고정밀 로터리 슬리터 블레이드가 귀하의 운영에 왜 중요한가요

You need high precision rotary slitter blades for your work. These blades help your machines run well and not break down. Sharp and balanced rotary slitter blades make clean cuts. They also help you use less material and waste less. This tool cuts wide rolls into smaller pieces with exact sizes. It helps you keep your products […]

로터리 슬리터 블레이드 교체: 단계별 가이드

If you do not perform a rotary slitter blade replacement the right way, you can lose time making products. About 25% of machine downtime occurs because tools break, such as blades. Good blades help you cut better and waste less. These blades also enhance workplace safety by reducing accident risks. There are many blade types and custom […]

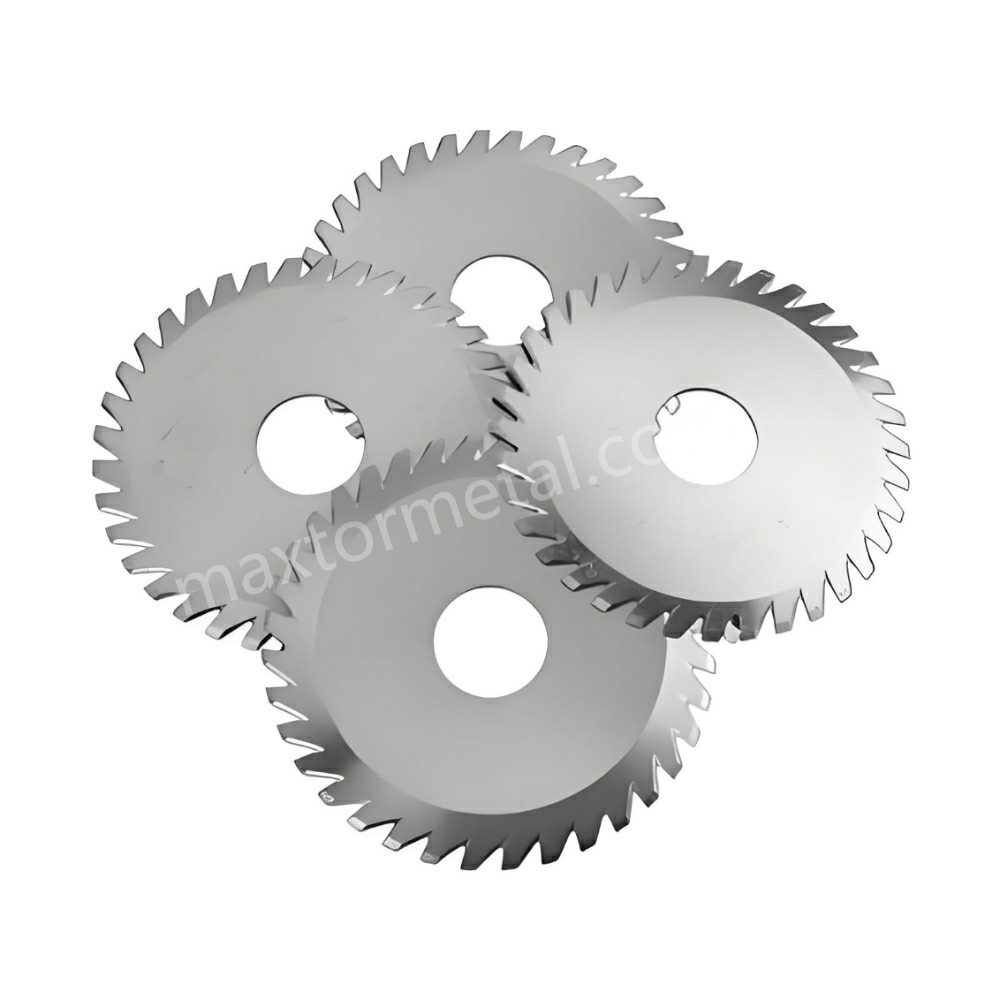

정밀 로터리 슬리터 블레이드 제조의 예술과 과학

You work with rotary slitter blade manufacturing. This job needs both smart engineering and skilled hands. People want blades that cut very well and very accurately. This need helps the market grow around the world: Nanjing Metal Industrial makes very good blades. They use ISO-certified places to make them. They use many kinds of materials and sizes. […]

고속 섬유 절단을 위한 최고의 로터리 슬리터 블레이드

When you choose the best rotary slitter blades for textiles, you enhance the speed and quality of your cutting process. Poor-quality rotary slitter blades can lead to several issues, such as: Nanjing Metal Industrial offers a wide selection of rotary slitter blades for textiles, crafted from premium materials. You can select blades with specialized edges, exceptional durability, […]

