Scegliere il giusto Materiale lama per taglierina rotativa helps you get cleaner cuts and work faster. You must pick a blade material that fits your substrate and process. This choice changes how often you need to fix things and how much money you use.

- Using the best blade material for your slitting process means less downtime and more production.

- If you work with a skilled supplier like Nanjing Metal, you get blades made for your needs and better results.

Punti chiave

- Pick the right rotary slitter blade material to get better cuts and have less machine stoppage.

- Learn about different slitting methods so you can pick the best blade for your materials.

- Always use sharp blades. Sharp blades make smoother cuts and create less waste, which helps you save money.

- Get materials ready and handle them with care. This helps blades last longer and keeps cutting good.

- Make sure the blade hardness matches the anvil. This stops uneven wear and helps you get clean cuts.

- Clean and sharpen blades often. This is important for the best blade performance.

- Think about how much blade materials cost in the long run. Buying strong blades can help you save money over time.

- Work with a skilled supplier. They can help you find custom solutions for your special cutting needs.

Fattori chiave

Slitting Process

You should know how slitting works before picking a blade. Different ways of slitting work better for certain materials and speeds. Here are some slitting methods you might use:

- Razor slitting uses sharp blades for thin, light stuff like films or foils. It cuts fast and clean but is best for soft materials.

- Shear slitting uses round knives that act like scissors. You can use this for things like paper, metals, and plastics.

- Log slitting cuts big rolls of flexible material right away. This saves time because you do not need to unwind the roll.

- Rewind slitting means you unwind a big roll, cut it, and then rewind the smaller rolls. This way, you can control the final product better.

You can look at how slitting methods are different:

| Slitting Technique | Descrizione | Requisiti della lama |

|---|---|---|

| Conventional Slitting | Uses round blades to slice coils into strips. | Sharp round blades for many steel types. |

| High-Speed Slitting | Uses fast machines to make narrow strips quickly. | Strong blades for fast work. |

| Automated Slitting | Uses machines for accurate and quick cuts. | Exact blades that can adjust quickly. |

| Multi-Blade Slitting | Uses many blades to cut wide coils at once. | Many sharp blades for even widths. |

Material to Be Cut

You need to match your rotary slitter blade material to what you want to cut. Some things are easy to cut, but others can wear out your blades fast. For example, materials with fillers like sodium sulfate, calcium carbonate, or barium sulfate are rough. These fillers can make the edges jagged and uneven. You might also get more heat and rubbing, which can cause tiny cracks or chips in your blades. Blown films with calcium carbonate are very hard on blades. If you use these materials, you need a blade that stays sharp and does not wear out quickly.

Operational Priorities

You should decide what is most important before picking a blade. Think about what matters most for your work:

- If you want smooth cuts, you need sharp blades. Dull blades can make rough edges and cause more rejected products. Some studies show 15% more bad products when blades are not sharp.

- If you want less waste, use blades that are sharpened well. Good cuts can lower waste by up to 25%, which saves money every year.

- If you want to keep your machines safe, do not use dull blades. Dull blades make machines work harder, which wears them out faster and costs more to fix.

When you think about these things, you can pick the best rotary slitter blade material for your job. This helps you get better results and save money in the long run.

Upstream Considerations

You should think about what happens before slitting starts. Things that happen earlier can change how well your rotary slitter blade material works. They also affect how long your blades last. If you get materials ready and handle them right, your blades stay sharp and strong.

Getting materials ready is very important. If you cut rough materials, your blades get dull faster. You need to check for fillers or rough bits in your materials. These can scratch the blade edge and make it wear out fast. Clean materials help you get smoother cuts. They also keep your rotary slitter blade material in good shape.

How you handle things matters too. If you move rolls with care, you stop dents and scratches. Damaged rolls make the blade work harder and cause bad cuts. You should keep rolls in a dry place. This stops rust and moisture from hurting your blades.

The temperature during cutting changes how long blades last. If things get too hot, the blade edge can get weak or bend. You should watch the temperature when you cut. Some rotary slitter blade materials, like high-speed steel, can take heat up to 600°C. Others, like tungsten carbide, do not wear out fast and last longer in hard jobs.

Taking care of your blades keeps them working well. You should clean blades after each use and add oil if needed. Good care stops rust and keeps the blade edge sharp. If you do not clean blades, they can get damaged and not last as long.

