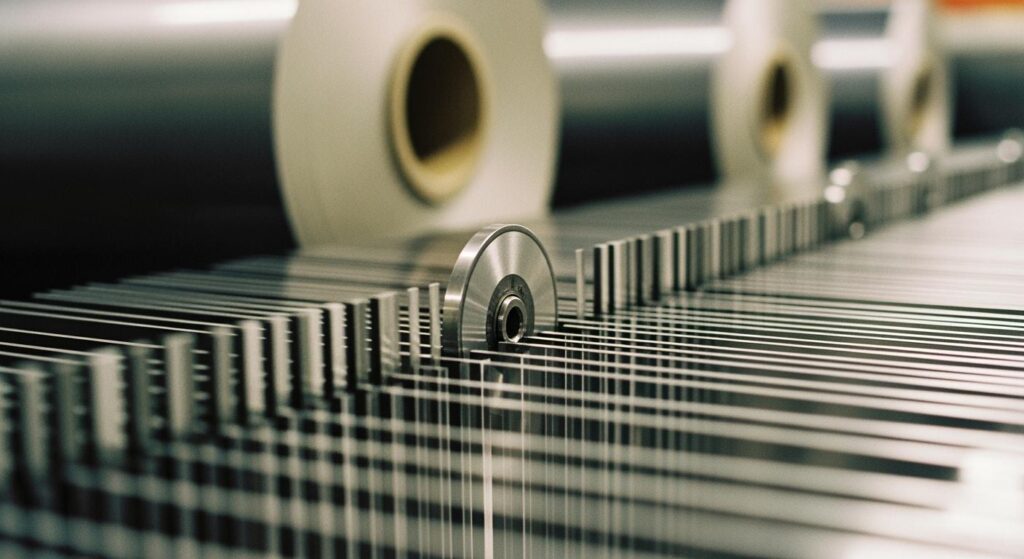

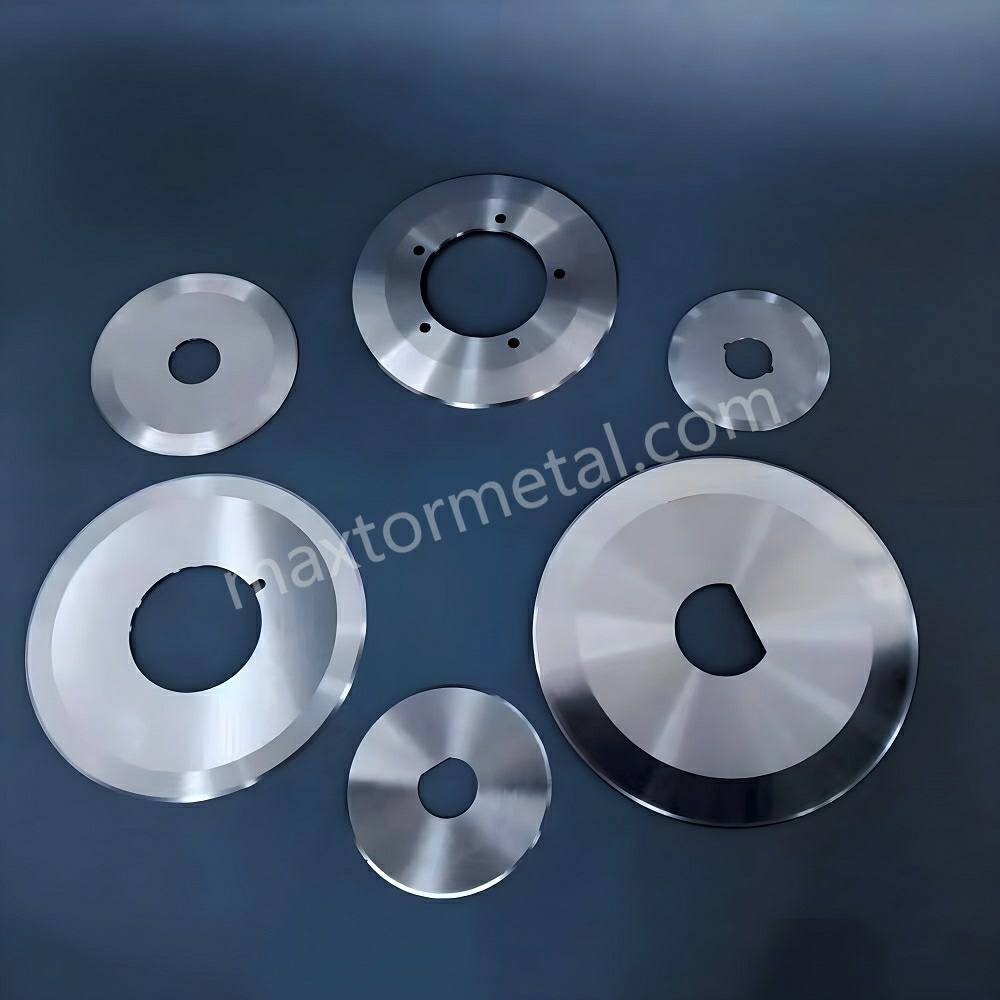

Você usa alta precisão Lâmina de corte rotativa para filme Para obter bordas suaves e limpas, estas lâminas de corte rotativo para filmes são essenciais para as suas operações, ajudando a produzir cortes precisos e a reduzir erros. A qualidade da lâmina é especialmente importante para fabricantes de filmes e empresas de embalagens.

- Muitas empresas relatam velocidades de produção mais rápidas e menos erros ao usar uma lâmina de corte rotativa de alta qualidade para filmes.

