Tails and fines are the twin enemies of pellet quality on PE/PP water‑ring (die‑face hot‑cut) lines. Tails start at the die face when the cut isn’t clean—often because of a worn edge, grooved die face, poor alignment, or off‑spec water conditions. Those tails then break off in the dryer, turning into fines and dust that erode yield, overload filters and dryers, and force unplanned cleanouts. You see the impact as lost uptime, higher total cost of ownership, and inconsistent appearance that customers notice.

This guide explains how PVD coated pelletizer knives can extend edge retention and reduce sticking, helping you cut cleaner pellets. With proper setup and maintenance, many plants see a conservative hypothesis band of −20% to −40% in tails + fines rate after validation, with additional upside from longer service intervals. You’ll learn failure mechanisms, coating selection, SOPs, ROI math, and a validation plan you can run on your own line.

Основные выводы

- Target one KPI: tails + fines rate at the dryer outlet, measured by sieve/wet analysis, then validate with controlled A/B runs.

- PVD coated pelletizer knives maintain a sharper, lower‑friction edge longer, supporting cleaner severance and fewer tails/fines when paired with correct overlap/pressure and water control.

- Expect conservative improvement bands (−20% to −40%) as a testable hypothesis; confirm with data before scaling.

- Standardize knife/die setup, water loop stability, and regrind/recoat documentation to lock in gains and extend service life.

Failure modes to fix

Tailing and smeared cuts

Tailing forms when the polymer isn’t cleanly sheared at the die face. Common drivers include a dull edge (growing edge radius), grooves or chips on the die cutting surface, too‑hot melt or process water that prevents rapid skin formation, or uneven contact from misalignment or shaft runout. The visual cue is a thin streamer on pellets and smeared surfaces at the cut face. Practical fixes focus on restoring a keen, evenly tracking edge, resurfacing the die if grooves are present, and balancing temperatures so the cut severs instead of smears. Industry troubleshooting notes emphasize that hot water and high melt temperature aggravate smearing at cut, while smooth, flat die faces and sharp knives promote clean severance. For a mechanisms primer, see the discussion in Plastics Technology’s troubleshooting article on underwater pelletizing issues in Mitigating and Troubleshooting Underwater Pelletizing (Plastics Technology, 2021+).

Fines and dust generation

Fines typically originate from those same tails: once pellets hit the dryer, protrusions snap off and become dust. Recirculating fines can then interfere with cutting and transport if filtration is weak. If your fines trend climbs after a knife change or die service, look first at cut cleanliness and water‑loop filtration. Closed‑loop systems with adequate flow and maintained filtration reduce re‑entrainment. OEM and trade sources emphasize that filtration and steady water conditions are necessary to avoid process disruptions that elevate fines; see Davis‑Standard’s overview of common pellet quality issues for additional context.

Edge chipping and micro-cracks

Micro‑chipping at the knife edge seeds tails and irregular pellets. It can be triggered by mismatched hardness between blade and die, particulate contamination, or brittle coatings with poor adhesion/stress balance. The tell is a roughened edge under 50–200× magnification and cyclic noise/vibration during cutting. Countermeasures include selecting tougher coatings/interlayers, verifying coating adhesion, and keeping the die face defect‑free. Maintain concentric tracking and verify bearing health to prevent contact shocks that chip the edge. Automated blade‑positioning can help stabilize contact; see MAAG’s EAC blade positioning concept.

Why PVD coated pelletizer knives double life

PVD coatings do not magically fix poor setup, but they do slow the pathways that create tails and fines. Think of the edge like a pencil: once it gets rounded or nicked, it smears instead of slicing. PVD adds hard, low‑friction armor that helps the “pencil tip” stay sharp and slick.

Hardness and wear resistance

Higher hardness and stable microstructure resist abrasive wear, delaying the edge‑radius growth that causes smear at the die face. Nitrides such as TiN and TiAlN are proven wear layers with good hot hardness. By preserving a crisp edge longer, they extend the interval between changeovers and reduce the time window where tails are likely to develop.

Low friction, anti-sticking

Low friction and low polymer affinity reduce sticking and buildup at the edge. CrN, TiCN, and DLC stacks are commonly used in polymer‑contact applications because they help the melt slip past the cutting edge instead of smearing onto it. Less buildup means a cleaner severance and fewer tails that later break into fines.

Toughness, stress, and adhesion

A coating that’s hard but brittle can micro‑crack or chip, creating new initiation sites for tails and fines. Proper interlayers and stress‑balanced stacks improve adhesion and toughness, so the coated edge resists chipping under intermittent contact and debris impacts. That translates to steadier pellet geometry and longer service life across regrinds.