Let’s see how different blade materials and coatings change how long blades last:

| Tipo di materiale | Caratteristiche principali | Lifespan Impact |

|---|---|---|

| Nitruro di titanio (TiN) | Makes less friction, helps blades last longer | Blades last 40% longer in tough jobs |

| Carbonio simile al diamante (DLC) | Makes blades harder, lowers heat stress | Blades last much longer |

| Acciaio rapido (HSS) | Good mix of strength and price, handles heat | Stays sharp when not under too much stress |

| Carburo di tungsteno | Very hard, does not wear out fast | Lasts much longer than HSS |

| Titanium-coated blades | Last 35% longer in fast jobs | Better for hard work |

Here are some tips to help your blades work better:

- Pick rotary slitter blade material that fits your material.

- Keep your work area clean so there is no dust.

- Watch the temperature when you cut to protect blade edges.

- Move rolls gently so they do not get damaged.

- Clean and oil blades often.

If you pay attention to these things, your rotary slitter blade material lasts longer. You get better cuts, save money, and have less downtime. Good prep and careful handling really help your slitting process.

Materiale lama per taglierina rotativa

Picking the right rotary slitter blade material changes how well you cut and how long your blades last. There are many choices, and each one is good for different jobs. Nanjing Metal Industrial has lots of these materials, so you can pick what works best for your job and what you are cutting.

Tipi di materiale

Acciaio al carbonio

High-carbon steel blades are very hard and do not wear out fast. People use these blades to cut paper, films, and other soft things. These blades stay sharp for a long time but can get rusty if not cared for. If you want to save money and do not cut rough stuff, high-carbon steel is a good pick.

Acciaio per utensili

Tool steel blades are super hard and do not wear down quickly. You can use them to cut metal sheets and thick things. These blades work well for hard jobs and keep their edge even when used a lot. Tool steel is harder to make, but it works well in tough places.

Acciaio ad alta velocità

High-speed steel (HSS) blades are strong and can take a lot of heat. You can use them for fast cutting when blades get hot. HSS blades stay sharp up to about 500°C. They work for both metals and plastics. If you want a blade that is not too expensive and lasts long, HSS is a good choice.

Carburo di tungsteno

Tungsten carbide blades are very hard and do not wear out easily. You use these blades to cut hard or rough things like steel, copper, or films with fillers. Carbide-tipped blades stay sharp much longer than steel blades, so you do not need to sharpen them as much. They can also handle heat up to 1000°C. If you want a blade that lasts the longest for hard jobs, tungsten carbide is the best.

Mancia: If you need a blade for a special job, you can ask for a custom blade. Go to the pagina delle lame personalizzate to see your choices.

Proprietà dei materiali

You should look at both how strong and how safe from chemicals a rotary slitter blade material is. The right properties help you get clean cuts and make blades last longer.

| Materiale | Key Mechanical Properties | Key Chemical Properties | Applicazioni adatte |

|---|---|---|---|

| Acciaio ad alto tenore di carbonio | Very hard, does not wear out fast | Can rust, needs care | Paper, films |

| Acciaio per utensili | Super hard, does not wear down quickly | Hard to make | Metal sheets, thick things |

| Acciaio ad alta velocità | Very hard, stays sharp up to 500°C | Gestisce bene il calore | Metals, plastics, fast cutting |

| Carburo di tungsteno | Very hard, does not wear out easily | Can break if hit hard | Hard things, steel, copper, rough jobs |

You should also think about how well the blade handles heat. High-speed steel stays good up to 500°C. Tungsten carbide can take even more heat, up to 1000°C. If you cut rough things, carbide-tipped blades last longer and do not need sharpening as much.

Matching Blade and Anvil Hardness

You need to make sure your blade and anvil are about the same hardness. If the blade is much harder or softer than the anvil, it can chip, break, or wear out unevenly. Here are some tips:

| Aspetto | Raccomandazione |

|---|---|

| Durezza della lama | Match to what you are cutting |

| Anvil Hardness | Make sure it fits with the blade’s hardness |

| Hard Material Consideration | Use tools that match to stop breaking |

| Case-Hardened Materials | Use special blades for smooth cuts |

| Overall Matching | Helps blades and anvils last longer and cut better |

If you cut hard things, use a blade and anvil that are close in hardness. This helps stop blades from breaking and keeps cuts smooth. For case-hardened or coated things, you might need a special blade.

Nota: Custom blades help you get the right match for your blade and anvil. Nanjing Metal Industrial can make custom blades and checks them for quality. You can send your drawing or needs to get a blade that fits your machine and what you cut.