- Um estudo mostrou que 22% redução de resíduos após a mudança para uma lâmina de corte rotativa para filmes com formatos de bisel aprimorados.

Nanjing Metal A Industrial é especializada na fabricação de lâminas de corte rotativas para filmes que atendem a rigorosos padrões de qualidade. Eles também oferecem lâminas de corte rotativas personalizadas, adaptadas às suas necessidades específicas.

Principais conclusões

- As lâminas de corte rotativas de alta precisão proporcionam cortes suaves e limpos, ajudando a reduzir erros no trabalho com filmes e folhas metálicas.

- Boas lâminas ajudam as máquinas a trabalhar mais rápido. Elas também reduzem o desperdício. Isso melhora todo o processo.

- Escolha a lâmina adequada para o seu material. Você pode usar lâminas de barbear, de corte por compressão ou de cisalhamento. Cada uma é mais adequada para diferentes trabalhos.

- Tolerâncias de fabricação rigorosas ajudam a fazer cortes limpos. Elas também ajudam a evitar desperdícios. Mesmo pequenas alterações podem afetar o resultado final.

- Cuide das lâminas limpando-as diariamente. Substitua-as quando necessário. Isso mantém as lâminas afiadas e ajuda a prolongar sua vida útil.

- Lâminas personalizadas podem ser fabricadas para necessidades de corte especiais. Elas funcionam melhor com materiais ou trabalhos específicos.

- O uso de materiais e revestimentos avançados aumenta a durabilidade das lâminas. Além disso, contribui para um corte mais eficiente e resultados mais satisfatórios.

- A automação no corte longitudinal ajuda as máquinas a trabalharem mais rápido. Ela reduz o desperdício de material e mantém a qualidade do produto.

O que é uma lâmina de corte rotativa para filmes?

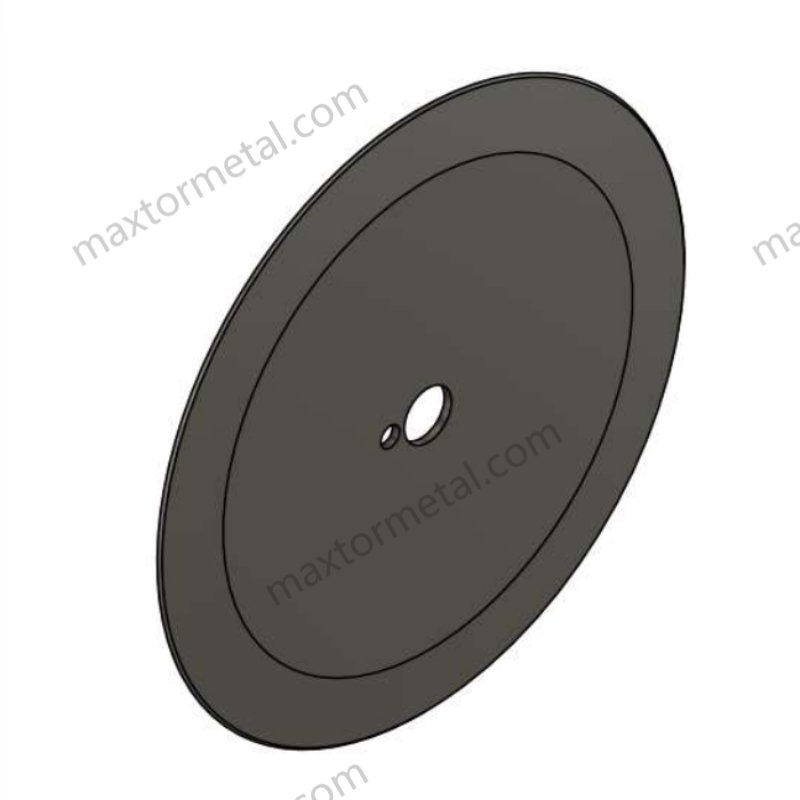

Uma lâmina de corte rotativa para filmes é uma ferramenta de corte especial. Ela é usada em máquinas de corte longitudinal. Essas máquinas recebem grandes rolos de material e os cortam em tiras menores. As lâminas ajudam a fazer cortes limpos e precisos em filmes plásticos, folhas e embalagens flexíveis. O design e a qualidade da lâmina são essenciais para cortes suaves e precisos.

As lâminas de corte rotativas para filmes são diferentes de outras lâminas industriais. Elas possuem características especiais. Você pode ver as principais diferenças na tabela abaixo:

| Recurso | Lâminas de corte rotativas para filmes | Outras lâminas industriais |

|---|---|---|

| Material | Aço inoxidável, revestido, metais duros, cerâmica | Varia bastante dependendo da aplicação. |

| Grossura | 0,40 mm e 0,20 mm | Varia bastante |

| Aplicação | Corte de materiais de embalagem flexíveis e sacos plásticos | Aplicações industriais gerais |

| Projeto | Design robusto com uma única ranhura oblonga | Diversos modelos baseados em necessidades específicas. |

| Desempenho | Corte de alta velocidade de filmes e materiais mais espessos. | O desempenho varia conforme o tipo de lâmina. |

Você usa lâminas de corte rotativas para filmes porque elas são feitas de materiais resistentes, como aço ferramenta ou carboneto. Isso faz com que durem muito tempo. O design robusto, com uma única ranhura oblonga, permite cortar materiais finos e espessos rapidamente.

Tipos de lâmina

Existem diferentes tipos de lâminas rotativas para corte de filmes. Os tipos mais comuns são:

- Corte com lâmina: Esta técnica é usada para cortar filmes, plásticos, fitas, cordões e vinil.

