Lame di taglio rotanti sono componenti essenziali nell'industria di lavorazione dei metalli e Nanjing Metal è un fornitore leader di queste lame industriali di alta qualità. Queste lame personalizzate vengono utilizzate in macchine per impieghi gravosi, eseguendo tagli precisi di lamiere. Le fabbriche si affidano alle lame a taglio rotante di Nanjing Metal per una produzione continua e ad alta velocità, garantendo bordi puliti e scarti minimi. L'industria della lavorazione dei metalli ha registrato una crescita significativa, con Il mercato delle cesoie idrauliche raggiungerà i 5,7 miliardi di dollari nel 2023 e si prevede un ulteriore aumento. I progressi tecnologici, come l'integrazione e l'automazione CNC, contribuiscono a mantenere l'affilatura della lama e a ridurre le sbavature, rispondendo alla richiesta di precisione in ogni taglio. Per ulteriori informazioni o per richiedere una lama personalizzata, contattare direttamente Nanjing Metal.

Punti chiave

- Le lame rotanti delle cesoie tagliano lamiere e bobine in modo rapido e preciso, aiutando le fabbriche a ridurre gli sprechi e a migliorare la qualità del prodotto.

- L'acciaio rapido e le leghe di acciaio come il D2 offrono elevata durezza e resistenza all'usura, facendo sì che le lame durino più a lungo e funzionino meglio con diversi metalli.

- Le lame di taglio rotanti personalizzate aumentano la produttività adattandosi a macchine e materiali specifici, riducendo gli errori e prolungando la durata delle lame.

- L'installazione corretta delle lame, l'allineamento e la manutenzione regolare mantengono le lame affilate, migliorano la precisione del taglio ed evitano costosi tempi di fermo.

- La scelta del materiale giusto per la lama e la sua attenta manutenzione consentono di ottenere tagli più puliti, meno scarti e una lavorazione più efficiente del metallo.