Quality checks are important. You want blades that pass hard tests for sharpness and strength. This helps you avoid problems and get the best results from your rotary slitter blade material.

Slitting Methods

Razor Slitting

Razor slitting uses a sharp blade to cut thin stuff. This way is common in packaging, film, and label making. You can use it for soft films like PE, EVA, PP, and thin PET. Razor slitting works fast and does not cost much. You get neat cuts if you use a grooved roll.

Pick rotary slitter blade material that stays sharp and does not wear out fast. High-carbon steel blades are good for razor slitting. These blades give sharp cuts and a nice finish. Tool steel is stronger and lasts longer. If you want blades to last even more, try titanium-coated blades.

Mancia: Razor slitting works best for thin, soft stuff. If you use it on thick or hard things, blades get dull fast.

Pro:

- Easy to set up

- Cheap to use

- Makes clean cuts

Contro:

- Blade gets dull quickly

- Heat can build up

- Not for thick or hard stuff

Crush Cut

Crush cut, or score slitting, pushes a blade down to score the material. You use this for thick stuff when you do not need a perfect edge. It is used for rubber, nonwoven fabrics, and some foams. The blade presses in and makes a controlled tear.

Choose rotary slitter blade material that can take pressure. Tool steel blades are good because they do not bend or chip. Tungsten carbide blades last longer if you cut rough or filled stuff.

Pro:

- Simple to set up

- Good for thick stuff

- Handles tough jobs

Contro:

- Cuts are not as neat

- Not for every material

- Edges can look rough

Shear Slitting

Shear slitting uses two round knives that cut like scissors. You use this for paper, textiles, coated films, and heavy PET. Shear slitting gives neat cuts and smooth edges. You must line up the blades just right for best results.

Pick rotary slitter blade material that keeps its edge and does not get dull from heat. High-speed steel blades are good for shear slitting. These blades stay sharp and work at high speeds. Tungsten carbide blades are best for hard or rough stuff.

Nota: Shear slitting needs careful setup. Blades last longer if you match blade and anvil hardness.

Pro:

- Makes neat cuts

- Smooth edges

- Both blades can be sharpened

Contro:

- Needs careful lining up

- Takes longer to set up

Here is a table to help you compare slitting methods and pick the right rotary slitter blade material:

| Slitting Method | Best Suited For | Materiale della lama consigliato | Vantaggi | Limitazioni |

|---|---|---|---|---|

| Razor Slitting | Soft films, thin PET | High-carbon steel, tool steel | Quick, clean, low cost | Blade wear, heat, speed |

| Crush Cut | Thick, rough materials | Tool steel, tungsten carbide | Simple, tough jobs | Less precise, rough edge |

| Shear Slitting | Paper, textiles, coated films, PET | Acciaio rapido, carburo di tungsteno | Precise, smooth, durable | Needs alignment, setup time |

You can make your slitting better by matching the right rotary slitter blade material to your method and what you cut.