- Corte longitudinal por esmagamento: Este método funciona bem para algumas máquinas de corte longitudinal rotativas.

- Corte por cisalhamento: Este processo utiliza uma ação de cisalhamento para cortes precisos.

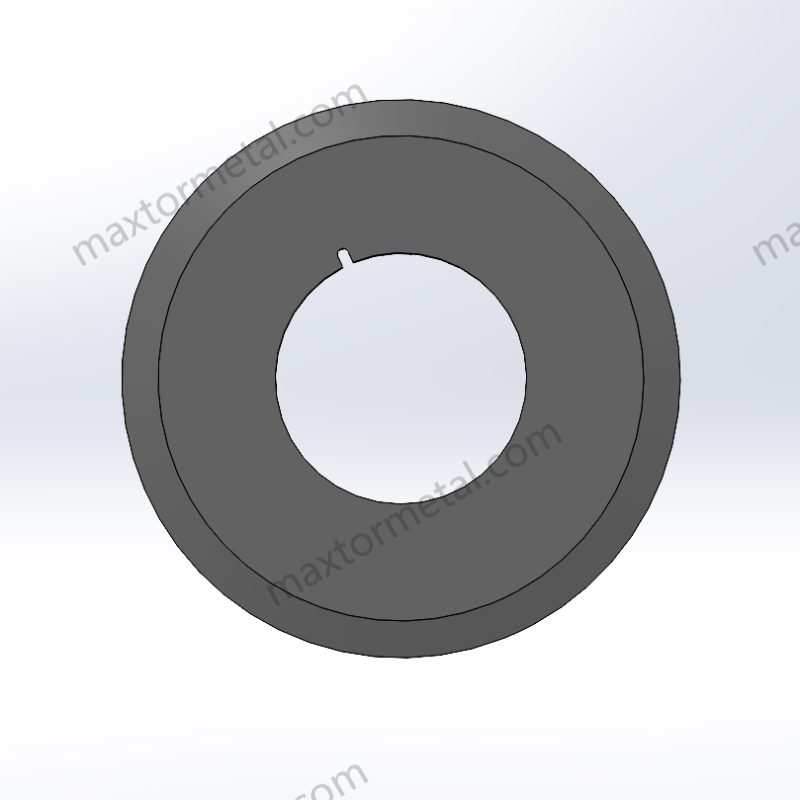

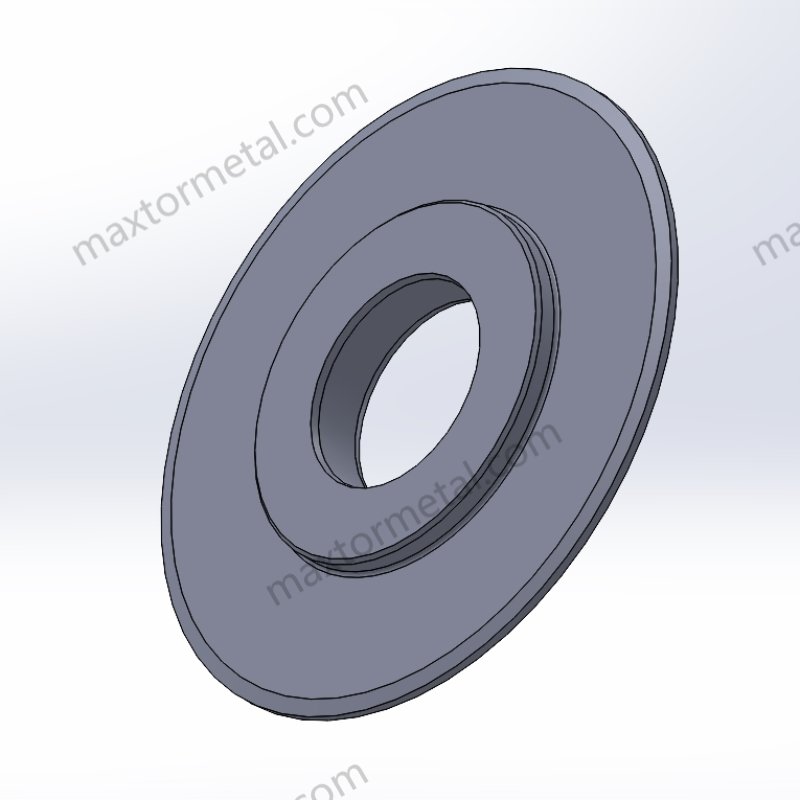

Camada única vs. Camada dupla

Você pode escolher lâminas de camada simples ou dupla. As lâminas de camada simples com borda fina são ideais para materiais mais duros. As lâminas de camada dupla com borda larga são boas para cortar materiais finos com alta precisão. Sua escolha depende do tipo de filme ou folha que você precisa cortar e do quão lisa você deseja que a borda fique.

Formulários

As lâminas de corte rotativas para filmes são importantes em diversos setores industriais. Você as encontrará em:

- Indústria de embalagens: Essas lâminas são usadas para cortar filmes e folhas para embalagens.

- Conversão de filmes e folhas: Utilizadas para cortar filmes plásticos, folhas de alumínio e laminados para embalagens, etiquetas e outros usos.

Filmes, folhas e embalagens flexíveis

Essas lâminas podem cortar filmes plásticos, folhas de alumínio e embalagens flexíveis. Isso ajuda na fabricação de produtos para embalagens de alimentos, suprimentos médicos e itens de consumo.