Panoramica delle lame di taglio rotanti

Cosa sono le lame di taglio rotanti

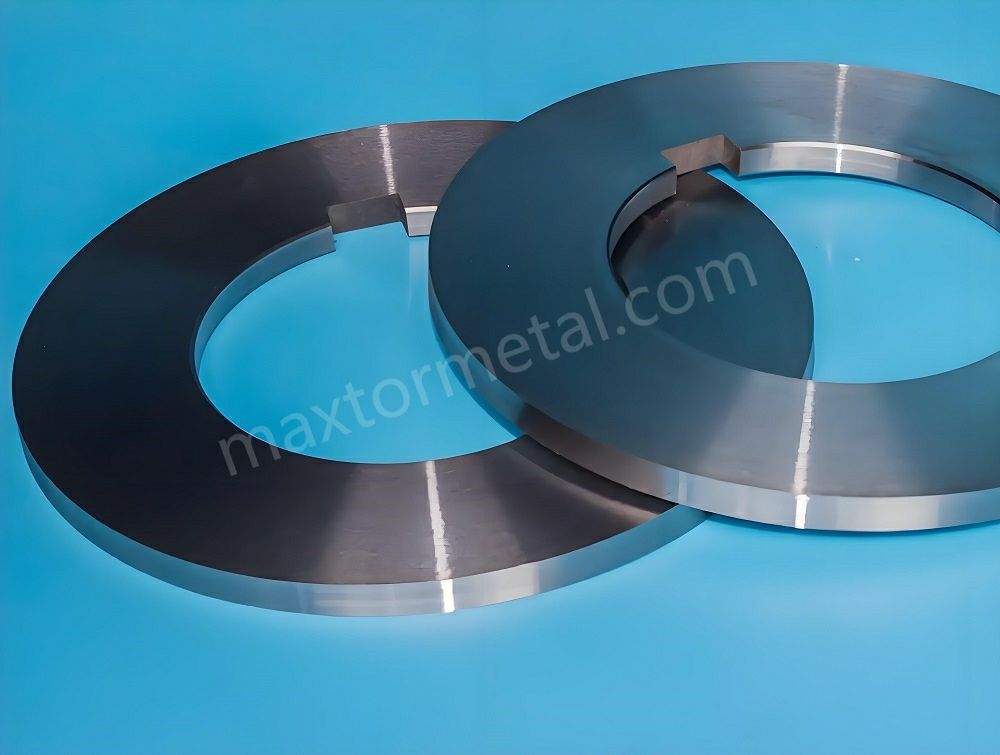

Le lame di taglio rotanti svolgono un ruolo fondamentale in lavorazione industriale dei metalliQueste lame sono utensili specializzati utilizzati nelle cesoie per tagliare e fendere lamiere e coil di metallo. Le fabbriche si affidano alle lame rotanti per la loro capacità di offrire tagli puliti e precisi ad alta velocità. La funzione principale di queste lame è quella di separare i materiali metallici riducendo al minimo gli scarti e le deformazioni. Le lame devono resistere a forze intense durante il processo di taglio, quindi i produttori utilizzano materiali di alta qualità come acciaio rapido, carburo e acciaio legato per utensili. Questi materiali offrono durezza, resistenza all'usura e tenacità, essenziali per durata ed efficienza.

Le cesoie dotate di lame rotanti possono operare a velocità fino a 2.000 metri al minuto. Le lame mantengono l'affilatura e resistono all'usura, anche durante il taglio continuo ad alta velocità. I processi di trattamento termico aumentano la durezza delle lame a livelli compresi tra 57 e 62 HRC. I rivestimenti superficiali, come il nitruro di titanio, ne prolungano ulteriormente la durata riducendo l'attrito. Le opzioni di personalizzazione consentono una precisione dimensionale precisa e una geometria della lama ottimizzata, migliorando le prestazioni di taglio e prolungandone la durata.

Nota: le lame per cesoie rotanti sono progettate specificamente per macchinari industriali. Non sono adatte per lavori di taglio manuali o non industriali.

Nomi alternativi

Le lame rotanti sono note con diversi altri nomi nell'industria metalmeccanica. Alcuni nomi alternativi comuni includono lame rotanti, lame circolari e lame a disco. Questi nomi riflettono la forma rotonda e il movimento rotatorio delle lame durante il processo di taglio. Le lame rotanti e le lame circolari si riferiscono allo stesso tipo di utensile, ma differiscono dalle lame dritte, utilizzate nelle cesoie a ghigliottina. I tipi di lame includono anche lame da taglio, lame da rifilatura e lame perforatrici, ciascuna progettata per specifiche attività di taglio o cesoiatura.

- Lame rotanti: utilizzate per il taglio rotativo continuo nelle linee di taglio longitudinale.

- Lame circolari: utilizzate in macchine che necessitano di lame rotanti e rotonde per una tosatura precisa.

- Lame a disco: utilizzate nelle operazioni di rifilatura dei bordi e di taglio longitudinale delle bobine.

Questi tipi di lame da taglio sono essenziali per ottenere elevata precisione e bordi puliti nella lavorazione industriale dei metalli.

Principio di funzionamento

Il principio di funzionamento delle lame rotanti per cesoie si concentra sul processo di taglio. In una cesoia, due lame ruotano in direzioni opposte. La lamiera o la bobina di metallo passa tra le lame. Ruotando, le lame applicano una forza concentrata lungo una linea sottile, provocando il taglio e la separazione netta del metallo. Questo metodo produce bave minime e preserva l'integrità del materiale.

Studi tecnici dimostrano che il processo di taglio comporta una forte deformazione di taglio. Durante il taglio, il la velocità di deformazione raggiunge circa 9.800 s⁻¹, che è molto più elevata rispetto alle operazioni di laminazione. Questa elevata velocità di deformazione attiva molteplici sistemi di scorrimento nel metallo, portando a una formazione di grani uniformi e ultrafini. Le misurazioni termografiche rivelano che il piano di taglio può raggiungere temperature di circa 190 °C. Questo aumento di temperatura causa un rammollimento termico, che aiuta le lame a tagliare più facilmente materiali tenaci.