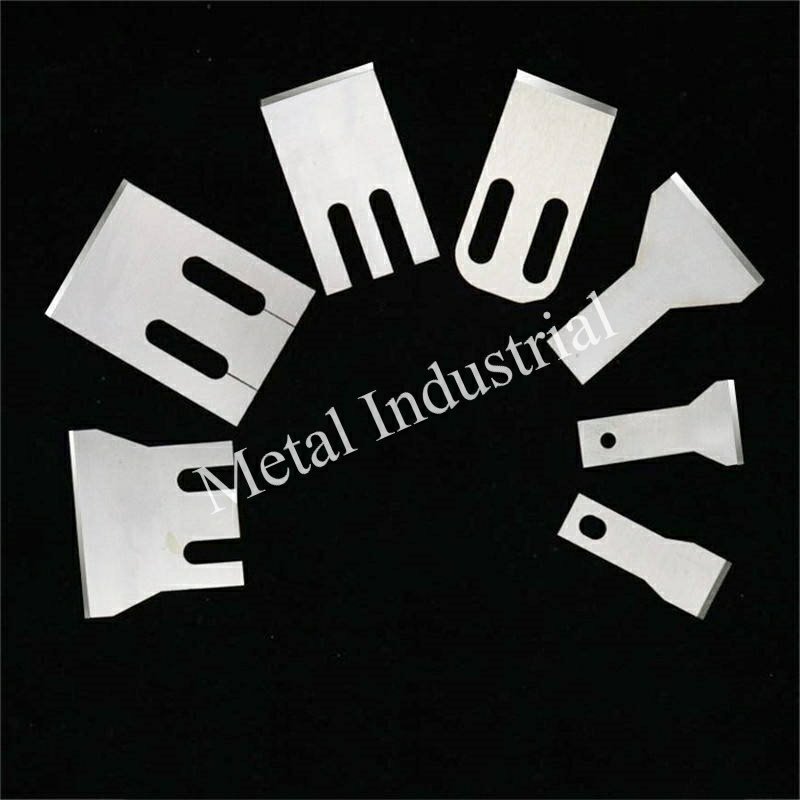

Pick the right coating

TiN, TiAlN: baseline and heat stability

TiN is a robust baseline for many tools: high hardness with dependable wear resistance. TiAlN improves hot hardness and oxidation resistance, useful where die‑face temperatures run hotter or where longer thermal stability is required. For unfilled PE/PP, these layers can deliver strong edge retention; however, if sticking has been a chronic issue, consider pairing with a lower‑friction layer or a different nitride.

CrN, TiCN: toughness and low adhesion

CrN and TiCN balance hardness with lower friction and lower polymer affinity. In practice, they help reduce smearing and buildup at the cut and resist edge micro‑chipping—particularly valuable with filled PP where abrasive fillers and tackiness coexist. Selection should weigh resin family, filler load, and your historical failure modes (tails vs. fines vs. chipping).

DLC stacks: friction and corrosion control

DLC offers the slickest interface and very high hardness, often deployed as a multilayer stack with adhesion interlayers. It’s attractive when anti‑stick performance is paramount or when water chemistry raises corrosion concerns. Confirm thermal limits and coating thickness so you preserve edge sharpness without creating a brittle lip.

Disclosure: MAXTOR METAL is our product. As a neutral example, process teams often align coating choice with regrind documentation and acceptance checks. A vendor such as MAXTOR METAL can supply PVD‑coated pelletizer knives and support regrind/recoat logging (serials, hardness, roughness, adhesion notes) so your QA and validation records stay audit‑ready. For broader maintenance concepts, see the internal guide on industrial blade maintenance tips.

Setup and maintenance SOP

Knife–die overlap and pressure

- Lockout/tagout and ensure guarding. Verify rotor bearings and shaft runout with a dial indicator at the knife hub; correct if TIR exceeds equipment limits. Uneven tracking seeds tails and noise.

- Establish even contact using your OEM’s contact‑pattern/no‑print method. Start at the lightest “kiss” contact, then ramp carefully while monitoring motor load and pellet shape. Automated blade‑position systems, where available, assist in maintaining consistent overlap.

- Inspect pellet geometry for uniform cylinders without smeared faces. If you observe cyclical marks, revisit alignment and contact uniformity before chasing water settings.

Water temperature and quality

- Aim for rapid skin formation at cut without embrittlement. Excessively hot water suppresses skinning and promotes smear; excessively cold water complicates drying. Tune within the resin window and keep it steady across shifts.

- Maintain adequate closed‑loop flow and effective filtration. Rising differential pressure across filters or visible recirculating fines are red flags—address them before they cascade into elevated fines and dryer load. For a process‑water fundamentals refresher and system context, review MAAG’s pelletizing systems overview.

