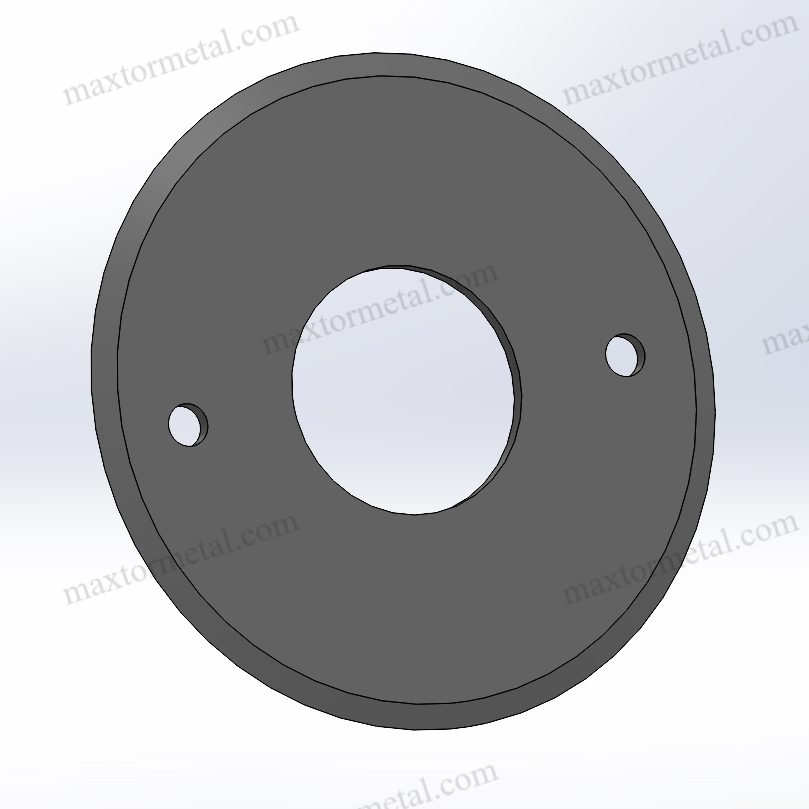

Outils de coupe circulaires

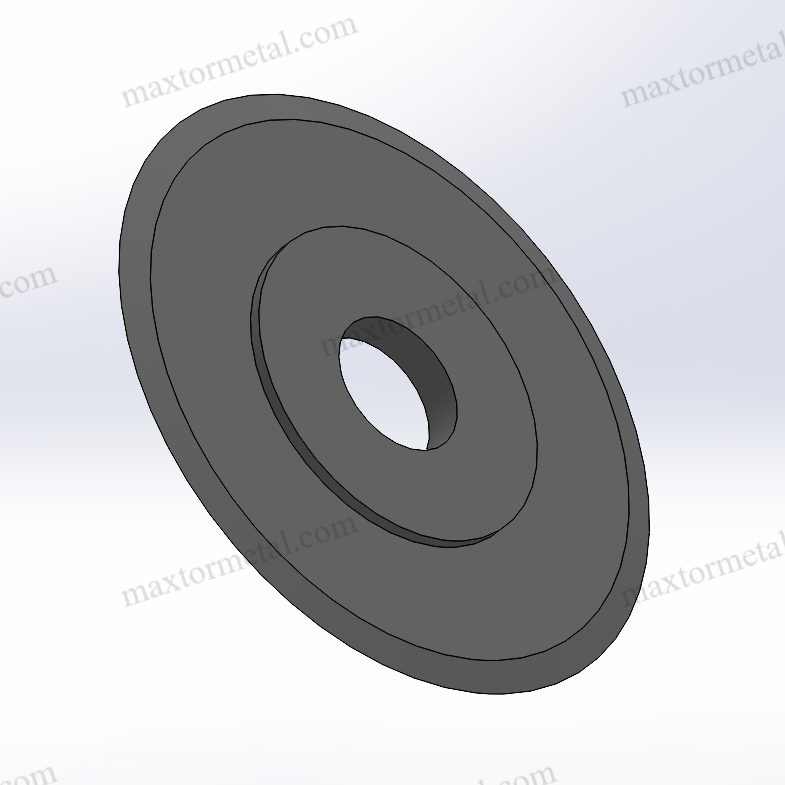

Les lames rondes sont des outils ronds utilisés dans les machines d'usine. Leur forme leur permet de tourner facilement pour une coupe en douceur. Ces lames sont disponibles en différentes tailles pour répondre à divers besoins. Elles permettent de couper le bois, le métal ou le tissu avec précision et rapidité.

Pourquoi ils sont importants dans les machines

Les machines ont besoin de lames rondes pour couper rapidement et proprement. Ces lames permettent d'économiser des matériaux et d'améliorer la qualité des produits. Des industries comme l'emballage alimentaire ont besoin de coupes nettes. Des lames robustes durent également plus longtemps, réduisant ainsi les temps d'arrêt des machines.

Comment fonctionnent les lames rondes

Comment ils coupent avec précision

Les lames rondes tournent rapidement pour couper les matériaux proprement. Leurs bords tranchants et leur mouvement rotatif empêchent les déchirures. Elles sont donc idéales pour couper du tissu ou des feuilles de métal avec précision.