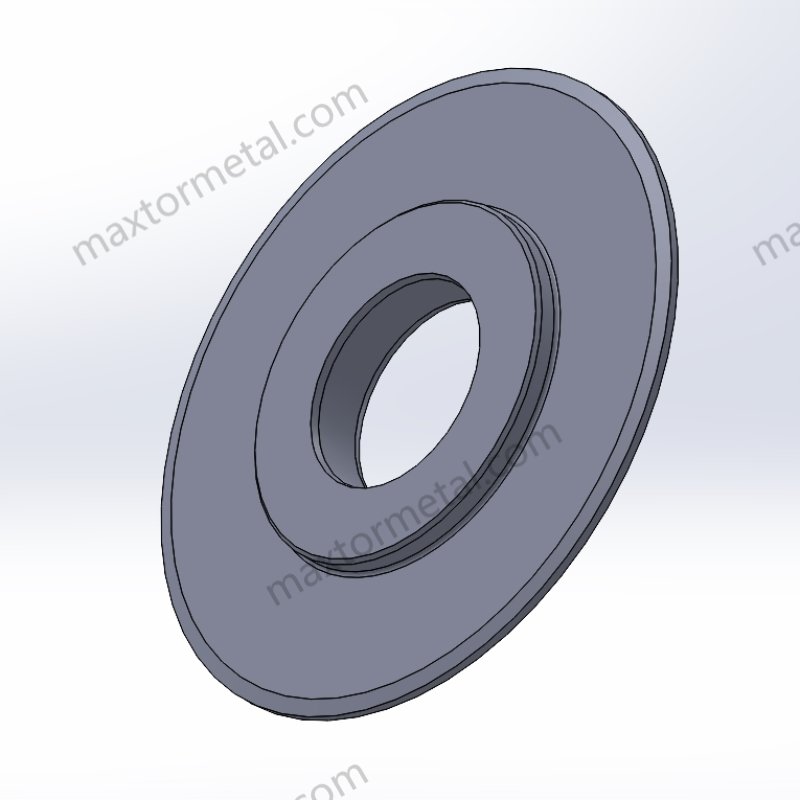

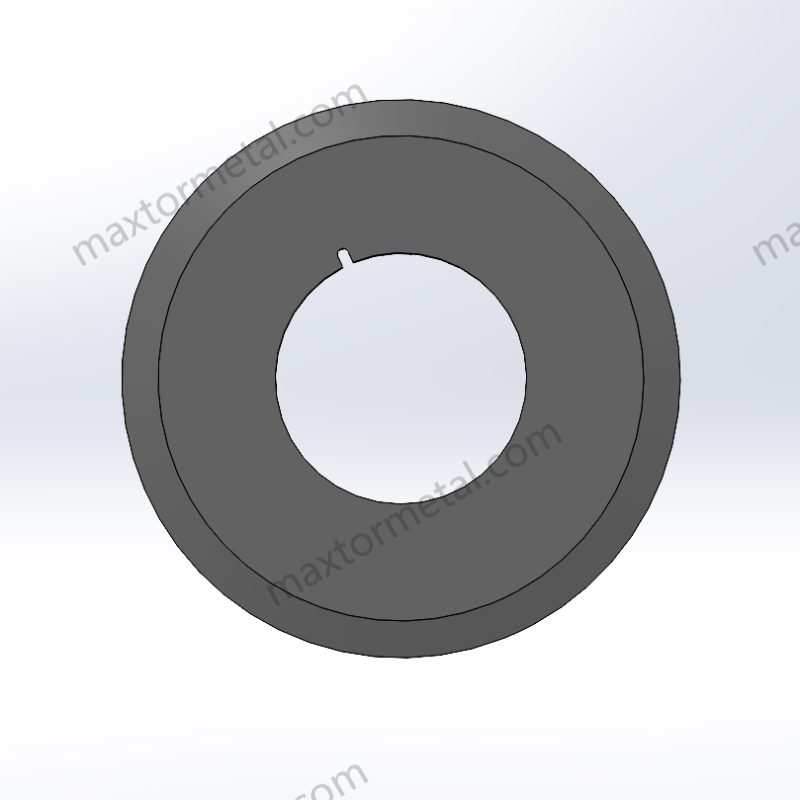

Blade Types and Edge Configurations

When you pick a rotary slitter blade material, you also need to think about the blade type and the edge shape. These things change how your slitting works and how long your blades last. The right blade and edge help you get clean cuts, waste less, and save money.

There are different blade types for different jobs:

- Single-layer blades are strong and cut hard things well.

- Double-layer blades are best for soft or thin things. They help you make smooth, neat cuts.

- Disc blades work for shear slitting. You use them for paper, films, and metals.

- Inserted blade knives let you change just the edge, not the whole blade.

- Shear cut knives cut like scissors. They make smooth edges with no burrs.

Nanjing Metal Industrial has all these blade types. You can pick the blade that fits your machine and what you want to cut.

The edge shape matters too. The edge radius is how round the blade tip is. This changes how well the blade cuts and how long it lasts. A sharp edge (small radius) cuts cleaner but gets dull faster. A rounder edge (big radius) lasts longer but may not cut as clean.

Here is a table to show how rotary slitter blade materials and edge radii work for different jobs:

| Materiale della lama | Idoneità del raggio del bordo | Le migliori applicazioni |

|---|---|---|

| Acciaio rapido (HSS) | 10–30 µm | Carta, pellicola di plastica, metalli teneri |

| Carburo di tungsteno | 20–50 µm | Thick rubber, abrasive materials, metals |

| Lame in Ceramica | 5–20 µm | Tagli ad alta precisione, pellicole elettroniche |

If you cut flexible packaging, a bigger edge radius can help. For example, one company made their blade edge radius bigger, from 10µm to 20µm. They had 15% fewer bad cuts and less waste. In cardboard slitting, using a micro-rounded edge (15µm) instead of a sharp edge (5µm) made blades last 25% longer. This means you change blades less and spend less money.