A Nanjing Metal Industrial oferece diversos tipos de lâminas para máquinas de corte longitudinal. Você pode escolher entre diferentes materiais, formatos e tipos de fio. Se precisar de algo especial, pode solicitar lâminas personalizadas. Visite o site. página de lâminas personalizadas Para saber mais sobre as opções que atendem às suas necessidades.

Características de alta precisão

Para cortes suaves e sem rebarbas, é preciso considerar três fatores: tolerâncias de fabricação rigorosas, materiais resistentes e o formato correto da lâmina. Esses elementos garantem cortes precisos e menor desperdício de material. A Nanjing Metal Industrial verifica a qualidade e seleciona materiais de alta qualidade, assegurando que cada lâmina de corte rotativo para filmes seja fabricada com excelência.

Tolerâncias de fabricação

Faixas de tolerância típicas

Para obter os melhores cortes, são necessárias tolerâncias muito precisas. Mesmo pequenas alterações no tamanho ou formato da lâmina podem afetar os resultados. Aqui estão as faixas de tolerância usuais para lâminas de corte rotativo de alta precisão:

| Parâmetro | Tolerância/Faixa típica |

|---|---|

| Tolerância ao paralelismo | ±0,001 mm a ±0,002 mm |

| Desvio axial e radial | Normalmente < 0,005 mm |

| Espessura da lâmina | Personalizável com precisão de +/- 0,001 mm |

| Diâmetro interno | Retificado com precisão para tolerância H7/H6 |

Essas tolerâncias rigorosas ajudam a manter a lâmina estável, reduzindo a probabilidade de cortes irregulares.

Impacto na qualidade do corte longitudinal

Se você usar lâminas com tolerâncias inadequadas, poderá ter problemas. Elas podem enroscar, formar bordas ásperas ou até mesmo estourar os rolos de filme. Veja algumas maneiras pelas quais a tolerância pode afetar seu trabalho:

- Se a lâmina for muito grossa, os rolos de filme podem estourar.

- Materiais finos podem enrolar, dificultando o corte.

- Alterações na tolerância podem causar curvatura e bordas ásperas.

- Pode ser necessário alterar o processo de corte se as tolerâncias não forem rigorosas.

Ao utilizar uma lâmina de corte rotativa para filmes com tolerâncias exatas, você obtém cortes mais limpos e menos desperdício. A Nanjing Metal Industrial monitora de perto as tolerâncias para ajudá-lo a obter os melhores resultados.

Opções de materiais

Aço de alto carbono, aço ferramenta, carboneto de tungstênio

O material que você escolher para sua lâmina influencia sua durabilidade e sua capacidade de corte. Veja a tabela abaixo para uma comparação. materiais comuns:

| Material | Vantagens | Desvantagens | Aplicações adequadas |

|---|---|---|---|

| Aço de alto carbono | Resistente, durável, não é caro. | Pode quebrar, pode enferrujar | Recortar papel e filmes |

| Aço ferramenta | Muito resistente, durável e funciona em altas temperaturas. | Custa mais, é mais difícil de fabricar. | Corte de chapas metálicas e materiais espessos. |

| Carboneto de tungstênio | É muito resistente e dura bastante tempo. | Pode quebrar, custa mais | Cortar materiais duros como o aço. |

Se você tem trabalhos longos e deseja reduzir o tempo de inatividade, o carboneto de tungstênio é uma boa opção. Para trabalhos curtos, o aço de alto carbono funciona bem. Lâminas mais finas proporcionam cortes mais precisos, o que é ideal para cortes detalhados de filmes. Lâminas mais grossas duram mais, mas podem não cortar com a mesma precisão.

Geometria de aresta

Perfis de borda

O formato da lâmina também é importante. Você pode escolher entre diferentes formatos, dependendo do que precisa cortar:

- Ângulos de afiação da ponta de 35 a 45 graus funcionam para a maioria das coisas.

- Ângulos de corte como 30, 45 ou 60 graus, ou combinações como 45 + 15 graus, ajudam a adequar a lâmina ao material.

- A melhor profundidade de sobreposição para cortes suaves geralmente é de 0,5 a 0,75 mm, mas você deve ajustar esse valor de acordo com a espessura da folha.

Escolher o formato de borda correto ajuda a obter bordas lisas e sem rebarbas. Isso significa que você não precisa fazer acabamento extra.

Estudo de caso: Resultados de corte longitudinal

Uma empresa de embalagens queria cortes mais precisos em filmes PET finos. Para isso, trocaram a lâmina de corte rotativa de borda reta por uma de borda chanfrada. Após a mudança, notaram uma redução significativa nas rebarbas. As bordas ficaram com melhor acabamento e houve menos desperdício. Isso demonstra que o formato de borda adequado pode realmente otimizar o trabalho.

Dica: Experimente diferentes formatos de borda e materiais para descobrir o que funciona melhor para seus trabalhos de corte de filme ou folha.

Benefícios da qualidade de corte

Bordas sem rebarbas

Você quer que seus filmes e folhas tenham boa aparência e funcionem bem. Bordas sem rebarbas ajudam a atingir esse objetivo. Ao usar uma lâmina de corte rotativa para filmes que faz cortes suaves, você evita bordas afiadas ou ásperas. Essas bordas limpas protegem seus produtos contra danos posteriores. Na fabricação de eletrônicos e baterias, cortes sem rebarbas garantem segurança e precisão. Você também reduz a probabilidade de travamentos ou quebras da máquina. Isso ajuda a prolongar a vida útil de suas máquinas e a manter a alta qualidade de seus produtos.

Dica: Bordas sem rebarbas ajudam a evitar problemas que podem prejudicar a qualidade do seu produto e o funcionamento do seu equipamento.