Pourquoi la coupe active est utile

L'utilisation de lames rondes accélère la production et réduit les efforts. Leur conception assure des coupes régulières, améliorant ainsi la qualité du produit. Elles peuvent traiter des matériaux résistants, ce qui les rend utiles dans les usines à forte activité.

Noms des lames rondes

Couteaux Circulaires

Les couteaux circulaires sont des lames rondes. Ils sont utilisés pour trancher, tailler ou fendre des matériaux. Leurs bords tranchants et leur rotation fluide sont parfaits pour les industries agroalimentaires exigeant des coupes nettes.

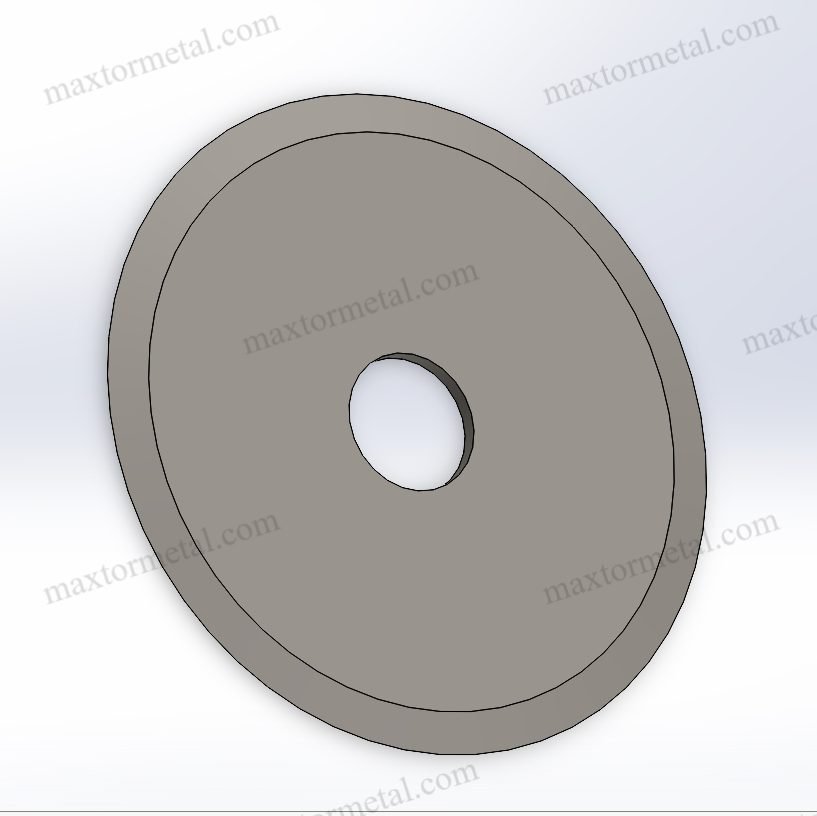

Lames de scie circulaire

Les lames de scie circulaire sont un autre type de lame ronde. Elles coupent le bois, le métal et d'autres matériaux durs. On les trouve dans les ateliers de menuiserie et sur les chantiers pour les travaux difficiles.

Caractéristiques clés des lames rondes

Options de taille

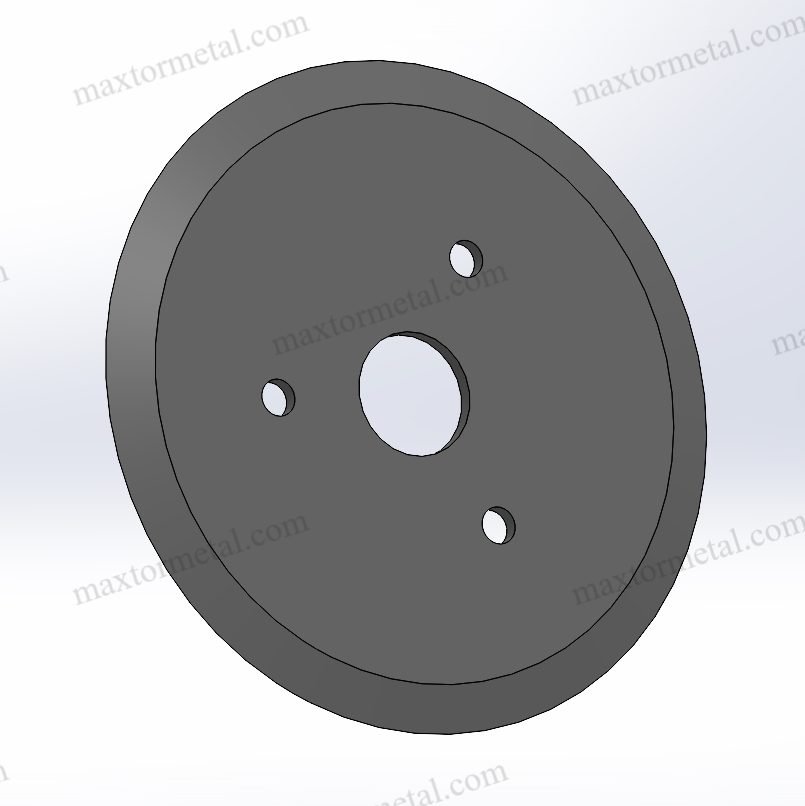

Les lames rondes existent en plusieurs tailles pour répondre à différents besoins. Les petites lames coupent les tissus fins, tandis que les grandes lames tranchent le métal épais. La taille de la lame influence la qualité et la précision de la coupe. Choisir la bonne taille permet d'économiser du matériel et de travailler plus efficacement.

