You want each cut from your corrugator to look neat. The right твердосплавные просечные ножи help you do this. Tungsten carbide is very hard and does not wear out fast. You change blades less often and have less machine stoppage with these knives. The first price may seem high, but you save money later because the blades last longer. New blade technology and regular care keep your machines working well and your products good.

Ключевые выводы

- Pick tungsten carbide blades because they are very hard. They stay sharp for a long time.

- Clean and sharpen blades often to keep them working well. This helps you avoid stopping work too much.

- Choose the right edge shape for better cuts. This helps you waste less material.

- Make sure blade details match your corrugator model. This helps the machine work its best.

- Put coatings on blades to make less dust. Coatings also help blades cut better.

- Watch how blades work to find problems early. This keeps things running smoothly.

- Think about the total cost, not just the price at first.

- Talk to suppliers to get good advice about which blades to use.

Selection Criteria for Carbide Slitting Knives

When you pick carbide slitting knives, you need to think about a few things. The blades should last a long time, cut well, and fit your machine. Here is what you should know.

Tungsten Carbide vs. Steel

Твердость и износостойкость

You want a blade that stays sharp and does not wear out fast. Tungsten carbide is much harder than steel. This makes it better for tough jobs and helps the blade keep its edge. The table below shows how tungsten carbide and steel slitting knives are different:

| Особенность | Карбид вольфрама | Steel Slitting Knives |

|---|---|---|

| Твердость | 92-95 HRA | 85-90 HRA |

| Износостойкость | Superior, handles abrasive materials | Limited, wears quickly on abrasives |

| Удержание края | Maintains geometry longer | Degrades under cutting loads |

| Увеличение срока службы лезвий | 300-500% longer in demanding conditions | Frequent changes needed |

You save time and money because you do not have to change blades as much. Your machine can run longer without stopping.

Longevity in Abrasive Conditions

Corrugated board can be rough on blades. Tungsten carbide slitting knives last longer when cutting these materials. You get more cuts before you need a new blade. This means your machine stops less and you make more products.

Edge Geometry and Thin Blade Technology

Achieving Burr-Free Cuts

The shape of the blade edge is important. If you want smooth cuts with no burrs, you need the right edge shape. Different bevels and serrations help the blade cut through corrugated material better. You will see fewer rough edges and less waste.

- The edge shape should match your material’s type and thickness.

- Special shapes like bevels and serrations help make cleaner cuts.

- The right edge shape also helps the blade last longer when cutting fast.

Matching Edge Angle to Production Needs

You need to match the edge angle to your speed and material. Thin blade technology lets you cut faster and with less force. If you run your machine fast, a sharper angle works better. For thicker board, a stronger angle keeps the blade from chipping.

Tip: If you need a special edge shape, you can look at the страница пользовательских лезвий.

Coatings and Surface Treatments

Reducing Adhesion and Dust

Coatings on carbide slitting knives help stop dust and keep material from sticking. This helps your cuts stay clean and your machine work well. You will see less build-up and fewer problems with printing.

Enhancing Blade Performance

Different coatings give different benefits. The table below shows some common coatings and what they do:

| Тип покрытия | Основные преимущества |

|---|---|

| Chromium Nitride | Low friction, high hot hardness, corrosion resistance, prevents chemical bonding with the tool. |

| Aluminum Chromium Nitride | Extra wear resistance, high oxidation temperature, works well in dry cutting. |

| Карбид вольфрама | Handles high temperature and friction, helps remove chips. |

| Triton | Resists corrosion, abrasion, and adhesion, good for nonferrous metals and plastics. |

| Zirconium Nitride | Adds lubricity, lowers friction, stops built-up edges, improves precision. |

| Titanium Nitride | Raises surface hardness, boosts wear resistance, lowers friction, safe for food handling. |

| Titanium Carbonitride | High hardness, better abrasion resistance, less friction, resists chipping and blistering. |

The right coating helps your blades last longer and cut better. Your blades will stay cleaner and sharper.

Note: When you pick carbide slitting knives, always check which coatings are best for your material and how you use your machine.