Le lame per cesoie devono soddisfare rigorose specifiche tecniche per garantire prestazioni affidabili. La tabella seguente riassume le specifiche principali e i dati prestazionali delle lame per cesoie rotanti:

| Specifiche / Aspetto prestazionale | Dettagli / Dati |

|---|---|

| Materiali della lama | Acciaio rapido (HSS), carburo |

| Tolleranze di fabbricazione | Stretto come ±0,001 mm a ±0,005 mm |

| Misurazione della durezza | Prove di durezza su scala Rockwell |

| Tecniche di fabbricazione | Lavorazione CNC, rettifica superficiale |

| Velocità di taglio | Fino a 2.000 metri al minuto (lame in carburo) |

| Durata della lama | Le lame in carburo durano 2-3 volte di più rispetto all'HSS in alcune applicazioni |

| Miglioramento della produttività | Aumento fino a 20% |

| Riduzione dei materiali di scarto | Riduzione 25-30% |

| Riduzione del consumo energetico | Riduzione di circa 15% |

| Miglioramento della velocità di produzione | Aumento fino a 40% |

| Riduzione dei materiali scartati | Riduzione fino a 50% |

| Pratiche di manutenzione | Riaffilatura ogni 200-300 ore, controlli di allineamento, corretta conservazione |

| Fattori critici di precisione | Regolazione del gioco della lama entro 0,01 mm, affilatura, allineamento, controllo del surriscaldamento |

| Benefici economici | Costi di manutenzione inferiori, meno sostituzioni, maggiore durata della macchina, qualità costante |

Le lame rotanti per cesoie supportano un funzionamento efficiente e affidabile nelle cesoie industriali. Le fabbriche segnalano fino a 25% miglioramento dell'affidabilità del processo Dopo aver ottimizzato le impostazioni di lame e macchina, questi miglioramenti portano a velocità di produzione più elevate, riduzione degli scarti e minor consumo energetico. Le lame di taglio, se opportunamente selezionate e sottoposte a manutenzione, garantiscono una precisione costante e una lunga durata in ambienti di lavorazione dei metalli impegnativi.

Lame di taglio per lamiera Metal: materiali e proprietà

Selezione del materiale giusto per lame di taglio per lamiera È essenziale per ottenere tagli puliti e prestazioni durature. Materiali diversi offrono proprietà uniche che influenzano la capacità delle lame di gestire diversi metalli e le diverse esigenze produttive.

Acciaio rapido (HSS)

Composizione chimica e proprietà

L'acciaio rapido contiene elementi come tungsteno, molibdeno, cromo e vanadio. Questi elementi conferiscono all'HSS la capacità di mantenere un filo affilato anche ad alte temperature. Le lame in HSS resistono al rammollimento durante il taglio rapido, rendendole affidabili per molte applicazioni industriali.

Durezza e resistenza all'usura

Le lame in acciaio HSS raggiungono livelli di durezza compresi tra 60 e 67 HRC. Questa elevata durezza consente loro di tagliare facilmente anche i metalli più teneri. Presentano inoltre una buona resistenza all'usura, soprattutto se utilizzate con una corretta manutenzione. Trattamenti superficiali, come i rivestimenti a base di titanio, possono prolungarne la durata di circa 40% nel taglio di metalli tenaci.

Applicazioni tipiche

Le industrie utilizzano lame in acciaio superrapido (HSS) per il taglio di acciaio a basso tenore di carbonio, alluminio e altri metalli più teneri. Queste lame sono adatte a produzioni di piccole e medie dimensioni. Il crescente utilizzo di macchine CNC ha aumentato la domanda di lame in acciaio superrapido (HSS), poiché garantiscono precisione ed efficienza nel taglio automatizzato.

IL mercato delle lame a nastro bimetalliche, che utilizza l'HSS, è in rapida crescita. Queste lame combinano l'HSS con leghe di cobalto, migliorando le prestazioni di taglio e la durata della lama. Settori come quello automobilistico e aerospaziale preferiscono le lame HSS per la loro resilienza ed efficienza operativa.

