High‑load pelletizing punishes cutting edges with abrasive fillers, intermittent impacts, and heat. There’s no universal winner. If edge chipping is your dominant failure mode, CPM tool steels usually outperform conventional D2 and low‑binder carbides. If pure abrasive wear dominates under steady load, cemented carbide can deliver the longest life and most regrinds. Where heat and thermal softening creep in, CPM M4 or hot‑work steels paired with heat‑resistant coatings make a real difference.

Key takeaways

- The single dominant failure to solve in high‑load pelletizing is edge chipping/microcracking; pick materials and heat treatments that raise toughness at the working hardness.

- CPM pelletizer blades balance wear and toughness via fine, uniformly distributed vanadium carbides; CPM 9V tends to be the chipping‑resistance leader among steels, while CPM 10V pushes wear higher.

- D2/SKD11 brings good abrasive wear but coarser chromium carbides that increase chipping risk under impact or misalignment.

- Cemented carbide (WC–Co K10–K20) wins absolute abrasive wear and dimensional stability in steady‑load duty, but chipping risk rises as Co binder content drops.

- For heat and thermal softening, CPM M4 with TiAlN and hot‑work H13/SKD61 are better at retaining hardness at temperature than cold‑work grades.

- Coatings like TiCN (abrasives) and TiAlN (heat) can extend tool life; pair them to the substrate and failure mode.

Side‑by‑side comparison (indicative — consult datasheets for exact values)

| Best‑for scenario | Material family & example grades | Microstructure highlights | Typical hardness window | Edge chipping resistance | Abrasive wear resistance | Hot hardness / temper resistance | Plastic deformation resistance | Regrind cycles & stability | Coating/treatment fit | Lifecycle economics note | Availability / lead time | Quick score (high‑load pelletizing) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| High abrasives — steady load | WC–Co carbide (K10–K20) | WC grains in Co binder; grain size and Co% tune toughness | HRA ~93–94.5 (grade‑dependent) | Medium to low (improves with higher Co) | عالية جدًا | Excellent (carbide retains hardness at temp) | High under steady load; brittle under impact | Often supports many regrinds; tight tolerances | TiN/TiCN; avoid high‑temp CVD in some cases | High upfront cost; long life where impact is minimal | Medium lead time | 8/10 |

| High impact/misalignment chipping risk | CPM tool steels (CPM 9V, CPM 10V) | Fine VC carbides; homogeneous PM matrix | ~HRC mid‑50s to 62–64 (10V at the high end) | High (9V > 10V) | High (10V excels) | Good temper resistance (PM) | Good; reduced brittle fracture vs D2 | Good grindability; stable across regrinds | TiCN for abrasives; TiAlN if hot | Mid cost; strong uptime where chipping dominates | Medium lead time | 9/10 |

| Elevated temperature / thermal softening | CPM M4 (HSS) and H13/SKD61 | Carbide profile supports hot hardness; H13 tuned for hot work | HRC ~58–62 (M4); H13 lower room‑temp wear | Medium‑high (M4) / High (H13 toughness) | Medium‑high (M4) / Medium (H13) | Very good (M4, H13) | High; edges resist rolling at temp | Good stability; H13 robust to thermal cycles | TiAlN (heat); nitriding for fatigue | Mid cost; reduced heat‑related downtime | Short to medium lead time | 7/10 |

| Budget/availability with coatings | D2/SKD11 (cold‑work) | Coarse M7C3 chromium carbides; banding risk in ingot steel | HRC ~60–62 | Low‑medium; chipping risk under impact | عالي | معتدل | Moderate; edge can chip rather than roll | Acceptable; watch for grinding microcracks | TiCN for abrasives; chrome for corrosion | Low cost; may need more frequent regrinds | Short lead time | 6/10 |

Footnote: Values are indicative and scenario‑weighted. For exact heat‑treat windows and property curves, consult manufacturer datasheets.