Matching Knives to Corrugator Production

Line Speed and Volume

You need to match your knife choice to how fast your line runs and how much you produce. High-speed lines and large production volumes put more stress on your blades. If your plant runs over 1,000 hours each month, you should use tungsten carbide. These blades last longer and keep your machines running with fewer stops. For moderate production, tool steel may work, but you will need to change blades more often.

If you use older equipment, tool steel thin knives can help because they fit machines with less precise controls. Low-speed lines, which run below 60 meters per minute, can use chromium steel knives to save money. Well-maintained machines benefit from carbide thin knives. These provide longer life and reduce downtime.

Tip: High-volume plants should choose premium models for longer blade life. If you run a smaller operation, affordable models make replacement easier and cost less.

Here is a quick guide to help you decide:

- Use tungsten carbide for high-volume, high-speed production.

- Choose tool steel for moderate volumes.

- Pick coated blades if you work with sticky adhesives.

Paper Type and Adhesive Content

The type of paper and glue you use affects your cutting results. Corrugated cardboard can be rigid or flexible. Some papers have more glue, which can stick to blades and cause problems. You need to think about these factors when you pick your knives.

- Rigid board needs a strong, sharp blade to avoid rough edges.

- Flexible board may need a different edge shape for clean cuts.

- Heavy glue content can cause build-up. Coated blades help reduce sticking and keep cuts clean.

- Your maintenance plan should match your paper and adhesive type. Clean and check blades often if you use a lot of glue.

Choosing the right blade material and keeping up with maintenance helps you get the best results for every type of board.

Compatibility with Grinding Systems

Your grinding system keeps your blades sharp. You must make sure your knives work well with your grinder. Some machines use automatic grinding, while others need manual sharpening. Carbide slitting knives need special grinding wheels and careful handling. If your grinder is not set up for carbide, you may damage the blade or shorten its life.

- Check your grinder’s specs before you buy new knives.

- Use the right grinding wheel for carbide to avoid chipping.

- Set up regular checks to keep blades sharp and aligned.

Note: Good grinding practices help your blades last longer and keep your cuts clean.