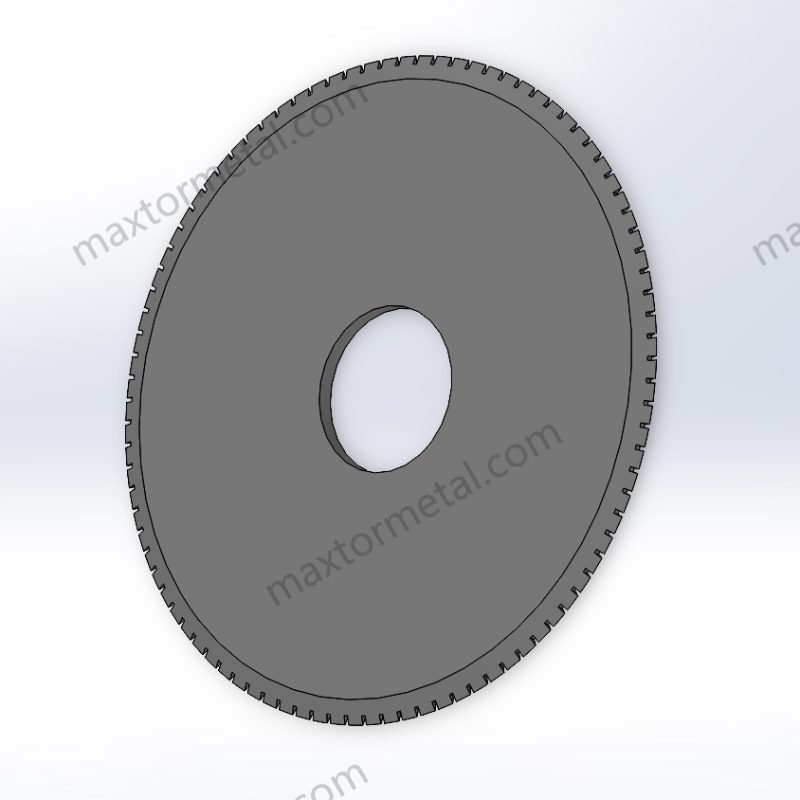

Formes de bord

La conception du tranchant de la lame est importante pour la coupe. Les bords droits permettent des coupes nettes, tandis que les bords dentelés adhèrent aux matériaux durs. Les bords biseautés permettent une coupe en douceur. Connaître ces conceptions vous aidera à choisir la lame adaptée à votre tâche.

Angles de coupe

L'angle de coupe influence le fonctionnement de la lame. Des angles aigus permettent des coupes précises pour les travaux de précision. Des angles plus larges sont plus résistants et coupent mieux les matériaux durs. Choisir le bon angle permet d'équilibrer tranchant et durabilité.

Lames rondes en usage

Comment ils fonctionnent

Les lames rondes tournent rapidement pour couper facilement les matériaux. Leur rotation maintient une pression uniforme et évite les coupes irrégulières. Ces lames réduisent la friction, prévenant ainsi la surchauffe et prolongeant leur durée de vie. Un alignement et un entretien réguliers contribuent à leur bon fonctionnement.

Utilisations dans les industries

Les lames rondes sont utilisées dans de nombreux secteurs grâce à leur flexibilité. L'industrie du bois les utilise pour façonner le bois. Metalworking les utilise pour couper des tôles. L'industrie agroalimentaire les utilise pour des tranchages nets. L'industrie textile les utilise pour couper des tissus, et les entreprises d'emballage les utilisent pour des découpes nettes dans le carton et le plastique. Leur polyvalence les rend indispensables aux usines.

Types et caractéristiques des lames rondes

Types de lames rondes

Lames de refendage

Lames de refendage Coupent des matériaux fins comme le papier et le plastique. Elles sont utilisées dans les industries de l'emballage et de l'impression. Ces lames sont tranchantes et robustes pour une coupe rapide.

Lames rotatives

Les lames rotatives sont idéales pour couper des matériaux souples comme le tissu. Leur rotation fluide permet des coupes nettes et précises. L'industrie textile les utilise pour un travail précis et rapide.

Lames de scie circulaire

Lames de scie circulaire sont courantes et coupent des matériaux durs comme le bois. Elles comprennent des lames de refendage, de perforation et de guillotine. Chaque type est conçu pour des tâches industrielles spécifiques.

Caractéristiques des lames rondes

Variations de taille

Les lames rondes sont disponibles en plusieurs tailles pour répondre à différents besoins. Les petites lames sont destinées aux tâches délicates, tandis que les grandes lames coupent les matériaux résistants. Choisir la bonne taille permet de gagner du temps et de réduire les déchets.

Conception des bords

Le tranchant de la lame influence sa qualité de coupe. Les bords droits permettent des coupes nettes, les bords dentelés saisissent les objets durs et les bords biseautés tranchent en douceur. Connaître ces caractéristiques vous aidera à choisir la bonne lame.

Angles de coupe

Les angles de coupe sont importants pour la performance de la lame. Les angles vifs sont parfaits pour les coupes précises. Les angles plus larges sont plus résistants pour la coupe de matériaux durs. Un angle correct équilibre tranchant et résistance.

Matériaux utilisés

Acier inoxydable

Les lames en acier inoxydable restent tranchantes et résistent à la rouille. Elles sont idéales pour les industries agroalimentaires où la propreté est primordiale.