Acciai legati (ad esempio, D2)

Composizione chimica e proprietà

L'acciaio legato D2 contiene circa 1,3% di carbonio, 12% di cromo, 1% di vanadio e 1% di molibdeno. Questa miscela conferisce al D2 un'elevata durezza e un'eccellente resistenza all'usura. La microstruttura dell'acciaio, con carburi piccoli e distribuiti uniformemente, aiuta a prevenire crepe e scheggiature.

Durezza e resistenza all'usura

Le lame D2 raggiungono livelli di durezza da 54 a 61 HRC. Offrono un'eccellente resistenza all'usura, rendendole adatte a lavori di taglio impegnativi. Un trattamento termico adeguato e la lavorazione criogenica ne migliorano ulteriormente la durata e la tenuta del filo.

Applicazioni tipiche

Le fabbriche utilizzano lame D2 per il taglio di acciaio inossidabile, leghe dure e lamiere spesse. Queste lame offrono ottime prestazioni in operazioni ad alto volume e ad alta intensità, dove una lunga durata e tempi di fermo minimi sono fondamentali.

Selezione del materiale per applicazione

Linee guida per la selezione di diversi Metal

- Scegliete le lame HSS per metalli più morbidi ed esigenze di produzione moderate.

- Selezionare lame in lega di acciaio D2 per metalli duri, acciaio inossidabile e ambienti ad alta usura.

- Per i lavori più impegnativi e per una durata maggiore, si consigliano le lame in carburo di tungsteno.

Consigli pratici per la scelta della lama

- Adattare la durezza della lama alla durezza del materiale da lavorare.

- Per ambienti corrosivi, utilizzare trattamenti superficiali come la nitrurazione.

- Regolare la geometria della lama e l'angolo di taglio per ridurre la forza di taglio e migliorare l'efficienza.

Tabella di confronto delle prestazioni dei materiali

| Materiale della lama | Durata tipica (tagli) | Resistenza all'usura relativa | Applicazioni adatte |

|---|---|---|---|

| Acciaio rapido (HSS) | ~5.000 tagli su acciaio a basso tenore di carbonio | Resistenza all'usura di base | Metalli più morbidi, produzioni da piccole a medie |

| Carburo di tungsteno | ~3 volte più lungo dell'HSS sull'acciaio inossidabile | Resistenza all'usura 2-3 volte superiore rispetto all'HSS | Taglio ad alta intensità e a lungo termine di metalli duri |

| Acciaio legato (D2) | ~8.000 tagli su fogli di alluminio | Resistenza all'usura da moderata ad alta | Lavori da moderati a pesanti, metalli duri |

Macchine da taglio e tipi di lame Dovrebbero corrispondere alle esigenze del materiale e della produzione. Una scelta corretta garantisce tagli puliti, riduce gli sprechi e prolunga la durata della lama.

Applicazioni delle lame di taglio in Metalworking

Le lame da taglio svolgono un ruolo chiave in molti processi industriali. Le fabbriche utilizzano queste lame nelle cesoie per ottenere elevata precisione ed efficienza. Le principali applicazioni delle lame da taglio si concentrano sul taglio longitudinale di coil, sul taglio di lamiere e piastre e sulla rifilatura dei bordi. Queste applicazioni sono specifiche dei macchinari industriali per la lavorazione dei metalli e non si applicano alle attività di taglio manuali o non industriali.

Taglio della bobina

Descrizione dell'applicazione

Il taglio longitudinale delle bobine utilizza lame di taglio per tagliare bobine metalliche larghe in strisce più strette. Questo processo richiede una cesoia in grado di gestire velocità elevate e carichi pesanti. Gli operatori si affidano a lame di taglio ad alta precisione per mantenere la precisione e ridurre gli scarti. L'azione di taglio deve produrre bordi puliti ed evitare sbavature. Gli stabilimenti di lavorazione dell'acciaio e i centri di servizio per bobine si affidano a questo metodo per una produzione rapida e affidabile.