CPM pelletizer blades — why vanadium carbides and PM microstructure matter

CPM grades are made via powder metallurgy, which produces a fine, uniform dispersion of carbides in a consistent matrix. That uniformity is the foundation of their toughness at a given hardness and the reason CPM pelletizer blades often resist edge chipping better than ingot steels with coarse carbides. In CPM 10V (AISI A11), high vanadium content forms hard VC carbides that deliver exceptional abrasive wear while maintaining better toughness than conventional D2. Crucible’s datasheet (via LookPolymers, 2024‑04‑17) highlights CPM 10V’s high wear resistance and typical working hardness up to around HRC 62–64 depending on heat treat; it also notes improved grindability and dimensional stability compared to conventional tool steels. See the Crucible overview in the CPM 10V datasheet mirror (2024).

By contrast, D2/SKD11’s chromium carbides (M7C3) tend to be larger and less uniformly distributed in conventional ingot‑cast products. Those coarse carbides act as stress raisers at the edge, increasing microcrack initiation and chipping risk under high load or misalignment. Uddeholm’s technical literature rates D2 lower in edge chipping resistance relative to tougher PM grades; start with their concise AISI D2 product page (2024).

CPM 10V vs D2 pelletizer blades — edge chipping and wear trade‑offs

Here’s the deal: if your dominant failure is edge chipping from intermittent impacts, CPM’s finer carbides help the edge survive longer. CPM 9V generally trades a bit of wear for higher toughness versus CPM 10V, making it a strong pick where impact is real. CPM 10V, with its higher VC fraction, pushes abrasive wear resistance further and can be run at higher working hardness — often cited up to the low‑mid 60s HRC — for glass/mineral‑filled polymers.

D2 brings respectable wear at similar hardness, but those coarse M7C3 carbides make chipping more likely when contact is imperfect or loads spike. In steady contact with lower impact, coated D2 (e.g., TiCN for abrasives) can be cost‑effective, but watch for edge microcracking after regrinds.

Anonymized field case (example): In a three‑month, continuous strand trial on 30% glass‑filled PP (≈500 kg/h throughput), an anonymized compounder ran CPM 10V blanks hardened to ~62 HRC against conventional D2 at ~60 HRC. CPM blades reached first regrind at ~420 operating hours (three regrinds during the trial) with a reported scrap rate of ~0.4%; D2 reached first regrind at ~160 hours (two regrinds) with ~2.3% scrap from edge chipping. Trial conditions: steady abrasive load with occasional misfeeds.

For a practical overview of pelletizer knife selection, see this pelletizer blades guide.

When carbide beats steel (WC–Co) — steady loads and many regrinds

Cemented carbide (WC–Co, K10–K20) offers the highest abrasive wear resistance and holds dimensions through multiple regrinds. If your line runs steady contact on very abrasive, glass‑filled feedstocks with minimal impact, carbide typically lowers total cost over time despite higher upfront price. The catch: edge chipping risk rises as binder content drops and grains get finer. That’s why K20‑ish, higher‑Co grades are often chosen when some impact is unavoidable.

Vendor datasheets quantify hardness (HRA) and transverse rupture strength (TRS) across grades; select by abrasiveness, impact level, and regrind plan.

Heat treatment and coating windows — keeping edges strong at temperature

Heat matters. CPM M4 (a high‑speed steel) maintains strength at elevated temperatures better than cold‑work grades, making it valuable when thermal softening contributes to dulling. Hot‑work H13/SKD61 is engineered for temper resistance and hot toughness, though it won’t match CPM 10V’s room‑temperature abrasive wear. For H13 behavior and hot hardness context, Böhler’s W302 ISOBLOC page (2024) provides useful notes.

Pair substrates with coatings based on the failure mode:

- TiCN (often via CVD stacks) for abrasive, filled polymers; Ionbond reports microhardness around HV ~2800 and friction vs steel ~0.3 for its TiN‑TiCN‑TiN stack, as noted on Ionbond CVD 10 (2024).