Carbure

Les lames en carbure sont très résistantes et durables. Elles coupent des matériaux durs comme le métal et la pierre, ce qui les rend utiles dans la construction.

Acier à haute vitesse

Les lames en acier rapide sont robustes et supportent bien la chaleur. Elles sont idéales pour couper rapidement le bois ou le métal sans s'émousser.

Depuis les années 1970, des études ont examiné l’impact de la conception des pales sur le bruit. Il est difficile de comparer ces études en raison des différentes méthodes de test.

Facteurs de performance

Durabilité de la lame

La durabilité indique la durée de vie d'une lame avant son remplacement. Le matériau et la forme de la lame influencent ses performances. Les lames dentelées en acier inoxydable SS420 sont idéales pour couper le pain. Elles empêchent les déchirures et permettent des tranches régulières. Les lames fines et droites avec revêtement DLC préservent la fraîcheur de la laitue plus longtemps, jusqu'à 8–10%. Choisir la bonne conception et le bon matériau de lame augmente la durabilité et réduit les temps d'arrêt.

Efficacité de coupe

Des lames performantes coupent mieux et gaspillent moins de matière. Les biseaux polis ou les bords festonnés contribuent à économiser les ressources. Les lames festonnées utilisées pour la découpe du coton réduisent les déchets de tissu de 18%. Les lames micro-dentelées pour le papier kraft coupent les bords plus proprement de 15%. Elles réduisent également les déchirures de bord de 26%. Les lames de scie circulaire à biseau large et à dents crochues fonctionnent plus longtemps, jusqu'à 10,5 heures, réduisant ainsi les interventions de maintenance de 42%.

Exigences en matière d'entretien

Un bon entretien permet de préserver le bon fonctionnement et la longévité des lames. Les lames à revêtement DLC, comme celles à revêtement DLC, nécessitent moins d'affûtage et de nettoyage. Les lames fines ondulées pour étiquettes thermiques améliorent la disponibilité de la machine de 21%. Les lames d'épaisseur moyenne sont idéales pour le papier et le tissu. Les lames plus épaisses sont idéales pour les matériaux résistants comme le plastique et le caoutchouc. Des contrôles réguliers et des remplacements réguliers permettent d'éviter les problèmes et de maintenir les performances.

Applications dans tous les secteurs

Applications du travail du bois

Lames de scie circulaire pour le bois

Les lames de scie circulaire sont essentielles au travail du bois. Elles coupent le bois pour les meubles, les armoires et autres objets. Elles permettent des coupes nettes et précises pour des produits de meilleure qualité. L'industrie du bois apprécie lames à pointe en carbure pour leur résistance et leur précisionLes lames à trait fin permettent d’économiser de l’énergie, de réduire les déchets et de diminuer les coûts.

Les lames de scie circulaire modernes sont dotées de dispositifs de sécurité, comme un système anti-rebond. Des protège-lames protègent également les opérateurs pendant l'utilisation. De nombreuses lames sont désormais compatibles avec les machines CNC pour une découpe automatisée, ce qui rend le travail plus rapide et plus précis.

Conseil: Choisir la bonne lame, comme une lame à pointe en carbure ou à trait fin, peut améliorer vos résultats de travail du bois.

Avantages de la découpe de précision

La découpe de précision permet d'économiser du matériau et d'obtenir des bords lisses. Cela signifie moins de ponçage et de finition nécessaires. Les lames de haute qualité sont idéales pour les conceptions détaillées et les coupes délicates. Elles offrent des résultats constants, rendant les projets de menuiserie plus efficaces.

- Principaux avantages:

- Moins de gaspillage de matériaux.

- Meilleure qualité de produit.

- Des outils plus sûrs avec des conceptions avancées.

Applications Metalworking

Explication des lames de cisaillement circulaires

Les lames de cisaillement circulaires sont des outils essentiels pour le travail des métaux. Elles coupent avec précision tôles, tuyaux et autres pièces. Ces lames sont fabriquées en matériaux résistants comme l'acier à outils, l'acier rapide et le carbure de tungstèneChaque matériau convient le mieux à des tâches spécifiques.

| Type de matériau | Propriétés clés |

|---|---|

| Acier à outils (D2, A2, O1) | Solide et résistant, idéal pour couper des tôles. |

| Acier rapide (HSS) | Reste dur même à chaud, parfait pour une coupe rapide. |

| Carbure de tungstène | Très dur et durable, dure plus longtemps pour les travaux difficiles. |

Ces matériaux aident les lames à rester tranchantes et à gérer les tâches difficiles sans se casser.

Importance de la durabilité

La durabilité est essentielle dans le travail des métaux. Les lames doivent supporter la chaleur et la pression pendant leur utilisation. Les lames en carbure de tungstène sont idéales pour couper rapidement des matériaux durs. Elles durent plus longtemps, réduisant ainsi les temps d'arrêt et les coûts de réparation. Choisir le bon matériau de lame permet de réaliser des économies et de maintenir des performances constantes.

Applications de transformation des aliments

Couteaux circulaires pour l'hygiène

Les couteaux circulaires sont essentiels à la transformation des aliments pour des coupes nettes et sûres. Ils tranchent la viande, les aliments surgelés et parent les os avec précision. Leurs lames tranchantes garantissent la sécurité et la propreté des aliments. Faciles à laver, ces couteaux sont parfaits pour les industries soucieuses de l'hygiène.