You should also match the blade type to your slitting method:

| Slitting Method | Vantaggi | Svantaggi |

|---|---|---|

| Shear Knife Slitting | Cuts many things, makes little dust, smooth cut | Needs careful setup, can fold narrow trim |

| Razor Knife Slitting | Easy to set up, cheap blades, easy to replace | Gets hot, blades do not last long, edge wears out |

| Crush Knife Slitting | Easy to set up, good for thick things | Needs new blades often, makes dust |

Mancia: Try different blade types and edge shapes to see what works best for your rotary slitter blade material and your product. You can ask your supplier for help with custom blade designs.

Picking the right blade type and edge shape helps you get the most from your rotary slitter blade material. You get better cuts, blades last longer, and your work goes smoother.

Criteri di selezione

Hardness and Toughness

Industry Standards and Ranges

When you choose a rotary slitter blade, you need to know about hardness. Blade hardness is usually measured on the Rockwell C (RC) scale. Most rotary slitter blades have hardness ratings between RC45 and RC60. Blades at RC45 are more durable and can handle impacts better. Blades at RC60 keep a sharper edge for longer but can chip more easily. You must balance these values to get the right mix of durability and sharpness for your job.

Impatto sulle prestazioni della lama

Blade hardness and toughness both affect how your blade works. Hardness helps the blade stay sharp and resist bending. Toughness lets the blade absorb impacts and avoid breaking. If you pick a blade that is too hard, it may chip when cutting tough materials. If you pick a blade that is too soft, it may dull quickly and need more sharpening. You want a blade that matches your cutting needs and keeps working well.

Balancing Hardness and Toughness for Different Materials

You need to find the right balance between hardness and toughness for each material you cut. Here are some key points:

- Hardness keeps the blade edge sharp and stops it from bending.

- Toughness helps the blade take hits and not break.

- You need both for the blade to last and work well, especially when cutting metals or films.

If you cut metal, you want a blade with more toughness to handle the force. If you cut films or soft materials, you want more hardness for a clean cut. Always match the blade to your material for the best results.

Resistenza all'usura

Material Properties Affecting Wear

Wear resistance is important for blade life. Several properties help a blade resist wear:

- Heat treatment makes the blade harder and helps it keep a sharp edge.

- Good durability means you do not need to replace blades as often.

- A strong blade keeps cutting cleanly, which is important in factories.

- Resistance to rust and fatigue helps the blade last in tough places.

You can also improve wear resistance by changing the blade’s microstructure with heat treatment and alloying. Making the grain size smaller and adding harder elements to the alloy can make the blade last longer.

Application-Specific Wear Considerations

The material you cut changes what kind of blade you need. If you cut abrasive materials, you should use harder blades like solid carbide or ceramic. These blades last longer and do not wear out fast. If you cut softer materials, you can use high-speed steel or tungsten carbide blades. These are easier to sharpen and cost less. The shape of the blade and any coatings also help with wear resistance.

Indicators of Excessive Wear

You need to watch for signs that your blade is wearing out. Here are some ways to check:

| Metodo | Descrizione |

|---|---|

| Decline in Cutting Quality | Uneven edges, burrs, or cracks in products show the blade needs replacing. |

| Increase in Cutting Resistance | If the machine works harder, the blade may need changing. |

| Decrease in Cutting Speed | Slower cutting means the blade is getting dull. |

| Increase in Cutting Noise | More noise during cutting can mean the blade is worn. |

| Visual Inspection of Blades | Look for notches, wear, or bending. If you see these, replace the blade. |

| Regular Maintenance Checks | Check blades on a schedule to plan replacements before problems start. |

If you see any of these signs, you should replace or regrind your blade to keep your cuts clean and your machine running well.

Compatibilità

Matching Blade Material to Substrate

You must match your rotary slitter blade material to what you are cutting. The right match gives you better cuts and helps your blades last longer. If you use the wrong blade, you may see more waste, shorter blade life, and more machine problems. Changing to a better blade material can make your machines run smoother and increase your production.

- The blade material should fit the substrate for clean cuts and less wear.

- The anvil’s hardness matters because it is harder to replace and affects how long your blade lasts.

Anvil and Blade Pairing

Pairing the right blade and anvil is important. The anvil supports the blade during cutting. If the anvil is too hard or too soft compared to the blade, you may see uneven wear or blade damage. Always check that your blade and anvil work well together to get the best results.