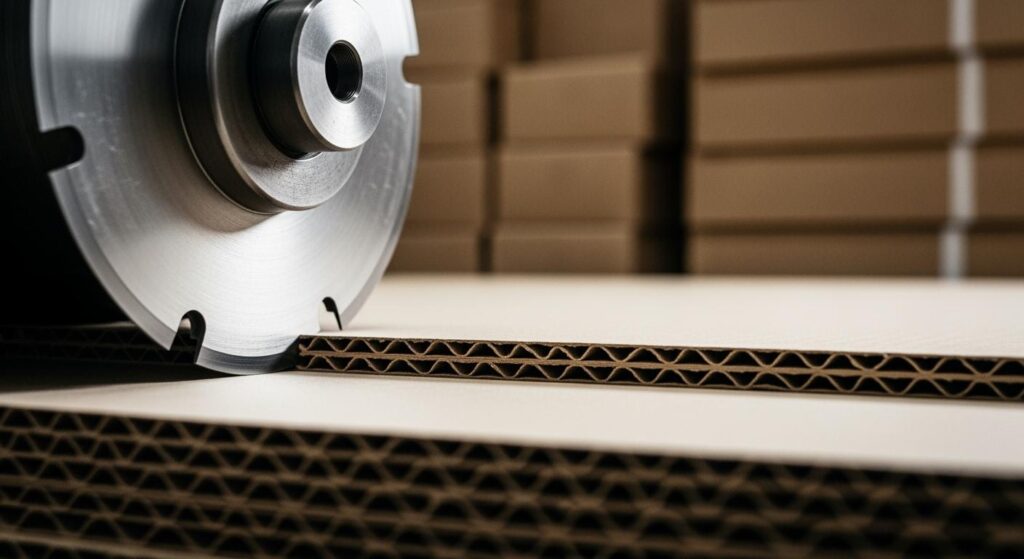

골판지용 로터리 슬리터 블레이드가 완벽한 포장의 핵심인 이유

You want every box to look neat and strong, right? Picking the right rotary slitter blade for corrugated board is very important. Good blades help you make clean and exact cuts. This means you waste less material and have fewer mistakes. You also save time because these blades stop your machines from breaking down. Your machines work […]

맞춤형 로터리 슬리터 나이프가 귀하의 비즈니스에 현명한 투자인 이유

Custom rotary slitter knives help you cut better. They last longer and work faster. When you pick a custom knife, it fits your business needs. You can get special sizes and strong materials. This helps you cut with less waste. Your machines can run more without stopping. These knives are used in many industries. Here are some […]

귀하의 최종 체크리스트: 로터리 슬리터 블레이드 구매 방법

When buying rotary slitter blades, you need to check every step to get the best results. Choosing the right blade prevents costly mistakes. Tooling issues, like using the wrong blade, cause about 25% of all manufacturing downtime. You can avoid this by using a careful checklist. You should always compare prices and look for trusted suppliers […]

로터리 슬리터 블레이드 문제 해결의 주요 실수와 수정 방법

Rotary slitter blade troubleshooting mistakes can cause big problems. If you avoid these mistakes, your blades work better. This keeps workers safe and helps things run faster. You should watch blade selection, installation, and maintenance. Doing this gives you many good results: Read this guide for fast fixes and long-term help. Key Takeaways Rotary Slitter Blade […]

블레이드 수명 연장: 로터리 슬리터 블레이드 연마에 대한 완벽한 가이드

You want your blades to last a long time. You also want to keep costs low. Rotary slitter blade sharpening helps with both things. Using good slitting blades gives you clean cuts. It also makes machines run smoothly. Regular care and expert sharpening help every day. Look at how you care for your blades now. Even small […]

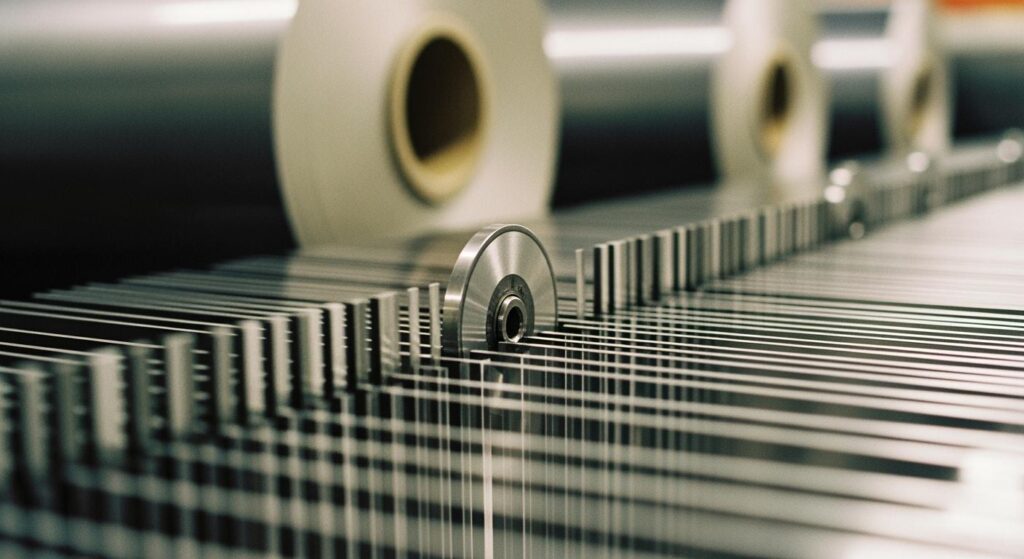

필름 및 포일 슬리팅을 위한 고정밀 로터리 슬리터 블레이드

You use high-precision rotary slitter blade for film to achieve smooth and clean edges. These rotary slitter blade for film are essential in your operations, helping you produce neat cuts and reduce errors. Blade quality is especially important for film makers and packaging companies. Nanjing Metal Industrial specializes in manufacturing rotary slitter blade for film that meet strict […]