Machine Model and Knife Specs

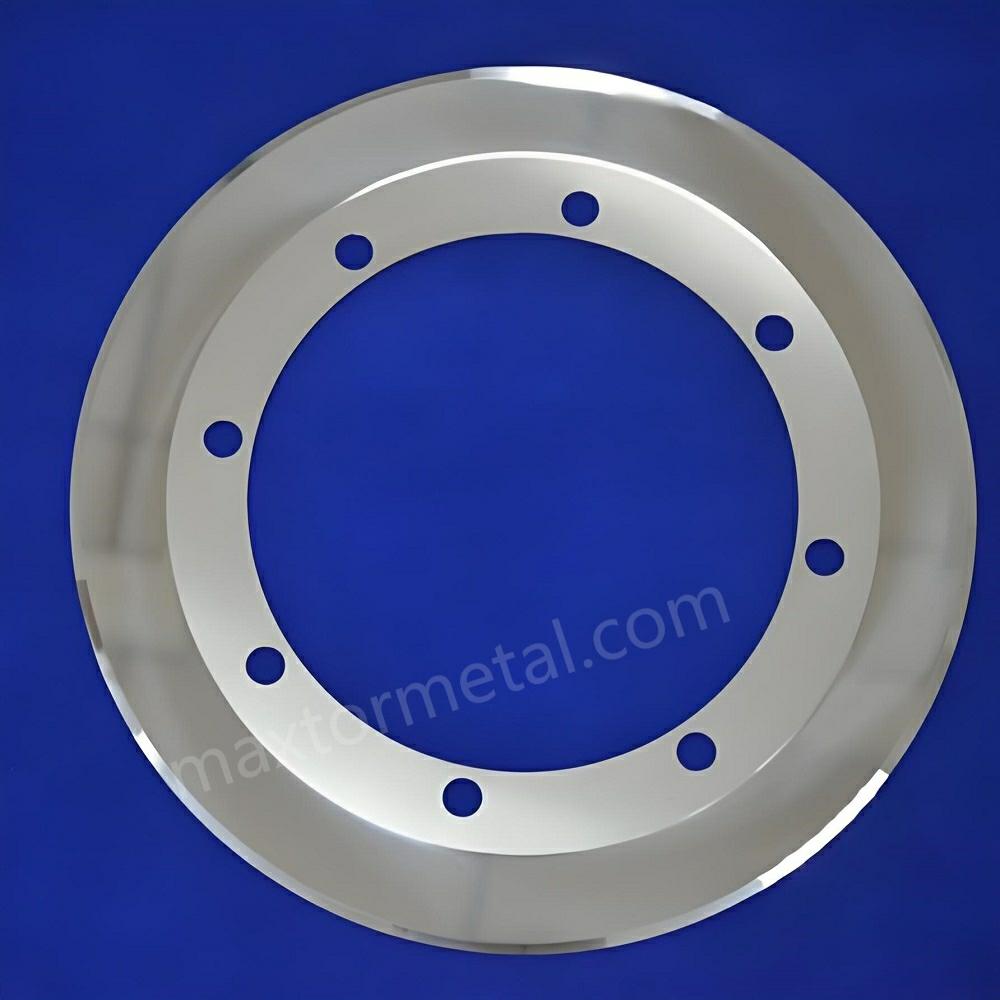

You must pick slitting knives that fit your corrugator. Every machine needs a certain blade size and thickness. The mounting holes also need to match. If you use the wrong blade, your cuts will not look good. Your machine may stop working more often.

Most companies sell standard and special blades for different machines. You can get blades for brands like Agnati, Fosber, BHS, and Marquip. These blades come in many sizes and hole shapes. Always read your machine’s manual or ask your supplier before you buy.

Here is an example of knife specs for a Marquip corrugator:

| Модель | Outer Diameter (mm) | Inner Diameter (mm) | Thickness (mm) | Holes (mm) |

|---|---|---|---|---|

| Marquip | 260 | 168.3 | 1.3 | 8×10.5 |

Other brands have tables like this too. Always check these numbers with your machine’s needs.

When you choose carbide slitting knives, look for blades made with ultra-fine tungsten carbide powder and cobalt powder. This mix makes the blade strong and accurate. Good production keeps the blade flat and the edge even. You get smoother cuts and the blade lasts longer.

Think about these things when picking knife specs:

- Make sure the outer and inner diameter fit your machine.

- Check the thickness for your material and speed.

- Count the holes and check their size for easy setup.

- Ask for special blades if your machine needs them.

Tip: If you get a new machine or change your line, check your knife specs again. This helps you avoid problems and keeps your cuts neat.

You make better choices when you know what your machine needs. The right specs help your blades work well and last longer.

Common Issues and Solutions

Chipping and Premature Wear

Sometimes, blades chip or wear out too soon. This can stop your work and cost more money. Many things can make blades chip or wear fast:

- Picking the wrong tool for your corrugator or material

- Not sharpening or treating the cutting edge the right way

- Using bad slitting settings, like wrong speed or pressure

- Machines that are not accurate, which makes cuts uneven

- Not matching the blade to your cardboard’s specific needs

Other reasons are using the wrong blade material or setting up the machine badly. Problems with the board can also cause trouble. If you use high-speed steel blades, they can get dull in 10 to 15 hours. Some carbide blades that are not tough enough can chip in 30 hours.

To fix these problems, pick the right blade for your job. Sharpen blades carefully and use the right method. Change machine settings to match your material and speed. Check your machines often to make sure they work well. If you see chipping, look at your slitting settings and try a tougher carbide blade.

Tip: Write down how your blades work in a log. This helps you find patterns in wear or chipping.

Fuzzy Edges and Poor Cuts

Fuzzy edges and rough cuts make your boxes look bad. You want sharp, clean edges for strong and nice packaging. Here are some ways to fix this:

| Проблема | Решения |

|---|---|

| Fuzzy Edges | Make the fine-grinding process better to keep edges sharp |

| Change the edge angle for your paper type | |

| Use finer-grain carbide grades like YG6X for sharper edges |

Check your grinding process first. A better fine-grinding method keeps blades sharp longer. Changing the edge angle helps if you use different papers. Finer-grain carbide blades stay sharp and help stop fuzzy cuts.

Note: Always match your blade’s edge shape to the board you cut. This helps you get cleaner cuts.

Dust and Printing Quality

Too much dust from cutting can hurt your machine and your products. Dust can build up on blades, so you need to clean more and might get jams. Dust on the board can also mess up printing and gluing.