Chemical and Thermal Compatibility

You also need to think about chemicals and heat. Some materials can cause rust or corrosion on your blades. High temperatures during cutting can weaken some blades. Pick a blade material that resists rust and can handle the heat from your process. This helps your blades last longer and keeps your cuts clean.

Mancia: If you are not sure which blade to use, talk to your supplier. They can help you pick the best rotary slitter blade material for your job and make sure it matches your machine and what you cut.

Considerazioni sui costi

Initial Investment vs. Lifecycle Cost

When you choose a rotary slitter blade, you need to think about both the price you pay at first and how much it costs to use the blade over time. Some blades cost less to buy, but you may need to replace them more often. Other blades cost more at the start, but they last longer and need less care. If you use your machine a lot, a blade that lasts longer can save you money in the long run.

| Materiale della lama | Costo iniziale | Typical Lifespan | Esigenze di manutenzione | Valore a lungo termine |

|---|---|---|---|---|

| Acciaio al carbonio | Basso | Corto | Frequente | Good for light jobs |

| Acciaio per utensili | Medio | Medio | Moderare | Balanced choice |

| Acciaio ad alta velocità | Medio-Alto | Lungo | Less frequent | Good for heavy use |

| Carburo di tungsteno | Alto | Very Long | Minimo | Best for tough jobs |

You should look at how often you need to change or sharpen your blades. If you pick a blade that lasts longer, you spend less time stopping your machine. This helps you make more products and lowers your total costs.

Cost-Benefit Analysis of Material Upgrades

Upgrading your blade material can seem expensive at first, but it often pays off. For example, switching from high-carbon steel to tungsten carbide can make your blades last much longer. You will spend less time changing blades and more time making products. Some coatings, like PVD or CVD, also help your blades resist wear and corrosion. These coatings can make your blades last even longer and keep your cuts clean.

- PVD coatings help your blades resist wear and rust.

- CVD coatings make your blades last longer and work better.

- Upgrading to tungsten carbide or ceramic blades can boost performance and save money over time.

You should think about how much you spend on new blades, sharpening, and machine downtime. If you use better blades, you may pay more at first, but you save money because you do not need to stop your machine as often.

Impact of Blade Longevity on Operational Costs

Blade longevity affects your costs every day. If your blades last longer, you do not need to buy new ones as often. You also spend less time stopping your machine to change or sharpen blades. This means you can make more products and keep your machines running smoothly.

Longer-lasting blades also help you avoid problems like rough cuts or machine damage. If you use the right rotary slitter blade material, you get better results and lower your costs. You should always look at both the price and the value you get from your blades.

Maintenance and Regrinding

Recommended Maintenance Intervals

You need to take care of your blades to keep them working well. Regular maintenance helps your blades last longer and keeps your cuts clean. Here are some tips for keeping your blades in top shape:

- Check hydraulic and pneumatic systems every week.

- Make sure rollers are lined up and blade clearance is correct.

- Replace hydraulic oil if it looks dirty.

- Watch your slitting knives and add oil to moving parts every month.

- Sharpen your blades as needed, based on what you cut and how often you use them.

If you follow these steps, you can catch problems early and keep your blades working their best.

Regrinding Frequency and Best Practices

You should regrind your blades when you see signs of wear. The right time to regrind depends on the blade material and how much you use it. Harder blades, like tungsten carbide, need less sharpening. Softer blades, like high-carbon steel, need more frequent care.

- Use PVD coatings to help your blades resist wear and last longer between regrinds.

- CVD coatings can make your blades even tougher and more efficient.

- Upgrading to better materials, such as tungsten carbide or ceramic, can reduce how often you need to regrind.

Always use the right tools and follow the manufacturer’s advice when sharpening your blades. This helps you avoid damage and keeps your blades sharp.

Signs of Blade End-of-Life

You need to know when to replace your blades instead of regrinding them. Here are some signs that your blade has reached the end of its life:

- The blade has deep notches or cracks.

- You see chips or missing pieces on the edge.

- The blade does not cut cleanly, even after sharpening.

- The blade is too thin after many regrinds.

If you notice these problems, it is time to get a new blade. Using a worn-out blade can damage your machine and lower your product quality.

Mancia: Regular checks and good care help you get the most from your blades. If you are not sure when to replace or regrind, ask your supplier for advice.

