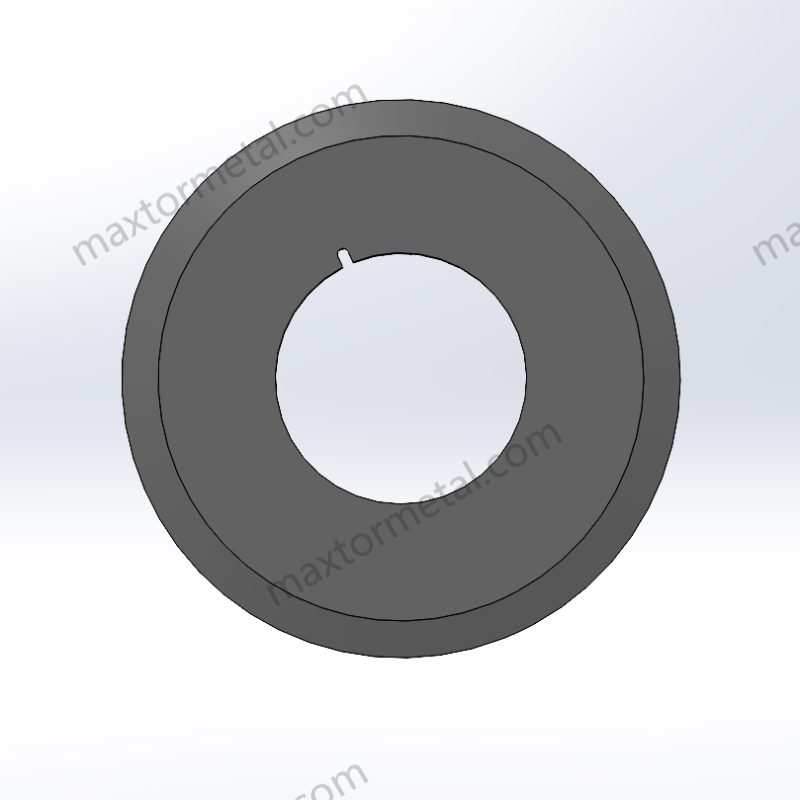

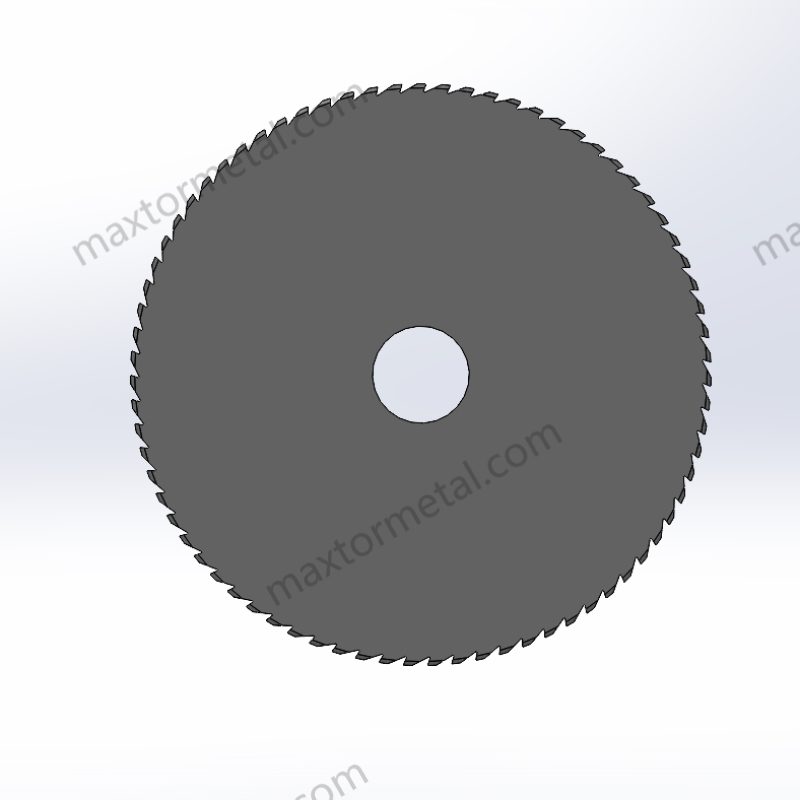

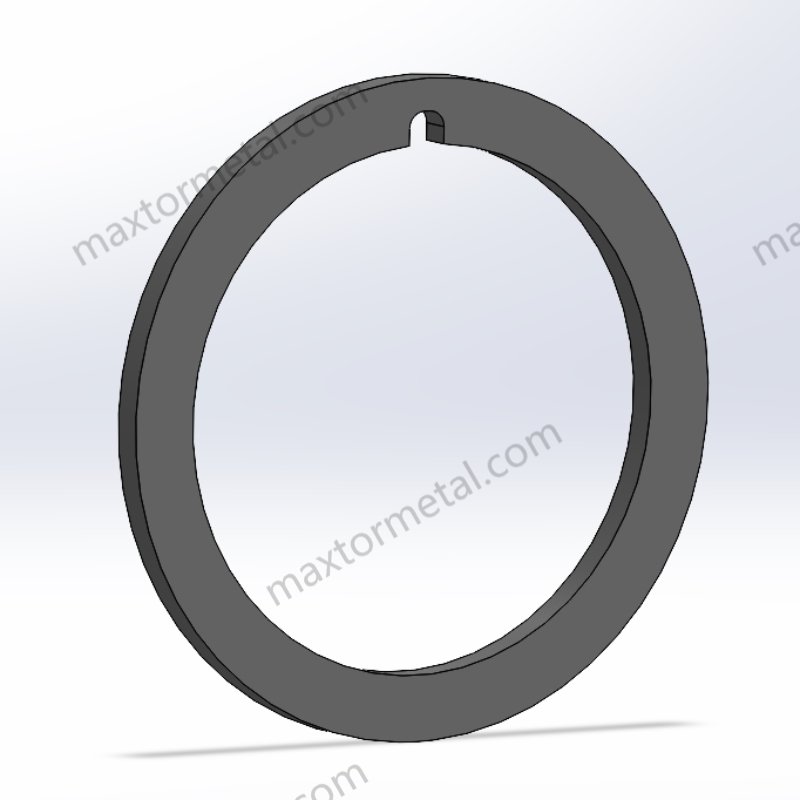

Developments and Innovations in Circular Slitter Knives: The Key to Enhancing Industrial Cutting Efficiency

Circular slitter knives are essential tools in many industrial applications, from packaging and paper industries to metalworking and plastics manufacturing. These blades are designed to make clean, precise cuts in a wide range of materials, improving production efficiency and quality. Nanjing Metal, with over 18 years of expertise in manufacturing industrial blades, is proud to be at the forefront of innovations in circular slitter knives. Our advanced manufacturing processes and commitment to providing customized solutions help businesses around the world achieve superior cutting performance. This article explores the development and innovations in circular slitter knives, highlighting key materials, coating technologies, and design advancements. It will also cover how these innovations […]