Note: Garder les couteaux circulaires propres empêche la contamination et répond aux règles de sécurité alimentaire.

Avantages de l'acier inoxydable

L'acier inoxydable est le matériau idéal pour les lames de préparation des aliments. Il ne rouille pas et reste tranchant longtemps. Il est également facile à nettoyer, ce qui est important pour la sécurité alimentaire. Les lames en acier inoxydable sont suffisamment robustes pour couper la viande congelée et autres aliments coriaces.

- Avantages des lames en acier inoxydable:

- Pas de rouille.

- Simple à nettoyer et à désinfecter.

- Reste tranchant pour une coupe efficace.

Dans la transformation alimentaire, les lames de scie circulaire et les couteaux améliorent la vitesse et maintiennent des normes d'hygiène élevées. Ils contribuent à maintenir la qualité des produits, ce qui les rend indispensables dans ce secteur.

Applications de l'industrie textile

Lames rotatives pour refendage

Les lames rotatives sont des outils essentiels dans l'industrie textile. Elles permettent de couper proprement les tissus et les matières souples. Leur rotation fluide permet des coupes précises sans abîmer le tissu. Leurs bords tranchants garantissent des coupes nettes, préservant ainsi la qualité du tissu. Qu'il s'agisse de soie douce ou de denim résistant, les lames rotatives offrent des résultats précis à chaque fois.

Les ouvriers du textile utilisent des lames rotatives pour découper les patrons et tailler les tissus. Ils préparent également les matériaux pour la couture. Ces lames sont rapides, réduisent les déchets et accélèrent la production. Elles sont donc très utiles pour les usines produisant de grandes quantités de textiles. L'utilisation de lames rotatives permet de gagner du temps et de maintenir les matériaux en bon état.

Avantages de l'acier trempé

L'acier trempé est un matériau robuste utilisé pour les lames rotatives. Il dure longtemps et ne s'use pas facilement. Même lors de la coupe de tissus épais ou multicouches, l'acier trempé reste tranchant. Cela réduit le nombre de remplacements de lames nécessaires.

Les lames en acier trempé offrent de nombreux avantages :

- Utilisation prolongée:Ils durent plus longtemps, donc vous les changez moins souvent.

- Coupes fiables:Ils effectuent des coupes régulières, gardant les lots de tissus cohérents.

- Économise de l'argent:Leur résistance réduit les coûts de maintenance au fil du temps.

Le choix de lames rotatives en acier trempé améliore l’efficacité et garantit une production textile de haute qualité.

Applications de l'industrie de l'emballage

Présentation des lames de refendeuse circulaire

Les lames de découpe circulaire sont des outils essentiels dans l'industrie de l'emballage. Elles découpent des matériaux comme le carton, les films plastiques et le papier. Ces lames réalisent des coupes nettes, essentielles à un emballage de qualité. Conçues pour un travail rapide, elles sont idéales pour les grandes lignes de production.

Les lames de coupe circulaires sont utilisées pour :

- Découpe de carton:Faire des bords lisses pour les boîtes et les cartons.

- Découpe de films plastiques:Création de rouleaux de film de largeurs uniformes.

- Découpe du papier:Découpe de feuilles soignées pour étiquettes et emballages.

Leur capacité à gérer différentes tâches rend les lames de coupe circulaires essentielles pour l'emballage.