Redução de resíduos

Você economiza dinheiro e materiais quando gera menos desperdício. Cortes limpos significam menos lixo. Quando suas lâminas funcionam bem, você não precisa corrigir rebarbas. Isso permite que você aproveite melhor seus materiais. Menos desperdício também significa menos tempo gasto limpando ou corrigindo erros. Você pode se concentrar em produzir mais em vez de resolver problemas. Isso ajuda você a trabalhar mais rápido e contribui para o crescimento do seu negócio.

- Você usa menos material.

- Você gasta menos tempo consertando coisas.

- Você reduz seus custos.

Desempenho consistente

Lâminas que funcionam sempre da mesma maneira garantem resultados consistentes. Quando as lâminas cortam sempre da mesma forma, seus produtos têm a mesma aparência e desempenho. Isso mantém seus clientes satisfeitos e fortalece sua marca. Além disso, você gasta menos tempo trocando lâminas ou consertando máquinas. A tabela abaixo mostra como o funcionamento consistente das lâminas beneficia sua produção:

| Descrição | Impacto no rendimento da produção |

|---|---|

| Menos trocas de lâminas te proporcionam 15-20% mais tempo para configurar as máquinas. | Agiliza o trabalho e reduz erros. |

| Boas lâminas fazem cortes e selagens limpas, mantendo os produtos resistentes. | Reduz erros e desperdícios na embalagem, resultando em mais produtos de qualidade. |

| Cortes precisos fazem com que os produtos tenham uma aparência melhor e durem mais tempo. | Faz os clientes felizes e ajuda a sua marca. |

| Lâminas de má qualidade fazem as máquinas trabalharem mais, por isso quebram com mais frequência. | As máquinas não duram tanto tempo, então você recebe menos produtos. |

| Lâminas resistentes utilizam menos material e ajudam o meio ambiente. | Ajuda você a fabricar produtos de forma mais sustentável. |

Você pode ver que usar as lâminas certas ajuda a produzir mais com menos esforço. Suas máquinas funcionam melhor e seus produtos ficam com uma aparência melhor nas lojas.

Critérios de seleção principais

Escolher a lâmina de corte rotativa certa para filmes, folhas ou embalagens flexíveis ajuda a obter bons resultados. É preciso combinar a lâmina com o material. Considere a espessura do material e a velocidade da sua máquina. Às vezes, você pode precisar de uma lâmina mais adequada. lâmina personalizada Para trabalhos especiais. Esta seção mostrará o que você deve levar em consideração.

Lâmina compatível com o material

Você deve sempre usar uma lâmina adequada ao material. Cada material é diferente. A lâmina correta proporciona cortes precisos, dura mais e gera menos desperdício.

Filme PET

O filme PET é resistente e flexível. É utilizado em embalagens, etiquetas e eletrônicos. Ao cortar filme PET, é necessário usar uma lâmina que mantenha o fio e não se desgaste rapidamente. Lâminas de aço ferramenta ou carboneto de tungstênio são boas opções. Também é importante verificar a dureza da lâmina. Lâminas mais duras duram mais, mas quebram com mais facilidade. Para filme PET, uma dureza de 58–62 HRC é considerada normal.

Folha de alumínio

A folha de alumínio é macia, mas pode riscar as lâminas. É necessário usar uma lâmina com fio afiado e revestimento antiaderente. Escolha uma lâmina com revestimento especial para evitar que a folha grude e reduzir o atrito. Lâminas de carboneto de tungstênio ou aço ferramenta revestido são boas opções. Além disso, é preciso aplicar a pressão correta para não danificar a folha.

Filme BOPP

O filme BOPP é fino e escorregadio. É usado para embalagens e rótulos de alimentos. Você precisa de uma lâmina muito afiada e lisa. Uma lâmina com um pequeno ângulo de bisel ajuda a evitar que o filme enrole. Você também deve combinar a espessura e o formato da lâmina com o filme e a velocidade da sua máquina.

Segue abaixo uma tabela para ajudá-lo a comparar os principais aspectos de cada material:

| Critérios | Filme PET | Folha de alumínio | Filme BOPP |

|---|---|---|---|

| Tipo de material | Aço ferramenta, carboneto de tungstênio | Carboneto de tungstênio, aço revestido | Aço ferramenta, aço de alto carbono |

| Dureza (HRC) | 58–62 | 60–65 | 56–60 |

| Precisão de borda | Alto | Muito alto | Alto |

| Geometria da lâmina | Bisel médio, perfil fino | Borda fina, revestimento antiaderente | Bisel baixo, perfil fino |

| Propriedades do revestimento | Opcional | Obrigatório | Opcional |

| Velocidade de corte | Médio a alto | Médio | Alto |

| Pressão de corte | Médio | Baixo | Baixo |

| Controle de temperatura | Não é crítico | Importante | Não é crítico |

| Ciclo de vida da lâmina | Longo | Médio | Médio |

| Compatibilidade com fita | Bom | Bom | Excelente |

Dica: Certifique-se sempre de que a lâmina seja adequada ao material. Isso ajuda a evitar rebarbas e bordas ásperas.

Espessura e Velocidade

Você precisa considerar a espessura do material e a velocidade da sua máquina. Materiais espessos exigem lâminas mais resistentes com um ângulo de bisel maior. Filmes finos exigem lâminas mais afiadas com um ângulo de bisel menor. Se sua máquina for de alta velocidade, use lâminas com revestimentos especiais para reduzir o calor e o atrito.