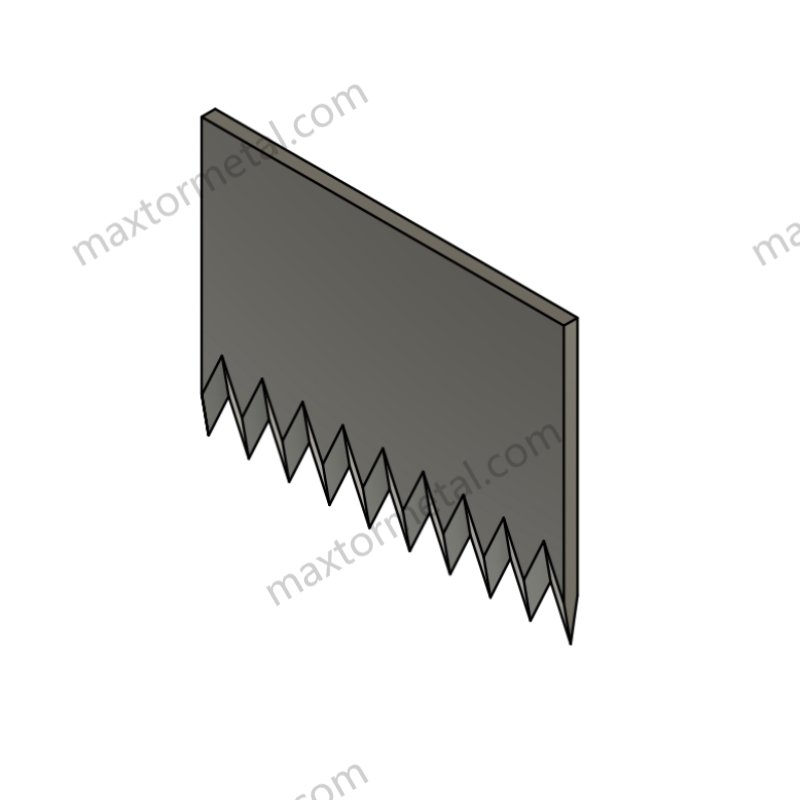

The Key Role of High-Quality Precision Industrial Blades and Knives in Food Processing: Secrets to Enhancing Efficiency and Safety

High-quality precision industrial blades and knives play a pivotal role in the food processing industry, where precision, efficiency, and safety are paramount. Whether in meat, poultry, or bakery production, the right cutting tools can drastically improve manufacturing processes, food quality, and worker safety. With 18 years of experience, Nanjing Metal is a trusted manufacturer of industrial knives, offering customized solutions tailored to the specific needs of food processors. In this article, we will explore the importance of high-quality blades and knives in food processing, focusing on how they enhance operational efficiency, ensure product quality, and safeguard food safety. Additionally, we will delve into the various types of blades used in […]

How Packaging Material Innovations Are Reshaping Cutting Equipment Performance? – Nanjing Metal’s Customized Solutions for Your Needs

Innovations in packaging materials are transforming industries, offering advancements in sustainability, cost-efficiency, and resource utilization. These breakthroughs are critical in an era focused on reducing environmental impact while optimizing operational efficiency. However, the shift to new materials introduces challenges, particularly in adapting industrial cutting blades and knives to handle varying physical and chemical properties effectively. Addressing these challenges is crucial for maintaining the performance and longevity of cutting equipment. At Nanjing Metal, we leverage our 18 years of expertise in manufacturing industrial knives and blades to provide customized solutions that align with these evolving needs. This article explores the interplay between packaging material innovations and cutting equipment performance, offering actionable […]

Machine Knives OR Blades Made in China: A Choice You Can Trust

The rise of China as a global manufacturing powerhouse is undeniable. Over the years, China has transitioned from being synonymous with low-cost production to a leader in quality and innovation. One sector that exemplifies this evolution is machine knives and blades. Today, Chinese-made machine blades are renowned for their reliability, quality, and competitive pricing. This article explores why machine blades and knives made in China are the go-to choice for international clients. I. A Global Market Leader A Growing Presence in the Machine Blade Market The global market for machine blades is forecasted to grow at a CAGR of 5.2% from 2023 to 2030, reaching an estimated value of $15.8 […]

Boosting Knife Efficiency and Cutting Costs: A Comprehensive Guide to the Benefits and Techniques of Industrial Blade Regrinding