To lower dust, use blades with special coatings or treatments. These coatings stop stuff from sticking and make blades smoother. Clean your blades after each shift and check for build-up. Changing your cutting speed and pressure can also help make less dust.

- Use coated blades to lower dust and sticking

- Clean blades often to stop build-up

- Watch your cutting settings to keep dust down

If dust hurts your printing, check your cleaning plan and blade choice. Clean cuts help printing look better and make stronger boxes.

Tip: Clean blades cut better and help your printing work well.

Adhesion and Build-Up

Adhesion and build-up can make your corrugator slow down. They also make your cuts look worse. Sticky adhesives and dust stick to the blade surface. This means you might stop your machine more often. You will need to clean the blades a lot. Carbide slitting knives with good coatings help fix these problems.

You can stop adhesion and build-up by doing these things:

- Put coatings on your blades. Coatings make the blade smoother and harder. This helps stop glue and dust from sticking.

- Use Physical Vapor Deposition (PVD) coatings. PVD coatings help blades last longer and fight rust. They also work well in tough jobs.

- Try Chemical Vapor Deposition (CVD) coatings. CVD coatings make a strong layer that does not wear out fast. This keeps blades cleaner and helps you work faster.

- Pick coatings that stop rust and handle high heat. These coatings help your blades last longer and stay sharp.

Blades with coatings stay cleaner and sharper. You do not have to clean them as much. You can spend more time making good cuts. You also lower the chance of blade damage from sticky stuff.

Tip: Check your blades often for sticky build-up. Clean and take care of them to keep your corrugator working well.

Misalignment and Vibration

Misalignment and vibration can cause many cutting problems. If blades are not lined up, your cuts will not be even. You will get more waste and your blades will wear out faster. Vibration can hurt the blade edge and make cuts look bad.

The table below shows how blade shape problems can hurt your work:

| Geometry Issue | Resulting Problem |

|---|---|

| Non-parallel edges | Misalignment, increased scrap |

| Blade alignment | Misalignment increases side loading and bevel wear |

You should check blade alignment often. Make sure the edges are straight and blades are put on right. Good alignment stops vibration and helps your blades last longer. You get better cuts and less waste.

Note: If you see vibration or bad cuts, check your machine. Fix blade alignment and look for worn parts to help your machine work better.

Practical Steps for Knife Selection

Assessing Machine and Maintenance

First, look at your corrugator and see how it works. Machines that run well help you get better cuts. They also make blades last longer. Check moving parts for any signs of damage or wear. Look at the blade holders to see if they are tight and not broken. Clean your machine often so dust and glue do not build up.

You should also check your maintenance plan. Regular checks help you find problems early. If blades get dull fast, look at your grinding system and sharpening tools. Machines that are well cared for let you use better blades. You will get more good cuts from each blade.

Tip: Write down every maintenance job in a logbook. This helps you see changes and spot problems that affect how blades work.

Checking Compatibility

Before you buy new blades, make sure they fit your machine. Check the blade size, thickness, and hole pattern. Each corrugator needs certain knife specs. If you use the wrong size, you might get bad cuts or break your machine.

Read your machine manual to find the right sizes. Compare these numbers with the blade specs from your supplier. If you get a new machine or change your line, check the fit again. This step helps you avoid mistakes and keeps your work going.

- Measure the outer and inner diameter of your blades.

- Count how many mounting holes there are and their size.

- Match blade thickness to your material and speed.

If you need help, you can visit Nanjing Metal Industrial for advice about blade fit.

Supplier Consultation

Talking to your supplier gives you expert help. Suppliers know which blades work best for your machine. When you talk to them, ask about blade material, cutting skill, and how long it lasts. Good suppliers have blades made from tungsten carbide. This material is very hard and does not wear out fast.

Here is a table to help you ask the right questions:

| Особенность | Описание |

|---|---|

| Материал | Tungsten carbide or cemented carbide with cobalt powder metallurgy |

| Применение | Used in corrugated paper production lines and carton plants |

| Режущая способность | Precise cutting for clean edges |

| Прочность | High wear resistance and long service life |

| Теплостойкость | Handles high temperatures during fast cutting |

| Устойчивость к коррозии | Resists rust and adhesive build-up |

Ask your supplier about these things. Find out if the blades have special coatings for heat and rust. Suppliers can also suggest blades that fit your grinder and match your speed.