Para filme BOPP, aqui está uma tabela com dicas de lâminas para diferentes espessuras e velocidades:

| Espessura do filme BOPP (μm) | Velocidade da máquina (m/min) | Espessura recomendada da lâmina (mm) | Ângulo de chanfro (°) | Revestimento necessário |

|---|---|---|---|---|

| 12–20 | 200–400 | 0,20–0,25 | 30–35 | Opcional |

| 21–30 | 100–300 | 0,25–0,30 | 35–40 | Opcional |

| 31–50 | 50–200 | 0,30–0,35 | 40–45 | Recomendado |

Observação: Se você aumentar a velocidade da sua máquina, poderá precisar de uma lâmina com um revestimento especial para evitar o superaquecimento.

Personalização

Às vezes, as lâminas comuns não são adequadas para o seu trabalho. Você pode precisar de uma lâmina personalizada para um material específico, uma máquina diferente ou um método de corte específico. As lâminas personalizadas ajudam a obter o melhor acabamento, a largura de corte ideal e menos desperdício.

Processo de fabricação de lâminas personalizadas

Se você precisa de uma lâmina de corte rotativa personalizada para filmes, pode trabalhar com uma empresa como a Nanjing Metal Industrial. Você pode enviar seu desenho ou explicar suas necessidades. A empresa selecionará o material, a dureza e o formato da lâmina adequados para o seu projeto. Eles utilizam máquinas especiais para fabricar e afiar a lâmina, garantindo que ela se encaixe perfeitamente na sua máquina e funcione com eficiência.

As lâminas personalizadas têm muitos pontos positivos:

- Você obtém a melhor borda para o seu material especial.

- Você pode cortar em várias espessuras e usar diferentes velocidades da máquina.

- Você trabalha mais rápido e desperdiça menos.

- Você pode atender às necessidades especiais de corte para novos produtos.

Dica: Lâminas personalizadas ajudam a resolver problemas de corte difíceis e a manter suas máquinas funcionando bem.

Seguindo essas dicas essenciais, você poderá escolher a lâmina de corte rotativa ideal para filmes, folhas ou embalagens flexíveis. Isso ajudará a obter cortes precisos, reduzir o desperdício e manter suas máquinas funcionando sem problemas.

Lâmina de corte rotativa para filme: Manutenção

Cuidar da lâmina da sua cortadora rotativa de filmes é importante. Isso ajuda a obter cortes suaves e mantém a máquina funcionando bem. Existem algumas medidas simples que você pode tomar para prolongar a vida útil das suas lâminas.

Limpeza

Procedimento de limpeza diária

Você deve limpar suas lâminas diariamente. Isso evita o acúmulo de sujeira e resíduos. Veja como é fácil limpar suas lâminas: Retire a lâmina da máquina com cuidado. Limpe a poeira e a sujeira com um pano macio. Use um limpador ou desengordurante específico para lâminas. Não use raspadores de metal ou produtos de limpeza abrasivos. Seque a lâmina completamente antes de recolocá-la. A limpeza após cada uso ajuda a prolongar a vida útil das lâminas e a melhorar o corte.

Agentes de limpeza recomendados

Escolher o produto de limpeza certo mantém suas lâminas em bom estado. Alguns produtos de limpeza funcionam melhor para determinados materiais de lâmina. Você pode ver as melhores opções na tabela abaixo:

| Indústria | Material da lâmina | Melhor método de limpeza | Frequência de limpeza |

|---|---|---|---|

| Corte de papel e filme | Lâminas revestidas de carboneto de tungstênio | Ar comprimido e álcool isopropílico | Após cada 20.000 cortes |

O álcool isopropílico remove sujeira pegajosa sem danificar a lâmina. O ar comprimido remove poeira fina. Produtos de limpeza específicos para lâminas também ajudam na remoção de sujeira incrustada.

Precauções

Ao limpar lâminas, tome precauções: Use sempre luvas para proteger as mãos. Certifique-se de que a lâmina esteja fria antes de tocá-la. Não utilize objetos ásperos que possam riscar a lâmina. Seque-a completamente antes de guardá-la. Guarde as lâminas em local seco e seguro para evitar ferrugem.

Dica: Limpar diariamente reduz o atrito, ajuda as lâminas a durarem mais e mantém seus produtos com boa aparência.

Afiação e Substituição

Quando substituir a lâmina

Você pode procurar sinais que indiquem quando trocar a lâmina. A tabela abaixo lista alguns deles. sinais comuns:

| Indicador | Descrição |

|---|---|

| Queda na qualidade de corte | Bordas irregulares, rebarbas ou rachaduras nos produtos indicam que a lâmina está gasta. |

| Aumento da resistência ao corte | Se o motor estiver trabalhando com mais intensidade, a lâmina pode precisar ser substituída. |

| Diminuição da velocidade de corte | Uma velocidade de corte mais lenta significa que a lâmina está se desgastando. |

| Aumento do ruído de corte | Sons altos de corte podem indicar desgaste da lâmina. |

| Inspeção visual das lâminas | Entalhes, desgaste ou deformação indicam que é hora de substituir a lâmina. |

| Verificações de manutenção regulares | Inspeções programadas ajudam você a saber quando trocar as lâminas. |

Verifique as lâminas com frequência. Troque-as se observar algum destes sinais.