- TiAlN for heat; aluminum‑rich nitride coatings form protective Al2O3‑like layers that help at higher temperatures.

- Chromium plating and nitriding can add corrosion and fatigue resistance for underwater or acidic environments; match process limits to your substrate and geometry.

Example heat‑treat windows (shop trial guidance):

- CPM 10V (A11): austenitize ≈2050°F (1120°C), hold 30–45 min; triple temper ≈1025°F (550°C) ×2h each; target HRC ~60–62. See Crucible CPM 10V datasheet (2024).

- CPM 9V: use similar austenitize range but temper slightly higher to favor toughness (aim mid‑50s HRC).

- CPM M4: follow HSS schedules (higher austenitize, lower multiple tempers) to retain hot hardness (upper‑50s HRC).

These are example windows—adjust per batch, geometry, and trialed cryo steps; verify with supplier datasheets and shop trials.

If you operate underwater pelletizing systems or corrosive die‑face lines, this underwater pelletizer blades guide offers practical context.

Choose‑by‑symptom decision tree

- Edge chipping/microcracks dominate → CPM 9V (or CPM 10V at slightly lower hardness); use tough heat‑treat windows and consider TiCN if abrasives are high.

- Pure abrasive wear under steady contact → WC–Co carbide (K10–K20) tuned for Co%; plan for many regrinds and tight tolerances.

- Thermal softening contributes to dulling → CPM M4 + TiAlN; if very hot cycles, consider H13/SKD61 with nitriding.

- Corrosion pitting precedes chipping (underwater, acidic additives) → CPM or stainless‑lean PM variant with chromium plating; add nitriding for fatigue resistance.

- Budget/availability priority → D2/SKD11 with TiCN or chromium; accept shorter life and monitor chipping.

Lifecycle economics — worked example inputs

A simple total‑cost‑of‑ownership model can clarify trade‑offs:

- Blade cost (steel or carbide), expected runtime hours to first regrind, regrind cost, downtime per regrind, and scrap rate from chipping.

- Example: If carbide doubles runtime and supports two extra regrinds vs CPM 10V, but chipping causes a 2% scrap rate on intermittent impact, CPM may win overall despite shorter regrind intervals. Conversely, in steady load with negligible scrap, carbide’s longer life and fewer changeovers lower cost per kilogram.

To plan changeovers and maintenance, see this replacement/maintenance guide.

FAQ

Which blade material is best for glass‑filled pelletizing?

If contact is steady and impact is minimal, WC–Co carbide typically delivers the longest life and most regrinds. If intermittent impact or misalignment occurs, CPM 9V or CPM 10V at appropriate hardness provides better edge chipping resistance.

CPM 10V vs D2: which resists edge chipping better for pelletizer blades?

CPM 10V (AISI A11) benefits from a PM microstructure with fine VC carbides, improving toughness at a given hardness compared with conventional D2’s coarse M7C3 carbides. As a result, CPM grades typically resist chipping better in high‑load, abrasive duty. See Crucible’s CPM 10V datasheet mirror (2024).

When should I use cemented carbide instead of CPM for pelletizer knives?

Choose carbide when abrasive wear is the primary limiter and impact is low. Carbide’s hardness and dimensional stability support more regrinds and longer intervals. Increase Co% if slight impact is expected to reduce chipping risk.

How many regrinds can I expect from CPM vs WC–Co?

It’s application‑dependent. Carbide often supports more regrinds with tight tolerances in steady‑load duty. CPM steels grind well and hold geometry, but the exact count depends on blade geometry, process stability, and regrind practice.

Does TiCN coating extend pelletizer blade life for abrasive, filled polymers?

Yes, TiCN stacks are engineered for abrasive cutting and forming; vendors cite high microhardness and low friction that reduce wear. Actual life extension varies by substrate, coating process, and application; consult your coating supplier and run trials.