| Misura delle prestazioni | Descrizione / Valore |

|---|---|

| Qualità della produzione | Minori incidenti di trascinamento del materiale e formazione di sbavature, con conseguente miglioramento della qualità del prodotto e riduzione degli sprechi. |

| Durata della lama | Estesa di 20-50% a seconda dei rivestimenti e della manutenzione; le lame ben manutenute durano 20-30% in più. |

| Riduzione dei tempi di inattività | Si risparmiano circa 30-45 minuti per ogni sostituzione della lama; il rilevamento tempestivo dell'usura riduce i tempi di fermo di circa 15% all'anno. |

| Risparmio sui costi di sostituzione | 15-20% di risparmio annuale sui costi di sostituzione delle lame grazie alla maggiore durata. |

| Efficacia del rivestimento | I rivestimenti TiAlN possono prolungare la durata della lama fino a 35-50%; TiN aumenta la durezza di circa 25%; i rivestimenti DLC durano fino a 50% in più sui metalli più morbidi. |

| Frequenza di riaffilatura | 100-300 ore a seconda della durezza del materiale; l'affilatura professionale mantiene la qualità del taglio e riduce l'usura. |

| Durezza della lama | Misurato in HV o HRC; il trattamento termico (tempra, rinvenimento) raggiunge 60-65 HRC per una resistenza all'usura ottimale. |

Materiali tipici delle lame

Le fabbriche selezionano acciaio rapido, acciaio legato D2 e altri acciai per utensili resistenti all'usura per il taglio delle bobine. Questi materiali aiutano le lame a mantenere la loro affilatura durante il taglio continuo. La scelta corretta del materiale della lama garantisce una lunga durata e una precisione costante.

Taglio di lamiere e piastre

Descrizione dell'applicazione

Il taglio di lamiere e piastre utilizza cesoie per tagliare lamiere e piastre metalliche in dimensioni specifiche. Questa applicazione di lame da taglio richiede bordi puliti e deformazioni minime. Gli stabilimenti di fabbricazione e i centri di assistenza per la lavorazione dei metalli utilizzano lame da taglio ad alta precisione per soddisfare rigorosi standard di qualità. Gli operatori verificano la presenza di bave, scheggiature e disallineamenti per garantire che ogni taglio soddisfi le specifiche richieste.

Studi sperimentali dimostrano che l'ottimizzazione della geometria della lama superiore nella cesoiatura a taglio rotante può ridurre l'irregolarità dei bordi di oltre 80%. Questo miglioramento porta a bordi più dritti e uniformi e a minori rilavorazioni. Le fabbriche utilizzano ispezione visiva, misurazione dimensionale e controllo statistico del processo per mantenere un'elevata qualità.

Materiali tipici delle lame

Per il taglio di lamiere e piastre, gli operatori preferiscono le lame HSS e D2. Questi materiali offrono la durezza e la resistenza necessarie per metalli più spessi o duri. Affilatura e manutenzione regolari mantengono le lame al massimo delle loro prestazioni.

Rifinitura dei bordi

Descrizione dell'applicazione

La rifilatura dei bordi rimuove bave e irregolarità dai bordi di lamiere o nastri metallici. Questa applicazione di lame da taglio è fondamentale in settori come quello automobilistico e della produzione di elettrodomestici. Le cesoie utilizzano lame ad alta precisione per ottenere finiture lisce e dimensioni precise. Il processo garantisce che il prodotto finale soddisfi rigorosi standard di tolleranza e qualità.

Materiali tipici delle lame

La rifinitura dei bordi si basa su lame in acciaio HSS e D2. Questi materiali offrono risultati costanti e resistono all'uso ripetuto. Le aziende scelgono queste lame per la loro capacità di mantenere affilatura e precisione durante il funzionamento continuo.

Nota: tutte le applicazioni delle lame di taglio qui descritte sono riservate esclusivamente a macchinari industriali per la lavorazione dei metalli.

Lame di taglio rotanti personalizzate

Vantaggi della personalizzazione

Le lame per cesoie a laminazione personalizzate svolgono un ruolo chiave in molte applicazioni industriali. Le fabbriche necessitano spesso di lame con forme, dimensioni o profili di taglio specifici per adattarsi a specifiche linee di produzione. La personalizzazione consente alle aziende di ottenere risultati migliori nei loro processi di taglio. Progettando lame per una macchina o un materiale specifico, gli ingegneri possono migliorare la velocità di taglio, ridurre gli sprechi e prolungarne la durata.