Note: A good supplier will help you test blades and pick the right one for your job.

If you want more details or need special blades, Контакты Nanjing Metal Industrial. Their team can help you choose and answer your questions.

Sample Testing and Trials

You want to check if your carbide slitting knives work well before buying many. Sample testing and trial runs help you see how the blades do in your plant. You can look at cut quality, blade life, and if the knives fit your machine.

First, ask your supplier for some sample blades. Put these blades on one line and use them in your normal work. Watch for smooth cuts, sharp edges, and less dust. Write down how long the blade lasts before it needs sharpening or changing. Compare these results to your old blades.

You should also try the knives with different corrugated boards and adhesives. Some blades work better with thick board. Others are good with sticky glue and have less build-up. Test the blades at slow and fast line speeds to see if they stay sharp and cut well.

Here is a simple checklist for your test:

- Look at cut quality on all board types.

- Measure how long the blade lasts in hours or cuts.

- Watch for dust, burrs, and build-up.

- Try the blades at slow and fast speeds.

- Check for any problems with fit or alignment.

Tip: Keep a log of your test results. This helps you compare different carbide slitting knives and pick the best one for your needs.

Sample testing gives you real facts. You can make a smart choice and avoid costly mistakes.

Cost vs. Performance Evaluation

You need to think about both cost and performance when picking carbide slitting knives for your corrugator. High-grade tungsten carbide blades cost more at first, but they last much longer than steel blades. You change them less, so you have less downtime and lower maintenance costs.

Look at the total cost, not just the price for each blade. A blade that lasts 100 times longer saves you money over time. You also get better cuts and fewer bad boxes, which helps your business.

Think about these things when you compare choices:

| Фактор | На что обратить внимание |

|---|---|

| Материал лезвия | High-grade tungsten carbide for toughness |

| Срок службы | Long-lasting blades reduce changeovers |

| Качество резки | Sharp edges and clean cuts |

| Потребности в техническом обслуживании | Less frequent sharpening and cleaning |

| Supplier Reputation | Reliable suppliers offer quality and support |

| Настройка | Blades tailored to your machine and production |

You should also think about custom blades and quality control. Blades made for your machine and board type work better and last longer. Suppliers with good quality control give you steady results.

Note: A blade that costs more at first can save you more money later if it lasts longer and cuts better.

Premium carbide slitting knives made from top materials are very strong and precise. You spend less time changing blades and more time making good boxes. This helps you work faster and reach your goals.

When you look at cost versus performance, do not just look at the price. Think about how the blade will help your plant run better and give you better results.

Maintenance for Carbide Slitting Knives

Шлифовка и заточка

You must keep your carbide slitting knives sharp for good cuts. Sharp blades last longer and work better. Grinding and sharpening often stops dull edges and bad cuts. Here are some easy steps to care for your blades:

- Осмотрите лезвие.

Look at your blade before sharpening. Check for chips, cracks, or dull spots. Make sure the edge and surface look good. - Sharpen with the Right Tools

Use a grinding machine that keeps the edge angle steady. For the top slitter blade, put it in a grinding jig. Use a boron nitride wheel at a 45-degree angle. For the bottom slitter band, use a diamond wheel. Grind the sides with coolant so the blade does not get too hot. - Replace Damaged Sections

If you see deep chips or cracks, change that part of the blade. This helps you get smooth and safe cuts. - Schedule Regular Inspections

Make a plan to check your blades often. Regular checks help you find problems early. - Очистка и смазка

Clean the blade after you use it. Put on lubricant to stop rust and corrosion. - Проверить выравнивание

Make sure the blade sits straight in its holder. Good alignment stops uneven wear.

Tip: Always use the right grinding wheel for carbide slitting knives. This keeps the blade edge strong and stops chipping.

Cleaning and Handling

Cleaning and careful handling help your carbide slitting knives last longer. Dirt and glue can stick to the blade and make it dull. You should:

- Clean the blade after every shift to get rid of dust, glue, and paper fibers.