Métodos de afiação

Afiar as lâminas ajuda a prolongar a sua vida útil. Você pode siga estes passosPrimeiro, fixe a lâmina superior da serra circular em um dispositivo de retificação. Use uma rebolo de nitreto de boro e retifique em um ângulo de 45 graus. Avance 0,02 mm por passada e mantenha a lâmina girando a 30-60 rpm. Use fluido de corte para manter a lâmina resfriada. Retifique a parte interna em um ângulo de 3 graus. Para a lâmina inferior da serra circular: fixe a lâmina no dispositivo de retificação. Use uma rebolo diamantado e retifique apenas as laterais. Avance 0,02 mm por passada com uma velocidade de 23-25 m/s. Mantenha a lâmina girando a 30-60 rpm e use fluido de corte. Afie suas lâminas com frequência para mantê-las funcionando bem.

Solução de problemas

Tabela de Problemas e Soluções Comuns

Você pode estar com problemas nas suas lâminas. Aqui estão alguns problemas comuns e como resolvê-los:

| Emitir | Solução |

|---|---|

| Lâminas cegas ou danificadas | Troque as lâminas para obter cortes limpos. |

| Qualidade de corte irregular | Ajuste as configurações da lâmina para obter melhores resultados. |

| Desalinhamento da lâmina | Verifique e ajuste o alinhamento da faca e o diâmetro da lâmina. |

| Penetração deficiente | Ajuste a profundidade da lâmina de acordo com a espessura do material. |

| Cortes brutos | Calibre a pressão da lâmina para cortes mais suaves. |

| A lâmina se desloca durante o corte. | Inspecione regularmente a instalação e as configurações da faca. |

Nota: Verificar e ajustar as lâminas com frequência ajuda a evitar problemas e garante o bom funcionamento delas.

Você pode manter a lâmina da sua cortadora rotativa de filmes em ótimas condições limpando-a, afiando-a e verificando o desgaste. Essas etapas ajudam você a obter resultados perfeitos sempre.

Aplicações industriais

A lâmina de corte rotativa para filmes é utilizada em diversos setores industriais. Essas lâminas são essenciais quando se necessita de cortes rápidos e precisos. As próximas seções mostrarão como utilizar as lâminas de corte rotativa para filmes em diferentes tarefas.

Produção cinematográfica

Na indústria cinematográfica, utiliza-se uma lâmina rotativa para cortar grandes rolos de filme em pedaços menores. Essas lâminas garantem que cada pedaço tenha o mesmo tamanho, o que é fundamental para a impressão e embalagem posteriores. O formato de disco afiado permite um corte rápido e preciso, proporcionando resultados superiores aos obtidos com ferramentas de corte tradicionais.

- As lâminas de corte rotativas ajudam você a cortar com alta precisão.

- Você pode atender às necessidades dos setores de fabricação de papel e filmes plásticos.

- As lâminas ajudam você a trabalhar mais rápido e a produzir produtos melhores.

- Você mantém os tamanhos iguais, para facilitar o manuseio.

Dica: Usar uma lâmina de corte rotativa para filmes economiza tempo e ajuda a cometer menos erros durante a produção do filme.

Embalagem Flexível

As embalagens flexíveis exigem cortes precisos e limpos. Para garantir que cada embalagem tenha o tamanho ideal, utiliza-se uma lâmina rotativa para corte de filme. Essas lâminas ajudam a atender normas como a ISO. Com lâminas de qualidade, seus produtos ficam protegidos e seus clientes satisfeitos.

- Os controles de qualidade ajudam você a atender às normas do setor.

- Você garante que seus produtos sejam bons e que as pessoas confiem em você.

- Boas lâminas ajudam você a vender em novos mercados.

- Você obtém a largura de filme adequada para embalagens de alimentos e medicamentos.

- Os tamanhos personalizados ajudam você a acomodar diversos tipos de produtos.

Você precisa de uma lâmina de corte rotativa para filmes, a fim de manter as embalagens de alimentos e medicamentos seguras. Elas também são usadas para embalagens de eletrônicos, onde o tamanho precisa ser exato.

Nota: Cortar com cuidado ajuda a cumprir as normas de segurança e higiene na embalagem.

Outros setores

A lâmina de corte rotativa para filmes é usada em muito mais do que apenas embalagens e filmes. Você encontra essas lâminas em muitas outras aplicações. Elas ajudam a cortar materiais para suprimentos médicos, roupas e baterias.

- Você usa lâminas de corte rotativas para cortar a folha.

- Empregos nas áreas médica e têxtil exigem essas lâminas para cortes precisos.

- Os fabricantes de baterias usam essas ferramentas para cortar os eletrodos com precisão.

| Setor | Utilização de lâmina de corte rotativa para filme |

|---|---|

| Indústria Médica | Corte de embalagens e suprimentos estéreis |

| Têxtil | Corte de tecidos e materiais não tecidos |

| Eletrônica | Preparação de filmes e lâminas para dispositivos |

| Bateria | Corte de eletrodos para células de bateria |

Como você pode ver, a lâmina de corte rotativa para filmes ajuda a trabalhar mais rápido e a obter melhores resultados em diversas tarefas. Você pode confiar nessas lâminas para cortes limpos e precisos onde quer que precise delas.

Tendências e inovações

Materiais Avançados

Novos materiais estão aprimorando as lâminas de corte rotativo para filmes. Esses materiais ajudam a cortar mais rápido e aumentam a vida útil das lâminas. Ao usar esses materiais avançados, você obtém cortes melhores e precisa trocar as lâminas com menos frequência. A tabela abaixo mostra alguns desses novos materiais e suas funções:

| Material/Revestimento | Benefícios |

|---|---|

| Carboneto de tungstênio | Muito dura e resistente. Ótima para cortar materiais ásperos. As lâminas duram mais e você precisa parar menos vezes. |

| Cerâmica Avançada | Super resistente e suporta altas temperaturas. Ótimo para cortes rápidos. Mantém o formato mesmo quando quente. |

| Nitreto de titânio (TiN) | Duro e resistente ao desgaste. Impede a ferrugem e reduz o atrito. |

| Carbono tipo diamante (DLC) | Muito resistente e não se desgasta. Mantém as lâminas afiadas e reduz o atrito. |

Você pode escolher o melhor material para a lâmina da sua cortadora rotativa de filmes. Esses novos materiais ajudam a obter cortes mais suaves e a reduzir o desperdício.