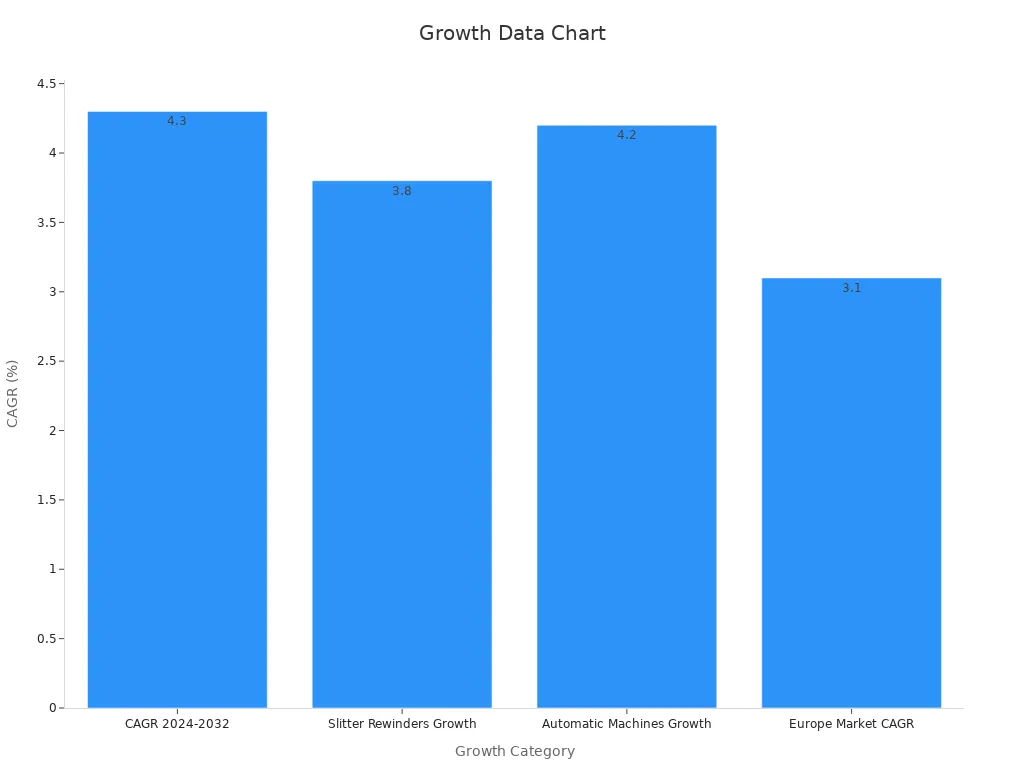

Il mercato globale delle lame di taglio personalizzate ha raggiunto i 2,76 miliardi di dollari nel 2023. Gli esperti prevedono che questo mercato crescerà fino a 4,03 miliardi di dollari entro il 2032, con un CAGR di 4,31 tonnellate per tonnellata. L'automazione e le nuove tecnologie guidano questa crescita. Molte fabbriche ora utilizzano macchinari avanzati che richiedono lame speciali per diverse applicazioni. Le lame personalizzate aiutano le aziende a stare al passo con le mutevoli esigenze produttive e i nuovi materiali.

| Aspetto | Dettagli |

|---|---|

| Dimensioni del mercato globale (2023) | 2,76 miliardi di dollari |

| Dimensioni previste del mercato (2032) | 4,03 miliardi di dollari |

| Tasso di crescita annuo composto (CAGR) (2024-2032) | 4.3% |

| Fattori di mercato | Automazione, progressi tecnologici, domanda di imballaggi flessibili |

| Vantaggi della personalizzazione | Produttività migliorata, riduzione degli sprechi, maggiore produttività, prestazioni costanti |

Le lame di taglio rotanti personalizzate offrono numerosi vantaggi:

- Aumento della produttività e della resa delle bobine

- Maggiore durata della lama e gestione semplificata

- Tagli precisi multi-larghezza con sbavature minime

- Errori di configurazione e tempi di onboarding ridotti

- Adattamento per diverse variabili della linea di taglio

Questi vantaggi rendono le lame personalizzate essenziali per le moderne applicazioni industriali.