Nanjing Metal, a professional manufacturer of industrial blades with 18 years of experience, is committed to delivering high-quality blades and solutions for industrial cutting needs. Companies often face challenges such as increased downtime due to frequent blade replacements, high costs of wear and tear, and the financial strain of purchasing new blades. Industrial blade regrinding offers a practical solution to address these issues. By restoring worn blades to their original sharpness and precision, regrinding not only reduces replacement frequency but also minimizes operational disruptions and long-term expenses. In this guide, we’ll explore the multifaceted benefits of industrial blade regrinding, the techniques and technologies involved, and how businesses can maximize their […]

Unveiling Laser Cutting Techniques: Enhancing Precision and Efficiency in Industrial Blade Manufacturing

In the realm of modern manufacturing, laser cutting techniques have emerged as a revolutionary force, redefining how machine blades and knives are produced. Precision, efficiency, and versatility are now prerequisites in industrial blade production, and laser cutting technology fulfills these needs seamlessly. This article explores the profound impact of laser cutting in blade manufacturing and how it elevates product quality while optimizing production processes. Advantages of Laser Cutting Technology 1. High Precision and Efficiency Laser cutting achieves unparalleled precision, enabling manufacturers to meet strict tolerances. By focusing a high-intensity laser beam, materials are cut with minimal error, ensuring consistent quality across batches. For instance, industrial studies reveal that laser cutting […]

Unlocking the Secrets of Machine Knife Manufacturing: A Comprehensive Guide to Heat Treatment for Enhanced Blade Performance!

In the world of industrial knife manufacturing, every detail matters. Among the many processes that define the quality of a blade, heat treatment stands out as a critical step. This transformative process not only dictates the performance of machine knives but also determines their durability, hardness, and resistance to wear. For instance, studies have shown that proper heat treatment can improve a blade’s hardness by over 40% while extending its life span by 50% or more. Such results underscore why heat treatment is not just a technical procedure but a cornerstone of exceptional blade manufacturing. In this article, we’ll explore the heat treatment process of machine knives in detail, shedding […]

Unlocking Rockwell Hardness: The Ultimate Guide to Industrial Knife Manufacturing Standards and Selection

Have you ever wondered why your industrial knives wear out too quickly, lose their edge, or fail to perform under stress? These issues often stem from a lack of understanding about a knife’s hardness and its suitability for specific applications. For manufacturers, understanding hardness standards is not just essential—it’s transformative. At Nanjing Metal, a trusted name with 18 years of expertise in industrial blade manufacturing, we recognize the critical role Rockwell Hardness plays in the performance, durability, and precision of industrial knives. From increasing blade lifespan to improving cutting accuracy, Rockwell Hardness has far-reaching implications. But what exactly is Rockwell Hardness, and why does it matter so much in industrial […]

The Ultimate Guide to Efficient Fish Processing and Industrial Knife Selection for Your Success

The fish processing industry plays a pivotal role in meeting the global demand for seafood, an essential source of protein for millions. With the seafood market valued at over $160 billion in 2022 and projected to grow significantly in the coming years, efficient fish processing methods have become critical to ensuring quality, sustainability, and profitability. Whether you’re a small-scale processor or a large industrial player, understanding the role of fish processing industrial knives in achieving operational excellence is key to success. The Basics of Fish Processing What Is Fish Processing? Fish processing involves a series of steps aimed at transforming freshly caught or farmed fish into high-quality products ready for […]

Innovations in Food Packaging Industrial Knives & Blades Applications: Key to Enhancing Food Safety and Efficiency

The global food packaging market plays a vital role in maintaining food safety, extending shelf life, and enhancing consumer convenience. As of 2023, the food packaging industry is valued at approximately $360 billion and is projected to grow at a compound annual growth rate (CAGR) of 5% from 2023 to 2030. This rapid expansion is driven by increasing consumer demand for ready-to-eat products, eco-friendly packaging, and food safety. Food packaging serves multiple critical purposes, including protecting contents from contamination, preserving freshness, and facilitating transportation. Behind the scenes, industrial knives and blades are indispensable in achieving these goals. These precision tools ensure clean cuts, reduce waste, and improve efficiency in packaging […]