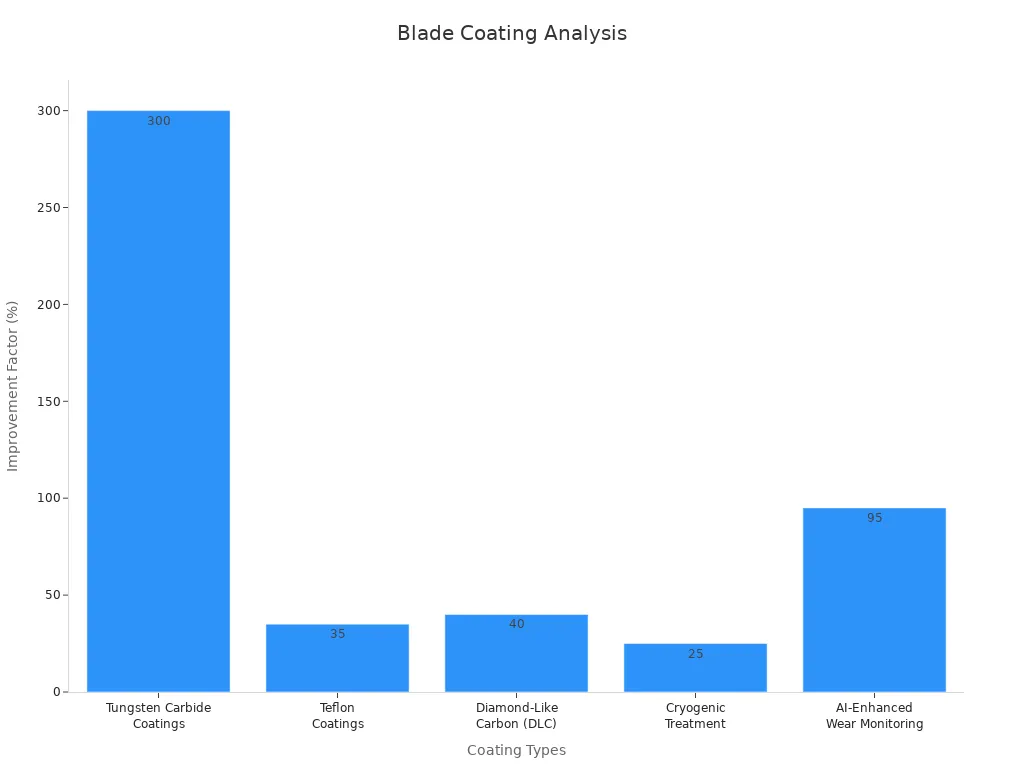

Innovations dans les revêtements de lames

De nouveaux revêtements ont amélioré le fonctionnement des lames de découpeuses circulaires. Des revêtements comme le carbure de tungstène et le DLC prolongent la durée de vie des lames. Ils réduisent également les frottements et nécessitent moins d'entretien. Ces améliorations permettent des économies de temps et d'argent.

| Type de revêtement | Description des avantages | Facteur d'amélioration |

|---|---|---|

| Revêtements en carbure de tungstène | Permet aux lames de durer 3 fois plus longtemps que l'acier ordinaire. | 300% augmentation de la durée de vie |

| Revêtements en téflon | Arrête l'accumulation de plastique, réduisant l'entretien grâce au 35%. | 35% réduction de la maintenance |

| Carbone de type diamant (DLC) | Réduit la friction de 40%, améliorant la vitesse de coupe. | 40% réduction des frottements |

| Traitement cryogénique | Rend les lames en acier 25% plus durables. | 25% augmentation de la durabilité |

| Surveillance de l'usure améliorée par l'IA | Prédit les changements de lame avec une précision de 95%, ce qui permet de gagner du temps. | 95% précision dans les prédictions |

L'utilisation de ces revêtements prolonge la durée de vie et le fonctionnement des lames, contribuant ainsi au bon fonctionnement des usines d'emballage.

Applications de l'industrie de l'impression

Lames circulaires pour la précision

Les lames circulaires sont très utiles dans l'industrie de l'impression. Elles découpent le papier, le carton et d'autres matériaux selon des formes spécifiques. Ces lames sont tranchantes et coupent en douceur, sans se déchirer. C'est essentiel pour des impressions nettes et professionnelles.

Les lames circulaires modernes sont conçues pour répondre aux besoins d'impression. Elles coupent rapidement et avec précision, pour des résultats constants. Que ce soit pour la réalisation de brochures, d'étiquettes ou d'emballages, ces lames garantissent des découpes nettes et précises.

Techniques d'ingénierie avancées

De nouvelles méthodes d'ingénierie ont permis d'améliorer les lames circulaires d'impression. De meilleurs matériaux et une conception plus performante les rendent plus résistantes et plus efficaces. Par exemple :

- Matériaux plus résistants:Les nouveaux revêtements et alliages résistent à l’usure et à la rouille.

- Un meilleur équilibre:Les conceptions avancées permettent aux lames de tourner en douceur.

- Bords améliorés:Des caractéristiques telles que les dentelures et les biseaux aident à couper plus rapidement.

Ces améliorations permettent de répondre à des normes d'impression élevées tout en réduisant les coûts. Des lames circulaires de haute qualité améliorent les produits imprimés et simplifient la production.

Matériaux et conceptions des lames rondes

Matériaux courants pour les lames rondes

Caractéristiques de l'acier inoxydable

L'acier inoxydable est un choix de choix pour les lames rondes. Il ne rouille pas et résiste aux produits chimiques. Il est donc idéal pour les industries agroalimentaires et chimiques. Il est suffisamment résistant pour couper efficacement les aliments surgelés et les aliments délicats. Cependant, la fabrication de lames en acier inoxydable est complexe et coûteuse, ce qui limite son utilisation dans certains domaines.

Pourquoi le carbure est utile

Les lames en carbure sont idéales pour les travaux de coupe difficiles. Extrêmement dures et résistantes à l'usure, elles sont idéales pour les tâches rapides comme la découpe du métal ou de la pierre. Elles restent affûtées longtemps et offrent des résultats constants. Cependant, elles peuvent se casser facilement en cas de choc violent. Coûteuses et difficiles à fabriquer, elles sont donc idéales pour des utilisations spécifiques.

Avantages de l'acier rapide

L'acier rapide (HSS) est solide, résistant à la chaleur et durable. Il est performant par temps chaud, ce qui le rend idéal pour la découpe du métal. Les lames HSS restent affûtées lors de tâches difficiles, comme le tranchage de tôles épaisses. Polyvalentes et abordables, elles sont utiles dans de nombreux secteurs.

Explication des conceptions de lames

Lames à biseau unique

Les lames à simple biseau possèdent un seul tranchant pour des coupes précises. Elles sont idéales pour les tâches de précision, comme la découpe de matériaux fins. Cependant, leur vitesse de coupe est plus lente que celle des lames à double biseau, ce qui les rend moins efficaces pour les travaux rapides.