Soluzioni Nanjing Metal

Nanjing Metal si distingue come fornitore e produttore leader di lame e coltelli industriali, con 18 anni di esperienza nel settore. L'azienda è specializzata nella progettazione e produzione di lame da taglio personalizzate per un'ampia gamma di applicazioni industriali. Il team si concentra su precisione e durata, garantendo che ogni lama soddisfi i rigorosi requisiti dei clienti.

Nanjing Metal utilizza acciai per utensili altolegati come D2 e M2. Il processo di produzione include trattamenti termici avanzati e rivestimenti moderni come il nitruro di titanio. Questi passaggi conferiscono alle lame durezza, resistenza all'usura e tenacità ottimali. L'azienda offre numerose opzioni di personalizzazione, tra cui diverse dimensioni, stili di filo e rivestimenti. Settori come l'industria alimentare, il confezionamento e l'automotive si affidano a Nanjing Metal per soluzioni di lame affidabili.

I clienti beneficiano di un chiaro processo di ordinazione in sei fasi e di un solido supporto tecnico. Il team di professionisti dell'azienda fornisce assistenza post-vendita e garantisce consegne puntuali. L'impegno di Nanjing Metal per la qualità e la soddisfazione del cliente ha ottenuto riconoscimenti in molti settori. Per maggiori informazioni sulle loro lame di taglio personalizzate, visitate il sito Homepage di Nanjing MetalColoro che sono interessati a discutere applicazioni o requisiti specifici possono contattare un tecnico commerciale tramite il Contatti pagina.

Migliori pratiche per l'uso della lama di taglio

Configurazione e funzionamento

Fase 1: Installazione della lama

Gli operatori devono maneggiare le lame di taglio con cura durante l'installazione. Devono ispezionare ciascuna lama per verificare la presenza di danni o detriti prima di posizionarla sulla macchina. Superfici pulite aiutano a prevenire disallineamenti e a garantire un funzionamento regolare.

Fase 2: Allineamento e posizionamento

Un corretto allineamento è fondamentale per la precisione. I tecnici utilizzano calibri e strumenti di misurazione per impostare le lame all'angolazione e alla distanza corrette. Un posizionamento accurato riduce l'usura irregolare e favorisce risultati di taglio costanti.

Fase 3: Fissaggio e fissaggio

Dopo aver allineato le lame, gli operai le fissano saldamente. Bulloni e morsetti ben serrati mantengono le lame stabili durante la cesoiatura ad alta velocità. Parti allentate possono causare vibrazioni e ridurre la precisione.

Fase 4: Esecuzione di prova e regolazione iniziale

Un breve test di prova verifica il sistema di taglio. Gli operatori ascoltano eventuali rumori insoliti e controllano la fluidità del movimento. Se necessario, regolano la posizione della lama per migliorare la qualità del taglio.

Fase 5: Calibrazione finale e controllo di sicurezza

La calibrazione finale garantisce che le lame soddisfino tutti i requisiti di precisione. I controlli di sicurezza confermano il corretto funzionamento delle protezioni e degli arresti di emergenza. Solo dopo aver superato questi controlli, la macchina può entrare in funzione a pieno regime.

Manutenzione e longevità

Ispezione e pulizia di routine

L'ispezione regolare di lame, alberi e rulli di taglio aiuta a rilevare tempestivamente usura o disallineamenti. La pulizia rimuove trucioli metallici e polvere, che possono compromettere la precisione.

Lubrificazione e cura della lama

Lubrificare le parti mobili come alberi e cuscinetti riduce l'attrito e il surriscaldamento. Questa cura prolunga la durata di vita sia delle lame che delle macchine.