Performance Tips

Installazione

You must put in your rotary slitter blade material the right way to get good results. First, check if the blade and anvil are the same hardness and size. Always clean where you will put the blade. If there is dust or dirt, the blade might not cut well or could get damaged. Make sure the blade lines up with the machine’s guides. If it is not lined up, your cuts may look uneven or messy. When you tighten the blade, use the right amount of pressure. If you use too much, the edge can chip. If you use too little, the blade might move.

Mancia: If you do not install the blade right, the cutting edges may not work well. This can break the blade faster and make it not last as long.

Manutenzione

Taking care of your rotary slitter blade material helps it last longer and work better. You should make a plan to check and care for your blades often. Here are some easy ways to keep your blades in good shape:

| Routine di manutenzione | Descrizione |

|---|---|

| Regular Blade Inspections | Look for dull spots, chips, or other damage. Change or sharpen blades if you see problems. |

| Blade Sharpening and Reconditioning | Sharpen blades instead of buying new ones. This helps blades last longer and saves money. |

| Proper Blade Alignment and Pressure | Make sure blades are lined up and tightened just right. This helps blades wear less and cut better. |

Keep your machine clean too. Wipe away dust and dirt after every shift. Oil moving parts so they do not rust or stick. If you see dirty oil or fluid, change it right away.

Nota: Good care helps you stop problems before they start and keeps your work going without delays.

Monitoring Wear

You need to watch your rotary slitter blade material for signs it is getting worn out. If you find problems early, you can stop bad cuts and machine trouble. Here are some things to look for:

| Indicatore | Spiegazione |

|---|---|

| Uneven trimming width | If one side is smaller, the blade might not be lined up or the strip steel is not flat. |

| Poor flatness of strip steel | Bumps or dips can hit the blade and break the edge. |

| Issues with rubber bonded spacers | Broken spacers can shake the blade and make it wear out faster. |

| Improper installation | If you do not put the blade in right, it can get damaged more easily. |

Check your blades at the start and end of every shift. Listen for strange sounds when cutting. Watch if the cuts look different or if it gets harder to cut. If you see any of these things, stop and look at the blade.

Mancia: Watching for wear helps you fix things before they break.

Risoluzione dei problemi

Sometimes, you might see problems with your rotary slitter blade material while working. Fixing these problems quickly helps you keep your products good and your machines safe. Here are some common issues and what you can do:

- Ragged or Fuzzy Cuts: If the edges look rough or torn, the blade is probably dull. Sharpen the blade right away. Make a plan to sharpen blades often so they stay sharp.

- Collapsed Board Edges: If the blade crushes instead of cutting, it means the edge is dull or the angle is wrong. Sharpen the blade and check the angle to get clean cuts again.

- Surriscaldamento della lama: If the blade gets too hot, it is usually because the edge is dull. Sharpen the blade as soon as you see it is not cutting well.

- Premature Blade Wear: If your rotary slitter blade material wears out too fast, check for these reasons:

- You might be using the wrong blade material for what you are cutting.

- You could be pressing too hard when cutting.

- The material you cut might have rough fillers inside.

- The blade might not be lined up right.

You should also think about the shape of the blade. The angle, tip size, and thickness all help the blade stay sharp longer. If the blade shape is wrong, it can wear out twice as fast. Always use the right blade shape for your job.

Another problem is when the blades are not lined up. If the top and bottom knives or razor holders are not straight, the blade will wear out unevenly. This can make the blade get hot and the edge break early. Always check if the blades are lined up when you put them in or after you fix them.

Mancia: Keep a troubleshooting checklist close by. Checking your blades often helps you find problems early and keeps your rotary slitter blade material working well.

Supplier Collaboration

Working with your blade supplier can help you get better results. If you work with a company like Nanjing Metal Industrial, you get high-quality rotary slitter blade materials made just for you. These special blades help you work faster, cut better, and make more products.

A good supplier will talk with you to learn about your material, machine, and what you need. You can tell them about any problems you have. The supplier will look at this information and help you pick the best rotary slitter blade material for your job. This way, you get better cuts, less downtime, and higher quality.

Suppliers can also give you advice about picking blades, blade shapes, and how to take care of them. They can help you save money by suggesting blades that last longer and do not need to be changed as much. If you need a special blade shape or size, a good supplier can make blades that fit your needs.

Nota: If you have a good relationship with your supplier, you will always have the right rotary slitter blade material. Talking with your supplier often helps you fix problems early and keeps your work running smoothly.