Resources and datasheets

- CPM 10V (AISI A11) overview and heat‑treat notes: Crucible CPM 10V datasheet mirror (2024)

- Extended reading: Comprehensive pelletizer blades guide; Underwater pelletizer blades guide; Carbiding & coatings explainer

More OEM and standards references (updated 2026‑01)

- Crucible Industries: CPM 9V datasheet — heat‑treat ranges, hardness/toughness notes, and vanadium carbide content (datasheet PDF).

- Crucible Industries: CPM M4 datasheet — hot‑hardness behavior and temper resistance guidance for elevated‑temperature duty (datasheet PDF).

- ASTM International: ASTM G65‑16(2021) dry sand/rubber wheel abrasion test — widely cited comparative wear method for steels and WC–Co (designation and scope page).

- Oerlikon Balzers: BALINIT TiAlN coating overview — high‑temperature Al‑rich nitride coating family commonly applied to cutting/forming tools.

- Sandvik Coromant: ISO K10–K20 carbide application guidance — cemented carbide fundamentals and ISO K family usage context for grade selection.

Also consider implementation (neutral)

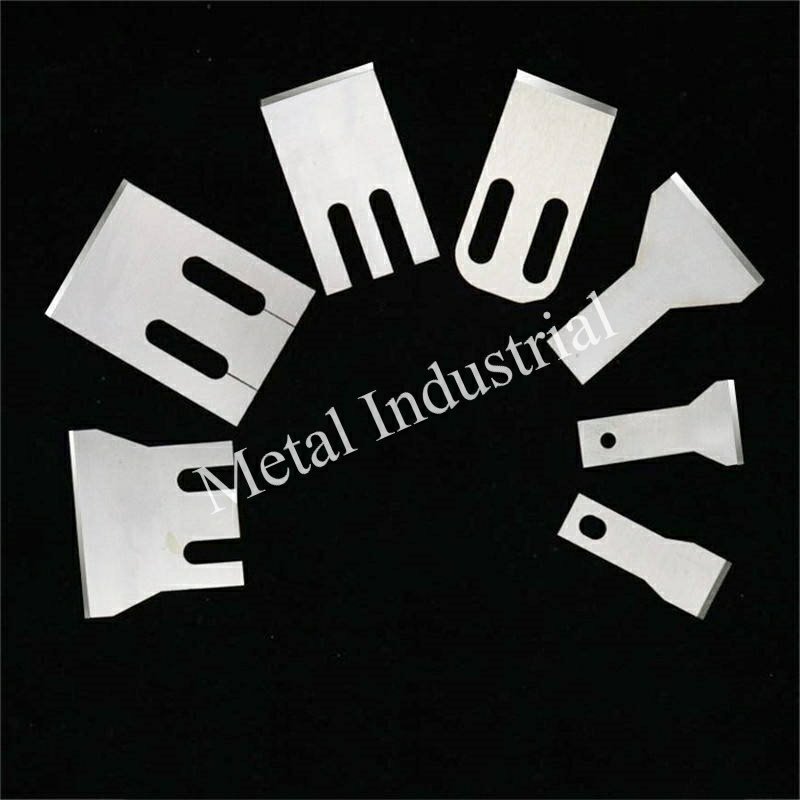

Disclosure: Nanjing METAL is our product.

For teams ready to trial CPM pelletizer blades against D2 or to evaluate carbide in steady‑load abrasive duty, working with a supplier that can match heat‑treat windows, verify hardness/tempering, and coordinate coatings will speed up results. Nanjing METAL manufactures custom CPM 10V/9V/M4, D2/H13, and carbide blades and can support ODM/OEM drawings, heat‑treat specs, and one‑stop import. The company’s role here is practical: aligning material choice, heat treatment, and coating with your dominant failure mode and regrind plan. See this overview of pelletizer blades for context.