- Use a soft cloth or brush so you do not scratch the blade.

- Store blades in a dry place to stop rust.

- Handle blades gently so you do not drop or bump them.

Cleaning often keeps the cutting edge sharp. Dull blades make more friction and heat. This can hurt your machine and make cuts worse. Clean blades work better and last longer.

Note: A clean blade helps you cut faster and keeps your corrugator working well.

Проверка выравнивания

You need to check the alignment of your carbide slitting knives for straight cuts. Bad alignment causes rough edges and uneven wear. Use these steps to keep your blades working well:

| Процедура | Описание |

|---|---|

| Blade and Spacer Spacing | Make sure the total height matches on both sides for even cuts. |

| Blade Gap and Clearance | Keep the right gap to stop rough edges or extra wear. |

| Arbor Parallelism | Measure and adjust so the difference stays under 0.03 mm. |

| Blade Axial Runout | Clean all parts and check runout to stop defects. |

| Термическая стабильность | Keep the room between 20–25°C when setting up blades. |

| Vibration Control | Balance the blades to stop shaking and get better cuts. |

| Bearing Condition | Check bearings often and use the right oil or grease. |

| Rubber Rings Replacement | Change rubber rings often to stop slipping. |

Tip: Write down your alignment checks in a logbook. This helps you find problems early and keep your carbide slitting knives working well.

Мониторинг производительности

You need to watch how your carbide slitting knives perform every day. Good performance monitoring helps you catch problems early and keep your corrugator running smoothly. You can use simple checks and records to make sure your blades stay sharp and last longer.

Start by looking at the cut quality. Check the edges of your corrugated board after each shift. If you see fuzzy edges, burrs, or dust, your blade may need attention. Write down any changes in cut quality in a logbook. This helps you spot patterns and fix issues before they get worse.

You should also track how long each blade lasts. Record the number of hours or cuts before you need to sharpen or replace the knife. Compare this data with past performance. If a blade wears out faster than usual, you can look for causes like poor alignment or wrong grinding.

Use a table to keep track of key performance indicators:

| Индикатор | Что проверить | Как часто |

|---|---|---|

| Качество резки | Smoothness, burrs, dust | Every shift |

| Жизнь лезвия | Hours or cuts before change | Each change |

| Частота заточки | Times sharpened per month | Ежемесячно |

| Выравнивание | Blade position and runout | Еженедельно |

| Build-Up | Adhesive or dust on blade | Every shift |

You can set up a simple checklist for your team. Ask them to check blade edges, alignment, and build-up at the end of each shift. Use a logbook or spreadsheet to record results. This makes it easy to see when performance drops and helps you plan maintenance.

Tip: Use colored stickers or tags to mark blades that need attention. This helps everyone on your team spot problems fast.

You should also listen for changes in machine noise or vibration. Unusual sounds can mean a blade is dull or misaligned. Teach your team to report these signs right away.

Regular performance monitoring helps you get the most from your carbide slitting knives. You will see fewer bad cuts, less downtime, and lower costs. Good records help you choose the best blades and keep your corrugator working at its best.

Durability Economics of Tungsten Carbide Blades

Cost Advantage Over Steel

If you look at tungsten carbide blades and steel blades, you will see a big difference in cost over time. Steel blades seem cheaper at first, but they wear out fast. You have to buy new steel blades often, and this costs more in the end. Tungsten carbide blades cost more when you buy them, but they last much longer. Here are some things to remember:

- Steel blades need to be replaced a lot, so you spend more money.

- Tungsten carbide blades cost more at first, sometimes two or three times as much.

- These blades can last five to ten times longer than steel blades.

- You do not have to buy new blades or fix them as often.

- Companies that need strong blades use tungsten carbide because it helps them work longer without stopping.

You save money over time because you do not have to stop your machine to change blades as much.

Общая стоимость владения

When you pick blades for your corrugator, do not just look at the price. The total cost of ownership means all the money you spend on blades, like buying, replacing, and fixing them. Tungsten carbide blades help you spend less because they last longer and need less care.

| Фактор | Стальные лезвия | Лезвия из Карбида Вольфрама |

|---|---|---|

| Первоначальная стоимость | Низкий | Выше |

| Частота замены | Высокий | Низкий |

| Потребности в техническом обслуживании | Frequent | Минимальный |

| Время простоя | More | Меньше |

| Total Life Cycle Cost | Выше | Ниже |

You get more from each blade. You also make less waste and your products look better. Over time, you save more money, so tungsten carbide is a smart choice for your plant.