Riferimento rapido

Tabella di confronto dei materiali

This table helps you compare common rotary slitter blade materials. It lists the main features, best uses, and how each material works. Use this guide to help you pick the right rotary slitter blade material for your job.

| Materiale della lama | Durezza (HRC) | Resistenza all'usura | Resistenza al calore | Il migliore per | Costo | Frequenza di affilatura |

|---|---|---|---|---|---|---|

| Acciaio al carbonio | 50–55 | Medio | Basso | Paper, films, soft jobs | Basso | Spesso |

| Acciaio per utensili | 55–60 | Alto | Medio | Metals, thick materials | Medio | Moderare |

| Acciaio ad alta velocità | 58–65 | Alto | Alto | Plastics, fast cutting | Medio-Alto | Less often |

| Carburo di tungsteno | 75–80 | Molto alto | Molto alto | Abrasive, hard jobs | Alto | Rarely |

Mancia: Always use rotary slitter blade material that matches what you are cutting. This gives you cleaner cuts and makes blades last longer.

Lista di controllo per la selezione

This checklist helps you choose the best rotary slitter blade material for your needs. Go through each step before you buy or put in a new blade.

- Know Your Substrate

- What will you cut? (Paper, film, metal, rubber, etc.)

- Check Blade Compatibility

- Does the blade material fit your substrate and anvil hardness?

- Decide on Operational Priorities

- Do you want blades to last longer, cut cleaner, or cost less?

- Review Slitting Method

- Are you using razor, crush, or shear slitting? Each method works best with certain blade materials.

- Consider Wear and Heat Resistance

- Will your work make a lot of heat or wear on the blade?

- Plan for Maintenance

- How often can you sharpen or change blades? Pick a material that fits your maintenance plan.

- Think About Cost Over Time

- Will a more expensive blade save money because it lasts longer?

- Ask for Expert Advice

- If you are not sure, ask your supplier about custom rotary slitter blade material choices.

✅ Checklist Complete? Now you are ready to pick the right rotary slitter blade material for your work!

When picking rotary slitter blade material, look at blade type, how hard the material is, how long blades last, if the blade fits your machine, and how fast you want to cut. Every choice changes how long blades work and how well your job goes. Check the quick reference table to see your choices. If you need a special answer, talk to Nanjing Metal Industrial. If you want help from an expert, Contatti a sales engineer.

Domande frequenti

What is the best rotary slitter blade material for cutting metal?

You should pick high-speed steel or tungsten carbide for metal. These blade materials stay sharp and do not wear out fast. Tungsten carbide is best for hard or rough metals.

How often should you replace or regrind rotary slitter blades?

Check your rotary slitter blade material often. Change or sharpen blades if they get dull, chipped, or cut badly. Tungsten carbide blades need sharpening less often because they are harder.

Can you use the same rotary slitter blade material for all substrates?

No, you need to match the rotary slitter blade material to what you cut. Use high-carbon steel for soft things. For hard or rough things, use tool steel, high-speed steel, or tungsten carbide.

How do you know if your rotary slitter blade material is worn out?

Watch for rough edges, louder cutting sounds, or slower cutting. If you see chips or cracks on the blade, it is time to get a new one.

Does blade hardness affect rotary slitter blade performance?

Yes. Harder rotary slitter blade material stays sharp longer but can chip. Softer blades do not break as easily but get dull faster. You need to find the right mix of hardness and toughness for your job.

What maintenance helps rotary slitter blade material last longer?

Clean blades after every use. Keep them in a dry place. Check if they line up and have the right pressure when you put them in. Taking care of blades helps them work better and last longer.

Can you get custom rotary slitter blade materials for special jobs?

Yes. Many suppliers can make custom rotary slitter blade material for you. You can ask for special shapes, sizes, or coatings to fit your machine and what you cut.

Why is matching blade and anvil hardness important?

Matching hardness helps stop uneven wear and blade damage. If the rotary slitter blade material is much harder or softer than the anvil, you might get chips or bad cuts.

Vedi anche

Come scegliere le lame per taglierine circolari giuste per prestazioni durature

La guida definitiva per scegliere la lama taglierina in gomma

Come massimizzare l'affilatura della lama della taglierina per prestazioni di taglio superiori

3 risposte

I don’t think the title of your article matches the content lol. Just kidding, mainly because I had some doubts after reading the article.

If you have any questions, feel free to reach out to me for a discussion.