Problemi comuni e risoluzione dei problemi

- Tagli smussati o sbavature: affilare o sostituire le lame.

- Vibrazioni eccessive: controllare l'allineamento e i dispositivi di fissaggio.

- Inceppamento del materiale: ispezionare la presenza di detriti e rimuovere eventuali ostruzioni.

Programma di sostituzione e affilatura

I registri di manutenzione aiutano a tenere traccia delle ispezioni e delle riparazioni. Una cura adeguata può prolunga la durata della lama fino a 50%La manutenzione predittiva, come il monitoraggio delle vibrazioni, contribuisce a evitare tempi di fermo imprevisti. La formazione degli operatori su pulizia, lubrificazione e ispezione contribuisce a garantire prestazioni a lungo termine.

Suggerimento: le lame di taglio ben tenute garantiscono una maggiore precisione e riducono i tempi di fermo macchina.

Per maggiori informazioni o per discutere di soluzioni personalizzate, i lettori interessati possono contattare un tecnico commerciale tramite la pagina dei contatti.

Le lame rotanti per cesoie rimangono essenziali nella lavorazione industriale dei metalli. Queste lame offrono tagli puliti, elevata precisione e prestazioni affidabili in numerose applicazioni. Le fabbriche utilizzano le lame rotanti per il taglio di coil, lamiere e la rifilatura dei bordi. La scelta del materiale, come l'acciaio rapido o l'acciaio legato, influisce sulla capacità delle lame di gestire ogni operazione di taglio. Una scelta corretta e una manutenzione regolare contribuiscono a prolungare la durata delle lame rotanti e a migliorare la sicurezza.

- Oltre 15 anni di esperienza nella produzione confermano l'affidabilità delle lame per cesoie industriali.

- La tecnologia avanzata e un team di ricerca e sviluppo qualificato garantiscono elevate prestazioni e innovazione.

- Un rigoroso controllo di qualità, che comprende molteplici fasi di ispezione, garantisce una qualità costante delle lame di taglio.

- Le opzioni di personalizzazione consentono ai clienti di adattare le lame a specifici requisiti di taglio.

- Un'ampia gamma di materiali e trattamenti termici specializzati aumentano la durata della lama.

- La certificazione ISO e i prezzi competitivi favoriscono la soddisfazione del cliente.

Soluzioni personalizzate Aiutiamo le aziende a soddisfare le specifiche esigenze di taglio. Un produttore affidabile di lame per cesoie rotanti offre lame su misura per ogni sfida industriale. Chi è interessato a discutere le proprie esigenze in materia di lame per cesoie può contattare un tecnico commerciale tramite la pagina dei contatti.

Domande frequenti

Qual è lo scopo principale delle lame di taglio rotanti?

Le lame rotanti tagliano e fendono lamiere o coils di metallo nelle macchine industriali. Aiutano le fabbriche a ottenere bordi puliti e dritti ad alta velocità e precisione.

Con quale frequenza gli operatori dovrebbero affilare o sostituire le lame delle cesoie?

Gli operatori dovrebbero ispezionare regolarmente le lame. La maggior parte delle fabbriche affila o sostituisce le lame dopo 200-300 ore di utilizzo. Lame smussate possono causare tagli bruschi o sbavature.

Quali materiali sono più adatti alle lame delle cesoie industriali?

L'acciaio rapido e l'acciaio legato D2 sono le scelte più diffuse. Questi materiali offrono elevata durezza e resistenza all'usura. Le fabbriche selezionano il materiale in base al tipo di metallo che lavorano.

Le fabbriche possono ordinare lame di taglio rotanti personalizzate per macchine speciali?

Sì. Molte aziende necessitano di lame personalizzate per macchine o materiali particolari. La personalizzazione migliora i risultati di taglio e prolunga la durata delle lame.

Cosa contraddistingue un produttore di lame per cesoie rotanti affidabile?

Un produttore affidabile di lame rotanti vanta anni di esperienza, team qualificati e un rigoroso controllo qualità. Per soluzioni personalizzate, i lettori possono contattare un tecnico commerciale tramite la pagina dei contatti.

Una risposta