Impact on Downtime and Efficiency

Downtime can hurt your work and cost you money. Every time you stop your machine to change or sharpen a blade, you lose time and money. Tungsten carbide slitting knives help you stop less often. These blades are very hard and do not wear out fast, so they stay sharp longer. You can run your machines for longer without stopping.

- You do not have to fix blades as much because they stay sharp.

- You can work longer without stopping your machine.

- Using better grades of tungsten carbide makes blades even harder and stronger.

- Coatings like Titanium Nitride help blades last longer and cut smoother.

- Good edge shapes help blades make cleaner cuts and last longer.

You help your plant work better by picking blades that last. Cleaner cuts mean less waste and better-looking boxes. When you use strong blades, your team can spend more time making products and less time fixing machines.

Picking the right carbide slitting knives helps you make neat cuts. Your blades will last longer and your machine will stop less. You should look at the blade’s material, edge shape, and coatings. Taking care of your blades often keeps them working well and your corrugator running smoothly.

- Tungsten carbide blades are very hard and cut better.

- Они не изнашиваются быстро, поэтому менять их приходится реже.

- Strong blades help you make more boxes and spend less money.

- Sharpening and checking blades often helps them last longer.

| Задача | Как часто | Что делать |

|---|---|---|

| Surface Wipe | Every day | Do this after each shift |

| Визуальный осмотр | Every day | Look for chips or bad edges |

| Тест на резкость | Every week | Try cutting real material |

| Измерение толщины | Every month | Use a caliper or micrometer |

To get better results, do these things:

- Check if blades are sharp, lined up, or worn out.

- Use machines where you can change blade settings.

- Make a plan to care for your blades often.

- Teach workers how to use blades safely and well.

- Try using better blades made from tungsten carbide.

You can help your plant work better and make nicer products by checking how your blades work now. If you want help or have questions about picking carbide slitting knives, свяжитесь с нашей командой.

Часто задаваемые вопросы

What are carbide slitting knives used for in corrugators?

Carbide slitting knives cut corrugated board into sheets or boxes. They help you make straight, clean cuts. Using these knives means you waste less material.

How often should I replace carbide slitting knives?

Replace carbide slitting knives if they get dull or make rough cuts. More dust on your board is also a sign. With good care, these knives last much longer than steel blades. Sometimes, they can last up to 100 times longer.

Can I use carbide slitting knives on any corrugator machine?

Most corrugator machines can use carbide slitting knives. Always check the blade’s size and thickness first. Make sure the holes match your machine before using the knife.

What is the main advantage of carbide slitting knives over steel blades?

Carbide slitting knives stay sharp much longer than steel blades. You do not need to change them as often. This means less downtime and better cuts. You save time and money in your plant.

Do I need special equipment to sharpen carbide slitting knives?

You need a grinding machine with the right wheel for carbide. Using the wrong tool can hurt the blade. Always follow the sharpening instructions for your knife.

How do coatings improve carbide slitting knife performance?

Coatings help stop glue and dust from sticking to the blade. They also lower friction and keep cuts clean. Some coatings protect the blade from heat and rust.

What should I do if my carbide slitting knives chip or wear out quickly?

Check if your machine is lined up right and running at the right speed. Make sure you use the right knife for your material. If you still have problems, ask your supplier for help or try a different carbide grade.

How can I tell if my carbide slitting knives need maintenance?

Look for dull edges or rough cuts on your board. More dust or new noises from your machine are signs too. Checking your knives often helps you find problems early and keep them working well.

Смотрите также

Вольфрамовый нож: стоит ли он своих денег? Плюсы, минусы и области применения в промышленности.

Как Затачивать и Обслуживать Ножи из Карбида Вольфрама

Карбид вольфрама против стали для промышленных лезвий: производительность, износ и стоимость.

Карбид Вольфрама против Быстрорежущей Стали (HSS): Что Подходит для Ваших Режущих Задач?