Revestimentos

Os revestimentos tornam as lâminas de corte rotativo para filmes ainda mais resistentes. Uma fina camada é aplicada na lâmina, aumentando sua durabilidade e melhorando a qualidade do corte. Aqui estão alguns revestimentos que podem ajudar suas lâminas:

- Revestimento PVDCria uma camada fina e resistente na lâmina. Essa camada impede o desgaste e a ferrugem, além de evitar que objetos grudem na lâmina.

- Revestimento CVDAumenta a vida útil das lâminas. Utiliza um produto químico para criar uma superfície resistente. Permite cortar mais vezes antes de precisar trocar a lâmina.

- Revestimento de carboneto de titânio: Ajuda as lâminas a cortarem melhor. Você gasta menos tempo trocando lâminas e mais tempo trabalhando.

Dica: Lâminas revestidas permitem cortar mais película e folha metálica antes de precisar parar para fazer reparos.

Automação

A automação está mudando a forma como as lâminas de corte rotativas para filmes são utilizadas nas fábricas. As máquinas agora funcionam de forma mais rápida e inteligente. Você pode produzir mais em menos tempo. A tabela abaixo mostra como a automação pode te ajudar:

| Tipo de benefício | Descrição |

|---|---|

| Melhorar a eficiência da produção | O corte rápido (até 1000 m/min) permite cortar mais filme e folha metálica rapidamente. |

| Reduzir a perda de material | As máquinas inteligentes aproveitam quase todo o material. Você desperdiça menos e economiza dinheiro. |

| Garantir a qualidade do produto | O controle de tensão mantém os cortes suaves e precisos. Seus produtos ficam com melhor aparência e desempenho. |

| Flexibilidade e personalização | Você pode alterar as configurações rapidamente. Isso ajuda a processar diferentes pedidos com agilidade. |

| Economia de energia e inteligência | Os novos motores e controles inteligentes consomem menos energia. Você economiza energia e pode atualizar seu sistema facilmente. |

É possível observar que a automação melhora o desempenho da lâmina de corte rotativa para filmes. Você produz mais, desperdiça menos e mantém a alta qualidade dos seus produtos.

Escolher a lâmina de corte rotativa certa para filmes ajuda a fazer cortes suaves. Você não terá bordas ásperas nem desperdiçará tanto material. Se você cuidar bem das suas lâminas, elas permanecerão afiadas. Suas máquinas funcionarão melhor e durarão mais. Ao comprar de um bom fornecedor, você adquire lâminas resistentes e dicas úteis. Analise como você corta o filme atualmente e veja se consegue melhorar. Se quiser cortes mais precisos, experimente usar lâminas melhores.

Quer melhorar seus trabalhos de corte? Fale com nosso engenheiro de vendas. para obter ajuda.

Perguntas frequentes

O que é uma lâmina de corte rotativa para filmes?

Uma lâmina de corte rotativa para filmes é uma lâmina afiada e circular. Ela é usada em máquinas de corte longitudinal para cortar grandes rolos de filme ou folha metálica em tiras menores. Essa lâmina ajuda a obter bordas limpas e retas.

Com que frequência devo substituir a lâmina de corte rotativa de filmes?

Você deve verificar sua lâmina com frequência. Troque-a quando notar bordas cegas, excesso de rebarbas ou cortes irregulares. A maioria dos usuários troca as lâminas após muitas horas de uso ou quando a qualidade do corte diminui.

É possível afiar a lâmina de uma cortadora rotativa para filmes?

Sim, você pode afiar a lâmina da sua cortadora rotativa de filmes. Use uma retificadora ou uma ferramenta de afiar. A afiação ajuda a manter a lâmina cortando bem e aumenta sua vida útil.

Quais materiais funcionam melhor com lâminas de corte rotativas para filmes?

Você pode usar lâminas de corte rotativas para cortar filmes de PET, BOPP e alumínio. Escolha o material da lâmina adequado, como aço ferramenta ou carboneto de tungstênio, para o seu tipo específico de filme ou folha.

Por que são necessárias tolerâncias rigorosas nas lâminas de corte rotativo para filmes?

Tolerâncias rigorosas ajudam a obter cortes suaves e sem rebarbas. Elas mantêm a lâmina firme e reduzem o desperdício. Você obtém melhores resultados e menos problemas com seu filme ou folha acabada.

Como limpar a lâmina de uma cortadora rotativa de filmes?

Remova a lâmina com cuidado. Limpe-a com um pano macio e use álcool isopropílico ou um detergente suave. Seque a lâmina antes de recolocá-la. Lâminas limpas cortam melhor e duram mais.

Que problemas podem ocorrer se você usar a lâmina de corte rotativa errada para filme?

Se usar a lâmina errada, poderá notar bordas irregulares, mais desperdício ou travamentos da máquina. O filme pode enrolar ou rasgar. Para obter os melhores resultados, utilize sempre a lâmina adequada ao material e à máquina.

Veja também

Como escolher as lâminas de corte circulares certas para um desempenho duradouro

O guia definitivo para escolher uma lâmina de corte de borracha

Como maximizar a nitidez da lâmina de corte para um desempenho de corte superior