Lames à double biseau

Les lames à double biseau possèdent deux tranchants tranchants pour une coupe plus rapide. Elles peuvent couper jusqu'à 20 000 fois par minute, tandis que les lames à simple biseau coupent jusqu'à 10 000 fois. Ces lames améliorent également la circulation de l'air, ce qui les rend idéales pour les travaux continus dans l'emballage et le textile.

| Conception de la lame | Vitesse de coupe (cpm) | Efficacité du flux d'air | Niveau de performance |

|---|---|---|---|

| Biseau simple | 10,000 | Inférieur | Moins efficace |

| Double biseau | 20,000 | Plus haut | Plus efficace |

Comment le design affecte le travail

Choisir la bonne lame améliore la coupe et la durabilité. Les lames à double biseau sont plus rapides et réduisent les temps d'arrêt. Les lames à simple biseau sont plus adaptées aux tâches de précision. Choisir la bonne lame permet de gagner du temps et d'économiser du matériel.

Nouvelles idées dans les matériaux des lames

Revêtements spéciaux

De nouveaux revêtements, comme le nitrure de titane (TiN) et le carbone amorphe (DLC), renforcent les lames. Les revêtements TiN prolongent la durée de vie des lames 40% dans les travaux difficiles. Les revêtements DLC les rendent plus dures et supportent mieux la chaleur. Ces revêtements prolongent la durée de vie des lames et les rendent plus performantes sous contrainte.

Alliages solides

Des alliages spéciaux allient dureté et flexibilité pour des lames de meilleure qualité. La fibre de carbone allie ces caractéristiques grâce à une base flexible. Recouvrir les métaux tendres de couches dures renforce la résistance des lames sans compromettre leur flexibilité.

Meilleure durabilité

Des études montrent l'impact positif des nouveaux matériaux sur les industries. Les lames revêtues de titane utilisées dans les emballages nécessitent moins de remplacements, ce qui permet d'économiser 20 000 £ par an et d'augmenter la production de 201 £ par an. Les lames en carbure de tungstène durent trois fois plus longtemps pour la découpe des métaux, ce qui permet d'économiser 15 000 £ par an. Ces améliorations améliorent l'efficacité des lames et réduisent les coûts.

| Nom de l'étude | Industrie | Matériel utilisé | Résultats |

|---|---|---|---|

| Étude 1 | Conditionnement | Lames revêtues de titane | 35% moins de remplacements, $20 000 économies |

| Étude 2 | Coupe Metal | Lames en carbure de tungstène | Durée de vie 3 fois plus longue, $15 000 d'économies |

Sélection de la bonne configuration

Facteurs à prendre en compte

Le choix de la lame appropriée dépend de la matière à couper. Les matériaux plus tendres comme le tissu nécessitent des lames rotatives. Les matériaux plus durs comme le métal fonctionnent mieux avec des lames de scie circulaire à pointe carbure. La taille de la lame est également importante. Les grandes lames coupent les matériaux épais, tandis que les petites lames permettent de réaliser des travaux délicats.

Pensez également à l'angle de coupe. Les angles vifs sont parfaits pour les coupes précises. Les angles plus larges sont plus résistants pour les tâches difficiles. La conception du tranchant de la lame est également importante. Les bords droits permettent des coupes nettes. Les bords dentelés agrippent les objets résistants. Les bords biseautés permettent un tranchage en douceur.

ConseilAdaptez le matériau et le design de la lame à votre tâche. Cela vous fera gagner du temps et réduira le gaspillage.

Adapter les lames aux tâches

Différentes lames sont conçues pour des travaux spécifiques. Les lames rotatives sont idéales pour couper les tissus souples. Les lames de scie circulaire sont idéales pour le bois et le métal. Les lames de refente sont idéales pour l'emballage et l'impression.

Utilisez des lames biseautées pour des coupes nettes. Les lames dentelées sont idéales pour trancher le pain ou les aliments durs. Les lames à double biseau coupent plus rapidement et améliorent la circulation de l'air, ce qui est idéal pour les usines à forte activité.

| Type de lame | Meilleur cas d'utilisation | Caractéristiques principales |

|---|---|---|

| Lames rotatives | Textiles | Rotation douce, coupes précises |

| Lames de scie circulaire | Travail du bois, Metalworking | Bords tranchants et durables |

| Lames de refendage | Emballage, impression | Coupe rapide, bords nets |

Importance de la personnalisation

Les lames sur mesure sont conçues pour répondre à vos besoins. Vous pouvez modifier la taille, le tranchant ou le matériau pour un travail plus précis. Par exemple, l'industrie agroalimentaire utilise des lames en acier inoxydable avec des revêtements spéciaux pour des raisons d'hygiène. Les entreprises d'emballage privilégient les lames de découpe avec revêtement antifriction pour des coupes plus nettes.

Les lames sur mesure permettent de gagner du temps et d'améliorer la qualité. Elles réduisent également les temps d'arrêt grâce à une efficacité accrue. Des experts comme Nanjing Metal peuvent vous aider à créer des lames parfaitement adaptées à vos besoins.

Note:Les lames personnalisées permettent d’économiser de l’argent et rendent la production plus facile et plus rapide.

L'importance des lames personnalisées

Avantages de la personnalisation : des solutions sur mesure pour des besoins industriels spécifiques

Lames Sur Mesure sont conçues pour répondre à vos besoins de production. Elles coupent plus rapidement et avec plus de précision, améliorant ainsi l'efficacité. Des lames robustes durent plus longtemps, réduisant les temps d'arrêt et les changements de lames. Vous pouvez ainsi vous concentrer sur la fabrication de vos produits. Par exemple, les fabricants de pneus utilisant des lames sur mesure ont vu leur production augmenter grâce à la 20%. Grâce à leur conception spéciale, les lames s'adaptent parfaitement aux machines, réduisant ainsi les déchets et optimisant les opérations.