- If unexplained smear or corrosion appears, check water chemistry and conductivity. Adjust treatment to protect both die and knife surfaces.

Regrind and recoat cycles

- Inspect edges at 50–200× magnification. Trigger regrind when edge radius growth or micro‑chips appear; avoid running into the smear regime. After die resurfacing, confirm flatness and a smooth cutting face under profilometry. A practical resurfacing overview is available in die‑resurfacing best practices for underwater pelletizing.

- Limit stock removal and preserve geometry. After a set number of regrinds, plan a recoat to restore surface properties and adhesion; confirm post‑coat edge sharpness and thickness uniformity.

- Keep a regrind/recoat log: serial, material/substrate, coating, regrind count, hardness and roughness notes, adhesion test notation, operator/date, and acceptance check. For inspection logic adaptable to pelletizer QA, see troubleshooting steps for industrial cutoff knives.

ROI and risk control

A short anonymized case (validated measurement): In a mid‑Europe PE regrind line running 3 t/h, the team replaced standard HSS knives with PVD‑coated TiCN knives and held overlap and water settings constant for an A/B campaign. Sampling used end‑of‑shift composite grabs and ASTM D7486 wet wash (plus D1921 dry sieves) across a 3‑week baseline and a 3‑week test period. Tails+fines fell from ~2.5% to ~1.8% by mass (≈−28%), with clearer dryer screens and fewer filter changes; operators stressed that stable overlap and water control were required to realize gains.

Changeover and uptime math

Quantify avoided downtime from longer service intervals. Example framework: Downtime avoided (h/year) × contribution margin ($/h) = uptime value. Add maintenance labor saved. Keep assumptions conservative and document knife‑on‑line hours pre/post change.

Scrap, fines, and quality yield

Your primary KPI is tails + fines rate at the dryer outlet by mass. Build a baseline over 2–4 weeks, then run A/B trials with the new knife/coating. If you measure a −20% to −40% reduction, translate it into yield and cost: Throughput (t/h) × operating hours × price/ton × yield gain minus scrap disposal and reprocessing. Fewer fines can also extend filter life and reduce dryer fouling; include those parts and labor savings. For context on mechanisms‑to‑outcomes, see The Path to Pellet Perfection (Plastics Technology).

Documentation and inspection

How do you know the improvement is real and repeatable? Validation requires discipline: log knife settings (contact proxy), water temperature, melt temperature/MFI, throughput, and sampling timestamps. Use ASTM‑aligned methods—dry sieving for particle size distribution and a wet wash for sub‑500 µm fines—so results are comparable. An accessible starting point is ASTM D7486’s wet analysis overview page. Apply a simple statistical test (t‑test or Mann–Whitney) to confirm significance before scaling plant‑wide. Keep acceptance criteria and regrind logs attached to each campaign.

For dry sieving of plastic pellets and granules (>500 µm size classes), reference ASTM’s 2018 D1921 Test Methods for Particle Size (Sieve Analysis) of Plastic Materials, which specifies sieve stack selection, agitation, and reporting for lot-to-lot comparisons.

Fit with your line

Gala/MAAG and other ecosystems

Water‑ring/underwater systems across OEMs follow the same fundamentals. Blade tracking, even contact, and steady water conditions apply whether your platform is a Gala/MAAG design or another ecosystem. Where available, automated blade‑position systems help maintain repeatability; consult your OEM manual for exact set‑points and torque specs.

Tolerances and surface finish

Die and knife interfaces must be flat, parallel, and free of defects. After die resurfacing, remove minimal stock with coolant‑controlled grinding and verify with 100% inspection. Keep the cutting interface smooth to avoid initiating smear; preserve geometry through each regrind and recoat.

Onboarding and spares plan

Before swapping coatings or suppliers, run a controlled validation on a stable recipe. Build a spares plan that covers knives, die‑face service windows, bearings and shaft components, filters/screens, and inspection tools (dial indicators, microscope, profilometer). Align regrind/recoat vendor lead times with your changeover cadence to avoid emergency purchases. For a fundamentals refresher on pelletizer blades in plastic processing, see this practical guide to industrial blades in plastics.

Заключение

Clean cuts at the die face are the fastest path to fewer tails and less dust. PVD coated pelletizer knives help by keeping the edge sharp and slick longer, but they deliver best when paired with disciplined setup and stable water conditions. Use the validation plan to test a conservative hypothesis band (e.g., −20% to −40% tails + fines) on your own line, then lock in the gains with regrind/recoat documentation and a spares plan.

Next steps: pick a coating aligned to your resin and failure modes, tune knife–die contact and water conditions methodically, and stand up a regrind/inspection log so improvements persist across shifts.