Les lames sur mesure améliorent également l'efficacité de la découpe du 10–15%, affirment les experts. Une meilleure efficacité réduit les coûts et améliore la qualité du produit. Que vous coupiez des matériaux tendres ou durs, les lames sur mesure s'adaptent à vos besoins. Elles garantissent des résultats constants à chaque fois.

Exemples : Couteaux circulaires personnalisés pour la transformation des aliments, lames de refente pour l'emballage

Les industries agroalimentaires et de l'emballage bénéficient grandement des lames sur mesure. Les couteaux circulaires pour la découpe des aliments privilégient la propreté et la précision. Les lames en acier inoxydable avec revêtement résistent à la rouille et se nettoient facilement, garantissant ainsi la sécurité alimentaire. Ces lames coupent la viande congelée, désossent et tranchent les légumes avec précision, garantissant ainsi une qualité optimale.

Dans le secteur de l'emballage, les lames de refente sont conçues pour couper le carton et les films plastiques. Leur revêtement antifriction leur permet une coupe plus rapide et nécessite moins d'entretien. Ces lames permettent d'obtenir des bords lisses pour les boîtes et les étiquettes, pour un résultat professionnel. Les lames sur mesure répondent aux exigences de l'industrie en matière d'hygiène, de résistance et de rapidité.

Société Nanjing Metal : Expertise dans la conception et la fabrication de lames rondes sur mesure

Nanjing Metal est un fabricant de lames industrielles de confiance. Fort de 18 ans d'expérience, il est reconnu pour ses conceptions sur mesure de haute qualité. Son équipe qualifiée crée des lames parfaitement adaptées à vos besoins. Que vous ayez besoin de couteaux pour la découpe alimentaire ou de lames pour la découpe d'emballages, Nanjing Metal vous garantit robustesse et précision.

Nanjing Metal utilise des outils de pointe et un savoir-faire expert pour fabriquer des lames de qualité. Son souci de la qualité en fait un partenaire fiable pour les solutions de lames sur mesure. Pour en savoir plus, visitez leur page d'accueil. ici. Si vous souhaitez discuter de vos besoins, Contact leur équipe de vente pour obtenir de l'aide.

Les lames rondes sont des outils essentiels qui améliorent le fonctionnement des usines. Elles permettent des coupes nettes sur de nombreux matériaux, ce qui explique leur utilisation dans des secteurs comme le travail du bois, la métallurgie et l'agroalimentaire. Choisir les bons matériaux et les bons modèles les rend plus durables et performantes. Les lames sur mesure sont encore plus performantes, car elles sont conçues pour des tâches spécifiques.

Le marché des lames rondes connaît une croissance rapide. D'ici 2033, il pourrait atteindre 1 735,63 millions USD, avec une croissance annuelle de 7 801 TP4T. La région Asie-Pacifique est en tête, avec plus de 34 71 TP4T de parts de marché en 2024.

| Métrique | Valeur |

|---|---|

| Taille du marché (2024) | 853,47 millions USD |

| Taille estimée du marché (2033) | 1 735,63 millions USD |

| TCAC (2025-2033) | 7.80% |

| Part de marché (Asie-Pacifique) | Plus de 34,7% en 2024 |

De nouvelles idées concernant les matériaux et la conception des lames les amélioreront encore davantage. Ces changements permettront aux lames rondes de conserver leur utilité et leur importance pour les usines de demain.

FAQ

Que sont les couteaux circulaires et en quoi sont-ils différents des autres lames rondes ?

Les couteaux circulaires sont des lames rondes conçues pour trancher et tailler. Contrairement aux lames de scie circulaire, qui coupent des matériaux durs comme le bois ou le métal, ils permettent des coupes nettes et précises, ce qui les rend parfaits pour les industries agroalimentaire et textile.

Comment prendre soin des couteaux circulaires ?

Nettoyez régulièrement les couteaux circulaires pour éviter l'accumulation de matière. Aiguisez-les au besoin pour qu'ils restent tranchants. Rangez-les dans un endroit sec et sûr pour éviter de les abîmer. Un bon entretien les aide à durer plus longtemps et à couper mieux.

Quelles industries utilisent le plus les couteaux circulaires ?

Les industries agroalimentaires, textiles et de l'emballage utilisent fréquemment des couteaux circulaires. Ils réalisent des coupes nettes pour garantir la sécurité alimentaire, des fentes nettes dans les tissus et des bords lisses sur le carton et le plastique.

Des couteaux circulaires peuvent-ils être fabriqués pour des tâches spéciales ?

Oui, les couteaux circulaires peuvent être personnalisés pour des travaux spécifiques. Vous pouvez choisir le matériau, la taille, le type de tranchant et le revêtement selon vos besoins. Les couteaux personnalisés sont plus performants et facilitent la coupe.

Quels matériaux sont utilisés pour fabriquer des couteaux circulaires ?

Les couteaux circulaires sont fabriqués en acier inoxydable, en carbure ou en acier rapide. L'acier inoxydable ne rouille pas, ce qui le rend idéal pour la cuisine. Le carbure est résistant aux travaux difficiles, tandis que l'acier rapide supporte la chaleur lors des coupes rapides.

Voir aussi

Comment garder la lame de votre couteau circulaire tranchante et durable